Patents

Literature

44results about How to "High strength bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

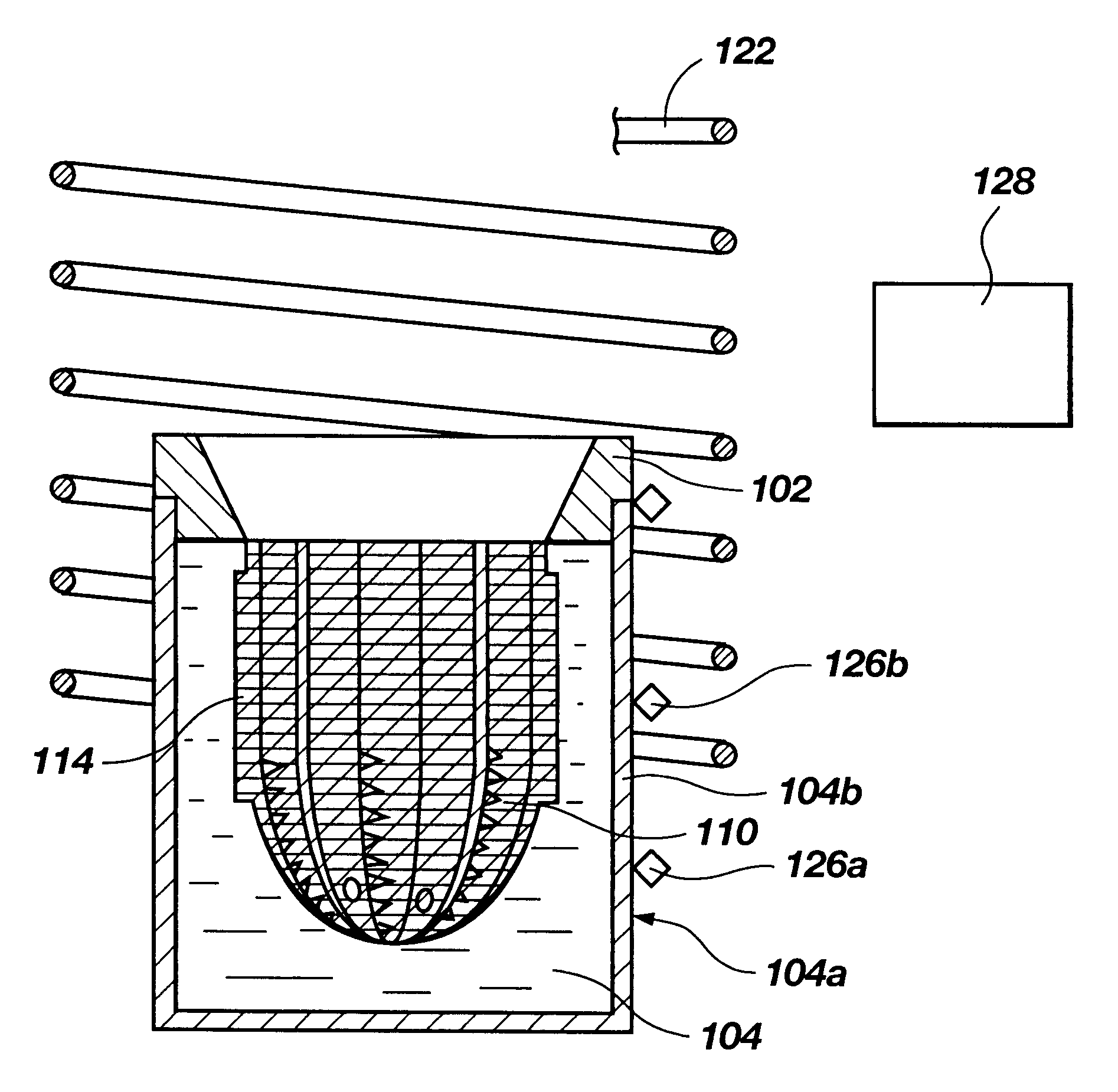

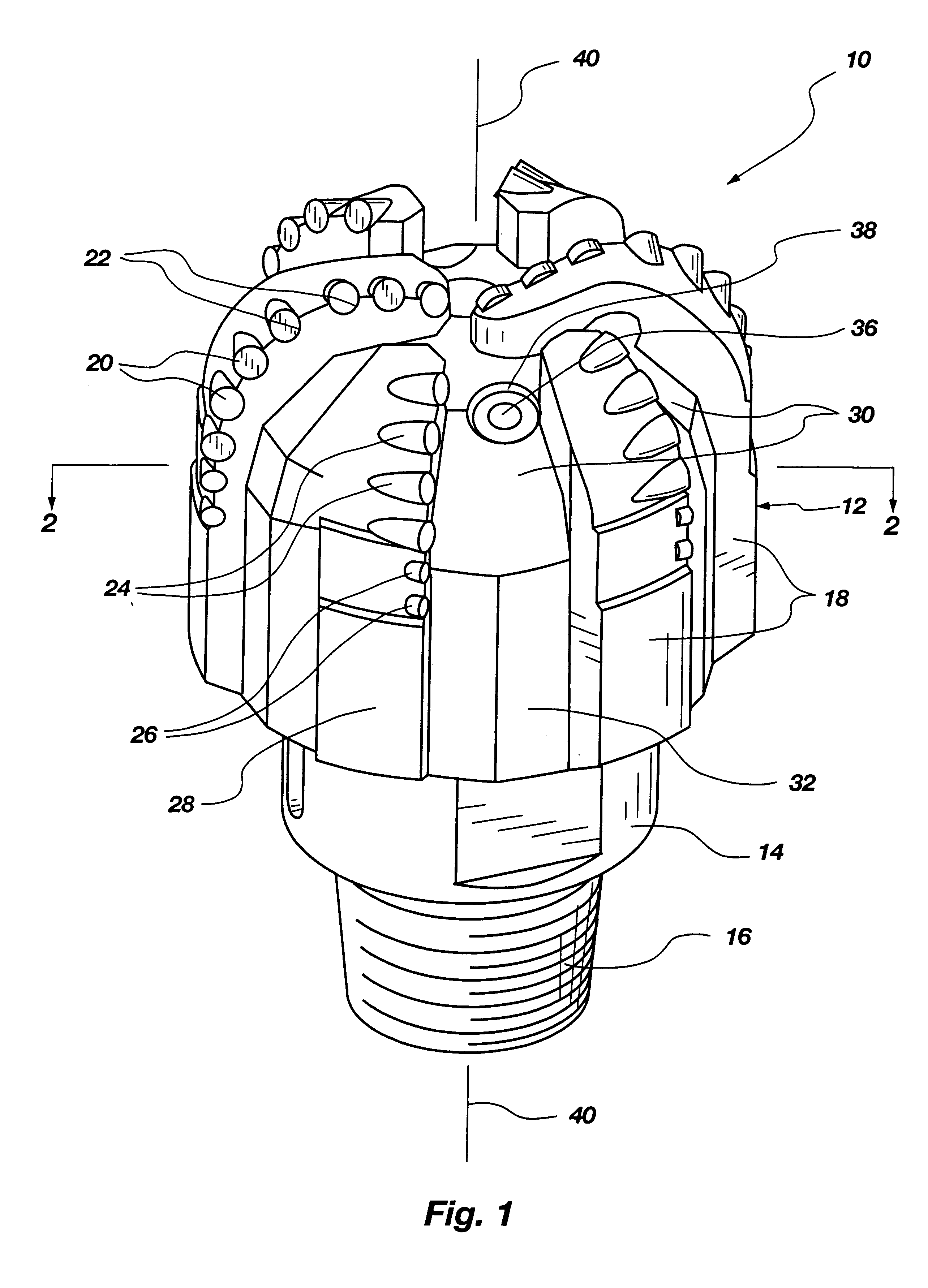

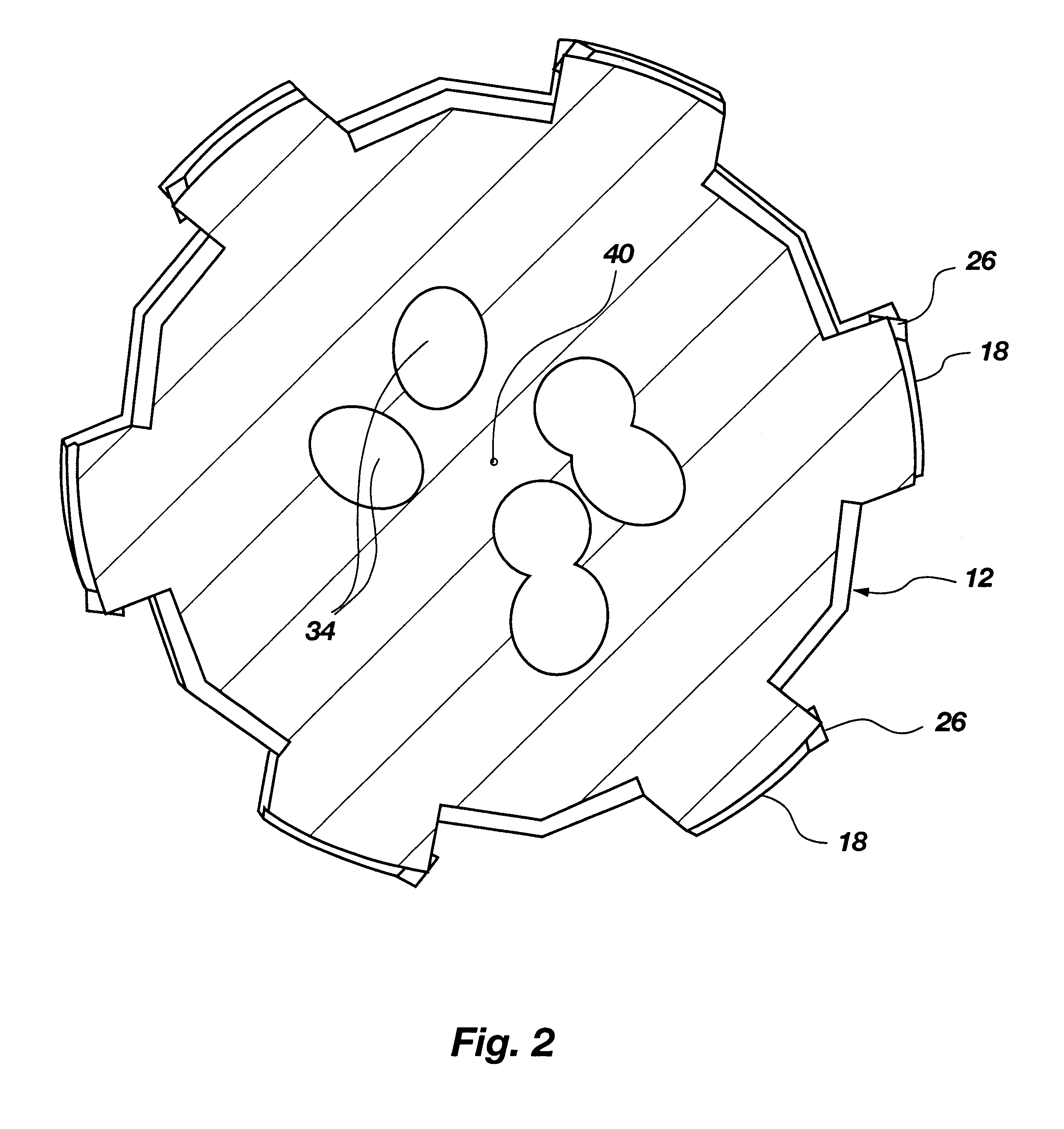

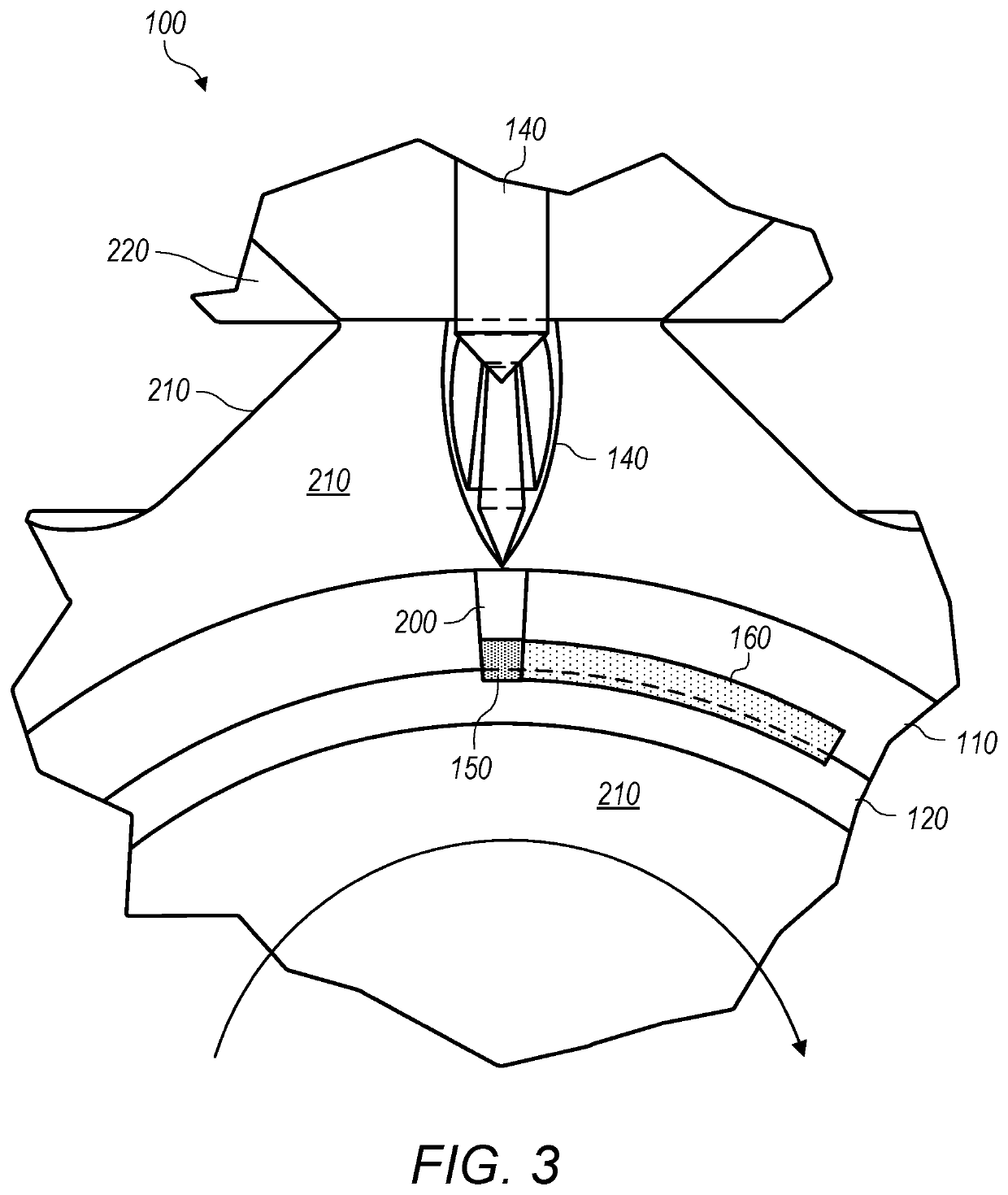

Methods of high temperature infiltration of drill bits and infiltrating binder

A method of manufacturing a bit body, other drilling-related component, or other article of manufacture, including fabricating a particulate-based matrix and infiltrating the particulate-based matrix with a binder that includes cobalt or iron. The binder may be a cobalt alloy or an iron alloy. The particulate-based matrix may be disposed within a non-graphite mold. The particulate-based matrix and binder are placed within an induction coil and an alternating current is applied to the induction coil in order to directly heat the binder, permitting the binder to infiltrate or otherwise bind the particles of the matrix together. The molten binder may then be directionally cooled by forming a cooling zone around an end portion of the bit body and increasing the size of the cooling zone relative to the bit body. The invention also includes a bit body, other drilling-related component, or other article of manufacture which includes a particulate-based matrix that is bound together with a binder that includes iron or cobalt.

