Manufacturing process of furred tongue cleaning flexible glue and product thereof

A manufacturing process and tongue coating technology, applied in the field of products prepared by the process, can solve problems such as loosening of tongue coating cleaning soft glue, and achieve the effects of good hygiene, high performance and high-strength cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A manufacturing process of soft glue for cleaning tongue coating, which is carried out in accordance with the following steps in sequence:

[0041] 1. Press-molded plastic elastomer film;

[0042] 2. Carry out hair head forming on the plastic elastomer film and synchronously compound it with the composite film to form a complex;

[0043] 3. The complex is bonded to the cloth base through an adhesive;

[0044] 4. Use an adhesive to bond the base surface of the cloth to the release film;

[0045] 5. Die-cut the cloth base composite;

[0046] 6. Remove the release film from the die-cut sheet and splice it on the release polyester film coil;

[0047] Seven, eliminate waste.

[0048] In this embodiment, the plastic elastomer is styrene-butadiene rubber, which is modified by white oil, and the hardness is Improves affinity for binders. The function of white oil is mainly to adjust the hardness of the plastic elastomer and produce a certain lubricating effect.

[0049]...

Embodiment 2

[0056] In this embodiment, a manufacturing process of soft tongue coating cleaning is carried out according to the following steps in sequence:

[0057] 1. Press-molded plastic elastomer film;

[0058] 2. Carry out hair head forming on the plastic elastomer film and synchronously compound it with the composite film to form a complex;

[0059] 3. The complex is directly bonded to the release film through an adhesive;

[0060] 4. Die-cutting the non-cloth-based composite;

[0061]5. Remove the die-cut sheet from the release film and splice it on the roll of the release polyester film;

[0062] Sixth, eliminate waste.

