Nanometer composite powder of silicon carbide/aluminum oxide-calcium oxide core-shell structure and preparation method

A nanocomposite powder and core-shell structure technology, applied in the field of material science, can solve the problems of low thermal conductivity of cordierite eutectic point and limit the high-temperature performance of honeycomb materials, so as to maintain high-temperature performance without deterioration and solve the problem of sintering temperature , the effect of excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

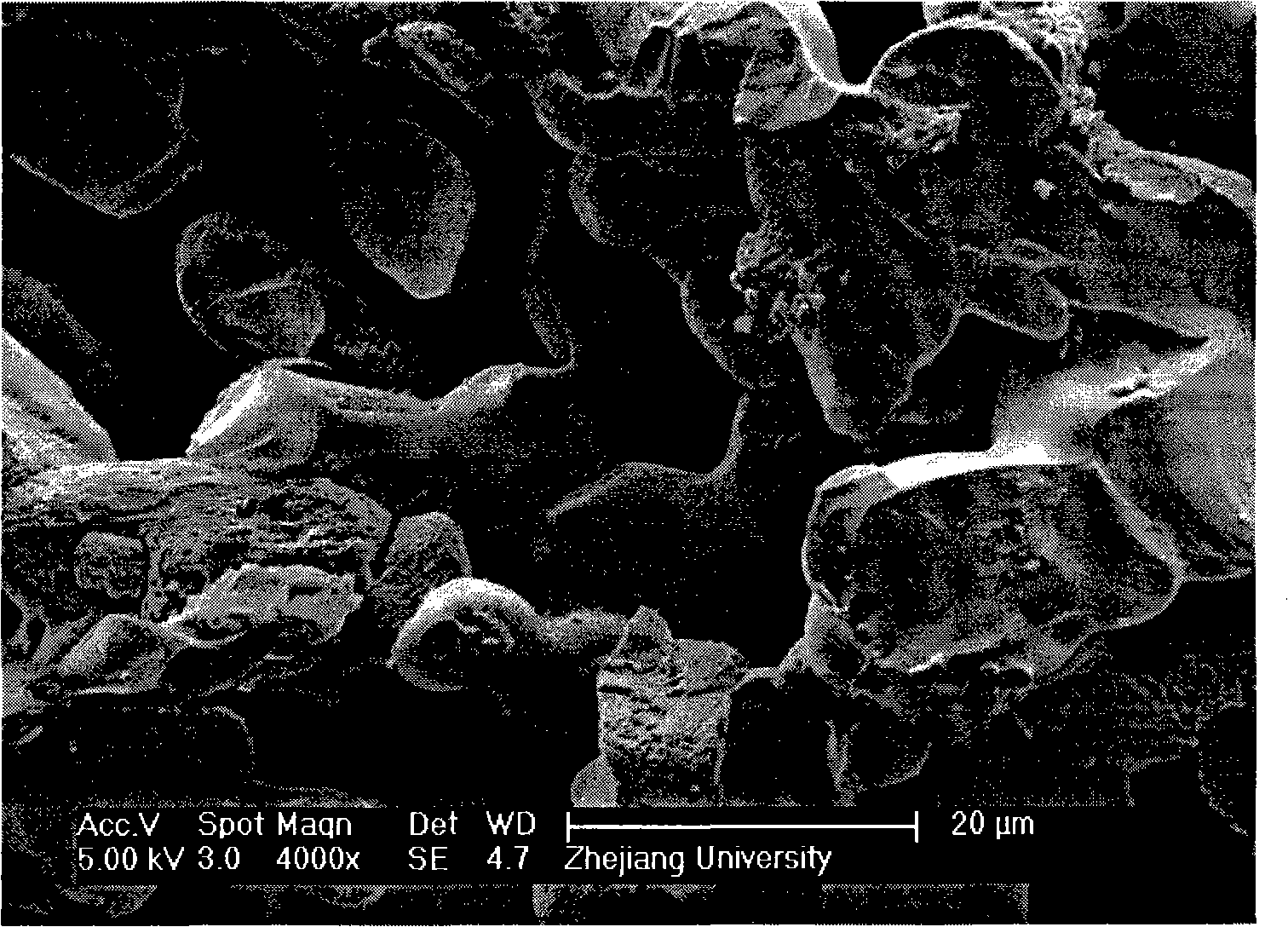

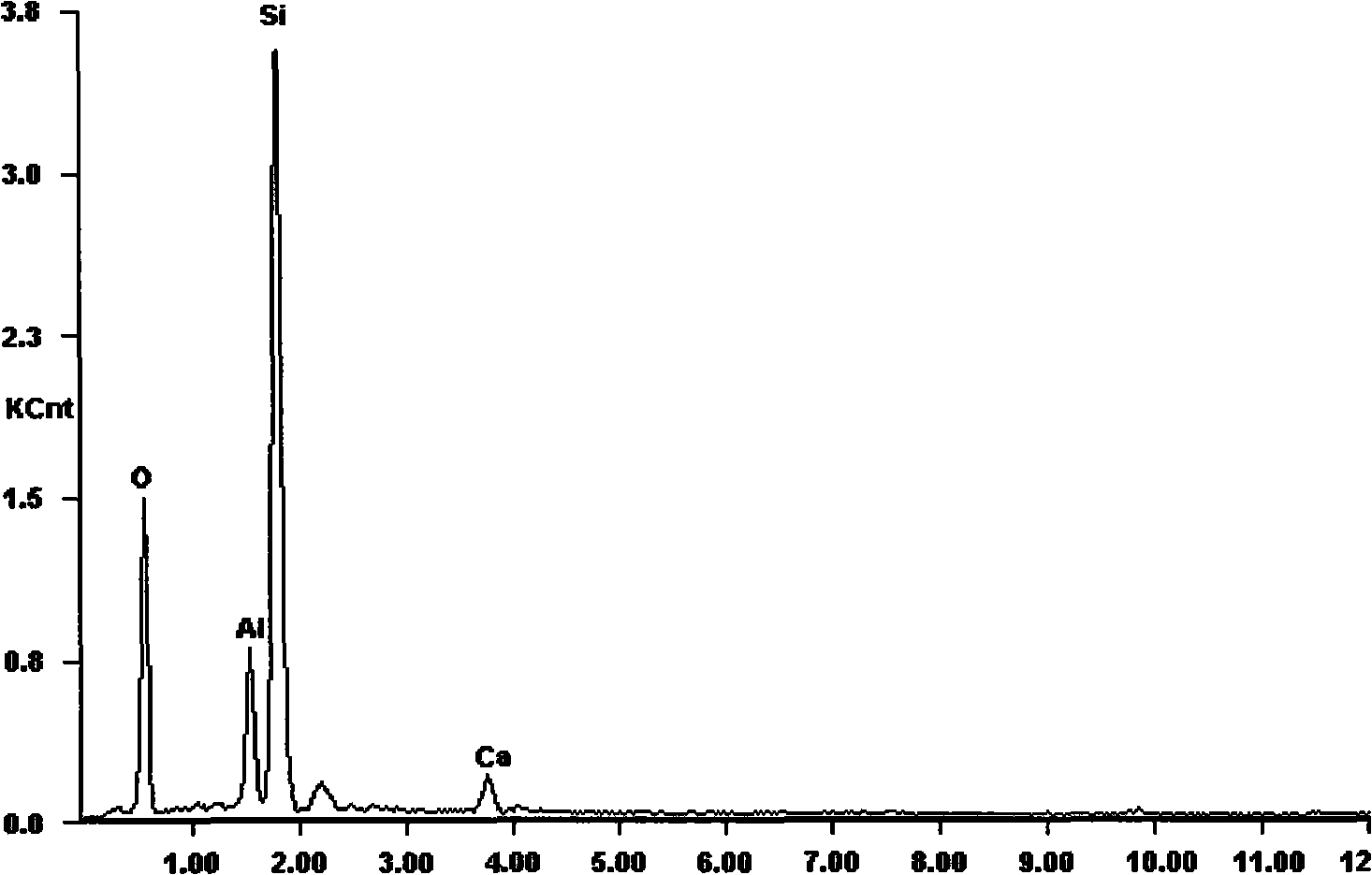

[0027] Take 10 kg each of large silicon carbide aggregates with an average particle size of 25 microns and small silicon carbide aggregates with an average particle size of 2 microns, and use the following same process conditions to coat alumina and calcium oxide shells.

[0028] Take by weighing 10 kilograms of SiC raw materials, 1.5 kilograms of alumina source raw materials Al(NO 3 ) 3 9H 2 O, 40 kg of water, prepared into a uniform suspension under stirring conditions. Then, slowly add ammonia water as a pH adjuster to the suspension to control the pH of the solution at 5.5, and the precipitation reaction takes about 20 minutes. After that, the reaction is hydraulically filtered and the precipitate is washed with water once. dried, then placed in an alumina crucible, placed in a muffle furnace for heat treatment at 280°C for 1 hour, and a product coated with an aluminum shell was obtained once; The intermediate product of the aluminum oxide layer.

[0029] Then the abov...

Embodiment 2