Owner:BAKER HUGHES INC

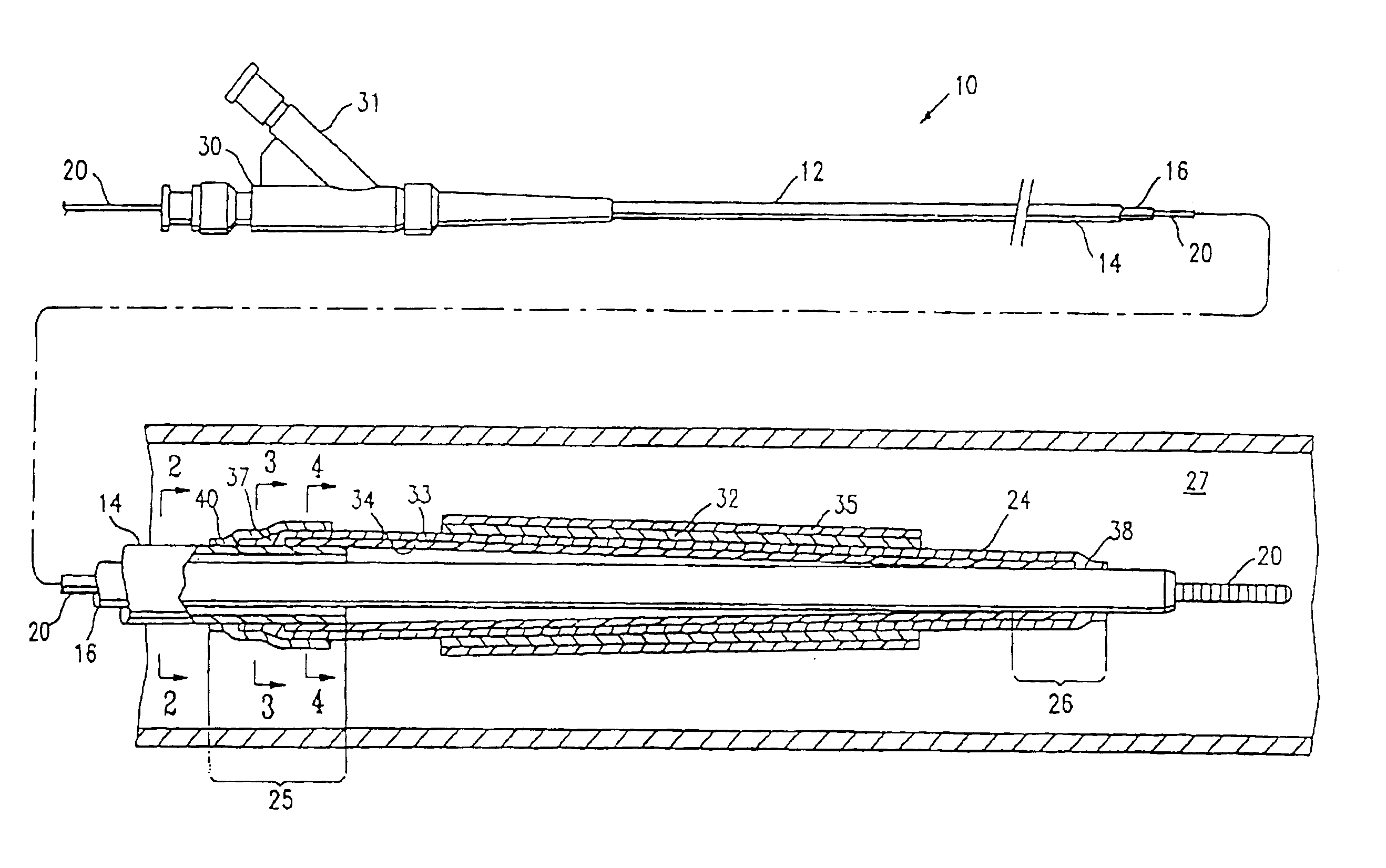

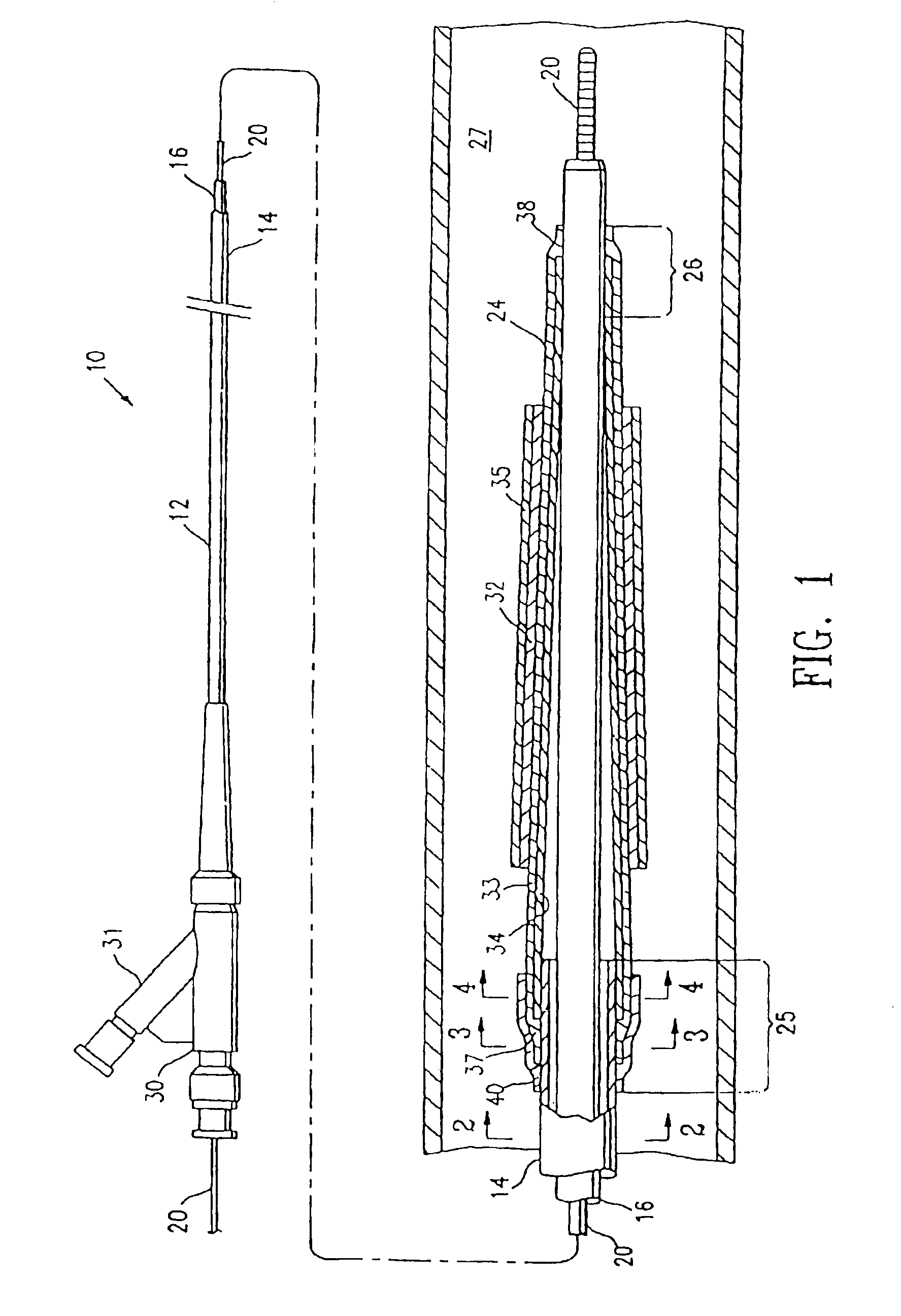

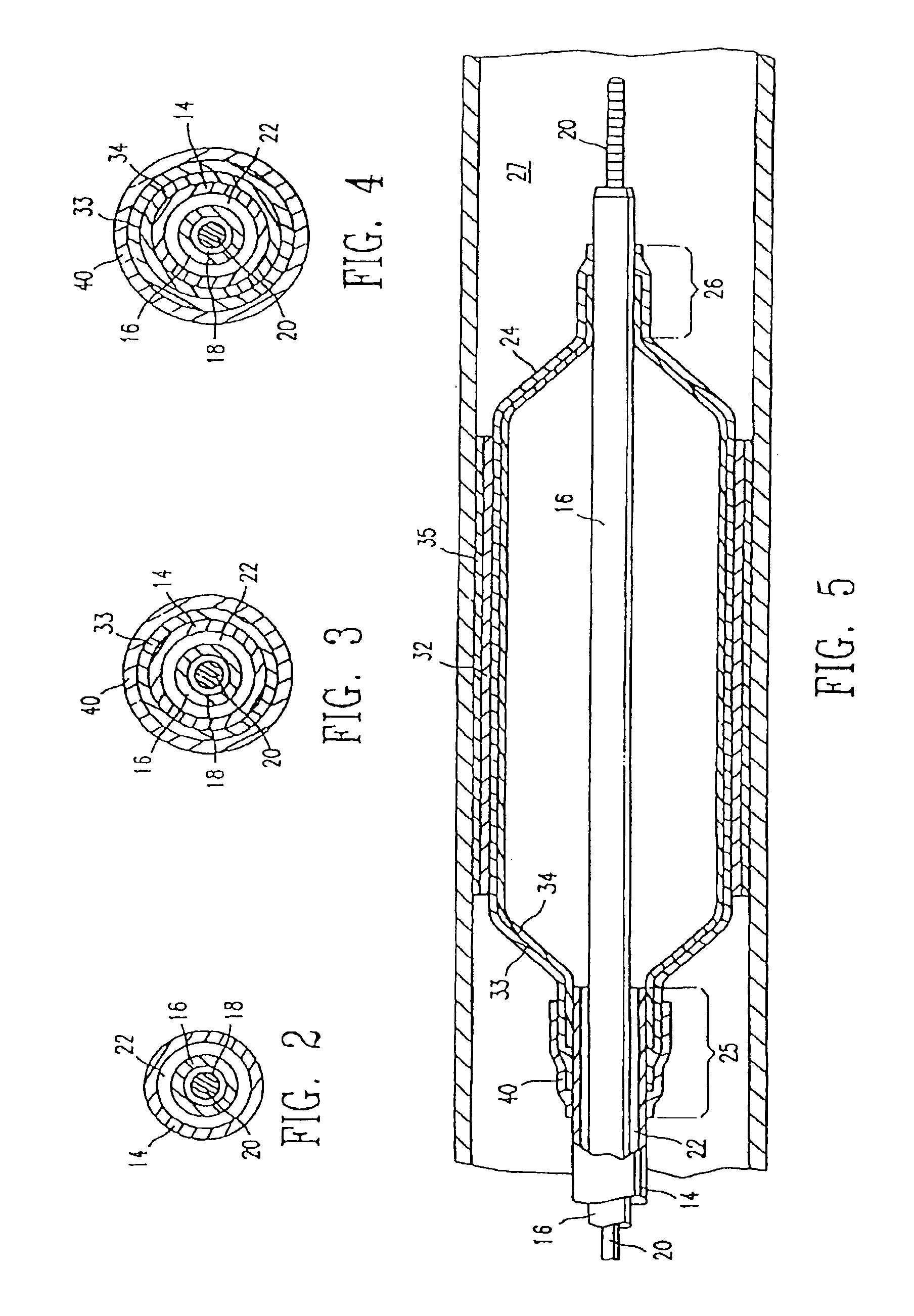

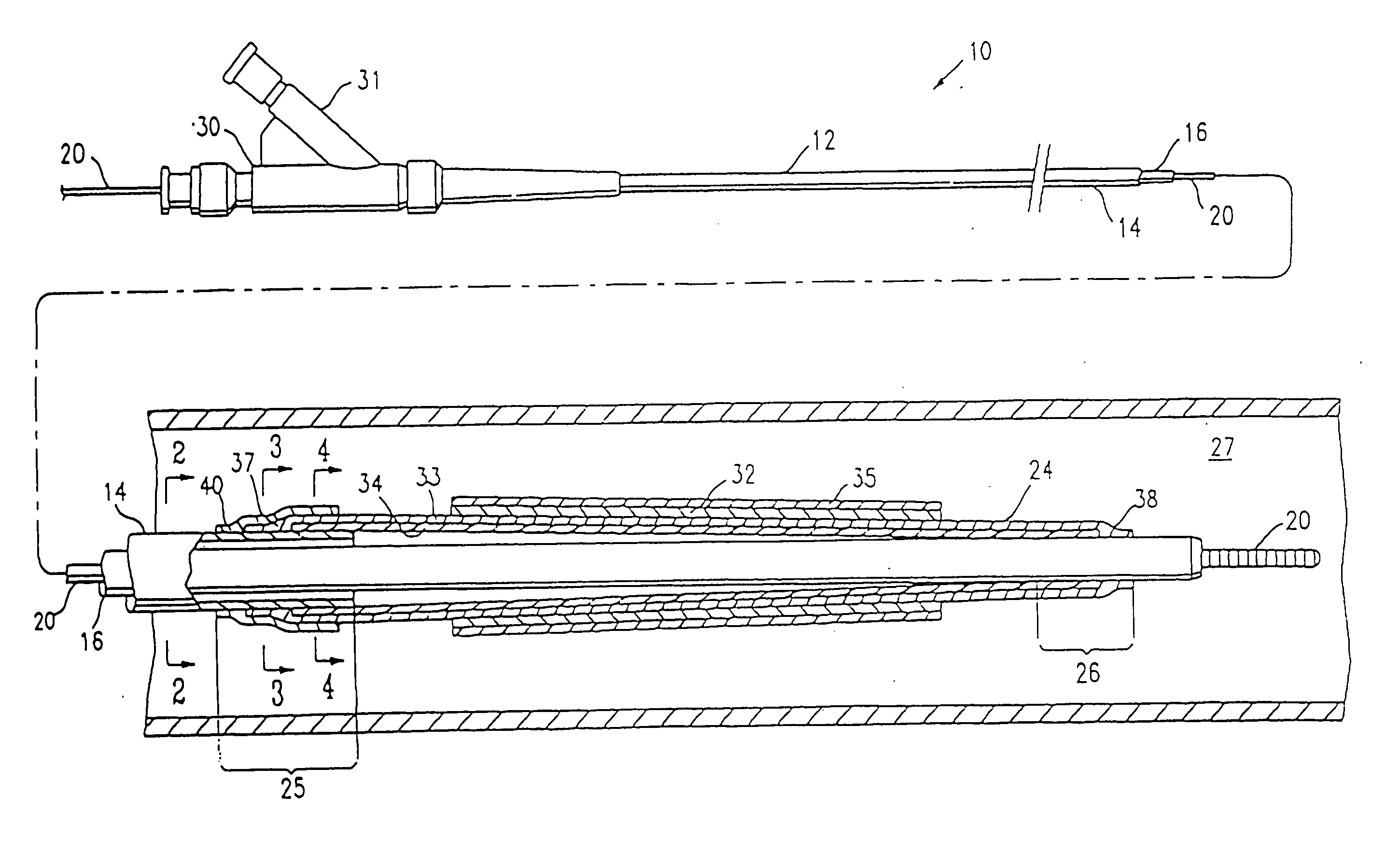

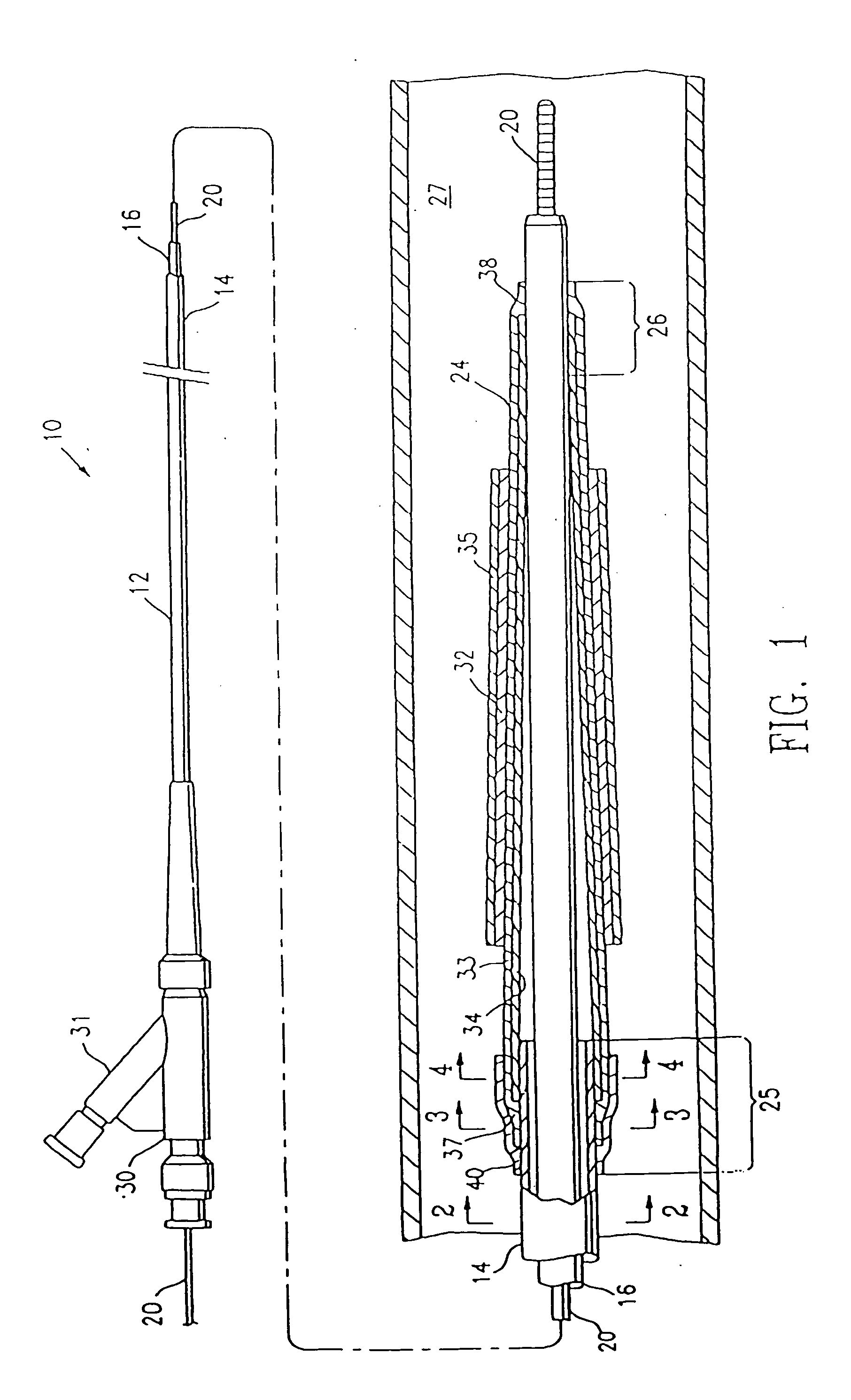

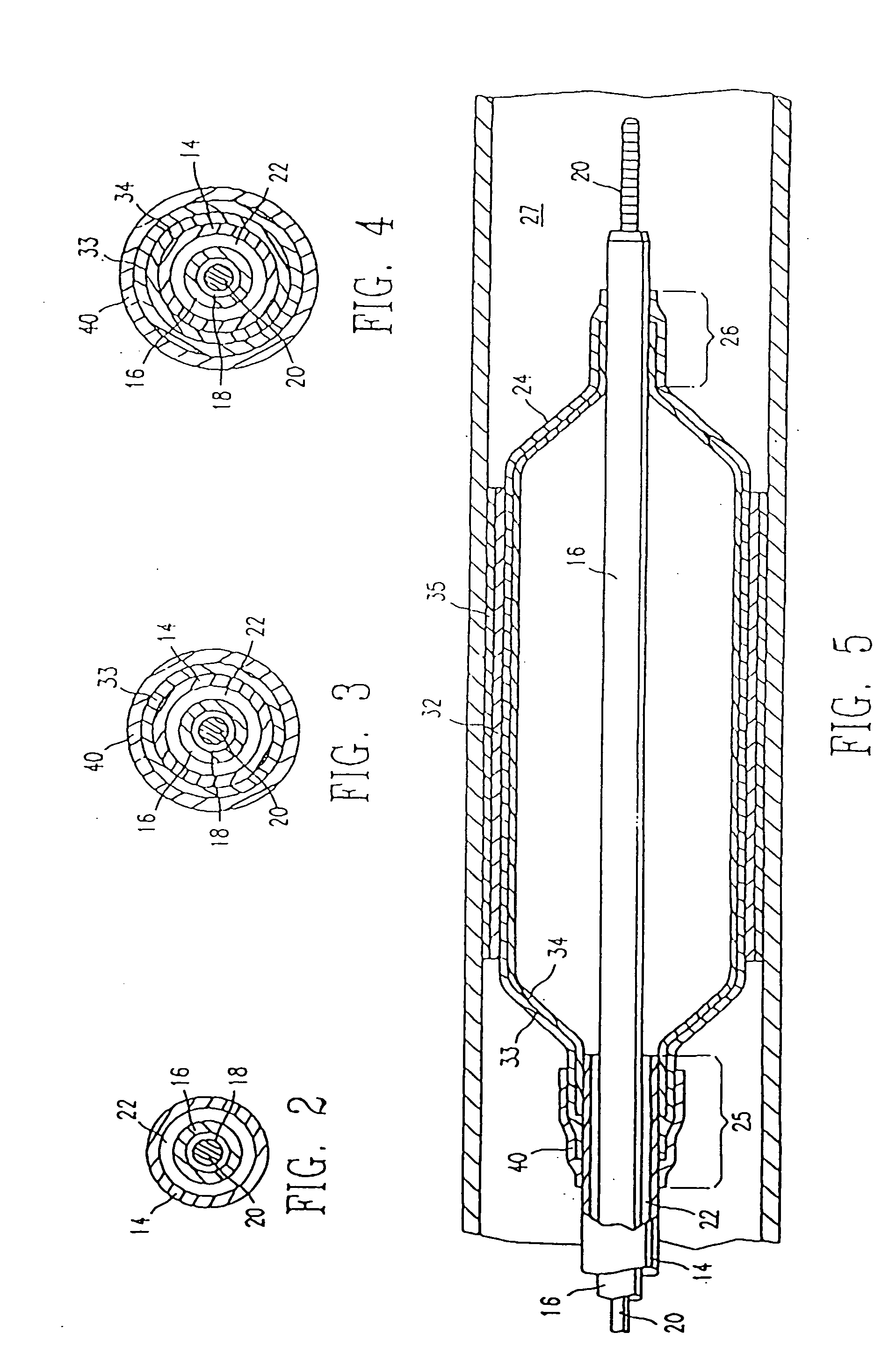

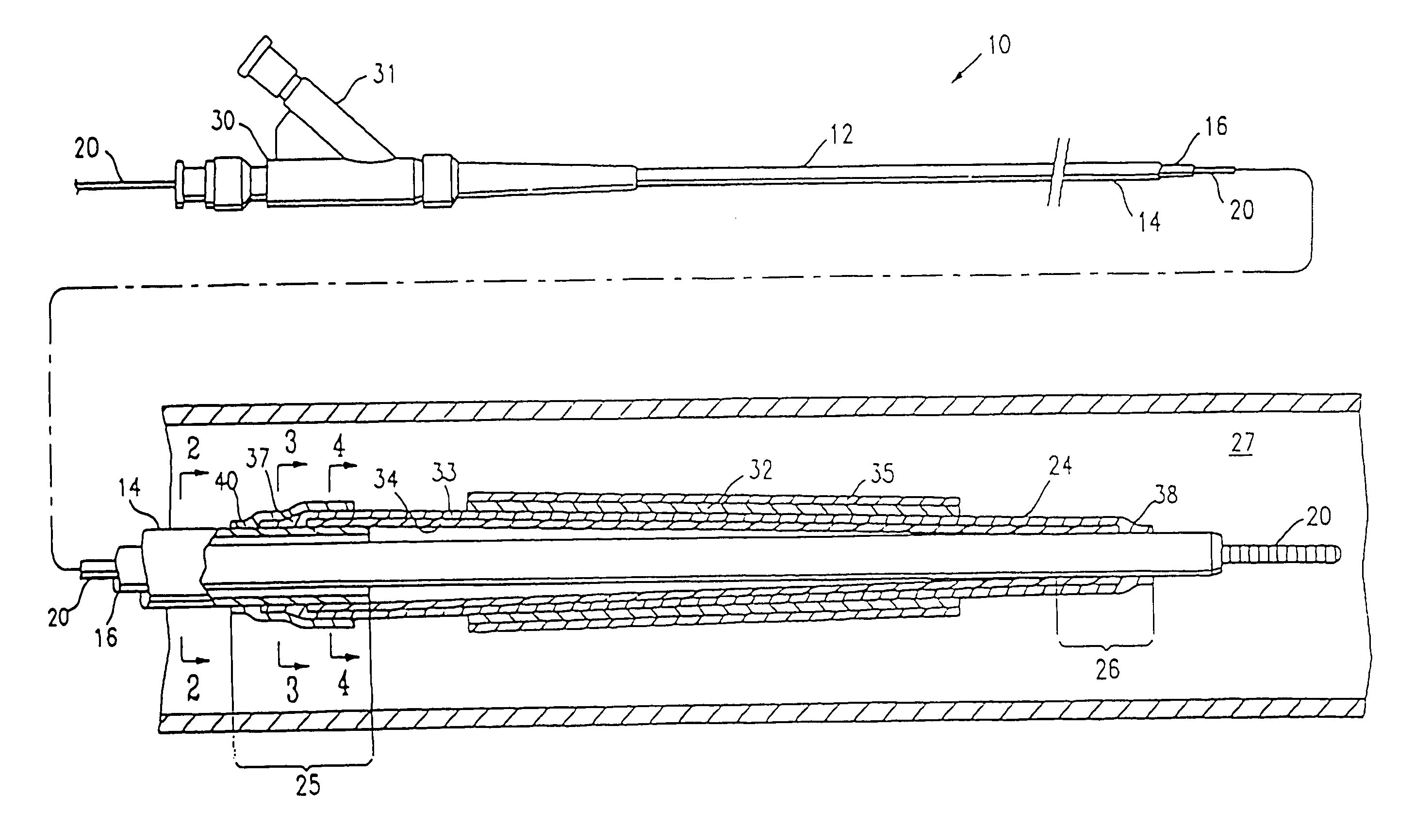

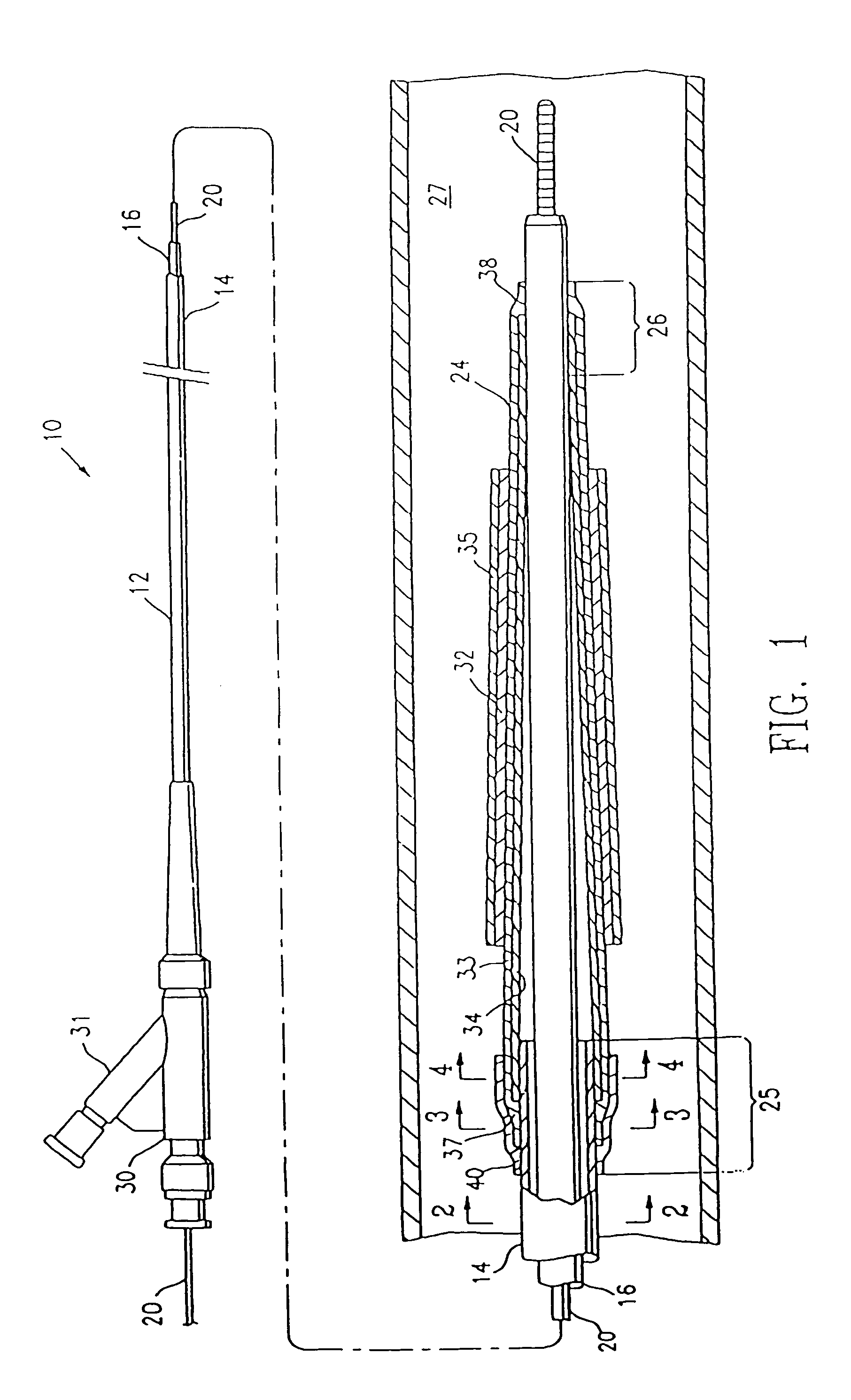

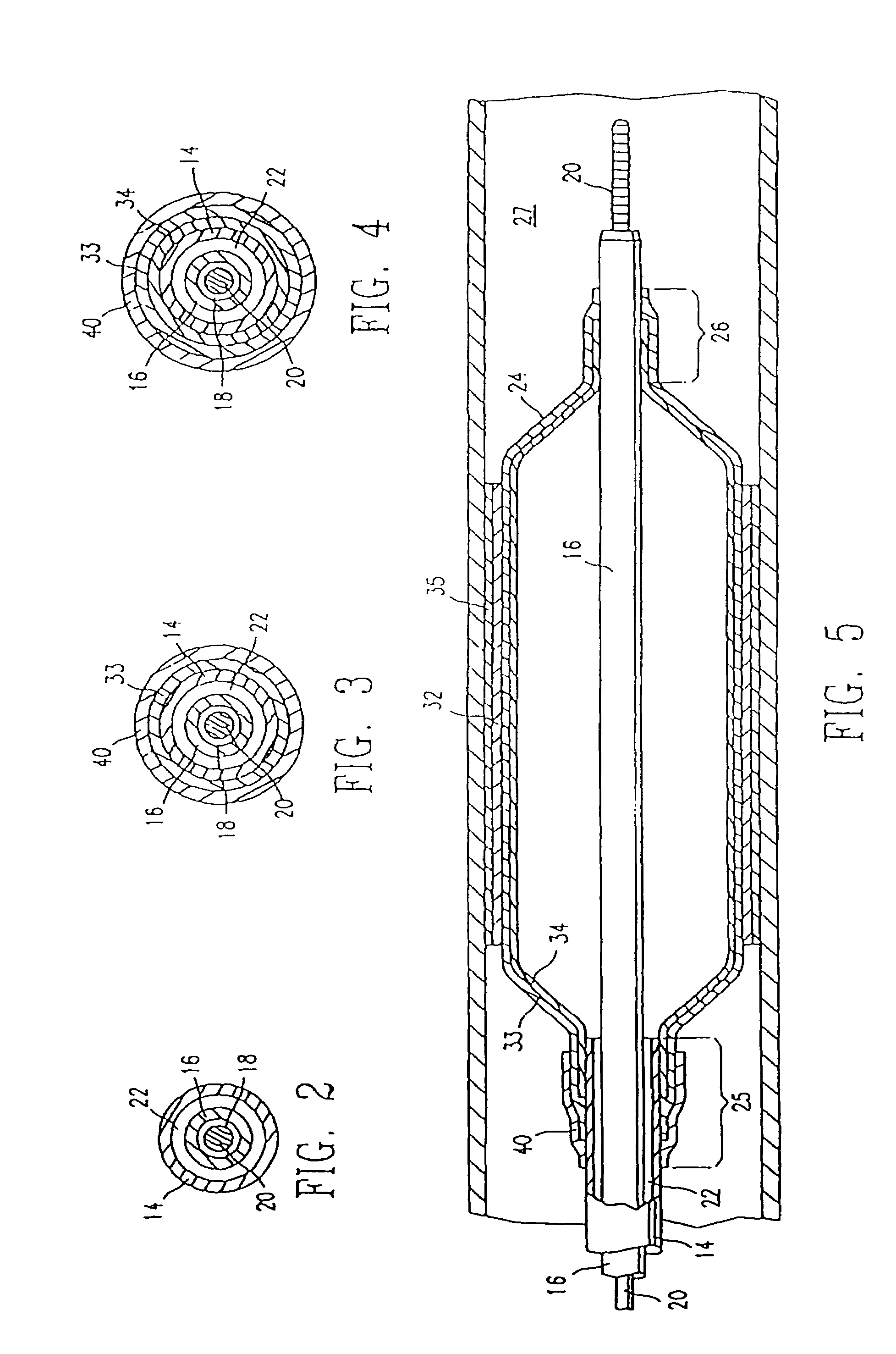

Surface modification of expanded ultra high molecular weight polyethylene (eUHMWPE) for improved bondability

InactiveUS6841029B2Improve bindingHigh bonding strengthBalloon catheterLamination ancillary operationsBalloon catheterUltra-high-molecular-weight polyethylene

A balloon catheter and a method of making the balloon catheter, having a balloon which is bonded to an elongated shaft, and which has a first layer and a second layer and an improved bond between the balloon and the shaft. One aspect of the invention is directed to a balloon in which the balloon first layer includes eUHMWPE and has at least a section that has been oxidized with a chromic acid solution to provide improved bondability.

Owner:ABBOTT CARDIOVASCULAR

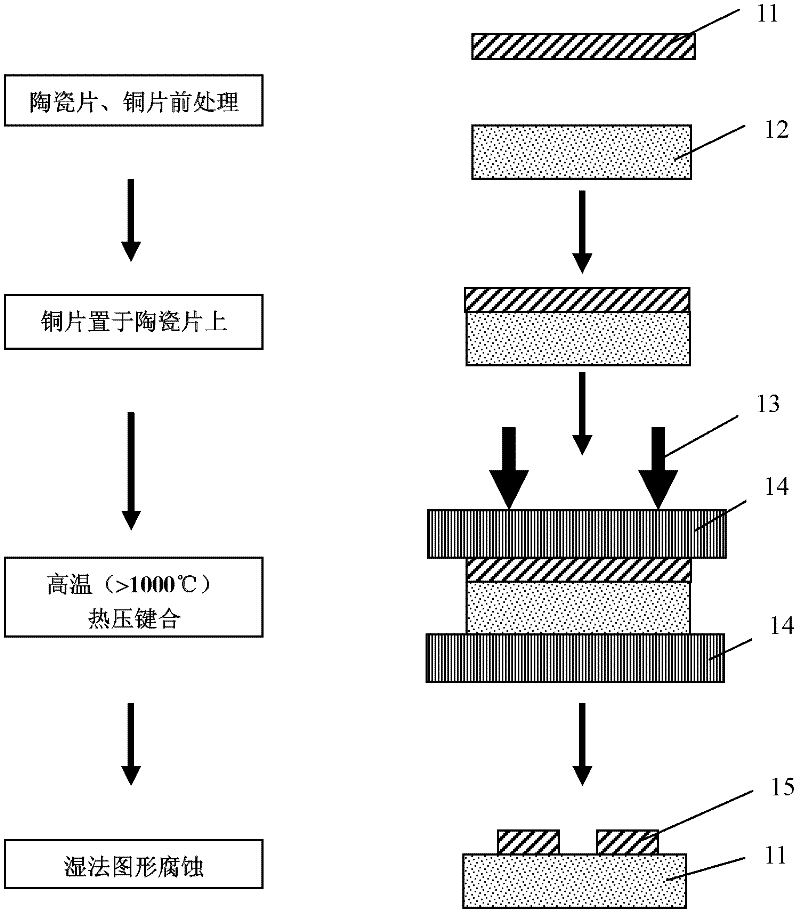

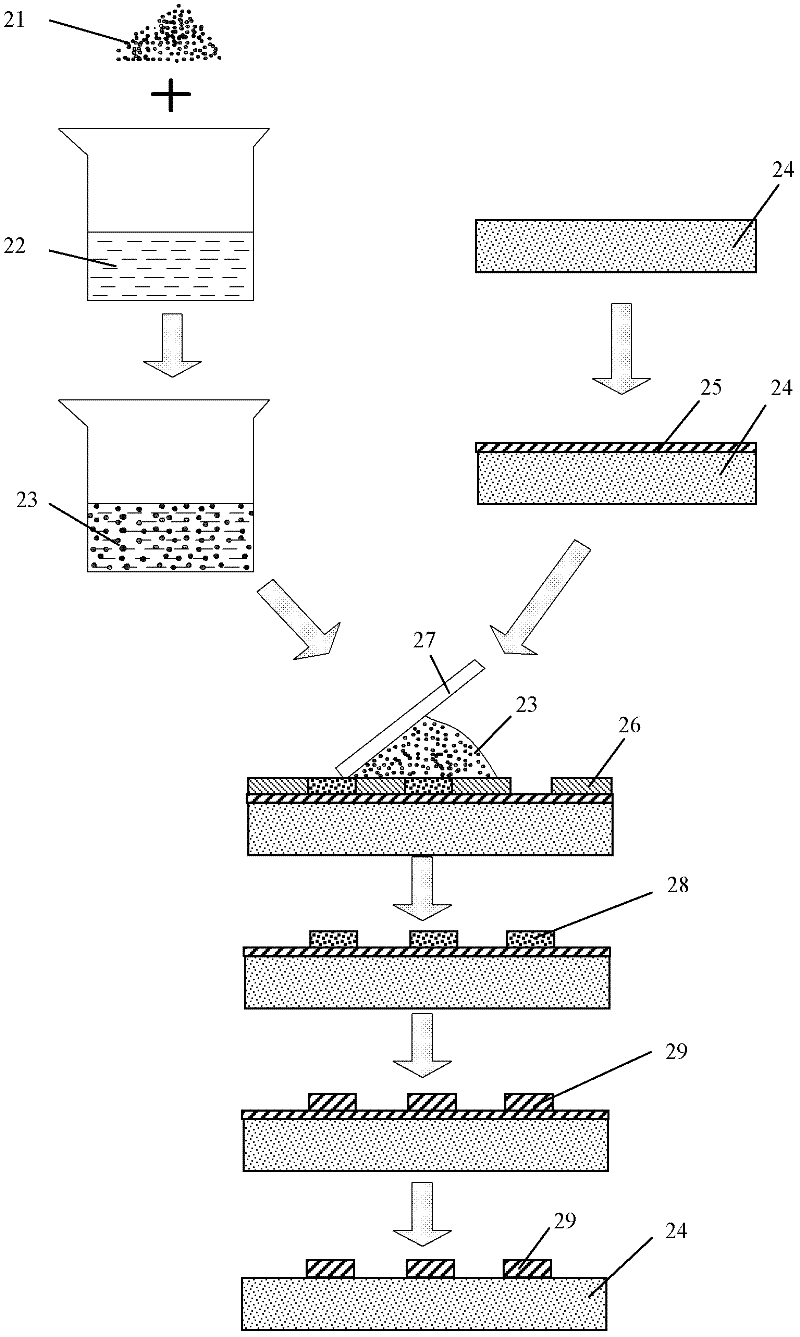

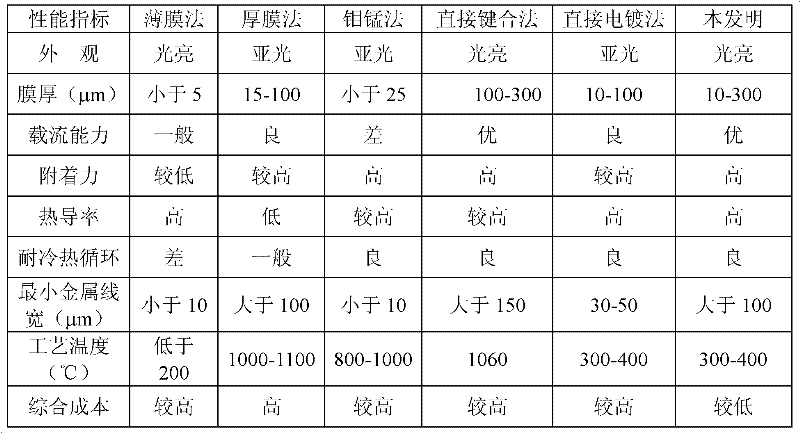

Method for preparing metallized ceramic substrate by low-temperature sintering

The invention provides a method for preparing a metallized ceramic substrate by low-temperature sintering. The method comprises completely mixing metal nanopowder with an organic matter to obtain metal nanopaste; and printing the metal nanopaste on the surface of a ceramic substrate by screen printing process to form a metal paste layer, and sintering at a certain temperature in an atmosphere to obtain the final product with a single-sided or double-sided metal layer. For the nanoscale effect, high-strength bonding between metal and ceramic is realized at a relatively low temperature. Compared with the prior thick film method (in which metal particles have diameter of micrometer scale) and DBC (direct bonded copper) art, the method has low temperature condition, and is particularly suitable for batch preparation of metallized ceramic substrates. The prepared metallized ceramic substrate has good performance including large adhesion and small thermal stress.

