Preparation method of carbon fiber/carbon nano tube/epoxy resin multi-dimensional hybrid composite

A technology of carbon nanotubes and epoxy resin, applied in the field of nanomaterials, can solve the problems of difficulty in achieving uniform dispersion, high surface energy of carbon nanotubes, and easy agglomeration, etc., and achieves simple and easy preparation methods, increased interface strength, and good Effect of interlaminar shear strength

Inactive Publication Date: 2010-08-25

TONGJI UNIV

View PDF3 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Carbon nanotubes have high surface energy and are prone to agglomeration, making it difficult to achieve uniform dispersion in polymers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

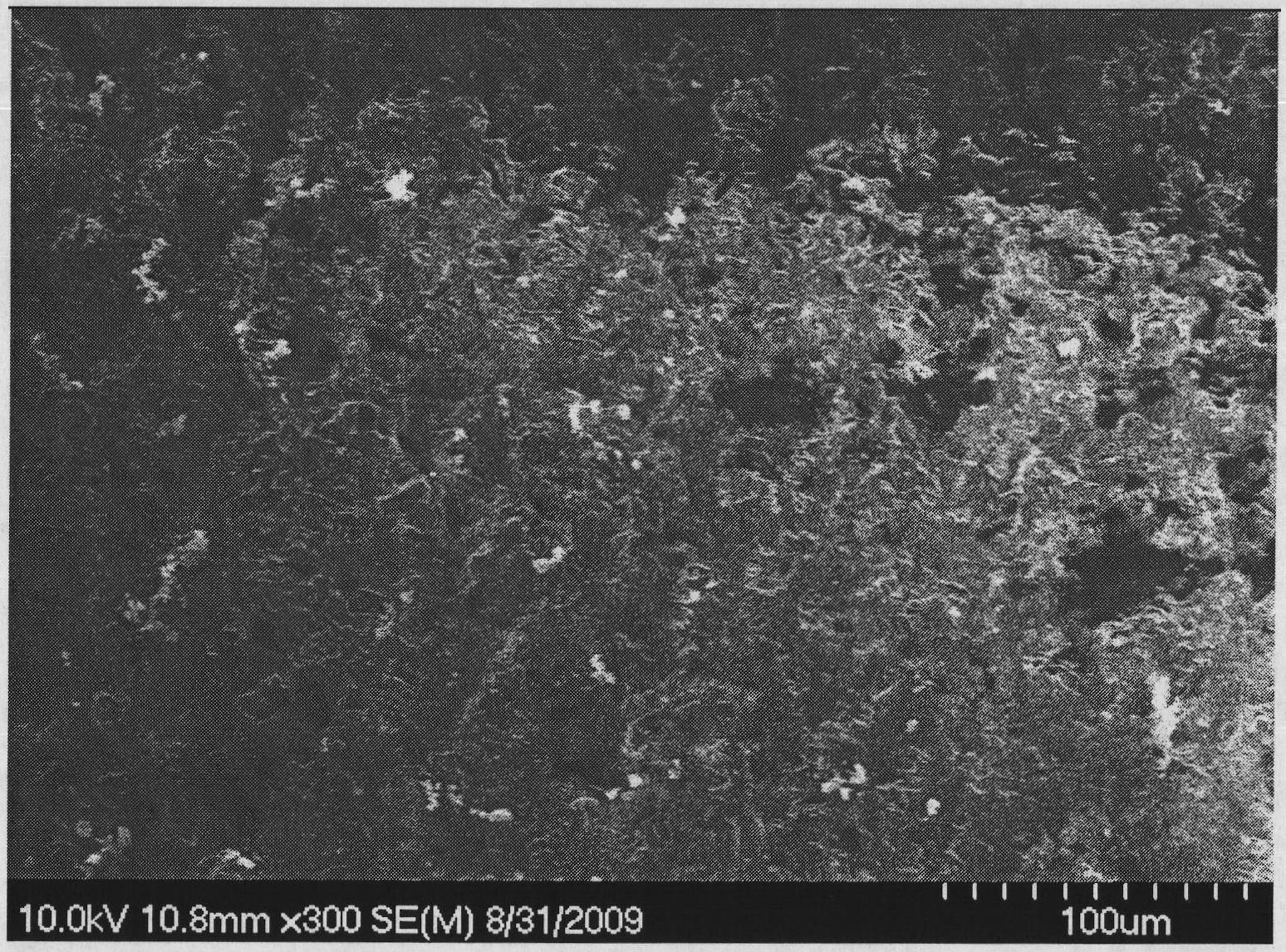

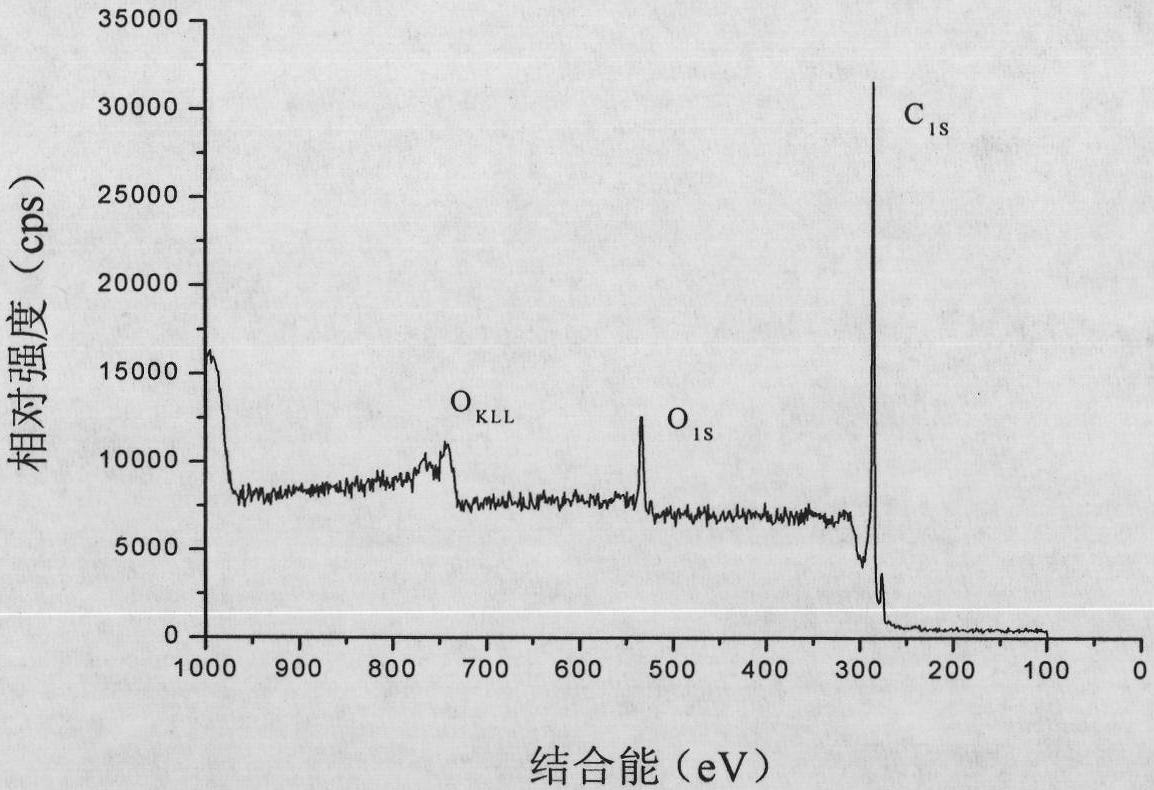

The invention belongs to the technical field of nano materials, and in particular relates to a preparation method of a carbon fiber / carbon nano tube / epoxy resin multi-dimensional hybrid composite. The invention comprises the following steps: carrying out surface carboxylation and chloride acetylation on carbon nano tubes and carbon fibers, introducing diamine or polyamine, and modifying the amino-grafted carbon nano tubes with small-molecule aromatic polyanhydride compounds to prepare carbon nano tubes carrying with anhydride groups; carrying out ultrasonic oscillation, stirring at a high speed to dispersing the carbon nano tubes in an epoxy resin matrix, and curing with organic anhydride curing agent to obtain an epoxy resin polymer containing carbon nano tubes; and using the epoxy resinpolymer containing the carbon nano tubes as the matrix for being compounded with the carbon fibers to form the covalently-bonded multi-dimensional hybrid composite structure. The invention has