[0032] Take respectively 10 kilograms of large particle silicon carbide aggregates with an average particle diameter of 35 microns and small particle silicon carbide aggregates with an average particle diameter of 3 microns, adopt the same alumina and calcium oxide coating process conditions as in Example 1, A silicon carbide / alumina-calcium oxide core-shell nanocomposite powder coated with two layers of alumina and two layers of calcium oxide is obtained. Adopt the same extrusion molding formula as in Example 1 to obtain a dry biscuit, put the above-mentioned extruded biscuit into an atmosphere sintering furnace, vacuumize and fill with nitrogen protection, heat up to 800 °C at 10 °C / min, and keep it warm 1 hour; continue to fill with nitrogen protection, heat up to 1525°C at 10°C / min, and keep warm for 3 hours; after that, cool down to 800°C at 20°C / min; then turn off the heating power and gas valve, and cool down to room temperature with the furnace. A Ca-α-sialon-combined ...

Embodiment 3

[0034] Take respectively 10 kilograms of large particle silicon carbide aggregates with an average particle diameter of 25 microns and small particle silicon carbide aggregates with an average particle diameter of 2 microns, adopt the same aluminum oxide and calcium oxide coating process conditions as in Example 1, The number of coating layers of alumina is 1, and the number of coating layers of calcium oxide is 3 layers. A silicon carbide / alumina-calcium oxide core-shell nanocomposite powder coated with 1 layer of alumina and 2 layers of calcium oxide is obtained. Adopt the same extrusion molding formula as in Example 1 to obtain a dry biscuit, put the above-mentioned extruded biscuit into an atmosphere sintering furnace, vacuumize and fill with nitrogen protection, heat up to 850 °C at 10 °C / min, and keep it warm 1.5 hours; continue to fill with nitrogen protection, heat up to 1500°C at 10°C / min, and keep warm for 5 hours; after that, cool down to 800°C at 20°C / min; then turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com