Owner:HUAZHONG UNIV OF SCI & TECH

Surface modification of expanded ultra high molecular weight polyethylene (eUHMWPE) for improved bondability

InactiveUS20050089655A1Improve bindingHigh bonding strengthEnvelopes/bags making machineryBalloon catheterBalloon catheterUltra-high-molecular-weight polyethylene

Owner:ABBOTT CARDIOVASCULAR

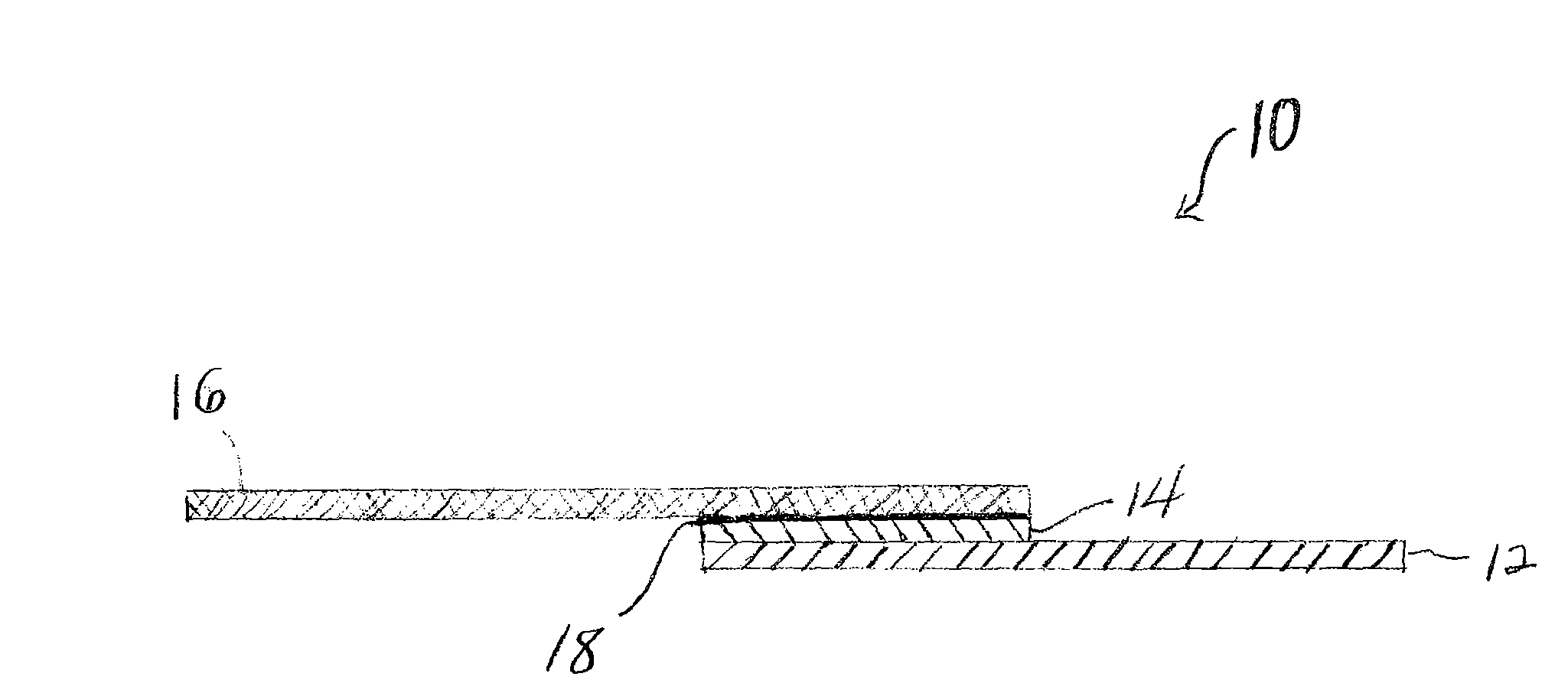

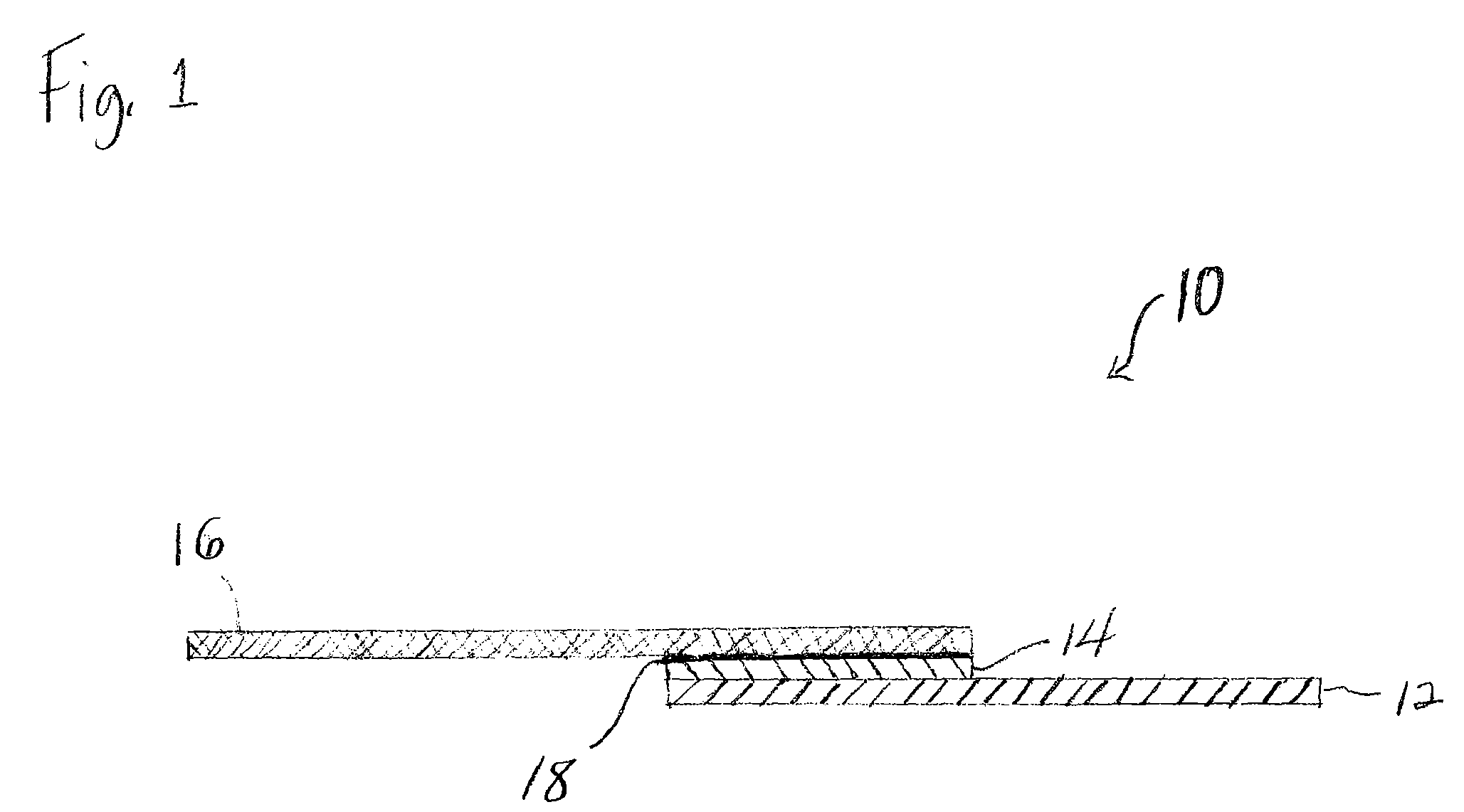

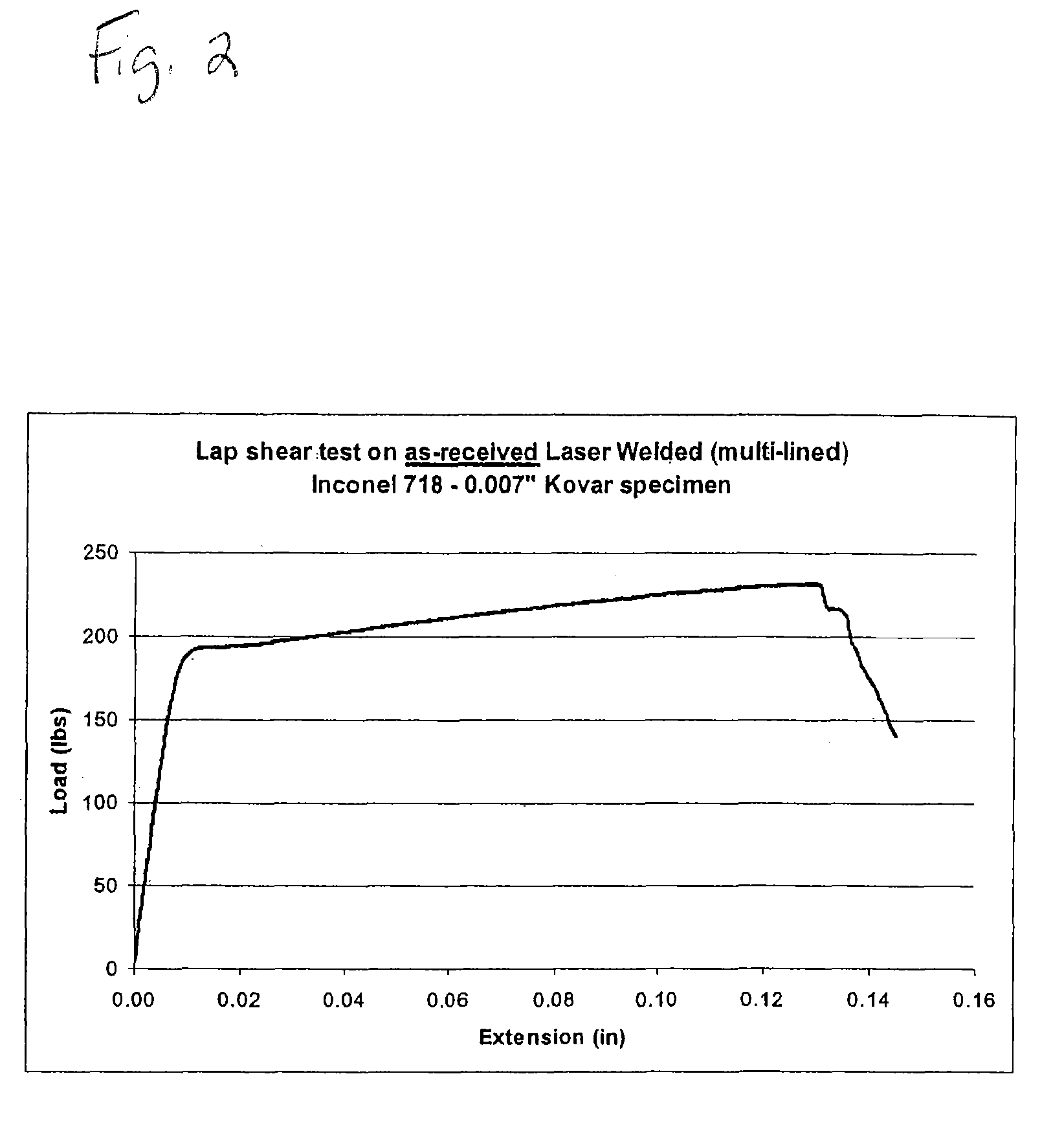

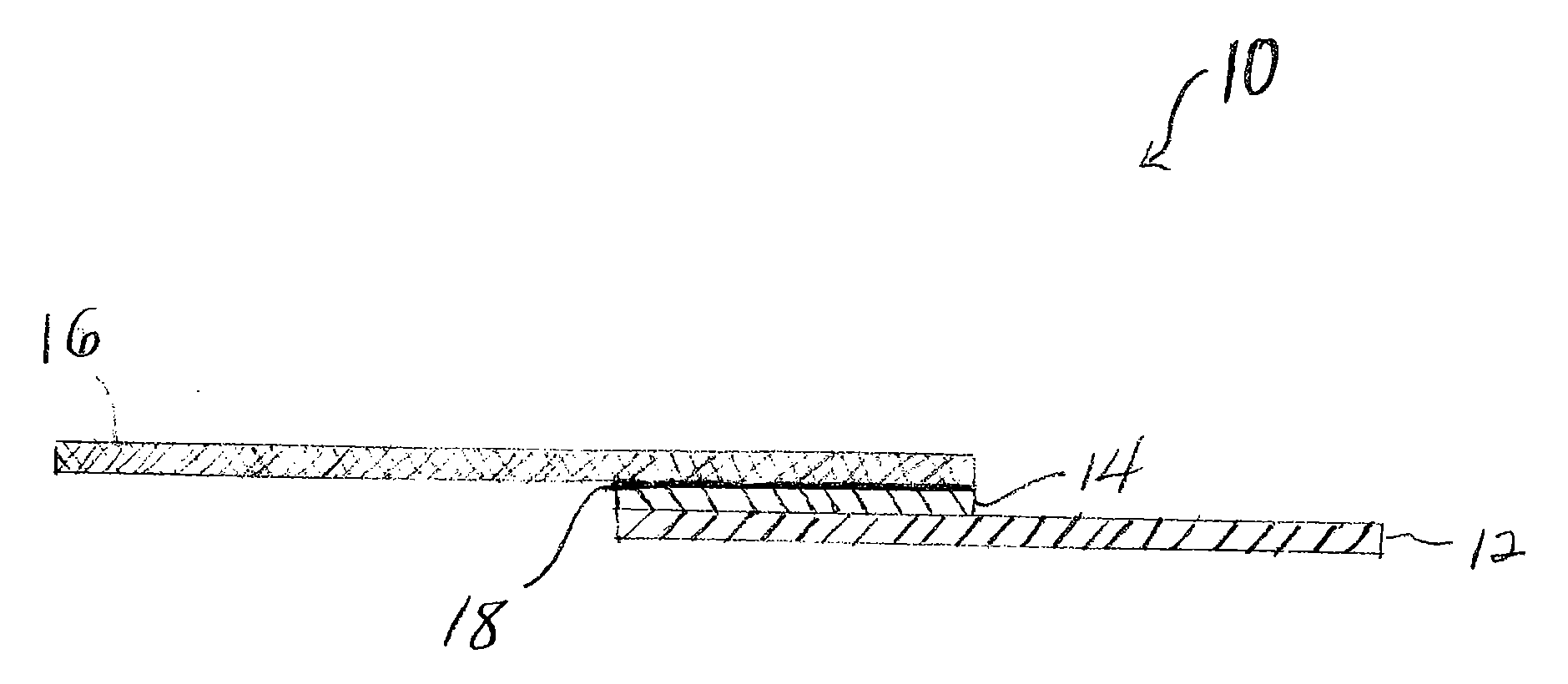

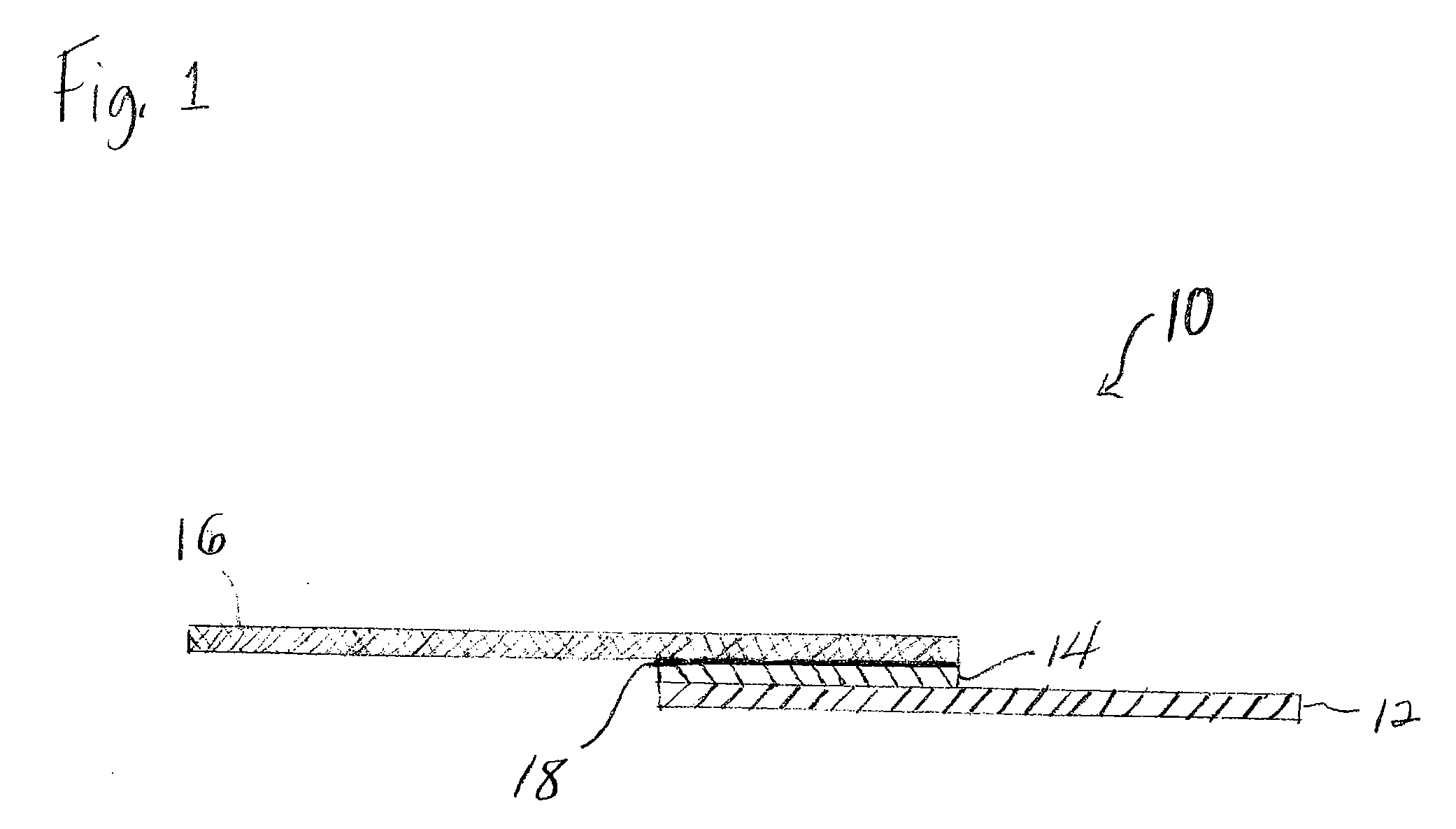

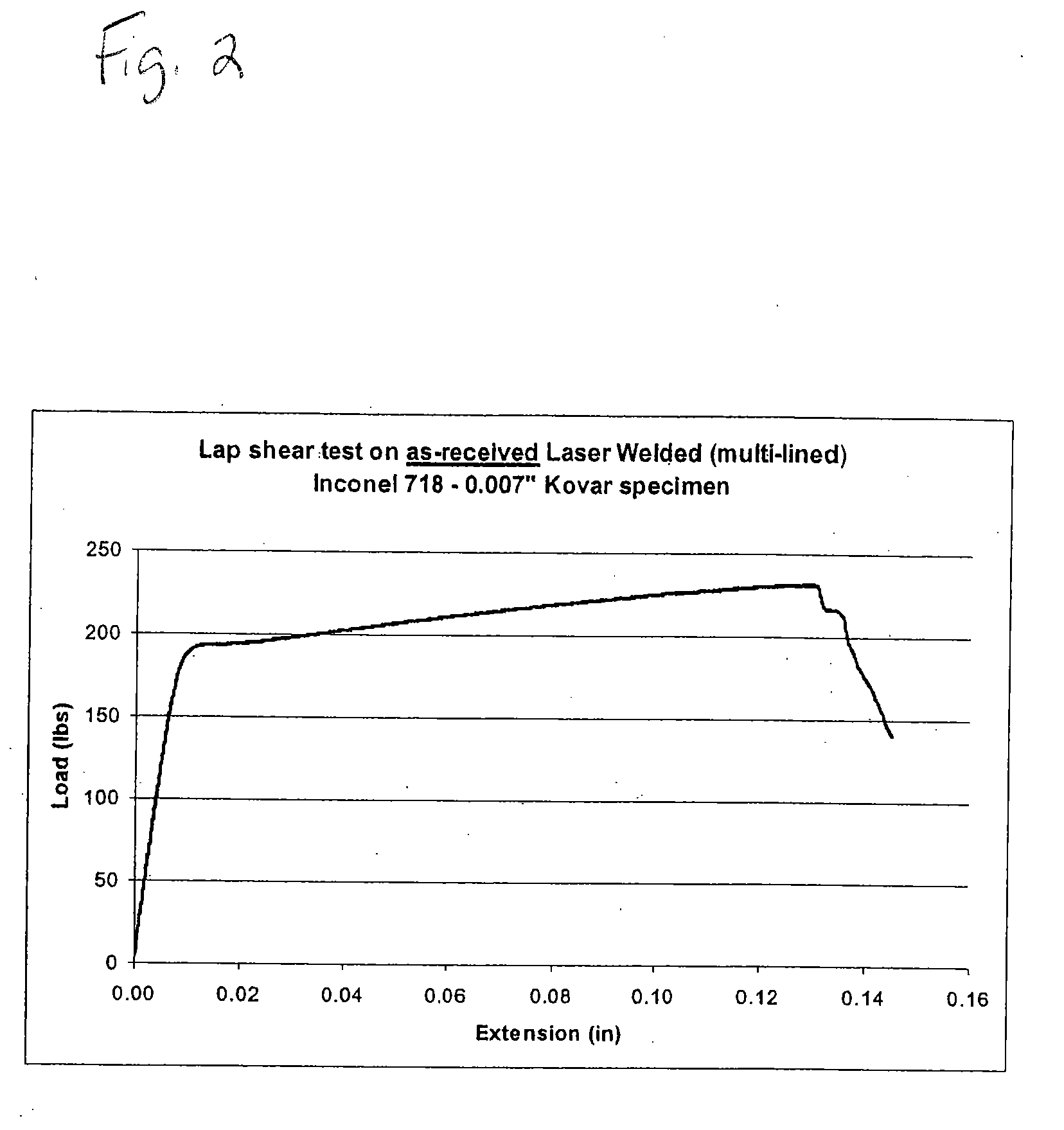

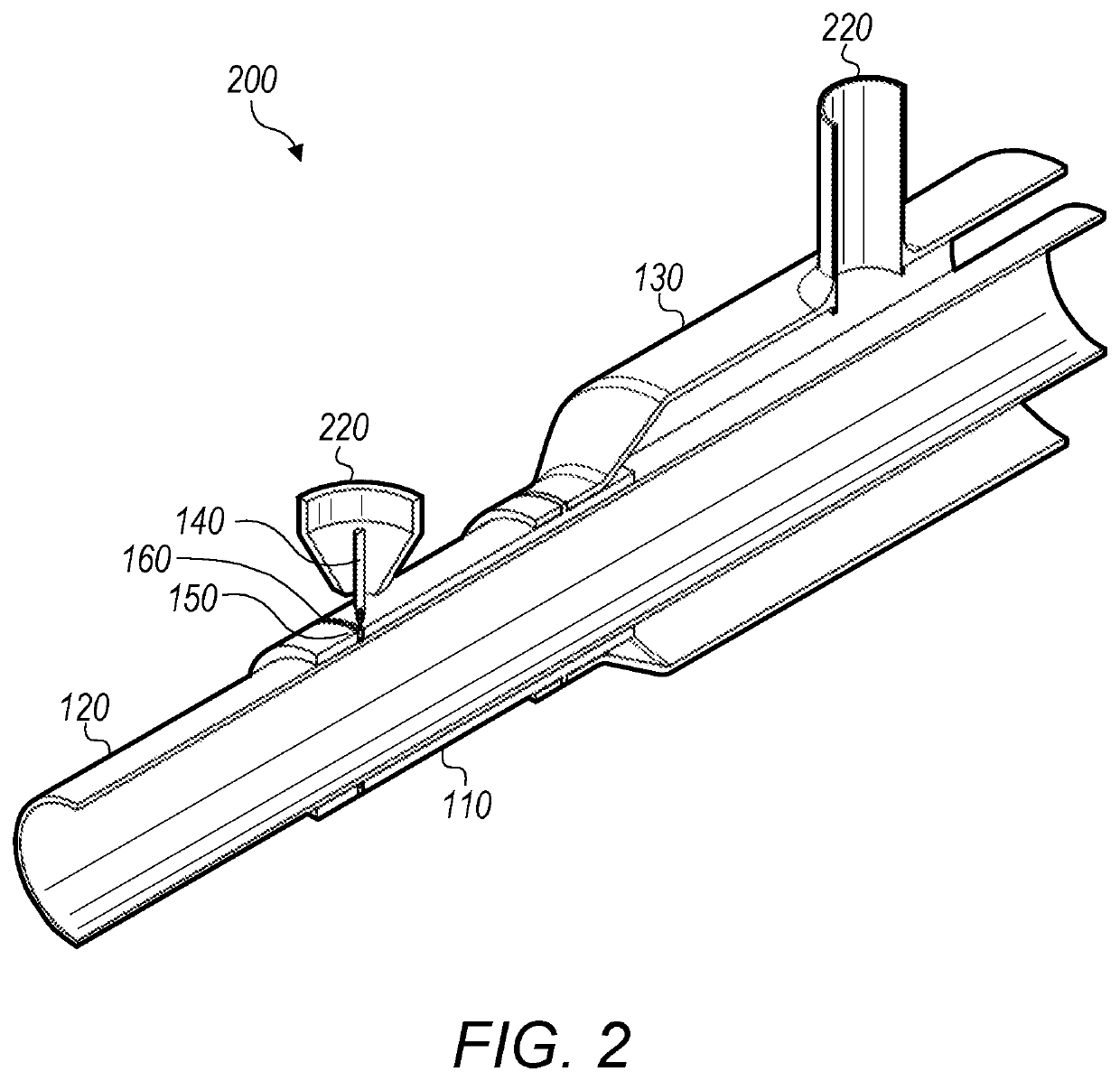

Method of joining metals to ceramic matrix composites

ActiveUS7857194B2Improve bindingHigh strength bondLayered productsWelding/cutting media/materialsThermal expansionHigh intensity

A method of joining metals to a ceramic material such as a ceramic matrix composite is provided which utilizes a compliant interlayer having a coefficient of thermal expansion between the coefficient of thermal expansion of the metal and that of the ceramic matrix composite. The compliant interlayer is bonded to the metal, and the ceramic matrix composite is then bonded to the bonded interlayer / metal. The method results in a high strength joint between a metal having a high coefficient of thermal expansion and a ceramic material having a low coefficient of thermal expansion.