the advantage of convenient preparation; the carbon nano tubes are endued with activity for participating in the reaction, and the anhydride groups on the carbon nano tubes and the epoxy groups in the epoxyresin generate chemical crosslink, thereby promoting the dispersion of the carbon nano tubes in the epoxy resin; and the epoxy resin is toughened by using the strength and the toughness of the carbonnano tubes to enhance the bonding strength with the carbon fiber substrate, thus improving the overall performance of the carbon fiber / carbon nano tube / epoxy resin multi-dimensional hybrid composite,and widening the application of the carbon fibers, the carbon nano tubes and the epoxy resin.

Description

Preparation method of carbon fiber / carbon nanotube / epoxy resin multidimensional hybrid composite material technical field The invention belongs to the technical field of nanometer materials, in particular to a method for preparing a carbon fiber / carbon nanotube / epoxy resin multidimensional hybrid composite material. Background technique Epoxy resin is a thermosetting oligomer with poor properties. In addition to being used as a stabilizer for polyvinyl chloride, it has no direct use value. But when it reacts with the curing agent to form a three-dimensional cross-linked network structure, it presents a series of excellent properties. Therefore, the chemical reaction between curing agent and epoxy resin is the basis and core of epoxy resin application. The behavior of the epoxy resin during the curing process and the performance of the cured product depend to a large extent on the performance of the curing agent and the interaction and reasonable coordination between it a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B82B3/00

Inventor 邱军陈典兵

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com