Perforated cloth tape, perforated cloth tape manufacturing method and cloth tape hole manufacturing device

A manufacturing method and a manufacturing device technology, which are applied in the field of cloth belt with holes and cloth hole manufacturing devices, can solve the problems of disappearance, unstable small holes, inability to adapt to different chain types, etc., and achieve high-strength bonding, practicability and Excellent applicability, simple and adjustable pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, this case is described in further detail.

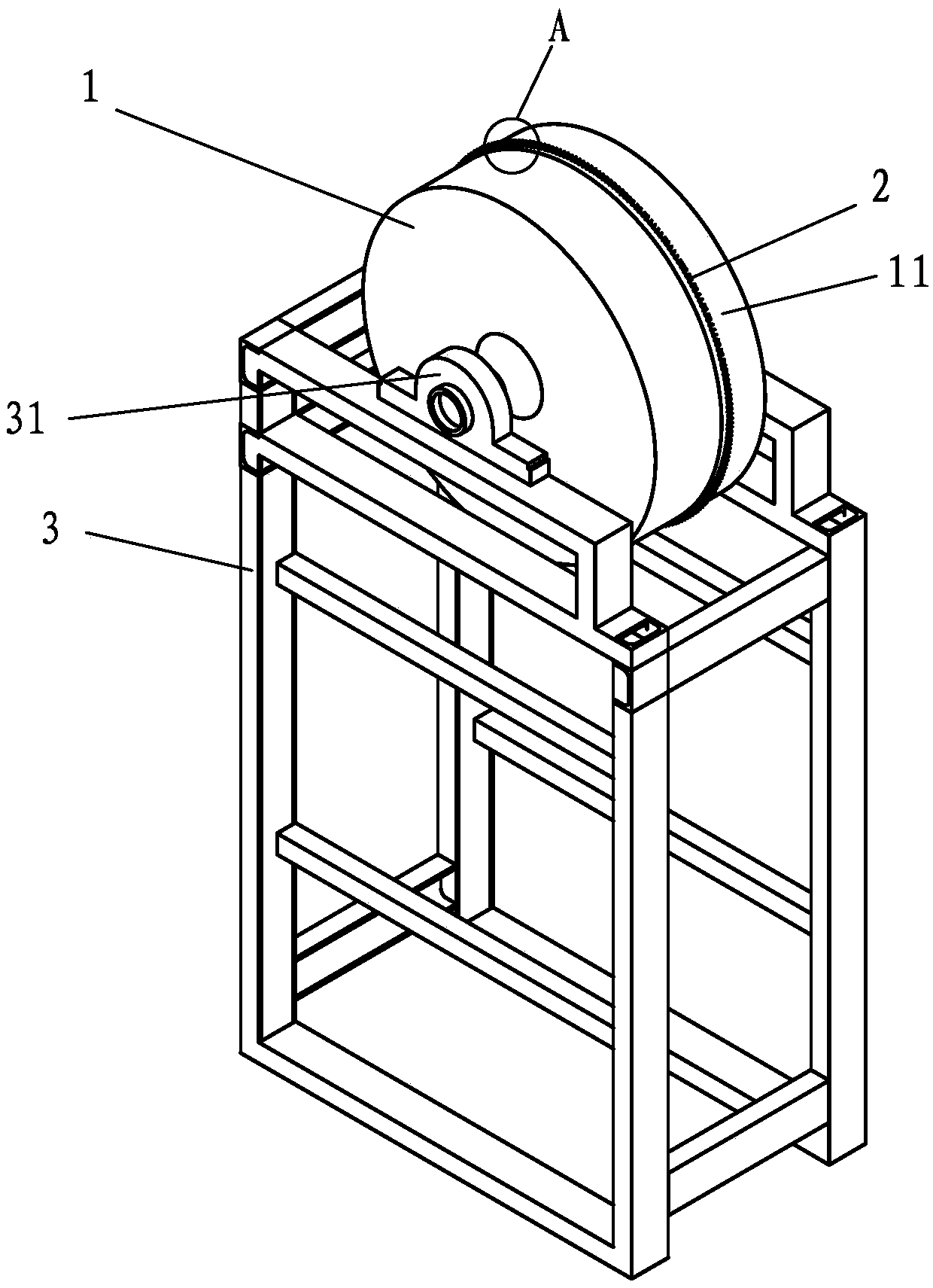

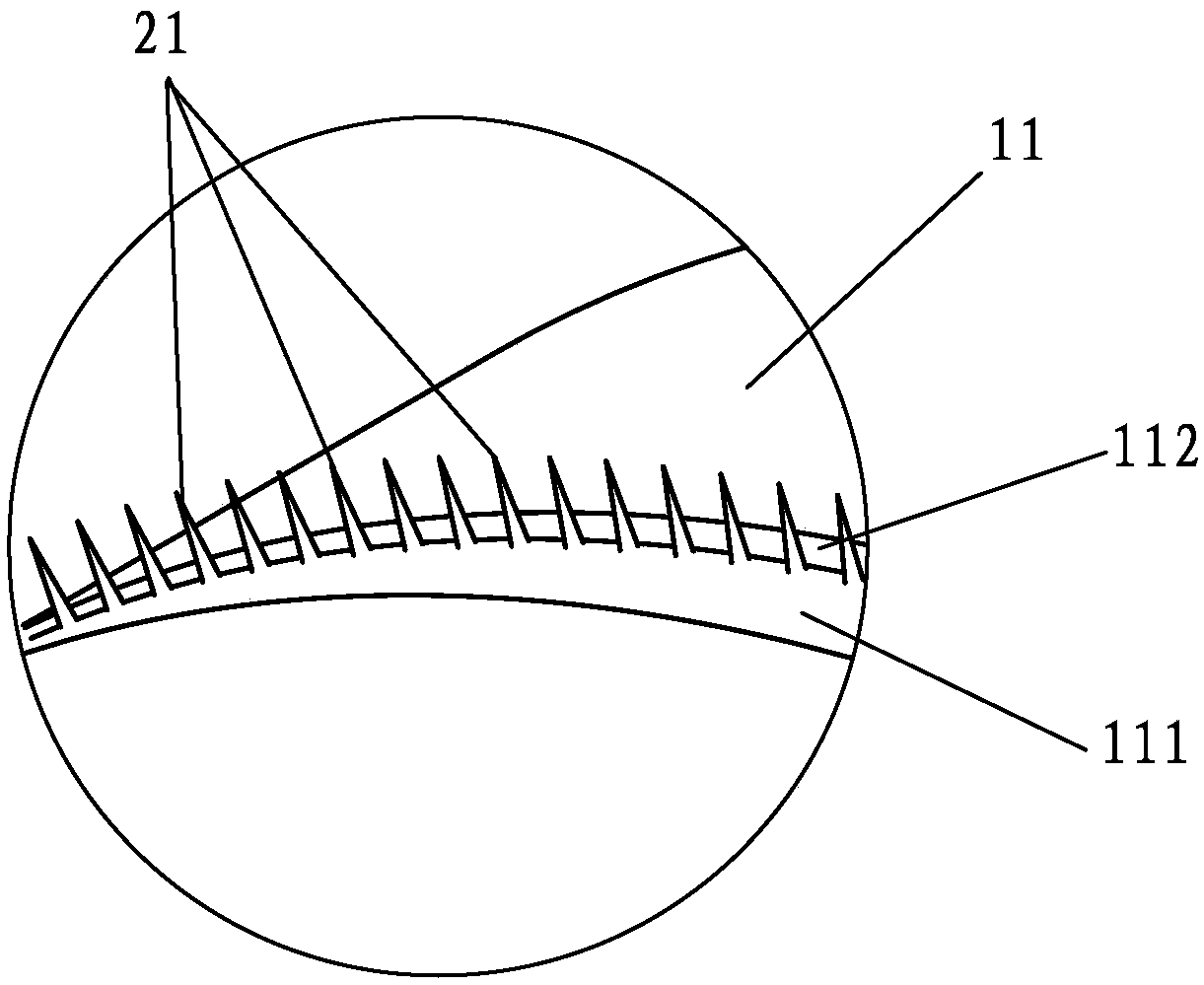

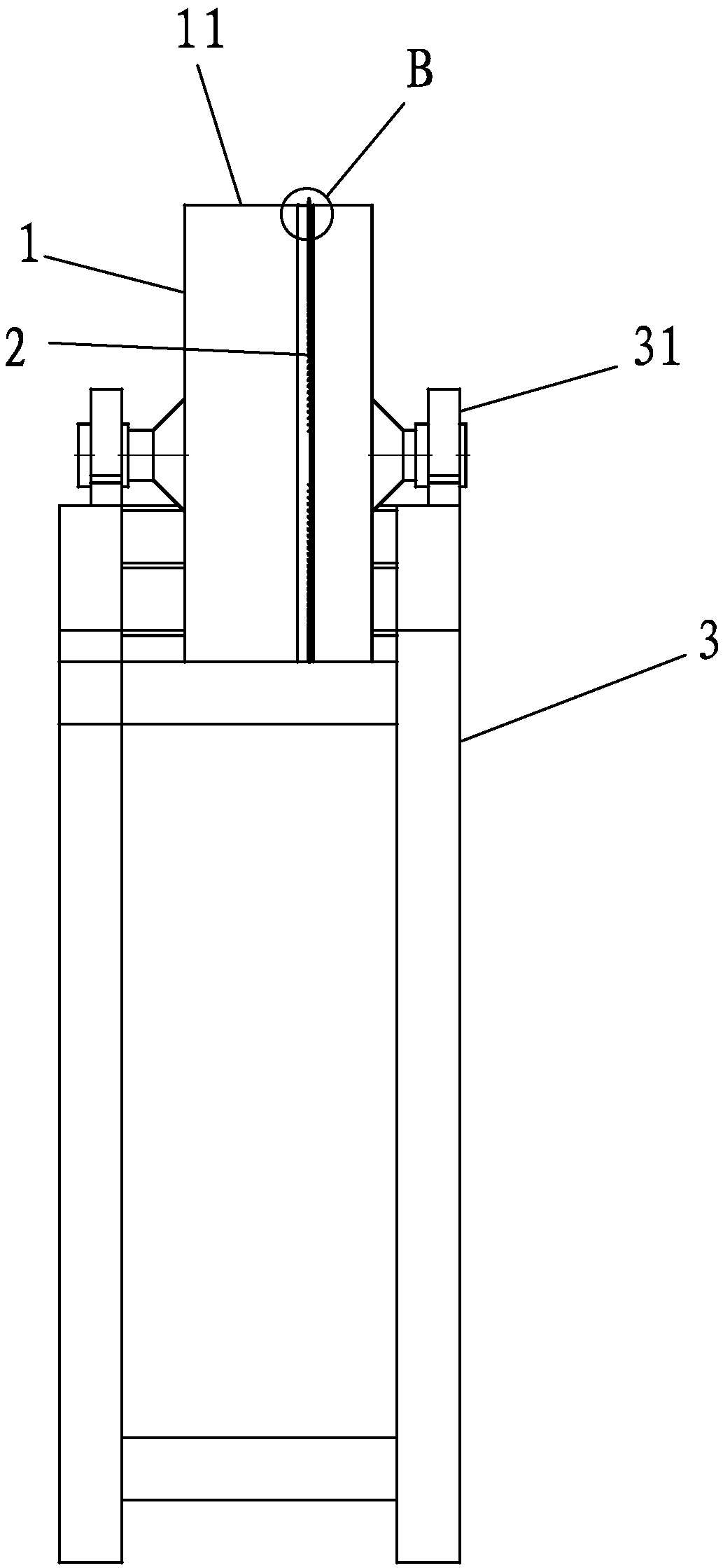

[0029] This case involves a method for manufacturing a cloth belt with holes. First, the gray cloth is woven according to the normal process, and then the gray cloth will undergo a series of known processes such as presetting, tape winding, dyeing, and drying according to the normal process. The innovative technology of this case is that the woven gray cloth is dried and needle-punched through the gray cloth during the drying process, and after the drying is completed, there is formed on the gray cloth a small ironing belt preserved by high temperature setting. Holes, i.e. fabric tapes with holes (see Figure 5 shown). When the tape is set at high temperature, the molecular chain of the tape material is rearranged, and the small holes of the ironing tape are stably preserved through the setting.

[0030] Preferably, the drying process is a treatment process after the gray cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com