Owner:UNIV OF DAYTON

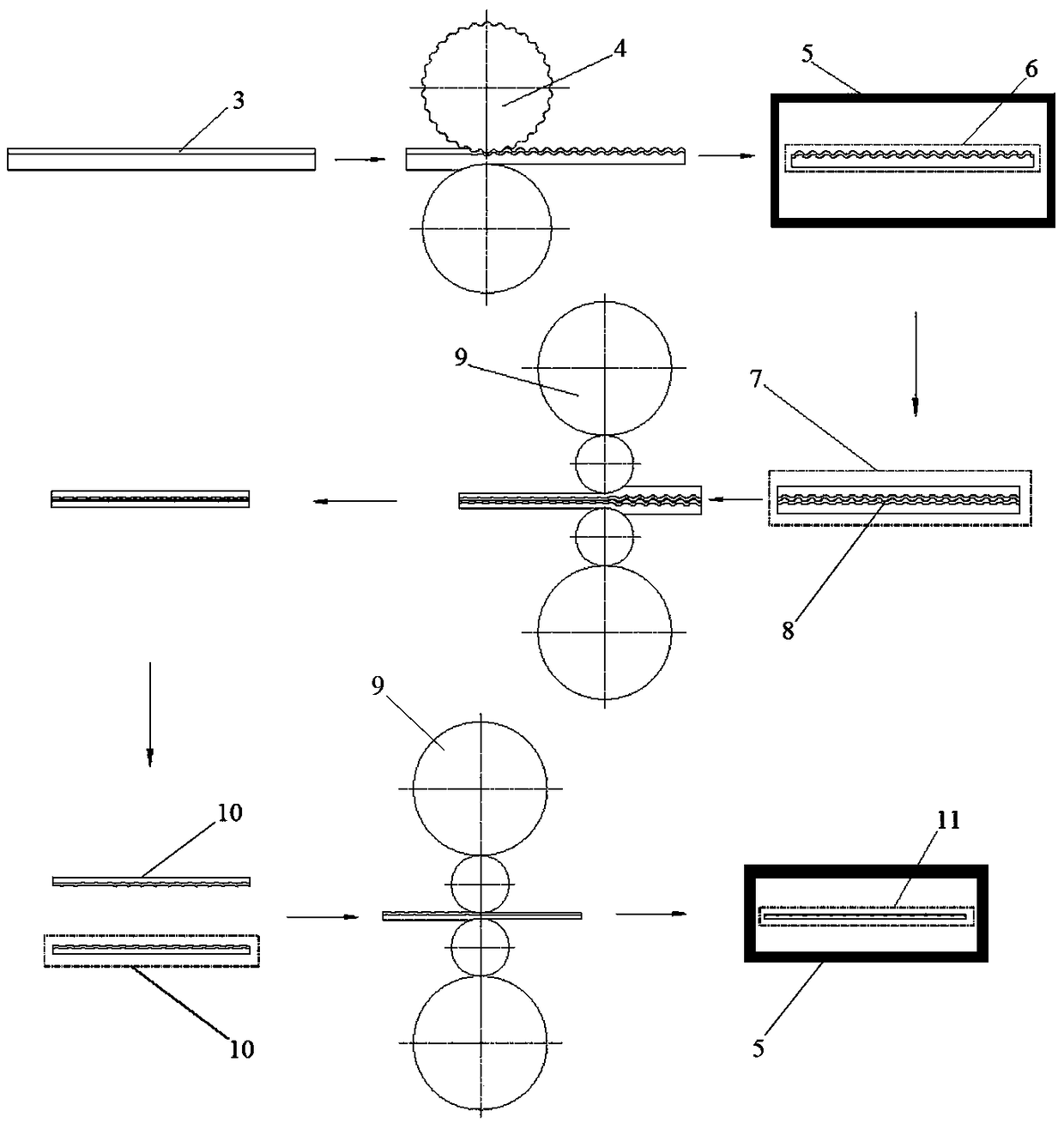

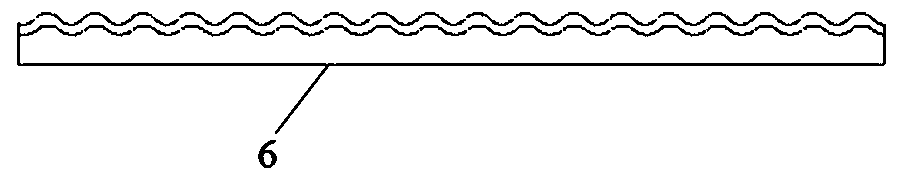

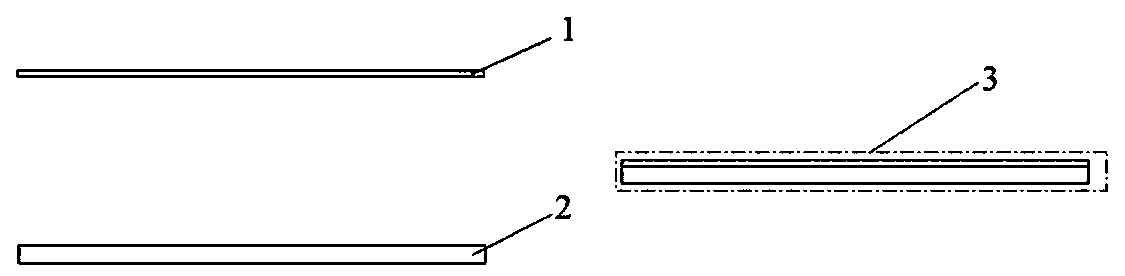

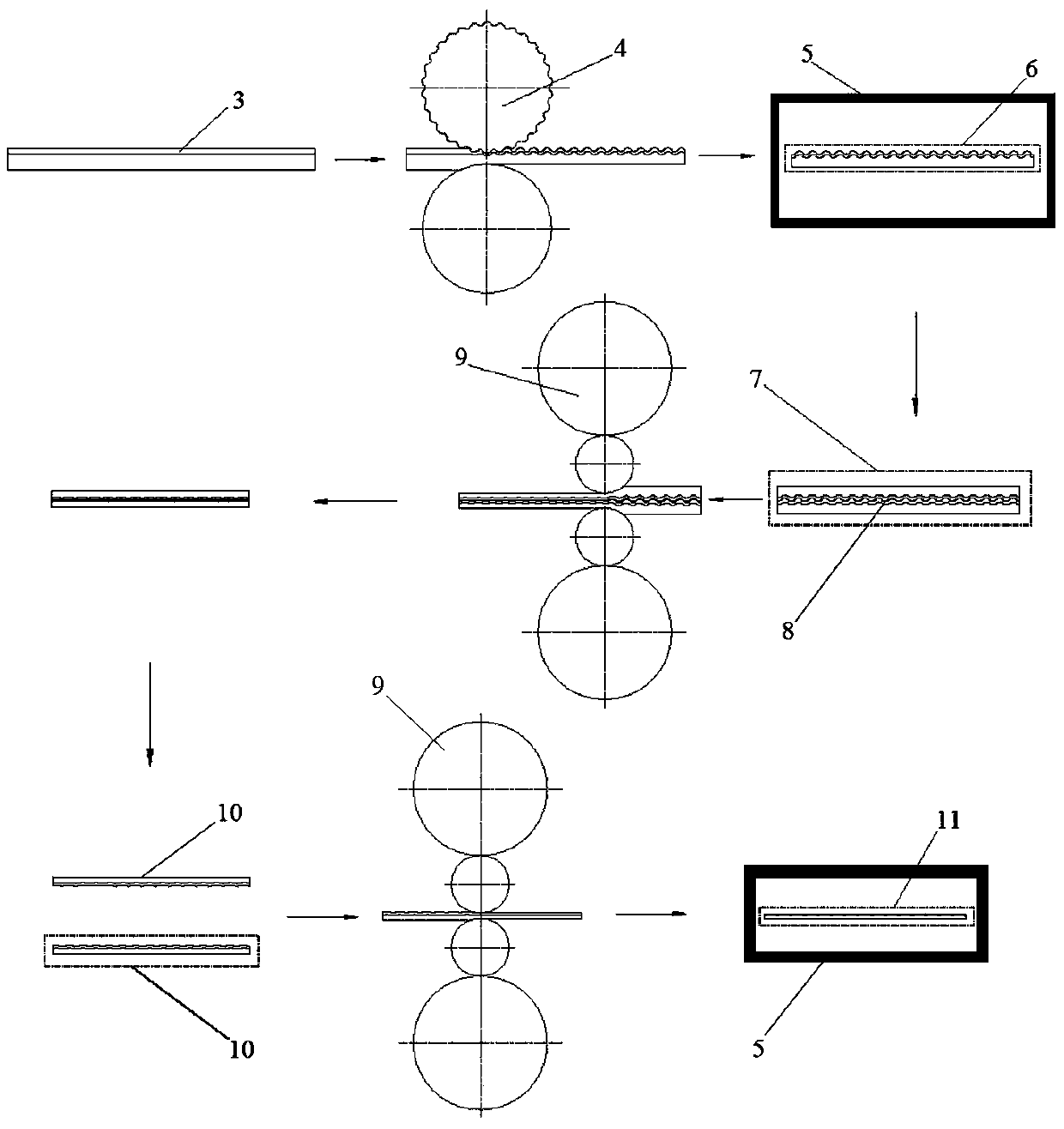

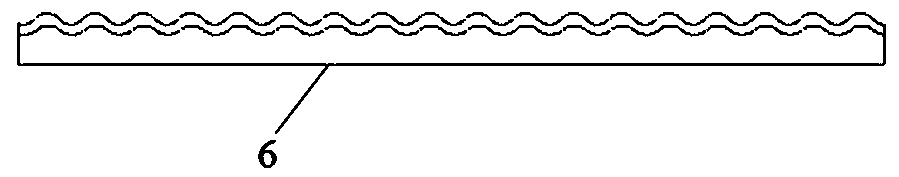

Continuous laminating and rolling method for corrugated interface double-metal composite board

ActiveCN108746204AHigh strength bondImprove bindingMetal rolling arrangementsHigh intensityPeak value

The invention belongs to the technical field of material machining of metal composite boards, particularly relates to a continuous laminating and rolling method for a corrugated interface double-metalcomposite board. The method is characterized in that blanks are rolled into corrugated composite boards by adopting a corrugated roller, the stress peak value is formed at wave troughs of the composite boards, and the combination of the wave troughs is promoted, rolling is carried out by adopting a flat roller, then the stress peak value is formed at the wave crests of the corrugated composite boards so that the relatively high strength combination is realized at the wave peaks, and the high-strength combination of the composite board from the local to the whole surface can be realized by utilizing the two stress peaks at different positions. The extension of metal in the rolling process of the corrugated composite board is mainly achieved through downward pressing of the metal at the position of the wave crests, flowing of the metal at the wave troughs is very small, so that the wave troughs of the corrugated composite boards are not prone to breakage in the flattening process, moreover, the downward pressing of the metal at the wave crest applies a reverse extrusion stress to the wave trough of the composite board at the other side, then the bonding strength at the original wavetrough is further improved, and the double-metal composite board with the good board shape is obtained.

Owner:TAIYUAN UNIV OF TECH

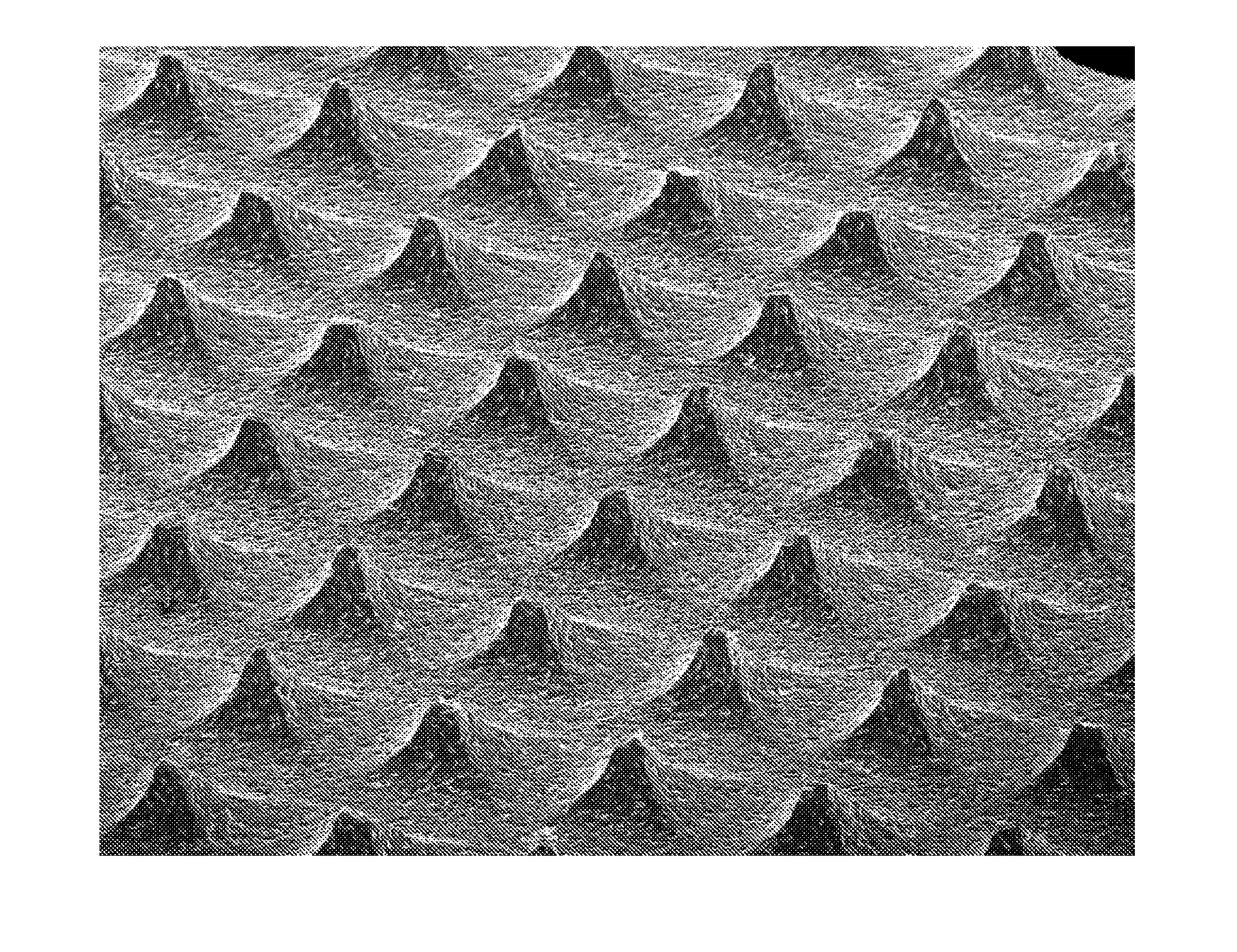

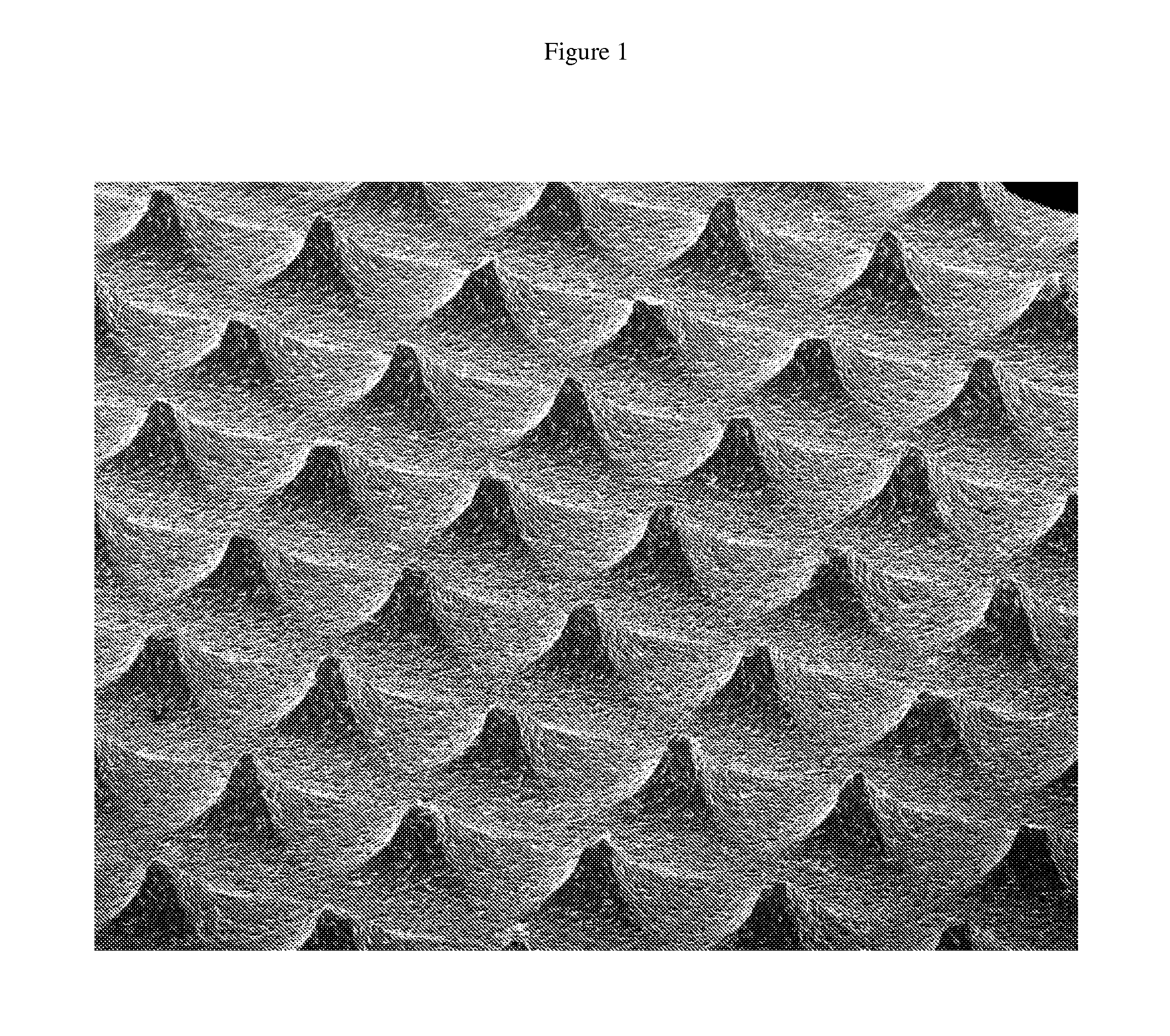

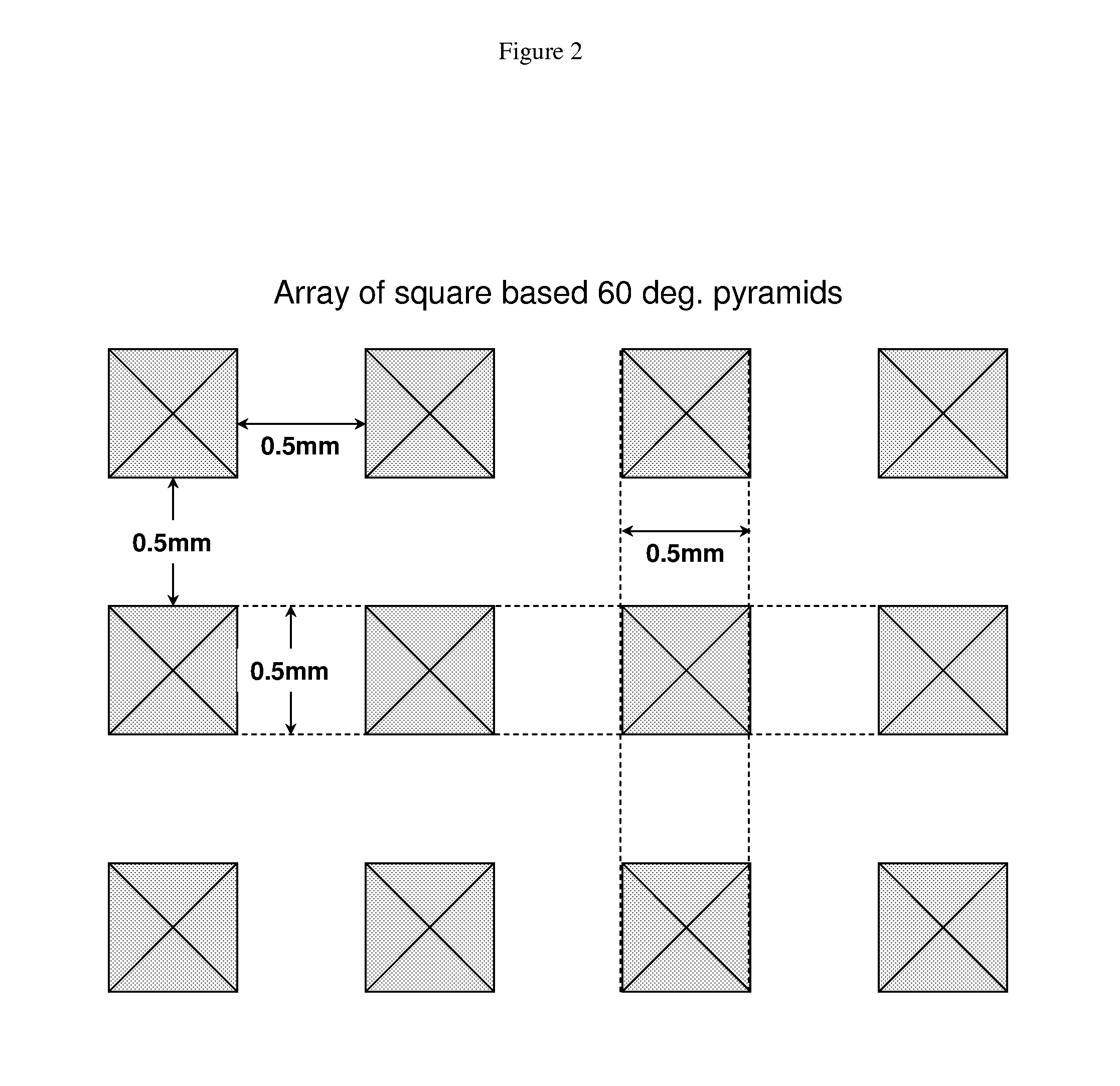

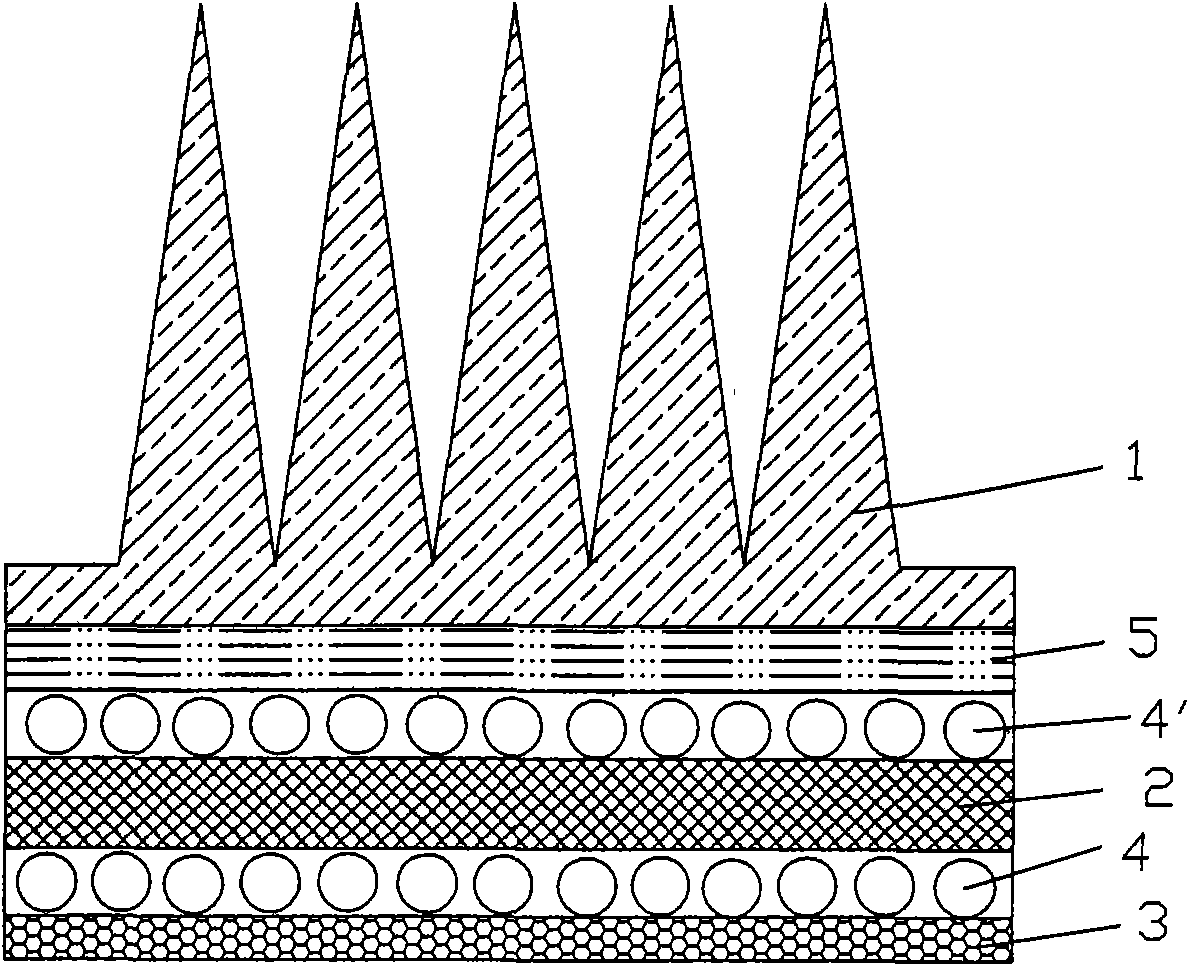

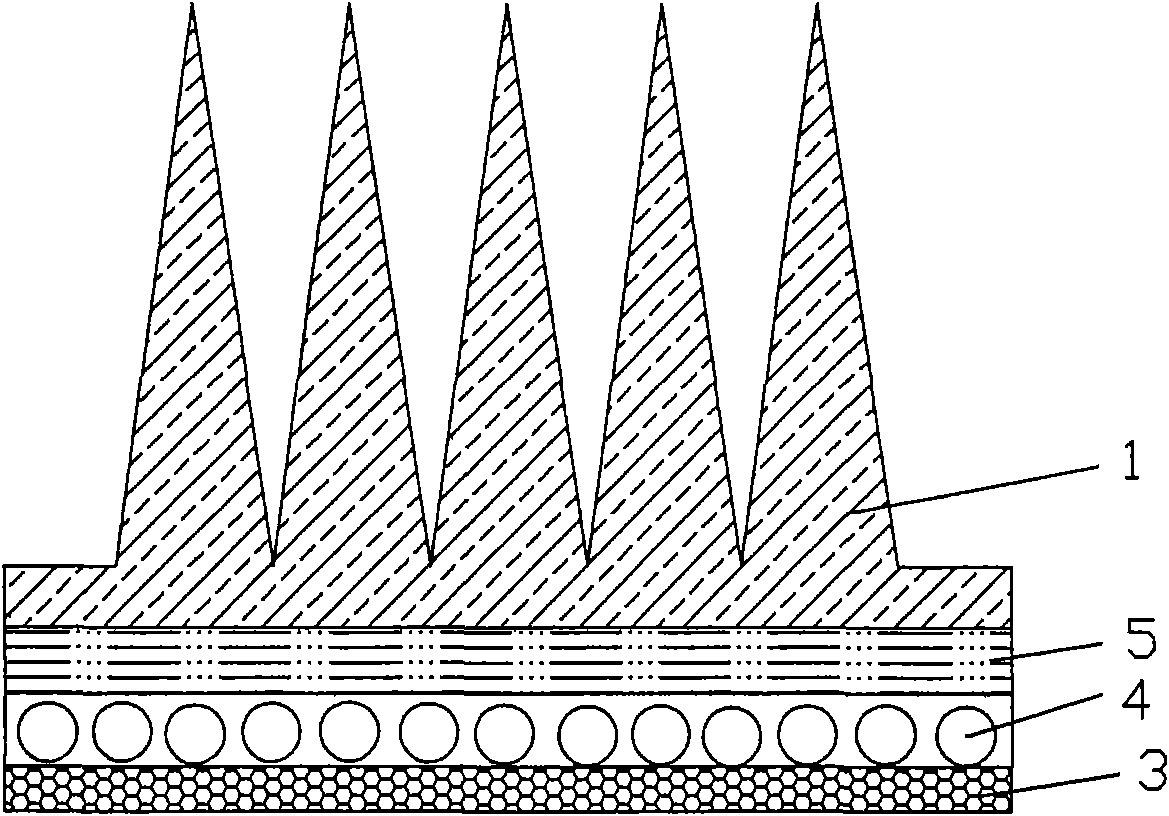

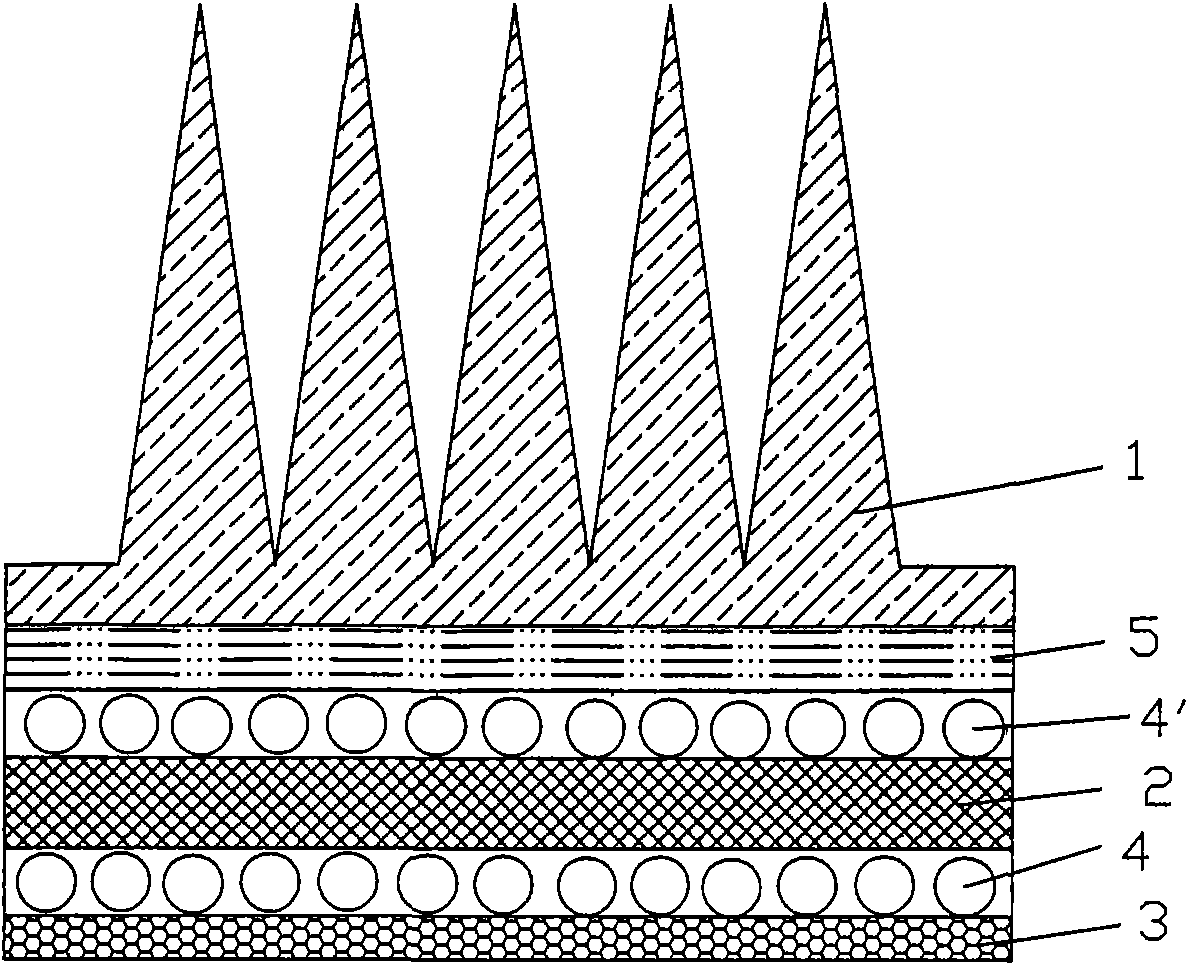

CMP PAD Conditioning Tool

InactiveUS20120171935A1High strength bondPreclude abrasive particle lossGrinding drivesBelt grinding machinesEngineering

The present disclosure provides a CMP pad conditioning tool with at least one integral abrasive protrusion. The present disclosure further provides a method for preparing this CMP pad conditioning tool, along with a method for using said tool to condition a CMP pad.

