An electric cylinder tensile load and life test device

A life test device and life test technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of inability to achieve closed-loop control, inaccurate results, and complicated control, so as to increase work safety and improve test efficiency. , to ensure the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

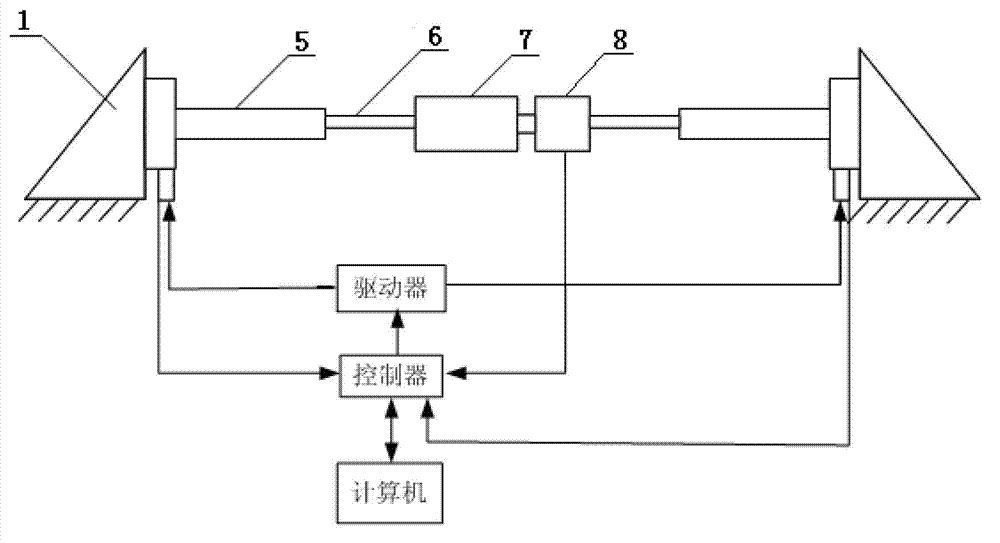

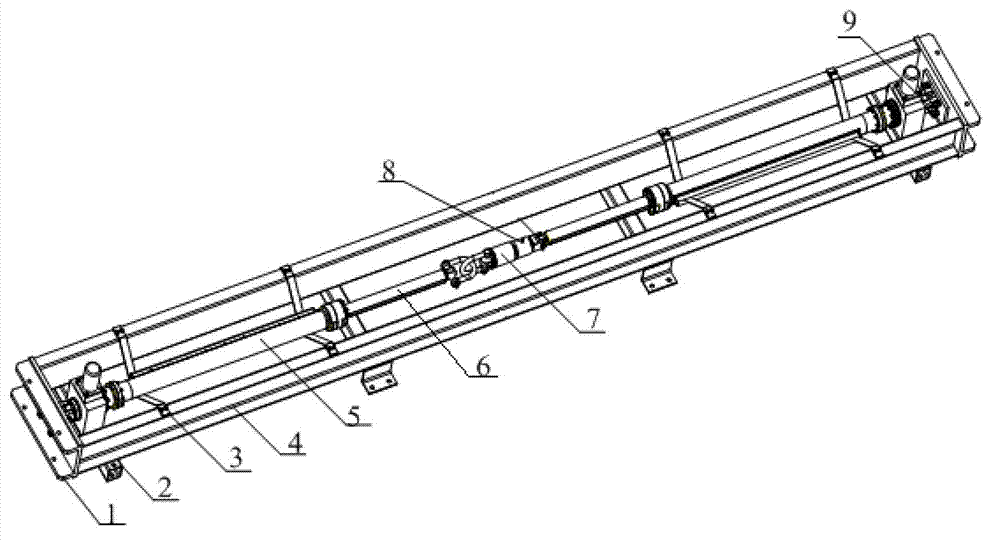

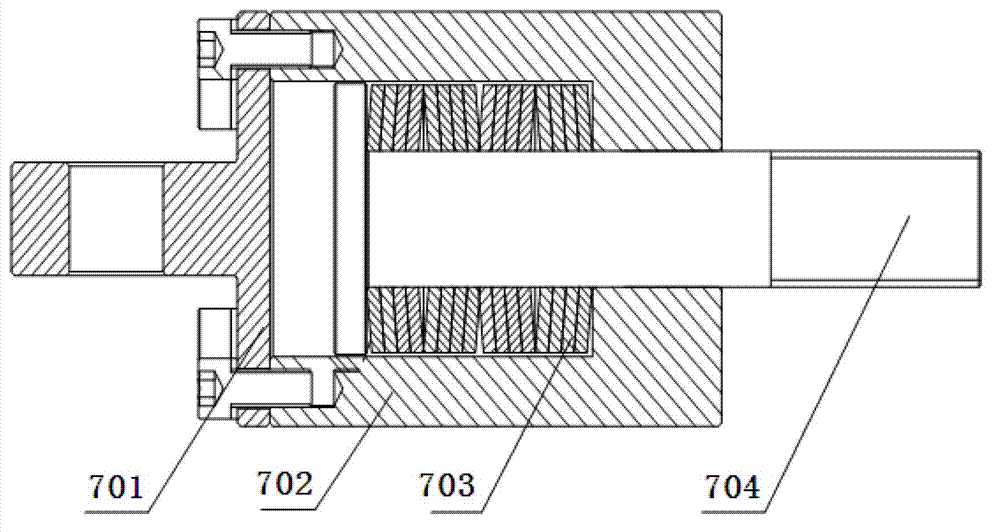

[0025] see figure 1 and figure 2 , the present invention includes a test bench 4 for supporting two electric cylinders 5, a connecting piece for connecting the drive rods 6 of the two electric cylinders 5, for fixing the two electric cylinders 5 respectively and keeping the two electric cylinders 5 at Auxiliary components in the same linear direction, and a control system for controlling the motor of the electric cylinder 5 and collecting the tension data or pressure data of the interaction between the two electric cylinders 5; Between the force sensor 8.

[0026] When carrying out the test, the electric cylinder 5 is respectively fixed on the test bench 4, and the force sensor 8 is connected with the free end joint of the drive rod 6 to complete the preparation for the test of the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com