Owner:DIAMOND INNOVATIONS INC

Method of joining metals to ceramic matrix composites

ActiveUS20080274362A1Improve bindingHigh strength bondLaminationLamination apparatusInter layerThermal expansion

A method of joining metals to a ceramic material such as a ceramic matrix composite is provided which utilizes a compliant interlayer having a coefficient of thermal expansion between the coefficient of thermal expansion of the metal and that of the ceramic matrix composite. The compliant interlayer is bonded to the metal, and the ceramic matrix composite is then bonded to the bonded interlayer / metal. The method results in a high strength joint between a metal having a high coefficient of thermal expansion and a ceramic material having a low coefficient of thermal expansion.

Owner:UNIV OF DAYTON

Water-based environment-friendly leather for shoes and preparation method of leather

The invention discloses a preparation method of water-based environment-friendly leather for shoes. The preparation method comprises the following steps that A, a surface-layer sizing agent is prepared, and a middle-layer sizing agent is prepared; B, release paper is coated with the prepared surface-layer sizing agent, and after drying and cooling are conducted, a surface layer is formed; C, the surface layer is coated with the prepared middle-layer sizing agent, and after drying and cooling are conducted, a middle layer is formed; D, a foaming-layer sizing agent is uniformly mixed on line through a pouring machine (A / B metering and discharging), coats the middle layer and is pre-dried into a semi-dry state; E, then the foaming-layer sizing agent fits base cloth, drying, cross-linking curing and ripening are conducted, finally the release paper is stripped, and the water-based environment-friendly leather for the shoes is obtained. The preparation method is simple in production process, low in production cost, friendly to the environment and beneficial for the physical health of workers; folded wrinkles on the surface of the prepared water-based environment-friendly leather for theshoes are fine, and the leather has high wear resistance; the finished product has few DMF residues and is friendly to the environment and healthy; the leather has good physical performance and usingperformance.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Method for bonding aluminum or aluminum alloy surface with resin material

InactiveCN101712765AAchieving a tight bondThe program steps are conciseAdhesive processes with surface pretreatmentAdhesive processes with adhesive heatingHigh intensityMaterials science

The invention discloses a method for bonding an aluminum or aluminum alloy surface with a resin material. The method comprises the following steps of: firstly, self-assembling high-polymer nano-membranes on the aluminum or aluminum alloy surface bonded with the resin material and on the surface of the resin material; spraying low-concentration organic peroxide and auxiliary vulcanizing agent solution on the surface of the high-polymer nano-membrane so as to modify the surface; and realizing high-intensity bonding of the aluminum or aluminum alloy and the resin material by heating and compressing. The invention adopts a self-assembly dipping method, so that the method can treat materials and components with complex shapes and can realize bonding aluminum or aluminum alloy with complex shapes and the resin material. The method belongs to an environment-friendly formula and has simple and convenient operation process. Moreover, the method realizes high bonding intensity between the aluminum or aluminum alloy and the resin material and high stability.

Owner:NORTHWEST A & F UNIV

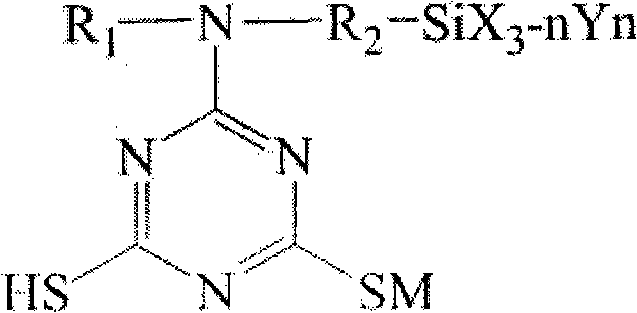

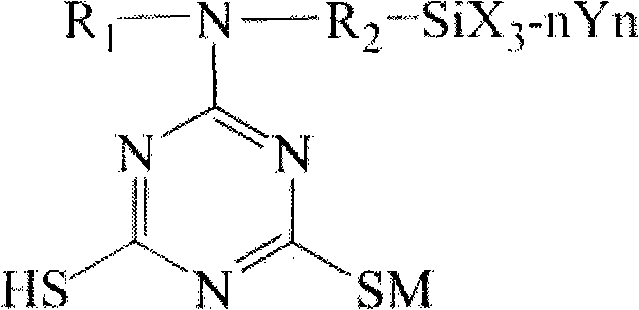

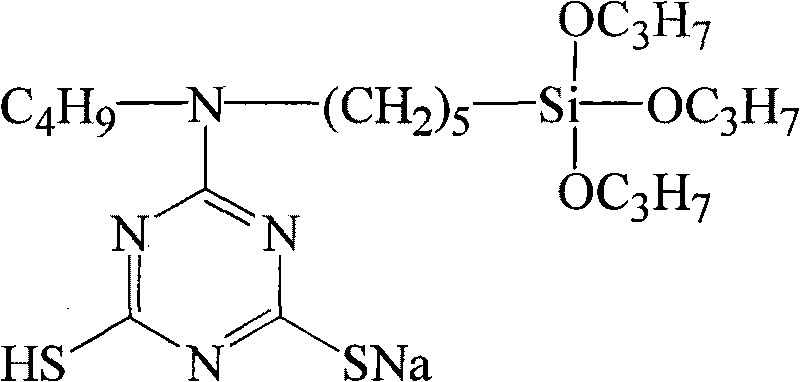

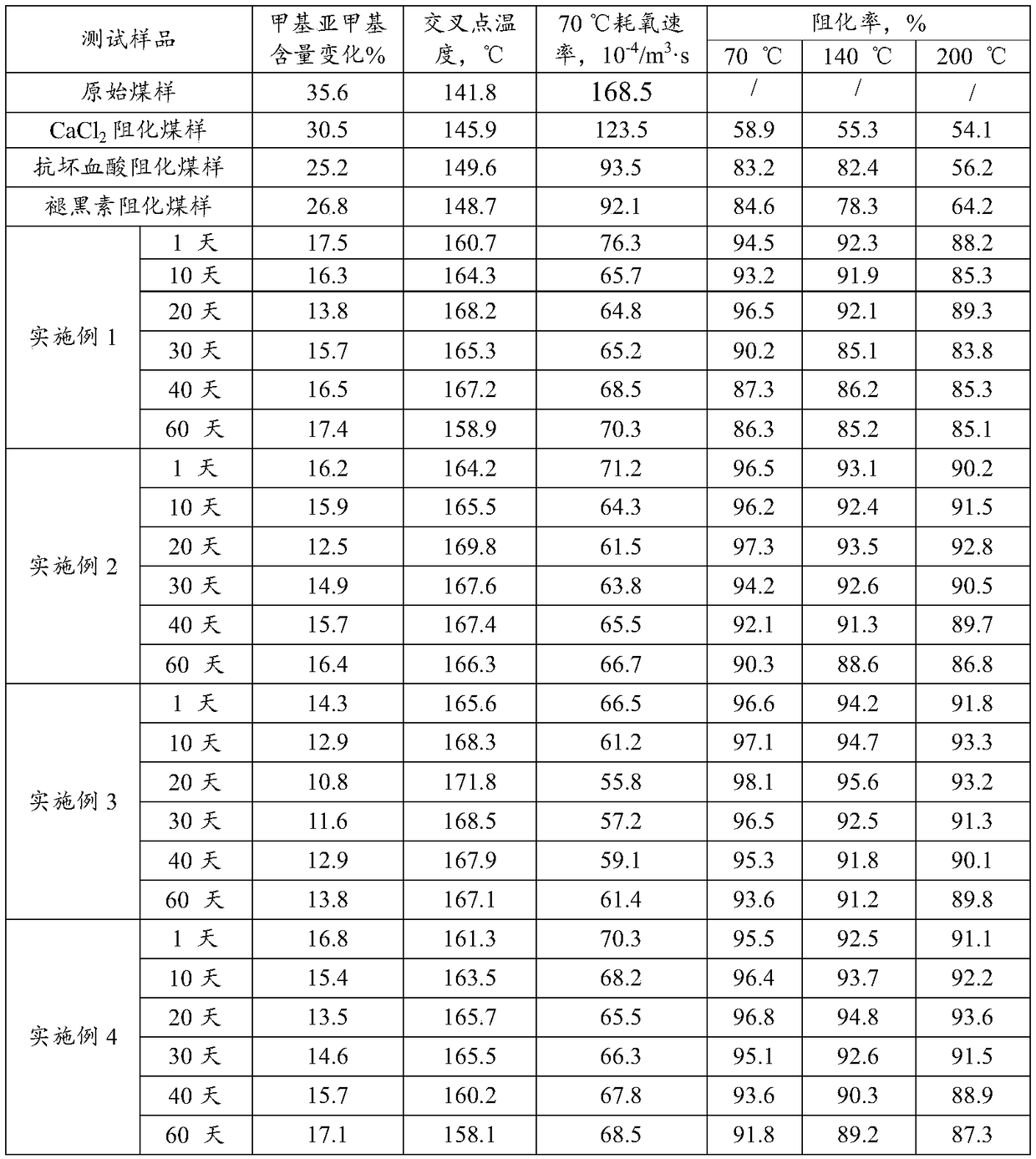

Oxidation reduction double blocking-based coal spontaneous combustion intelligent compound retardant and preparation method thereof

ActiveCN108641266AHigh strength cross-linking propertiesFast water absorptionDust removalFire preventionGuar gumHydroxyl radical

The invention discloses an oxidation reduction double blocking-based coal spontaneous combustion intelligent compound retardant. The retardant is prepared by compounding high molecular copolymer, aldehyde-amine and a penetrating agent in an optimally screened specific proportion, wherein the high molecular copolymer is prepared by the steps of hydrophobically modifying acrylic acid-acrylamide-guargum copolymer which is obtained by a solution polymerization method to prepare ferrocene butyryl chloride grafting modified acrylic acid-acrylamide-guar gum copolymer. The coal spontaneous combustionintelligent compound retardant belongs to the technical field of coal mine fire prevention retarding materials, the high-molecular copolymer frame has high water absorption and strong adhesive property, has the oxidation reduction double intelligent adjusting characteristic of grafted functional group ferrocene, can be used for eliminating carbon radical and hydroxyl radical in the coal spontaneous combusting process based on the oxidation reduction characteristic; and the penetrating agent can penetrate into the inside of float coal, carbon radical which does not react at large structure canbe eliminated, and constant efficient prevention and control of a coal spontaneous combustion zone can be realized.

Owner:CHINA UNIV OF MINING & TECH

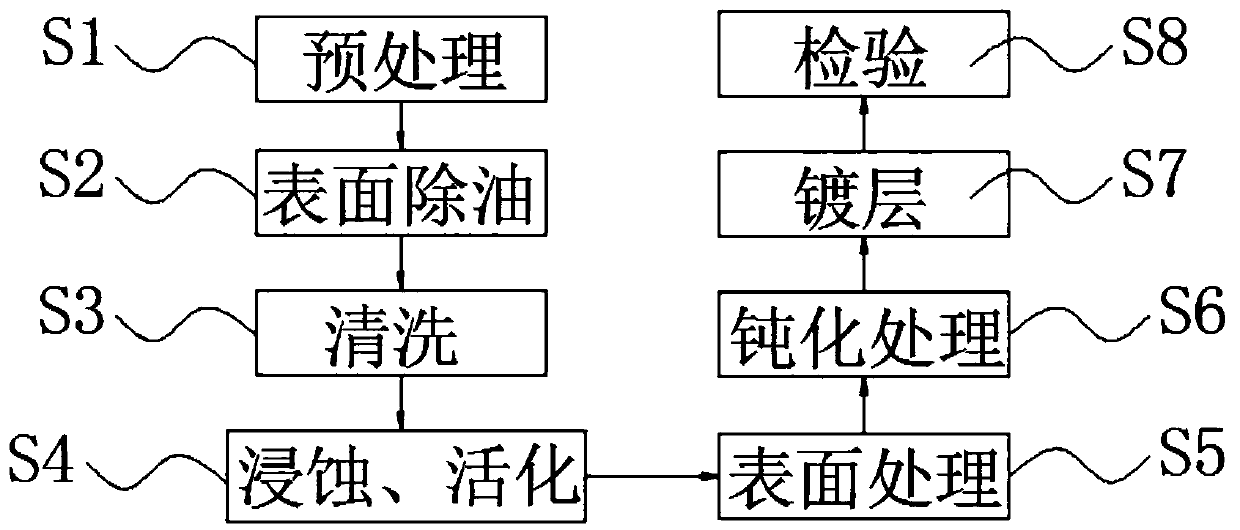

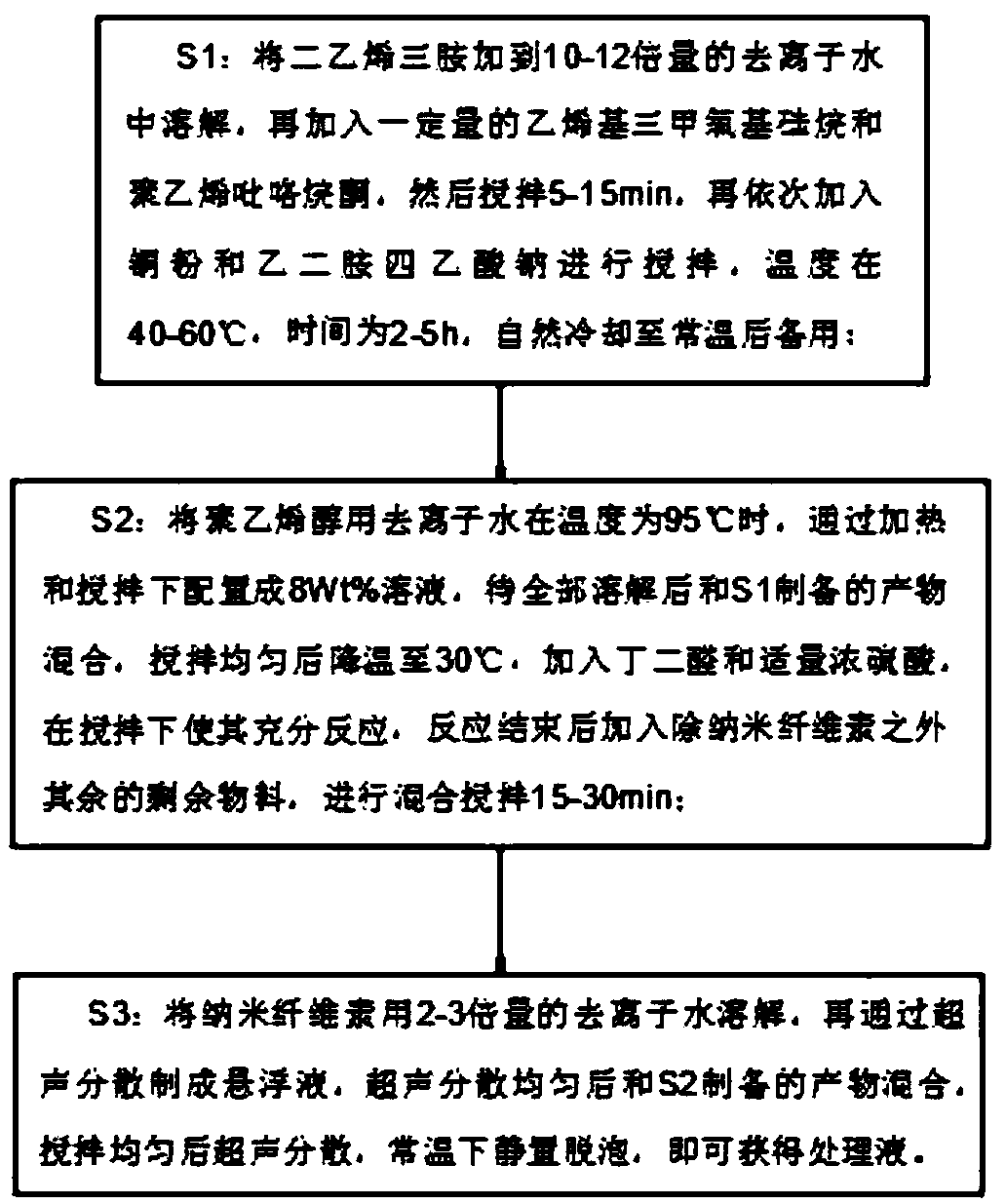

Processing technology of zinc-nickel plating alloy

The invention discloses a processing technology of a zinc-nickel plating alloy. The processing technology comprises the following steps: S1, pretreatment; S2, surface oil removal; S3, cleaning; S4, etching and activation; S5, plating; S6, passivation treatment; S7, surface treatment; and S8, inspection. During actual use, a zinc-nickel alloy coating layer is plated on the surface of a workpiece; the high-strength bonding force with a workpiece can be realized; the zinc-nickel plating alloy plating layer is fine in appearance, free of pinholes and free of blistering; the attractiveness of the workpiece is further improved; meanwhile, after the workpiece plating is finished, the surface is treated by a treatment liquid; the surface of the workpiece can be further protected, so that the workpiece has good thermal stability, corrosion resistance and oxidation resistance, the surface of the workpiece soaked in the treatment liquid is smooth and complete, and holes and redundant parts are avoided; the process is easy to operate, and the corrosion resistance of the plating layer is still superior to that of a pure zinc plating layer after the plating layer is processed.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

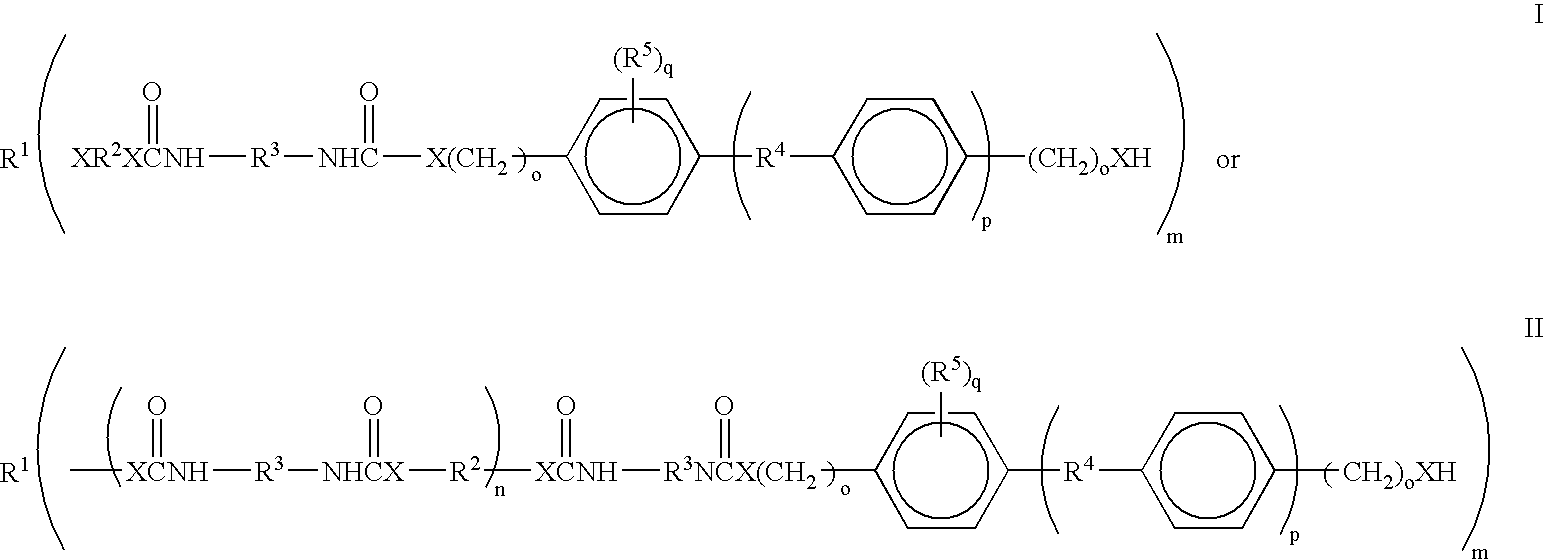

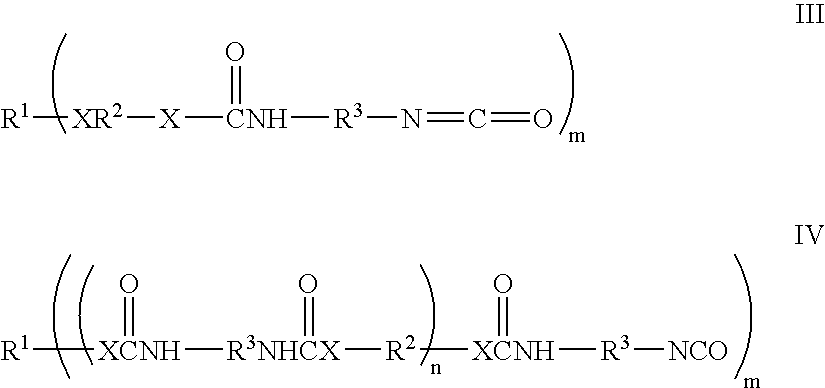

Process for applying a streamable epoxy adhesive

ActiveUS20080009589A1Low viscosityHigh strength bondAdhesive processes with adhesive heatingEpoxy resin adhesivesPrepolymerIsocyanate

The invention is a composition comprising applying to a substrate a stream of an adhesive comprising: one or more epoxy resins; one or more rubber modified epoxy resins; one or more toughening compositions comprising the reaction product of one or more isocyanate terminated prepolymers and one or more capping compounds having one or more phenolic, benzyl alcohol, aminophenyl, or, benzylamino groups wherein the reaction product is terminated with the capping compounds; one or more curing agents for epoxy resins and one or more catalysts which initiate cure at a temperature of about 100° C. or greater; and optionally; fillers adhesion promoters, wetting agents or rheological additives useful in epoxy adhesive compositions; wherein the adhesive composition has a viscosity at 45° C. of about 20 Pa·s to about 400 Pa·s. The composition can be used as an adhesive and applied as a stream using a high speed streaming process.

Owner:DOW GLOBAL TECH LLC

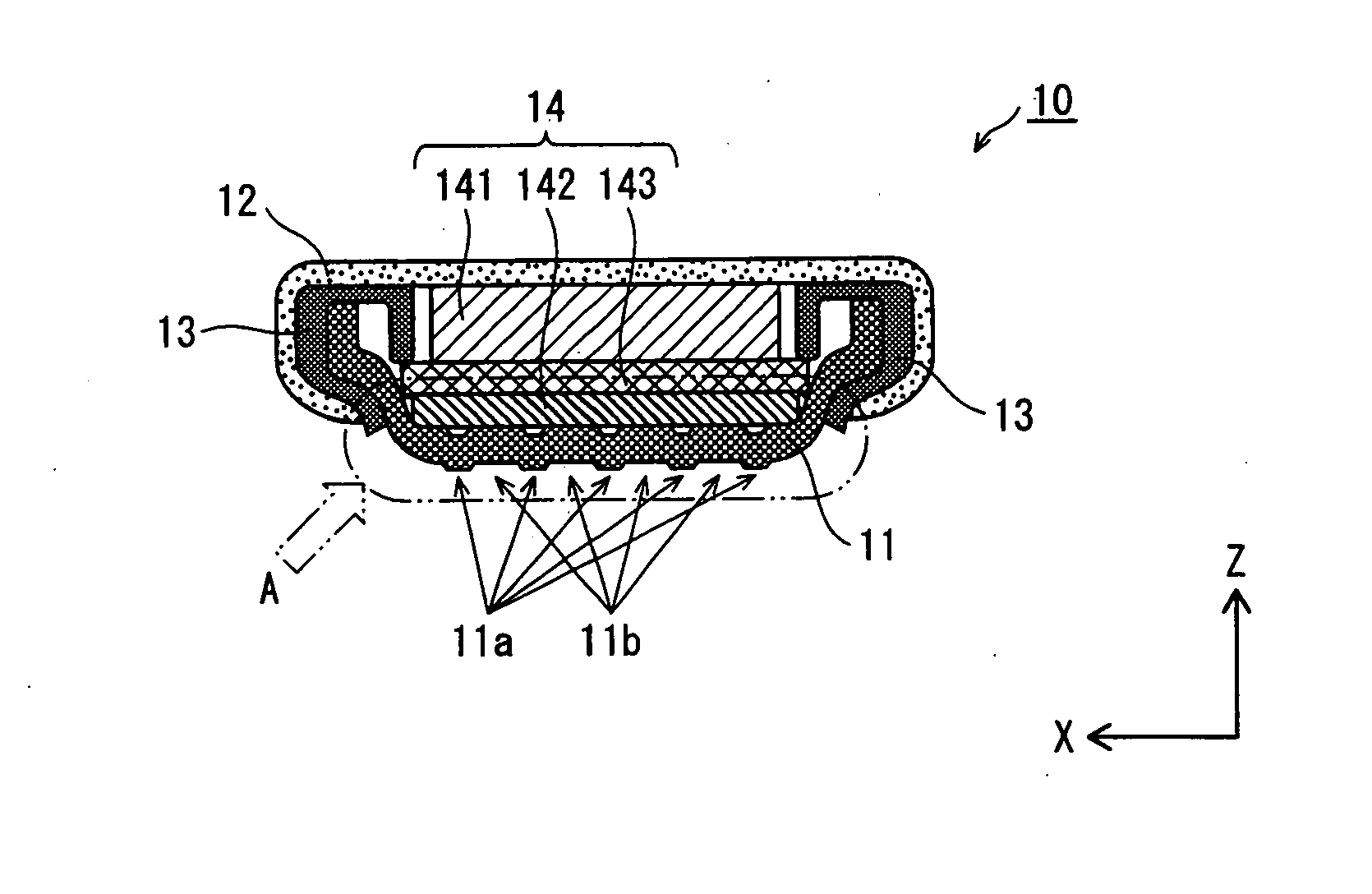

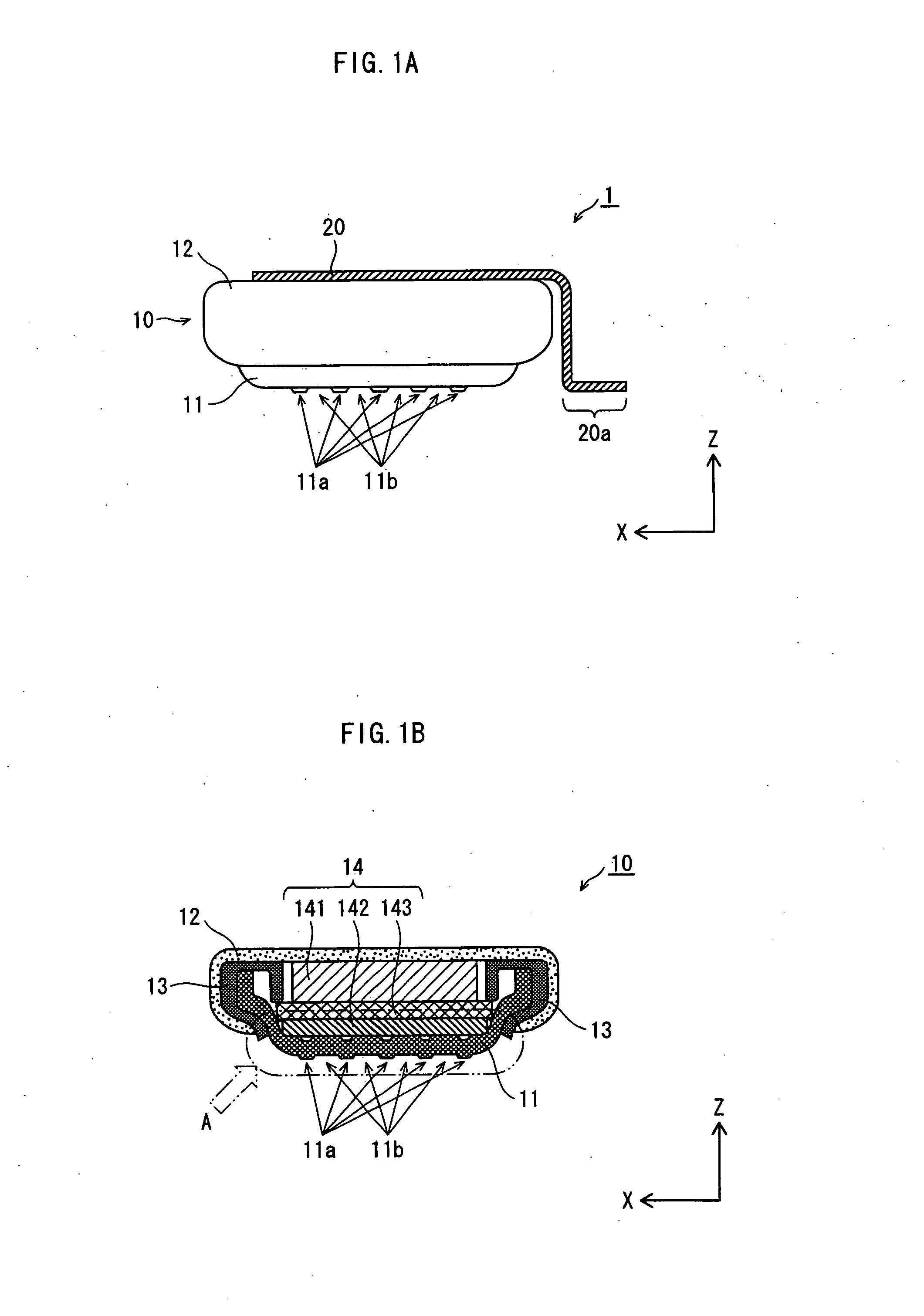

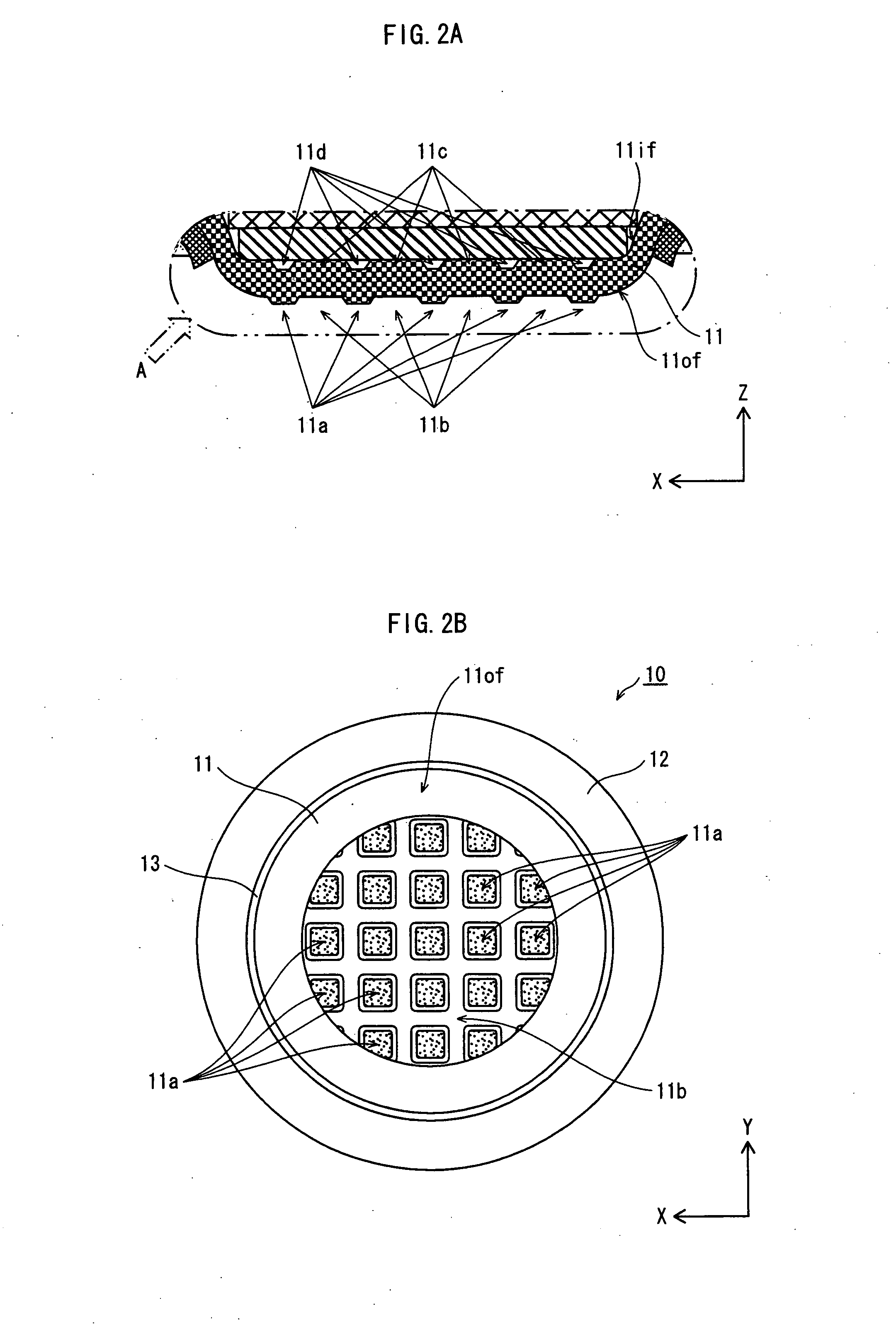

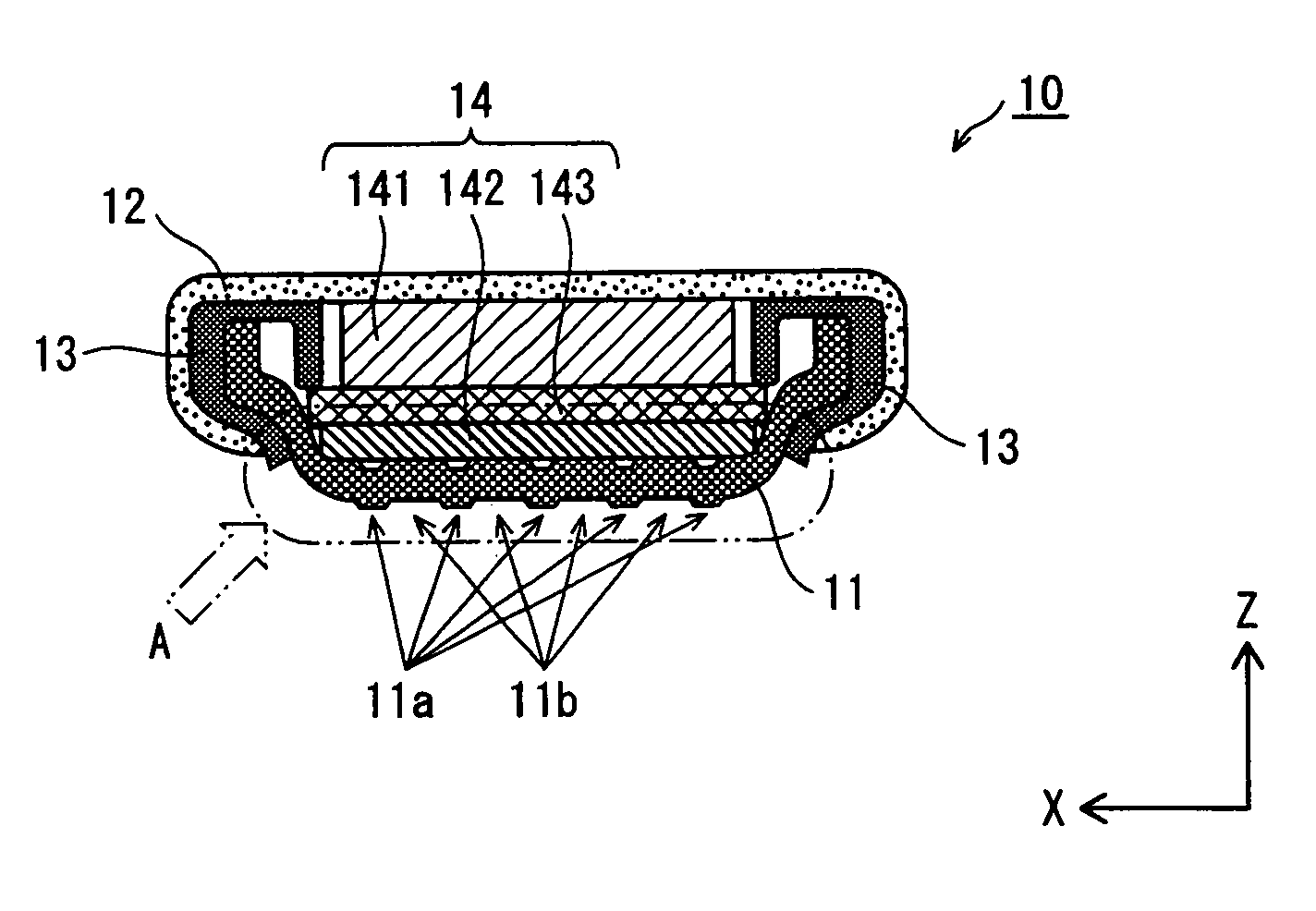

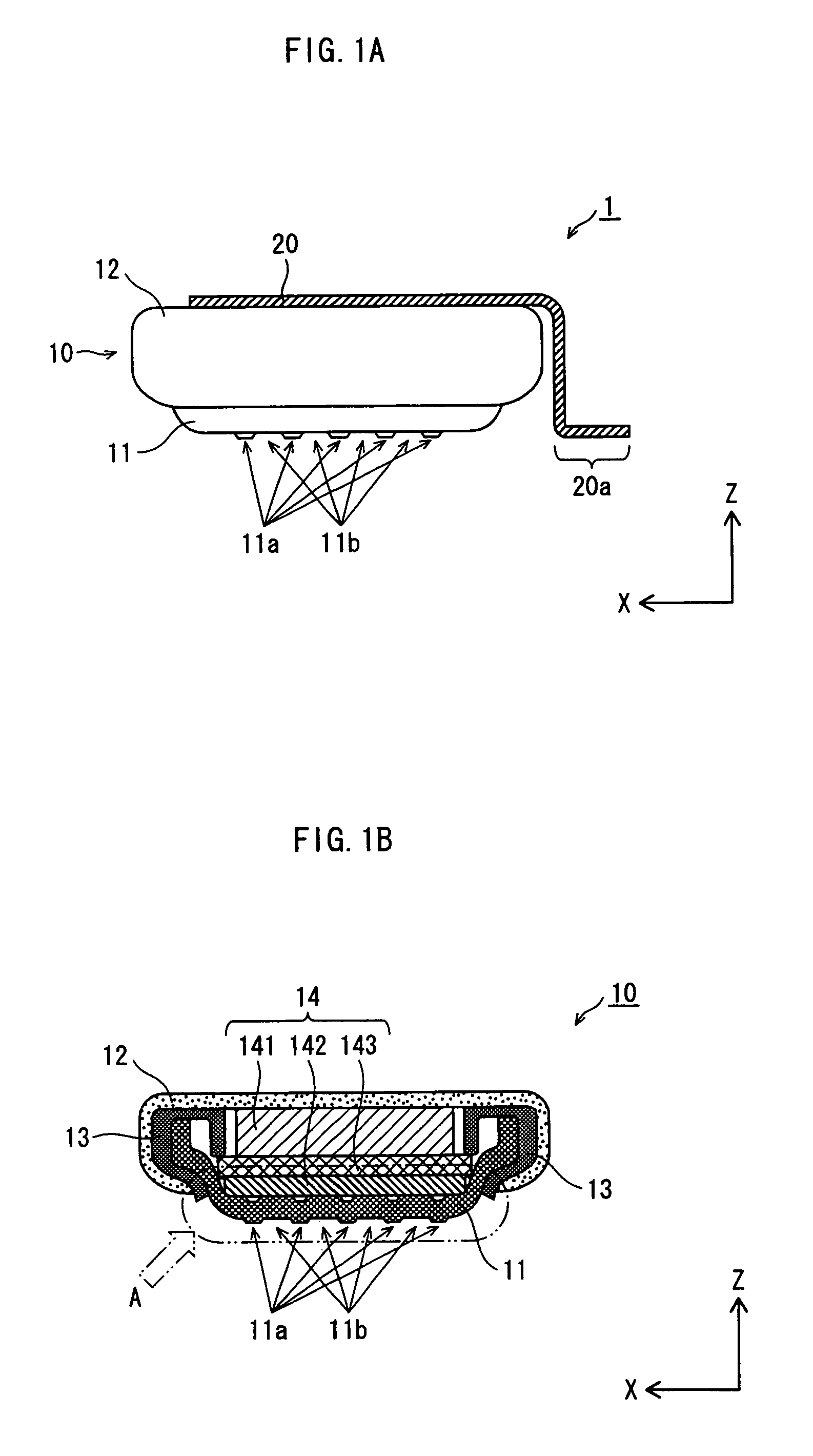

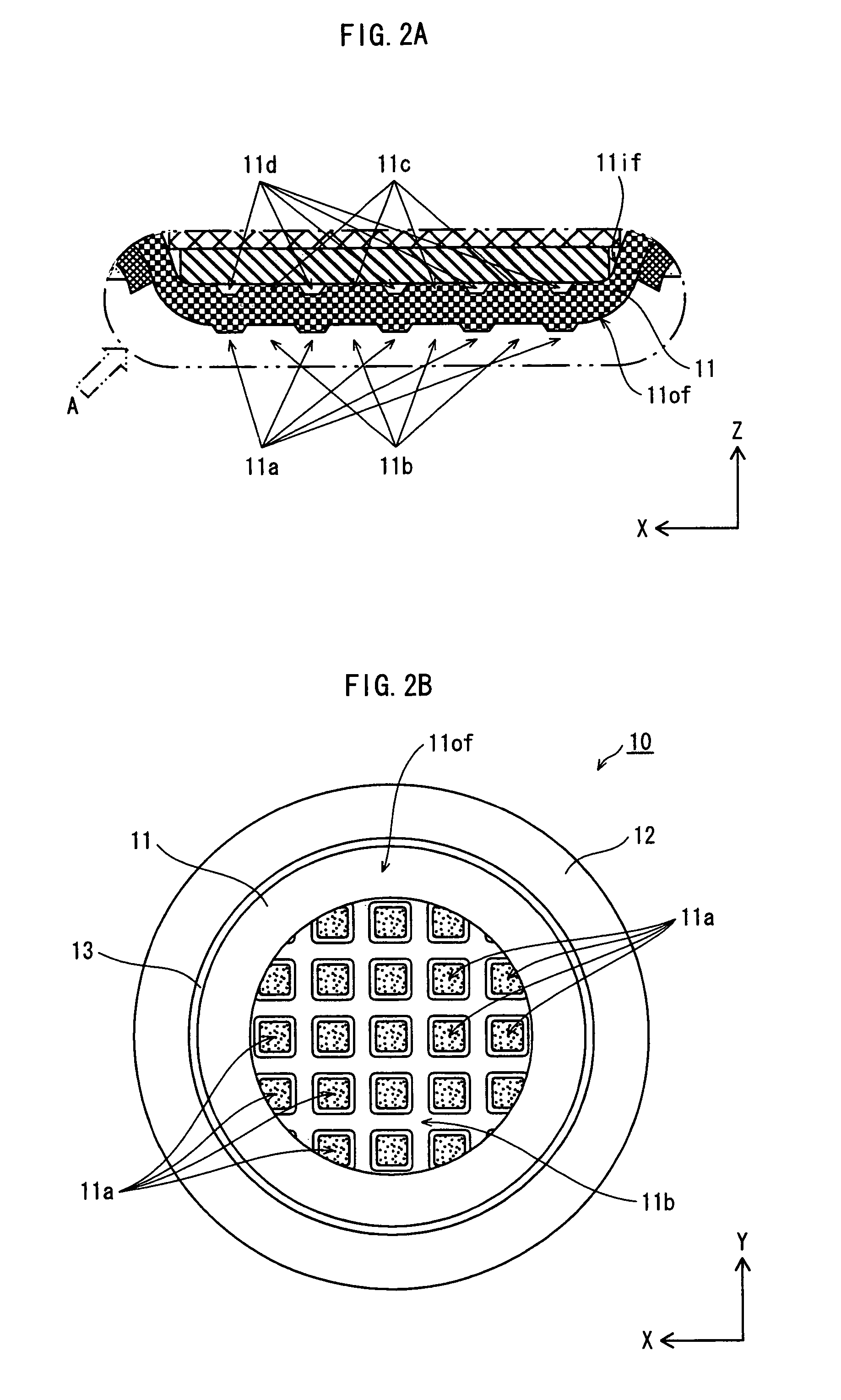

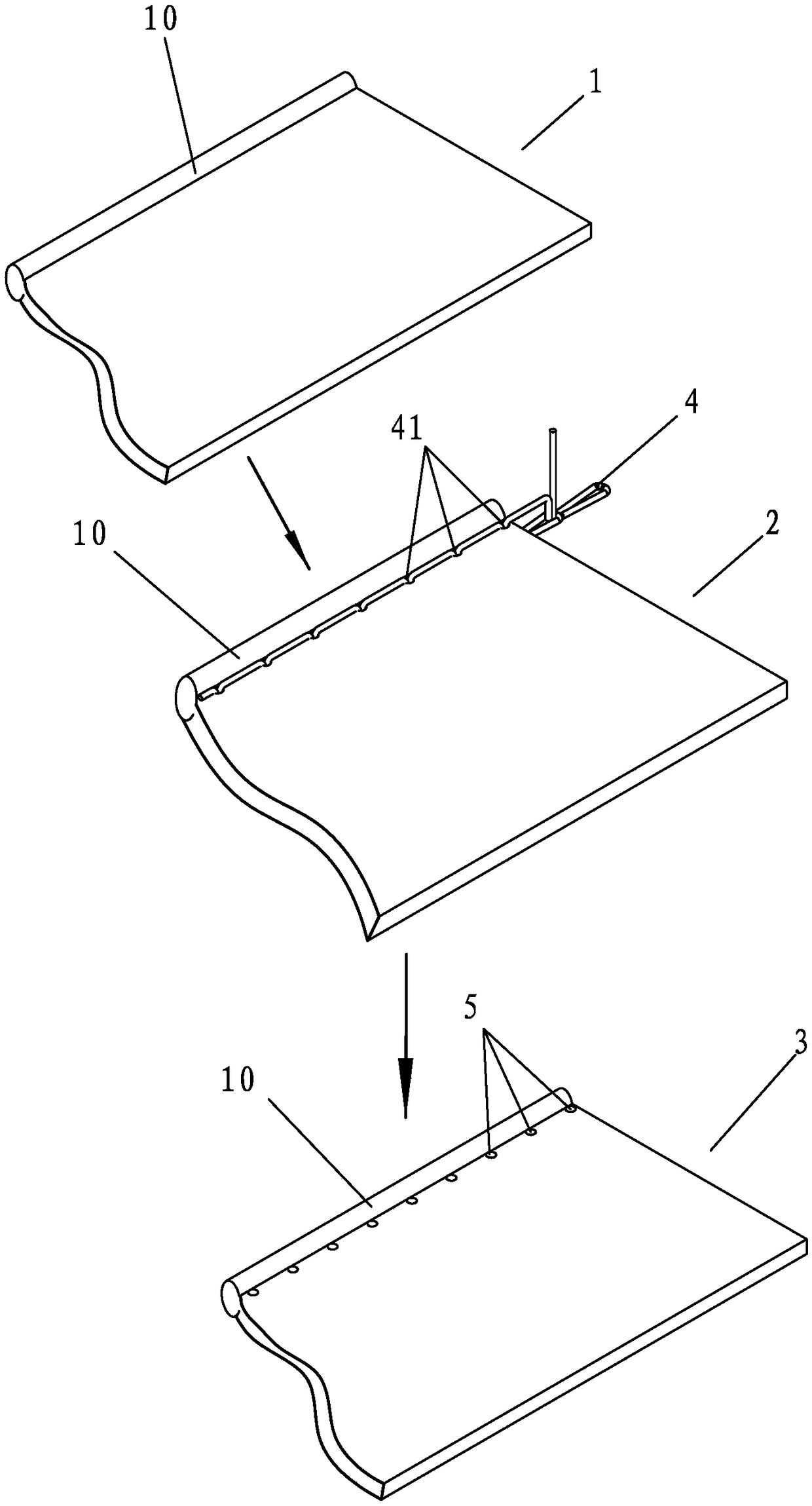

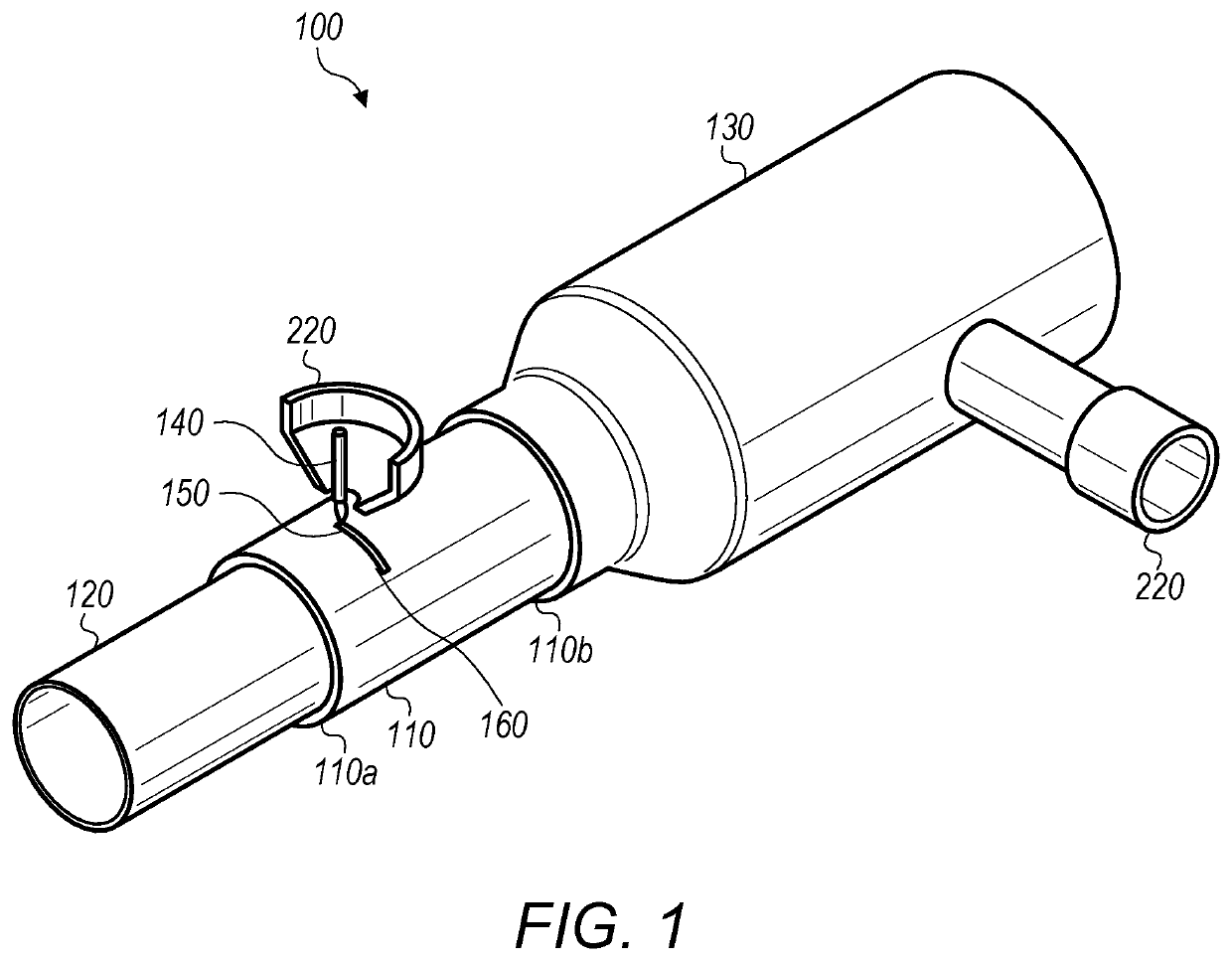

Lead plate-attached coin-type battery whose lead plate is attached to exclusively either an outer can or a cap

InactiveUS20080081253A1Prevent outflowReduced footprintFinal product manufacturePrinted circuit aspectsEngineeringElectrical and Electronics engineering

A lead plate-attached coin-type battery is constituted from a combination of a coin-type battery and a positive lead plate. In the coin-type battery, a negative cap seals the aperture of a positive outer can. In a lateral view, the positive lead plate is crank-shaped, and one end thereof is attached to the outer surface of the positive outer can of the coin-type battery. A lead plate is not attached to the negative cap. One or more projections that project in the Z axis direction are provided on the negative cap. In the lead plate-attached coin-type battery, the positive lead plate and negative cap have been attached to respective conductive lands on a circuit board by a solder reflow method.

Owner:FDK CORP +1

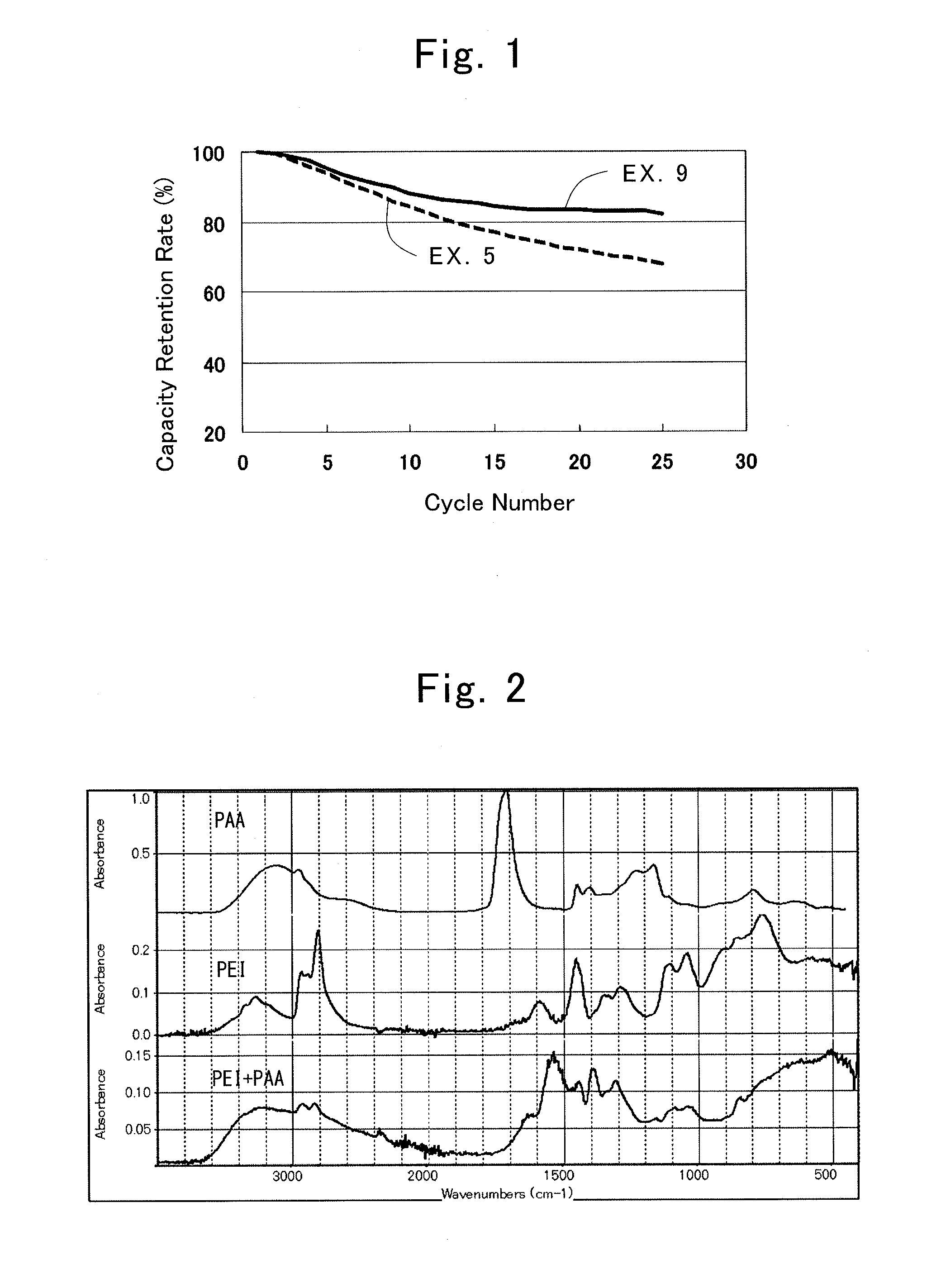

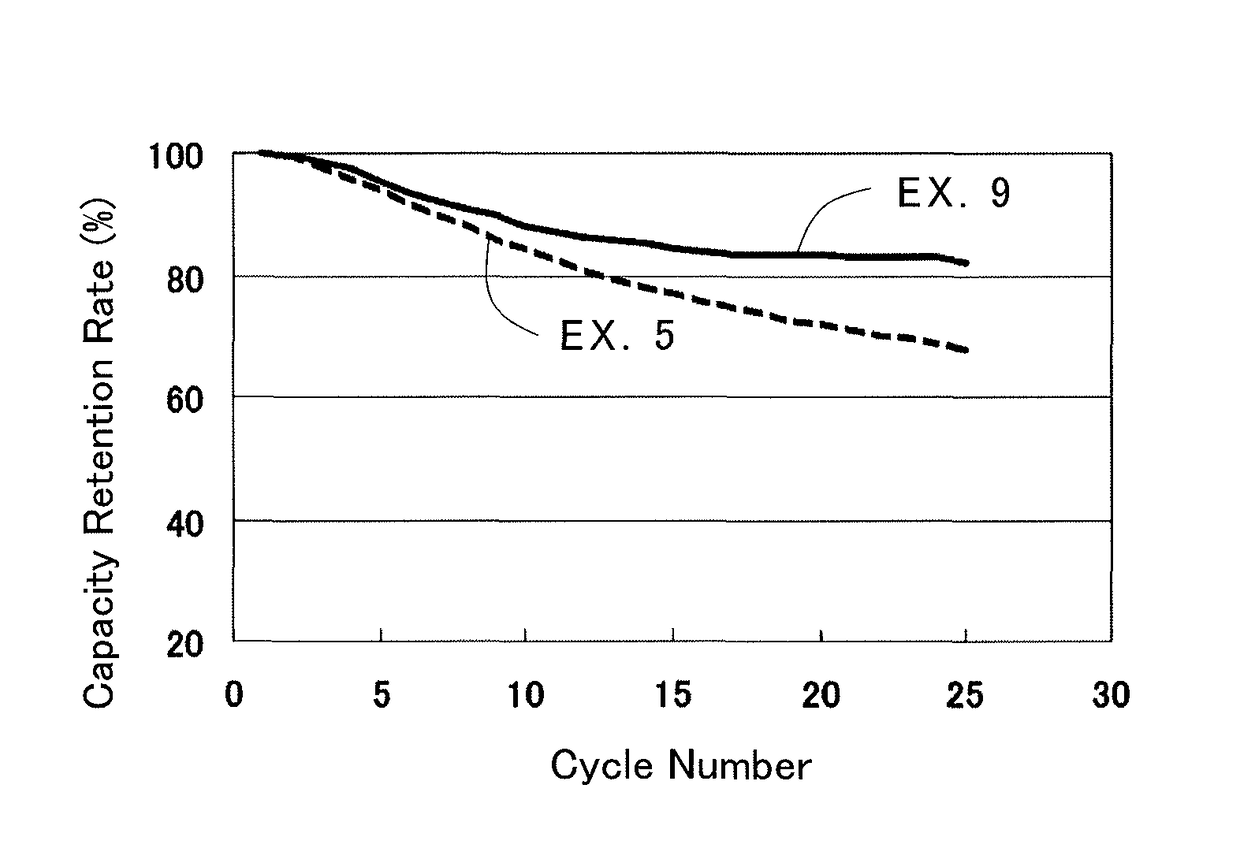

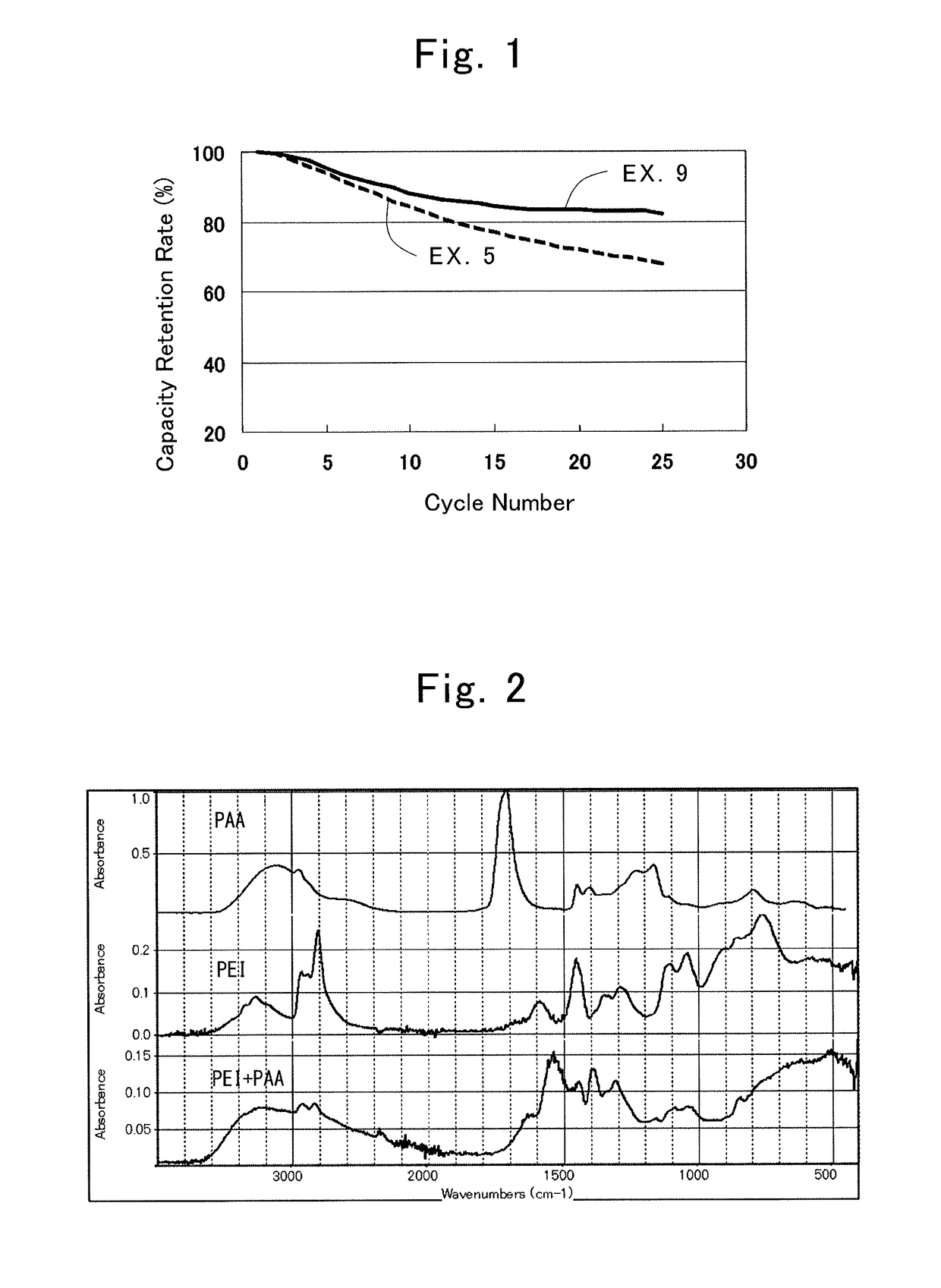

Positive electrode for secondary battery, method for producing the same, and nonaqueous secondary battery

InactiveUS20150118551A1High strengthLarge capacityElectrode carriers/collectorsSecondary cellsZeta potentialHigh intensity

A positive electrode active material layer comprises a coating layer for coating at least part of surfaces of positive electrode active material particles. The coating layer comprises alternate layers of a cationic material layer containing a cationic material having a positive zeta potential and an anionic material layer containing an anionic material having a negative zeta potential under neutral conditions, and a material layer having a zeta potential of opposite sign to that of the positive electrode active material particles is bonded to the surfaces of the positive electrode active material particles. The coating layer is thin and uniform, and has a high strength for bonding to the positive electrode active material particles, so the coating layer suppresses direct contact of the positive electrode active material particles and an electrolytic solution even when a nonaqueous secondary battery is used at a high voltage.

Owner:TOYOTA IND CORP

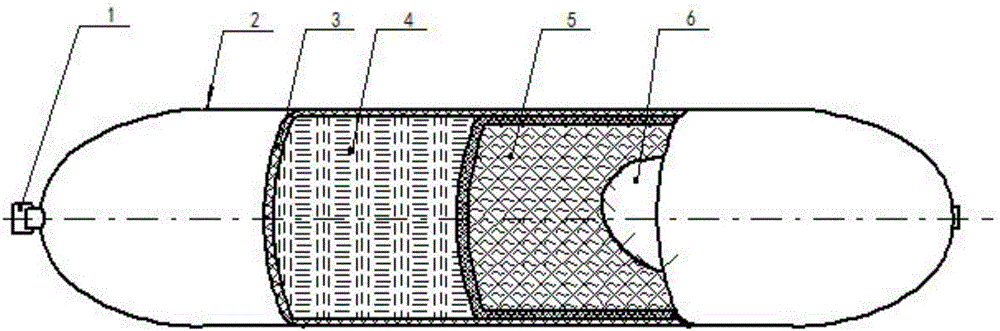

Light high-pressure weight carrying gasbag

ActiveCN106809760AIncrease the ultimate burst pressureImprove airbag performanceLifting devicesAirbag deploymentPhysics

The invention relates to a light high-pressure weight carrying gasbag. The light high-pressure weight carrying gasbag is composed of a gasbag body and an inflating valve, and a sealed gasbag cavity is formed in the gasbag body. The light high-pressure weight carrying gasbag is characterized in that the gasbag body is composed of a wearproof layer, a puncture-resisting layer and an airtight layer, the wearproof layer, the puncture-resisting layer and the airtight layer are coaxially arranged from the outside to the inside of the gasbag body in sequence, and are tightly bonded with each other; a binder is uniformly smeared between adjacent two layers of rubber layers, and the included angle of twining directions is 60-70 degrees. The light high-pressure weight carrying gasbag is good in airtightness, under safe working pressure, the pressure of the gasbag is not lower than 98% of initial pressure after the gasbag is stored for 24 hours at the indoor temperature, the burst pressure is increased to 5MPa, high working pressure and safe coefficient can be obtained, and thus the gasbag has high bearing performance and safety.

Owner:青岛永泰船舶用品有限公司

Dental adhesive resin and preparation method thereof

InactiveCN104970982AHigh strengthHigh strength bondImpression capsDentistry preparations(Hydroxyethyl)methacrylatePhosphoric acid

The invention relates to a dental adhesive resin and a preparation method thereof, and belongs to the field of medical dental materials. The dental adhesive resin comprises the following raw materials by weight: 10-18 parts of 37% phosphoric acid, 20-30 parts of MTAD, 25-35 parts of bisphenol A glycidyl methacrylate, 18-28 parts of hydroxyethyl methacrylate, 25-30 parts of hexafluorosilicate, 12-20 parts of bismethacrylate, 8-15 parts of a nanometer silicon filler, 1-5 parts of an antimicrobial agent, 15-30 parts of ethanol and 10-25 parts of water. The dental adhesive resin provided by the invention is easy to use and strong in bonding force, the formed film is thin and uniform, and the restored teeth are beautiful.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

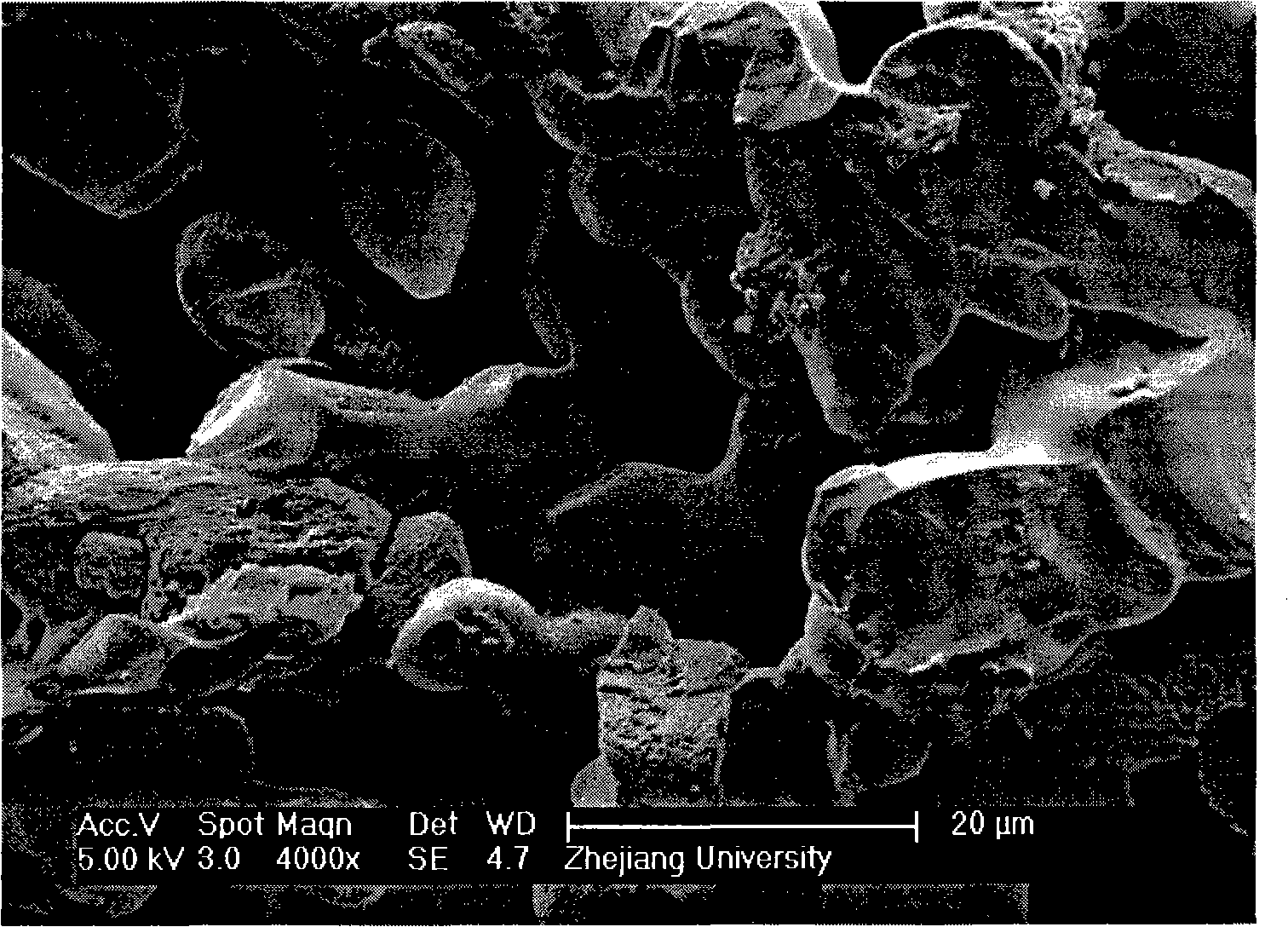

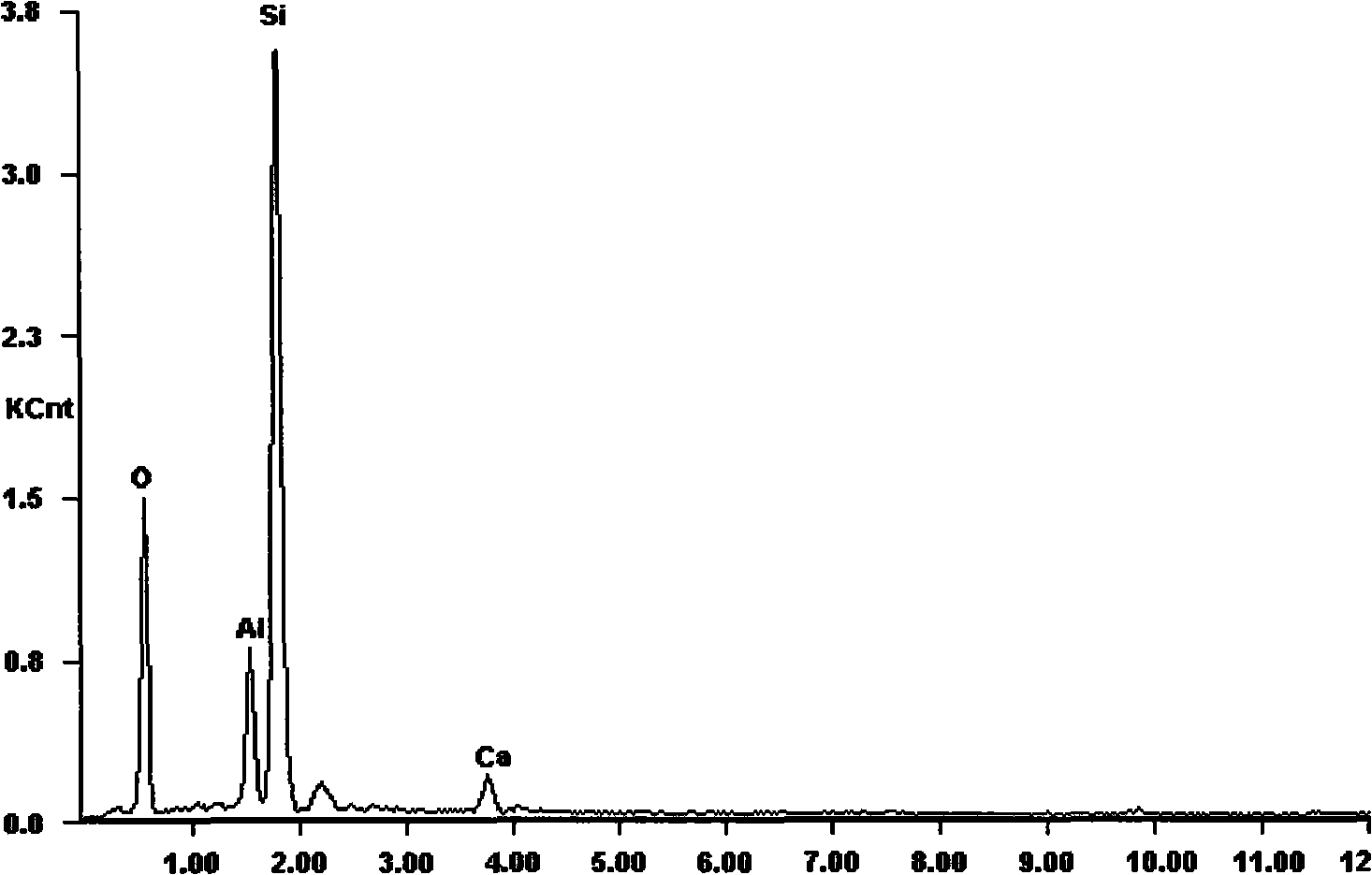

Nanometer composite powder of silicon carbide/aluminum oxide-calcium oxide core-shell structure and preparation method

The invention discloses carborundum / alumina-calcium oxide nano-compound powder in core-shell structure, which is nano-compound powder with engineering ceramics-used carborundum granules as the core and nano-thickness alumina-calcium oxide covered on the surface as the shell. The invention further discloses the application of the nano-compound powder in the preparation of honeycomb ceramics. Carborundum honeycomb ceramics can be gotten with Ca-Alpha theron ceramic phase as carborundum granule aggregate coupling phase by using the nano-compound powder as aggregate at the temperature far below the carborundum recrystallization temperature and under specific nitrogen atmosphere processing conditions. The carborundum honeycomb ceramics prepared which takes Ca-Alpha theron ceramic phase as carborundum granule aggregate coupling phase has the advantages of low sintering temperature, high strength and high resistance to high temperature and so on.

Owner:ZHEJIANG UNIV

Surface modification of expanded ultra high molecular weight polyethylene(eUHMWPE) for improved bondability

InactiveUS7425357B2Improve bindingHigh bonding strengthDecorative surface effectsSurgeryBalloon catheterUltra-high-molecular-weight polyethylene

A balloon catheter and a method of making the balloon catheter, having a balloon which is bonded to an elongated shaft, and which has a first layer and a second layer and an improved bond between the balloon and the shaft. One aspect of the invention is directed to a balloon in which the balloon first layer includes eUHMWPE and has at least a section that has been oxidized with a chromic acid solution to provide improved bondability.

Owner:ABBOTT CARDIOVASCULAR

Method For Reversible Bonding

ActiveUS20190240918A1Reduce the total massHigh strength bondDomestic sealsNon-macromolecular adhesive additivesPolyesterOligomer

A method of reversible bonding based on deposition of a coating capable of an indefinite number of reversible bonding cycles as enable by bond exchange reactions is provided. This is accomplished by deposition of crosslinkable aromatic polyester oligomers on a substrate. The coated article is heated to produce a fully thermoset network by condensation reactions. The fully thermoset network has access to a type of bond exchange reaction within the resin that permits the dynamic exchange of ester bonds within the resin. To execute the bonding step a source of heat is applied at a pressure. To debond, there is applied force in tension and / or shear that causes the coating to fail. The reversibility of the process is contingent on the cohesive (rather than adhesive) failure of the coating—that is, the coating must not delaminate from the substrate. Failure must occur in the resin of the reversible coating.

Owner:ATSP INNOVATIONS INC

Siloxane Composition, Agglomerate, and Method of Preparing

InactiveUS20070249757A1Safe handlingEnsure transportation safetyOther chemical processesSolid fuelsParticulatesEpoxy

A siloxane composition, comprising from 70 to 99 parts by weight of a solid particulate having a median particle size of from 0.1 to 3000 μm and from 1 to 30 parts by weight of a binder having a median particle size of from 5 to 250 μm, wherein the composition is a powder and the binder comprises a siloxane resin having the formula: (R13SiO1 / 2)w(R12SiO2 / 2)x(R1SiO3 / 2)y(SiO4 / 2)z, wherein each R1 is independently selected from hydrogen, hydrocarbyl, substituted hydrocarbyl, —O═NR2R3, —OR2, —O—R4—OR2, and an epoxy-substituted organic group, wherein R2 is C1 to C8 hydrocarbyl, R3 is R2 or —H, R4 is hydrocarbylene, w+x+y+z=1, y / (w+x+y+z) is at least 0.67, and the siloxane resin has a softening point of from 30 to 115° C.; an agglomerate, and a method preparing the agglomerate.

Owner:DOW CORNING CORP

Lead plate-attached coin-type battery whose lead plate is attached to exclusively either an outer can or a cap

InactiveUS7625666B2Reduced footprintHigh strength bondFinal product manufacturePrinted circuit aspectsElectrical and Electronics engineeringLead plate

A lead plate-attached coin-type battery is constituted from a combination of a coin-type battery and a positive lead plate. In the coin-type battery, a negative cap seals the aperture of a positive outer can. In a lateral view, the positive lead plate is crank-shaped, and one end thereof is attached to the outer surface of the positive outer can of the coin-type battery. A lead plate is not attached to the negative cap. One or more projections that project in the Z axis direction are provided on the negative cap. In the lead plate-attached coin-type battery, the positive lead plate and negative cap have been attached to respective conductive lands on a circuit board by a solder reflow method.

Owner:FDK CORP +1

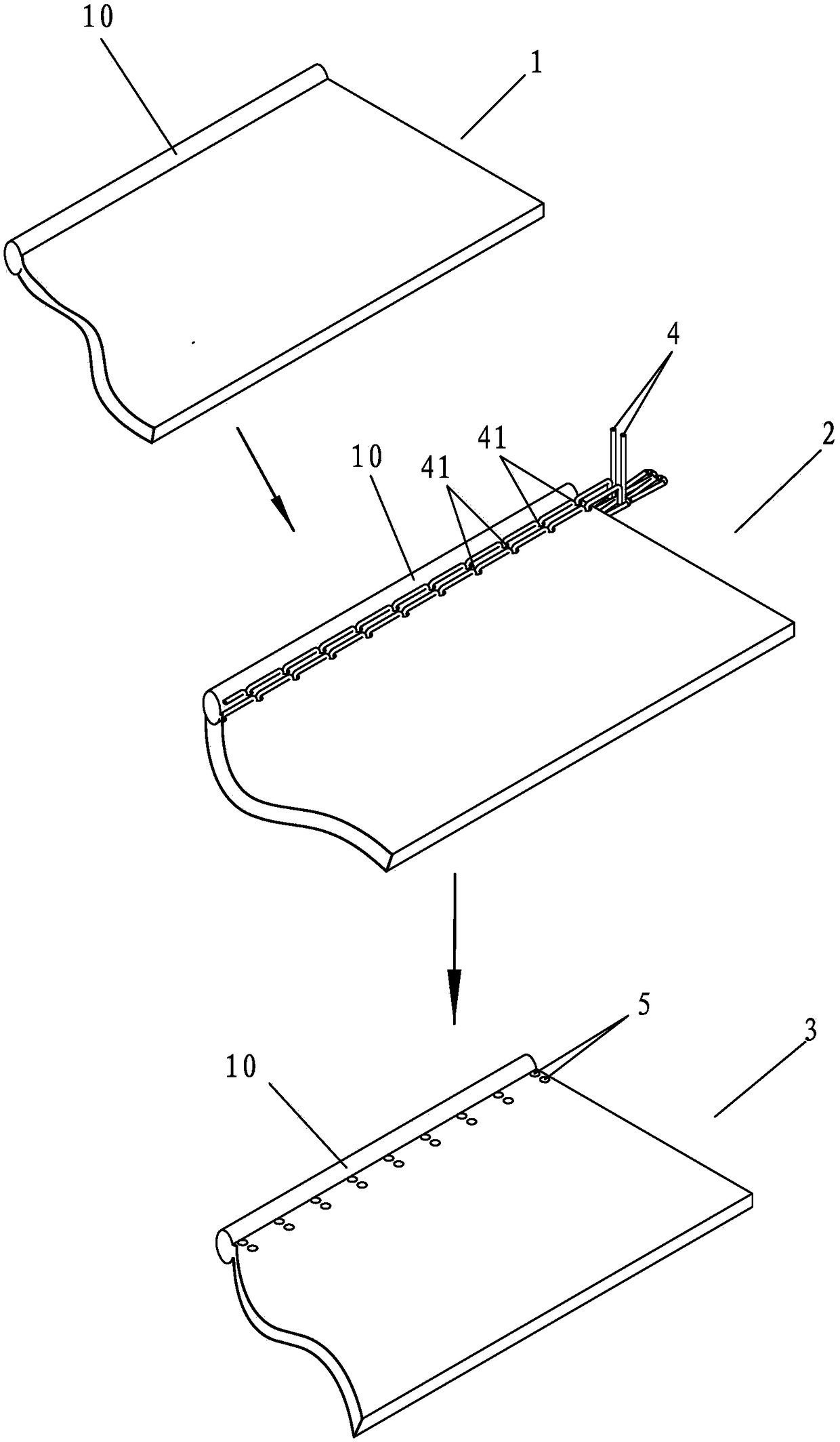

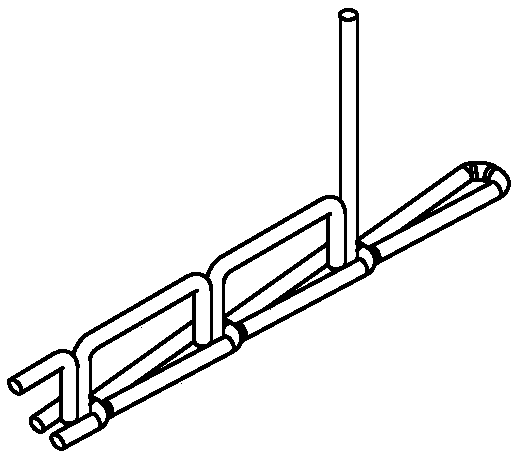

An injection-molded zipper cloth tape and a manufacturing method thereof

The invention discloses an injection-molded zipper cloth tape and a manufacturing method thereof. The method comprises the following steps: 1) weaving a common injection-molded zipper blank tape according to a normal process; 2) sewing a wire penetrating the blank tape on the blank tape, and the seam holes of the seam line penetrate the blank belt are correspondingly distributed according to the small holes of the injection moulding chain teeth to be arrange by the zipper cloth tape. 3) finalizing, winding, dyeing and drying the sewn blank tape to obtain the finished cloth tape. The inventionadopts an innovative design concept to form small holes in the cloth tape, and the small holes are not damaged and kept intact in the molding process, so as to ensure the effective high-strength bonding of the injection moulding chain teeth and the quality of the injection moulding chain teeth zipper cloth tape. Moreover, the invention can form one row, two rows or more rows of small holes by simply changing the needle spacing and the needle number of the sewing machine, and realize the effect of simple and variable hole spacing, and can also form the tape small holes with controllable size bydifferent thickness of the sewing machine, the transformation is very flexible, and the practicability and the application value are very prominent.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

Autogenous submerged liquid diffusion welding of titanium

ActiveUS10926347B2High strength bondLow costArc welding apparatusElectron beam welding apparatusLiquid diffusionAlloy

In some embodiments, a method may bond titanium to an intermediate alloy. The method may include layering a portion of an intermediate alloy onto a portion of titanium. The method may include focusing a controlled heat source on a spot of the intermediate alloy to form a weld pool in the intermediate alloy at the spot. The method may include superheating the intermediate alloy in the weld pool above the melting point of the intermediate alloy but below the melting point of titanium such that liquid intermediate alloy contacts the surface of the portion of the titanium heating the portion of the titanium. The method may include diffusing the portions of titanium and intermediate alloy together such that upon the intermediate alloy cooling below the melting point of the intermediate alloy the portions of the intermediate alloy and titanium are bonded forming a weldment.

Owner:PACKLESS INDS

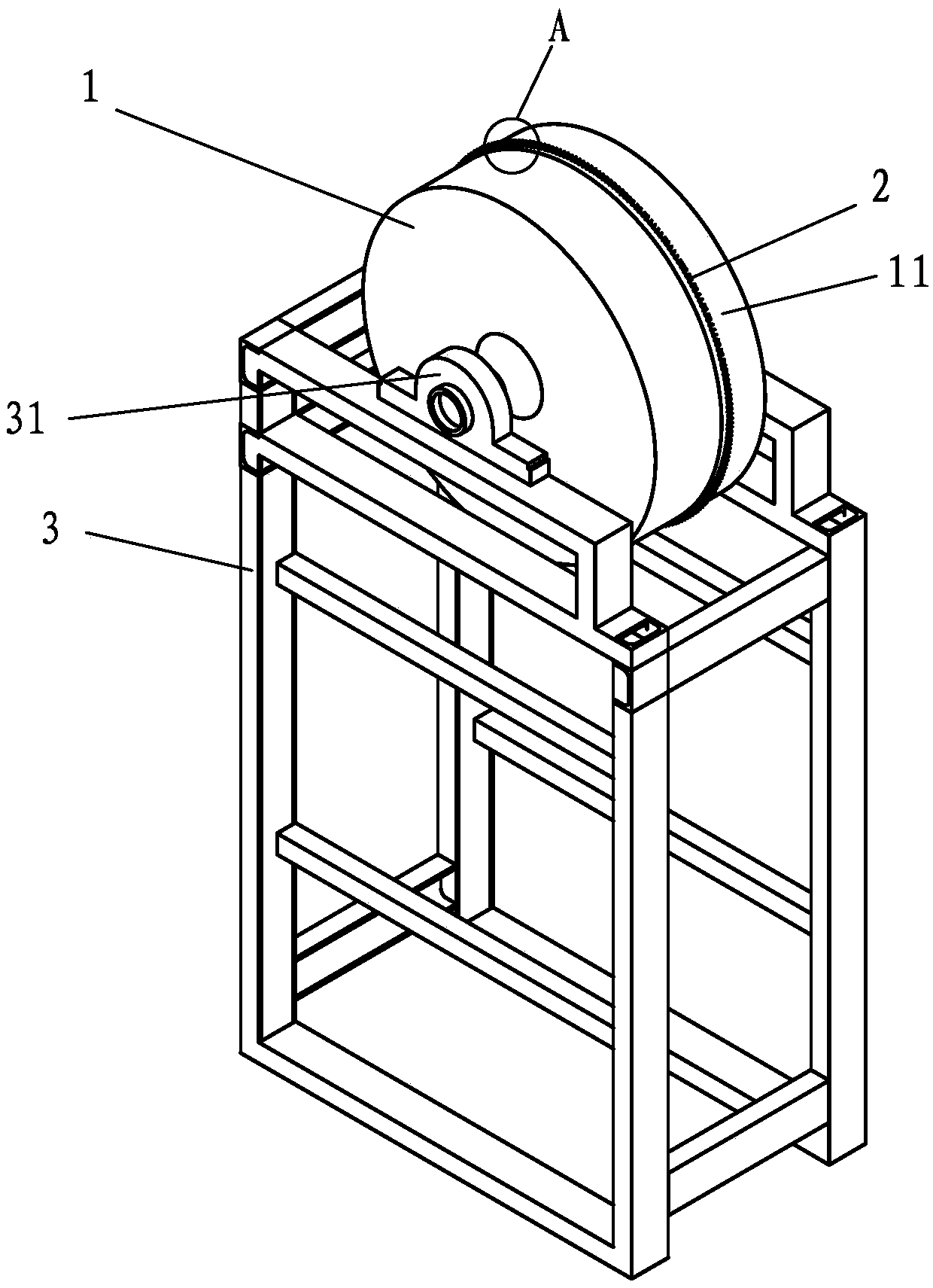

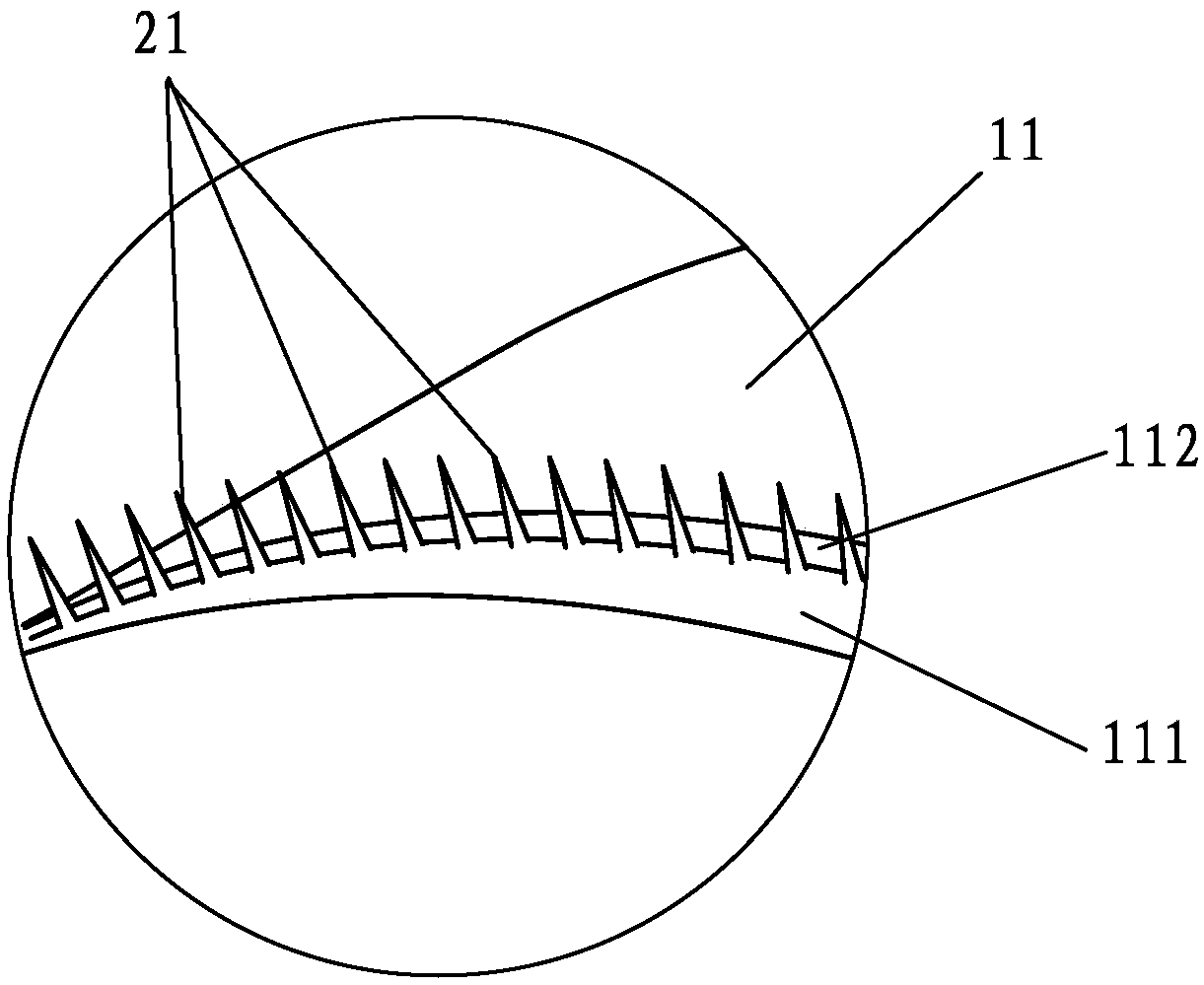

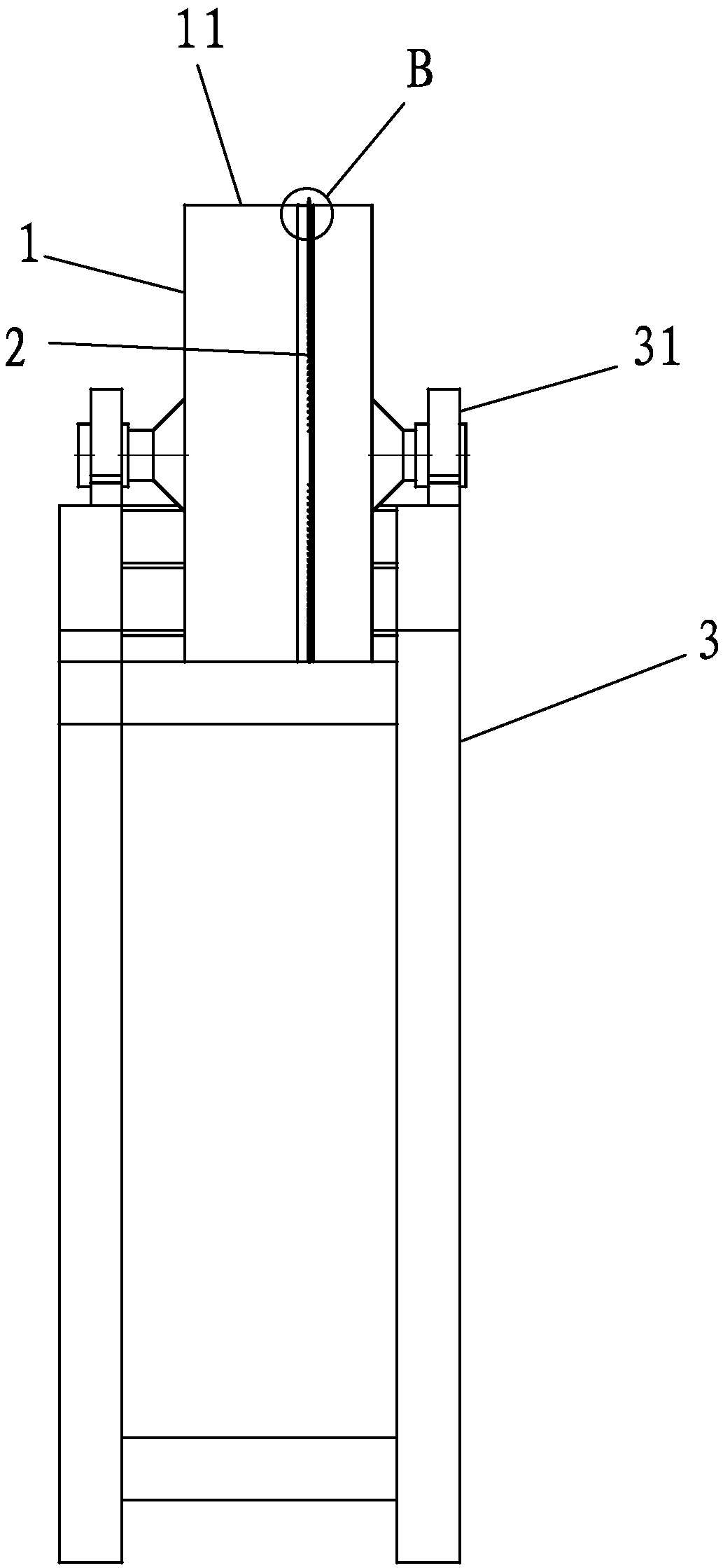

Perforated cloth tape, perforated cloth tape manufacturing method and cloth tape hole manufacturing device

The invention discloses a perforated cloth tape, a perforated cloth tape manufacturing method and a cloth tape hole manufacturing device. The device comprises a drying drum and perforating components,wherein the perforating components are arranged on the drum surface of the drying drum in an annular form. A piece of gray cloth, which is woven by a normal process, is thoroughly perforated while being dried, so that ironed small holes, which are formed through high-temperature molding, are formed on the gray cloth. According to the scheme, an innovative technology is adopted to manufacture theperforated cloth tape, so that the gray cloth, which is dried, has the ironed small holes which are formed through high-temperature molding; the ironed small hole structure is stable, free from damageand is kept complete, so that effective and high-intensity binding of an injection-molded chain on the cloth tape is guaranteed. According to the scheme, based upon simple transformation of preset holes which are different in diameter and distributing situation of the holes, a beneficial effect of simply regulating and controlling size, spacing and distribution of the ironed small holes; and therefore, the invention is excellent in practicability and application.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

Manufacturing process of furred tongue cleaning flexible glue and product thereof

The invention discloses a manufacturing process of furred tongue cleaning flexible glue and a product thereof. The method comprises the following steps: forming a plastic elastomer film by pressing; synchronously conducting burr forming and compounding a composite membrane; bonding a complex on a cloth substrate; bonding the cloth substrate on a release film; carrying out die-cutting molding; removing the release film from the sheets after die-cutting molding, and then splicing the sheets on the roll material of a release polyester film; and finally removing wastes. A product structure is as follows: the cloth substrate is bonded on the upper surface of the release film; the composite membrane is bonded on the upper surface of the cloth substrate; and a furred tongue elastomer which is made of the plastic elastomer film is bonded on the upper surface of the composite membrane. The manufacturing process has the advantages of low cost, high performance, good hygienic properties, ultraviolet resistance, high initial viscous force, good durable viscous force and the like. No three-waste emission and unsafe factors occur in the production process; and the employed materials comply with SGS authentication of EU ROHS standard, and have strong weatherability and strong ageing resistance.

Owner:朱阿奎

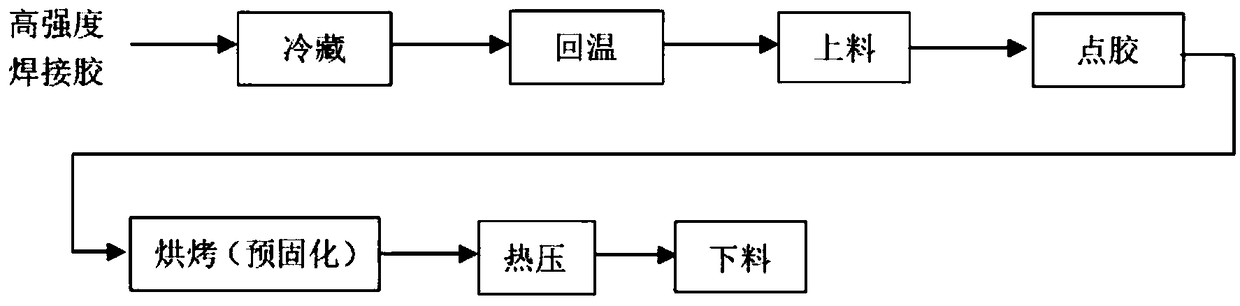

Procuring process of welding glue

InactiveCN109181558AHigh strength bondNon-macromolecular adhesive additivesAdhesive processes with adhesive heatingManufacturing technologyHigh intensity

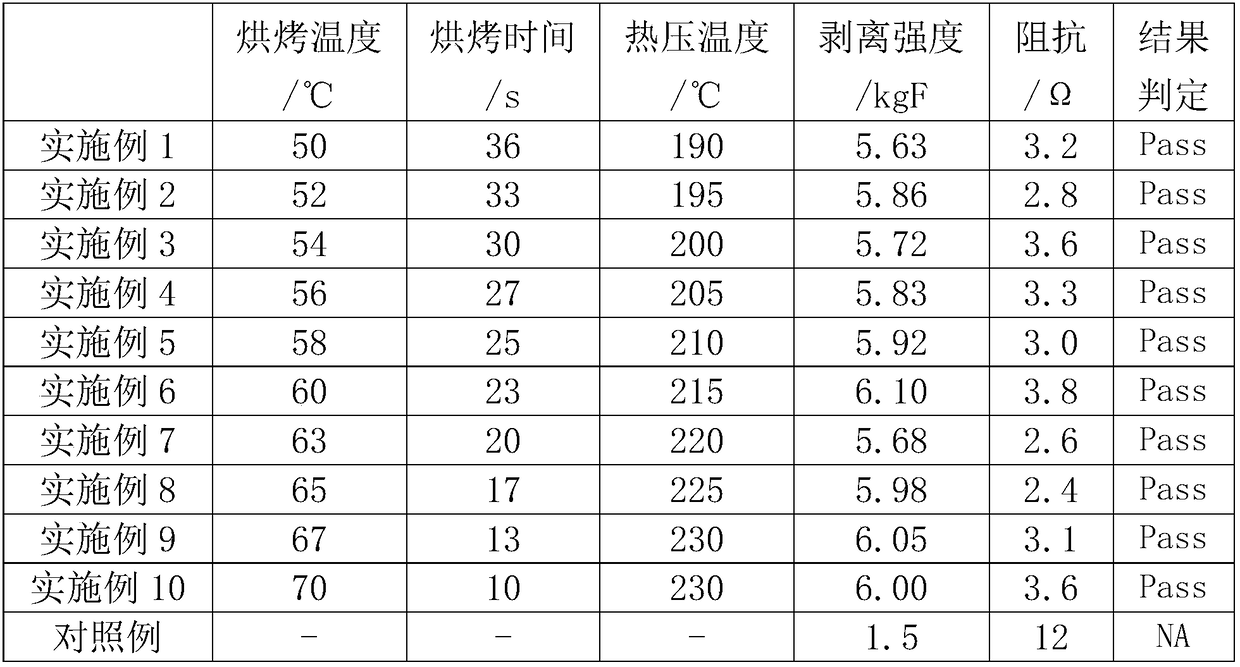

The invention belongs to the technical field of manufacturing of electronic parts and components and relates to a procuring process of welding glue. The procuring process comprises the following steps: freezing the welding glue at -20 DEG C; taking out the welding glue, and standing at 25 DEG C for 2 hours so as to form a fluid with moderate viscidity; injecting the welding glue fluid into glue dispensing equipment; dispensing the welding glue fluid to gluing seams of a product with the length of 20mm+ / -1mm in a speed of 0.6mg / s+ / -0.05mg / s; baking at 50-70 DEG C; carrying out hot-pressing at ahigh temperature, so as to completely cure the welding glue; and after the hot-pressing, carrying out discharging and packaging on the welding glue. According to the process, the characteristics of the glue can be adequately utilized, and the tight combination between a high-strength bonding effect and high-frequency conduction is realized through measures of glue dispensing, baking, hot-pressingand the like.

Owner:昆山建皇光电科技有限公司

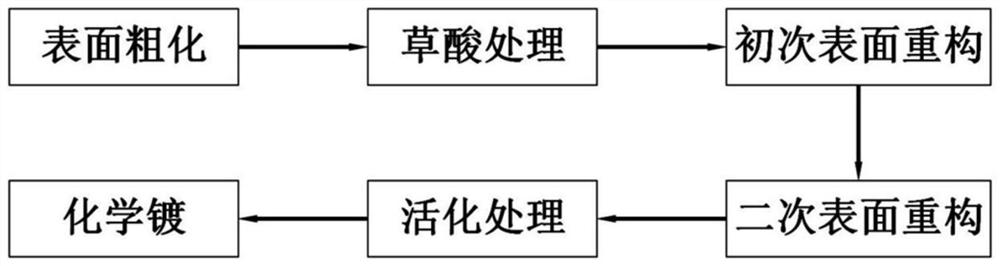

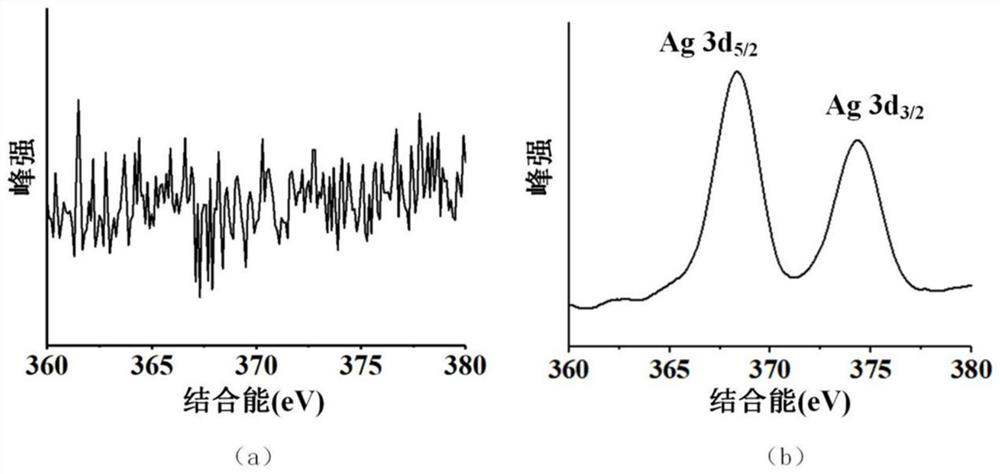

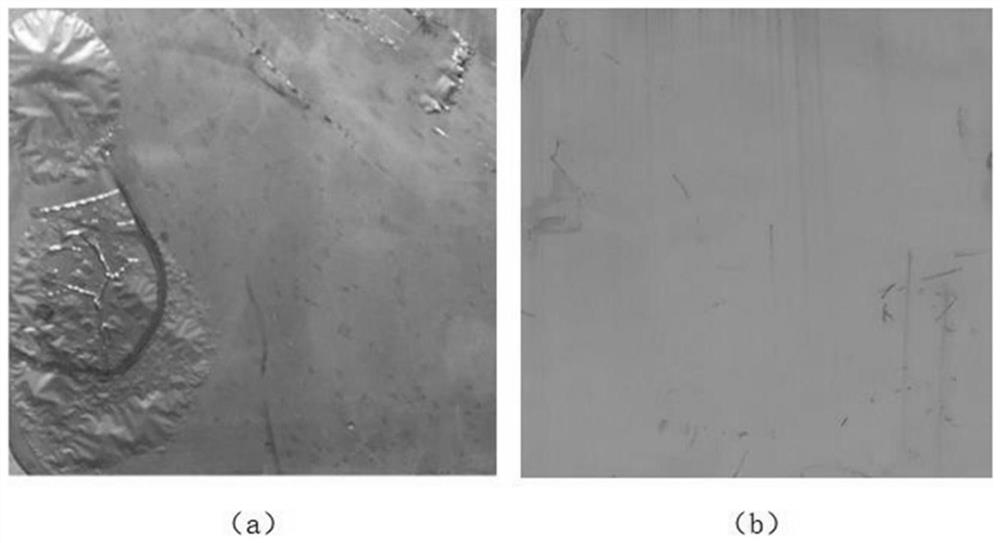

Surface modification system before electroless plating and method for double modification of polymer substrate surface

ActiveCN111501030BRealize the secondary functionGood adhesionLiquid/solution decomposition chemical coatingChemical platingPolymer substrate

The invention relates to the field of surface modification technology and polymer metallization technology. It discloses a surface modification system before electroless plating and a method for double modifying the surface of a polymer substrate. The scheme is: first use roughening to pretreat the polymer substrate to improve the surface properties, and then use the oxidative self-polymerization reaction of catecholamine compounds to deposit the roughened substrate on the surface to form a polymer layer to realize the initial Surface reconstruction modification, through the Michael addition and Schiff base reaction between the polymer layer and specific amino acids, secondary surface reconstruction modification is carried out on the surface of the substrate to introduce active functional groups that can strongly adsorb metal ions, thereby achieving The tight bond between the deposited metal layer and the substrate after electroless plating.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

A method for continuous stacking and rolling of corrugated interface bimetallic clad plates

ActiveCN108746204BHigh strength bondImprove bindingMetal rolling arrangementsHigh intensityPeak value

The invention belongs to the technical field of material machining of metal composite boards, particularly relates to a continuous laminating and rolling method for a corrugated interface double-metalcomposite board. The method is characterized in that blanks are rolled into corrugated composite boards by adopting a corrugated roller, the stress peak value is formed at wave troughs of the composite boards, and the combination of the wave troughs is promoted, rolling is carried out by adopting a flat roller, then the stress peak value is formed at the wave crests of the corrugated composite boards so that the relatively high strength combination is realized at the wave peaks, and the high-strength combination of the composite board from the local to the whole surface can be realized by utilizing the two stress peaks at different positions. The extension of metal in the rolling process of the corrugated composite board is mainly achieved through downward pressing of the metal at the position of the wave crests, flowing of the metal at the wave troughs is very small, so that the wave troughs of the corrugated composite boards are not prone to breakage in the flattening process, moreover, the downward pressing of the metal at the wave crest applies a reverse extrusion stress to the wave trough of the composite board at the other side, then the bonding strength at the original wavetrough is further improved, and the double-metal composite board with the good board shape is obtained.

Owner:TAIYUAN UNIV OF TECH

Positive electrode for secondary battery, method for producing the same, and nonaqueous secondary battery

InactiveUS9876232B2Large capacityHigh strength bondPositive electrodesElectrode collector coatingZeta potentialBattery cell

A positive electrode active material layer comprises a coating layer for coating at least part of surfaces of positive electrode active material particles. The coating layer comprises alternate layers of a cationic material layer containing a cationic material having a positive zeta potential and an anionic material layer containing an anionic material having a negative zeta potential under neutral conditions, and a material layer having a zeta potential of opposite sign to that of the positive electrode active material particles is bonded to the surfaces of the positive electrode active material particles. The coating layer is thin and uniform, and has a high strength for bonding to the positive electrode active material particles, so the coating layer suppresses direct contact of the positive electrode active material particles and an electrolytic solution even when a nonaqueous secondary battery is used at a high voltage.

Owner:TOYOTA IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com