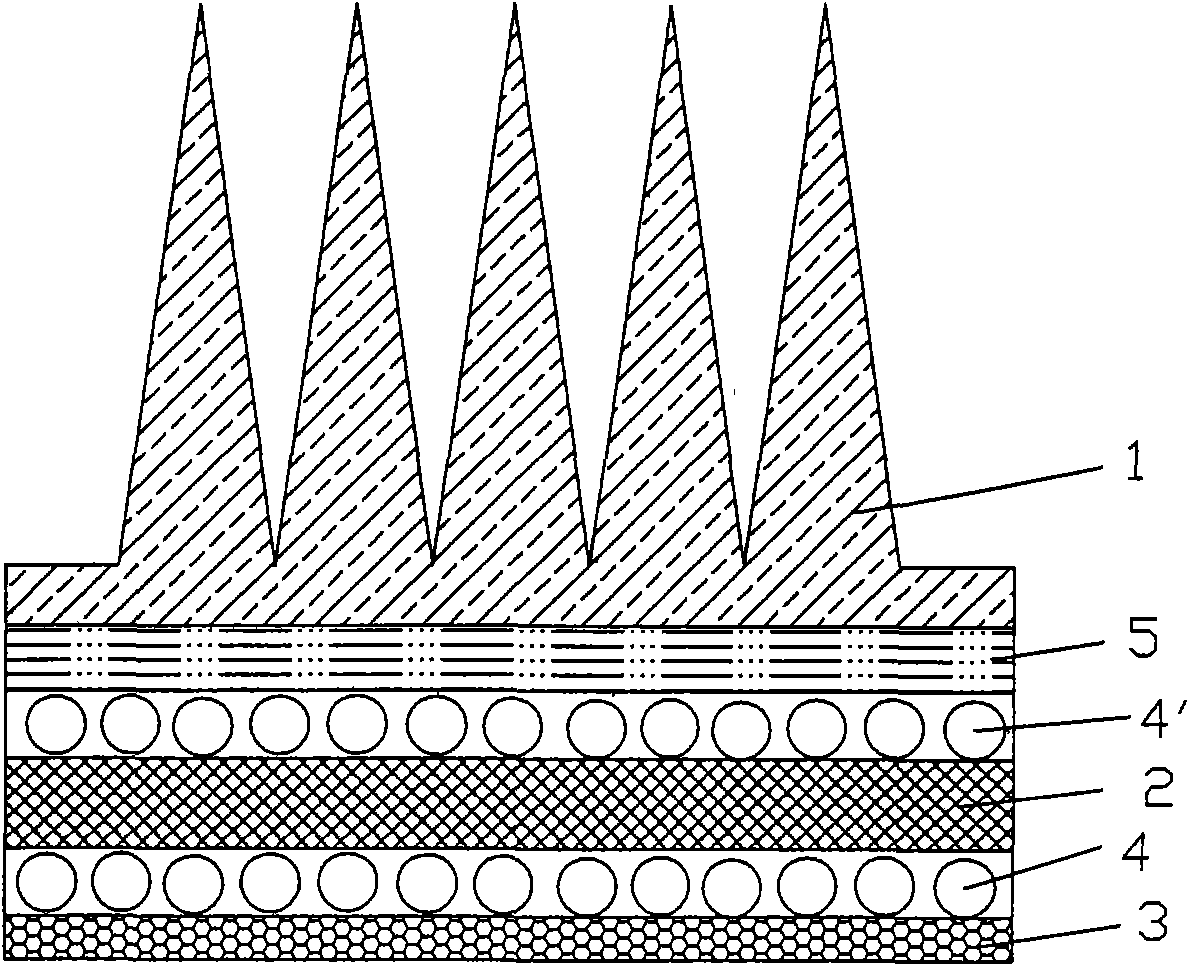

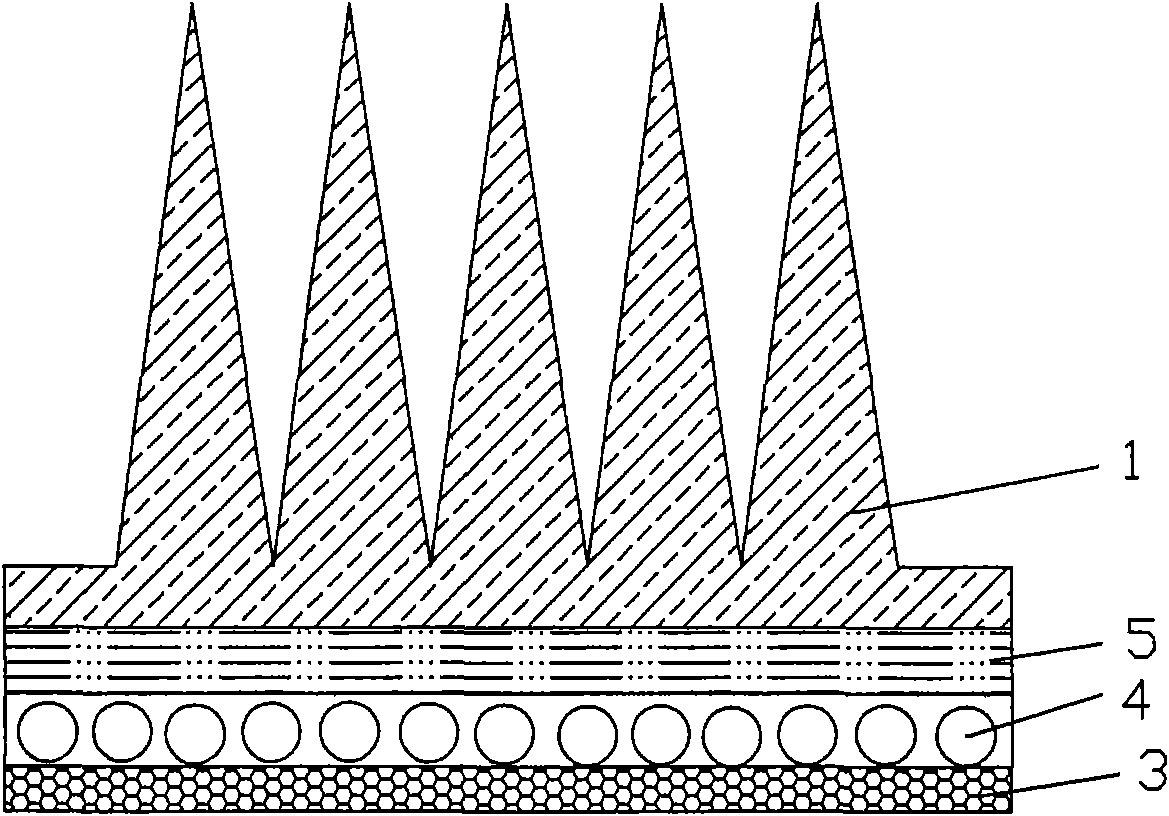

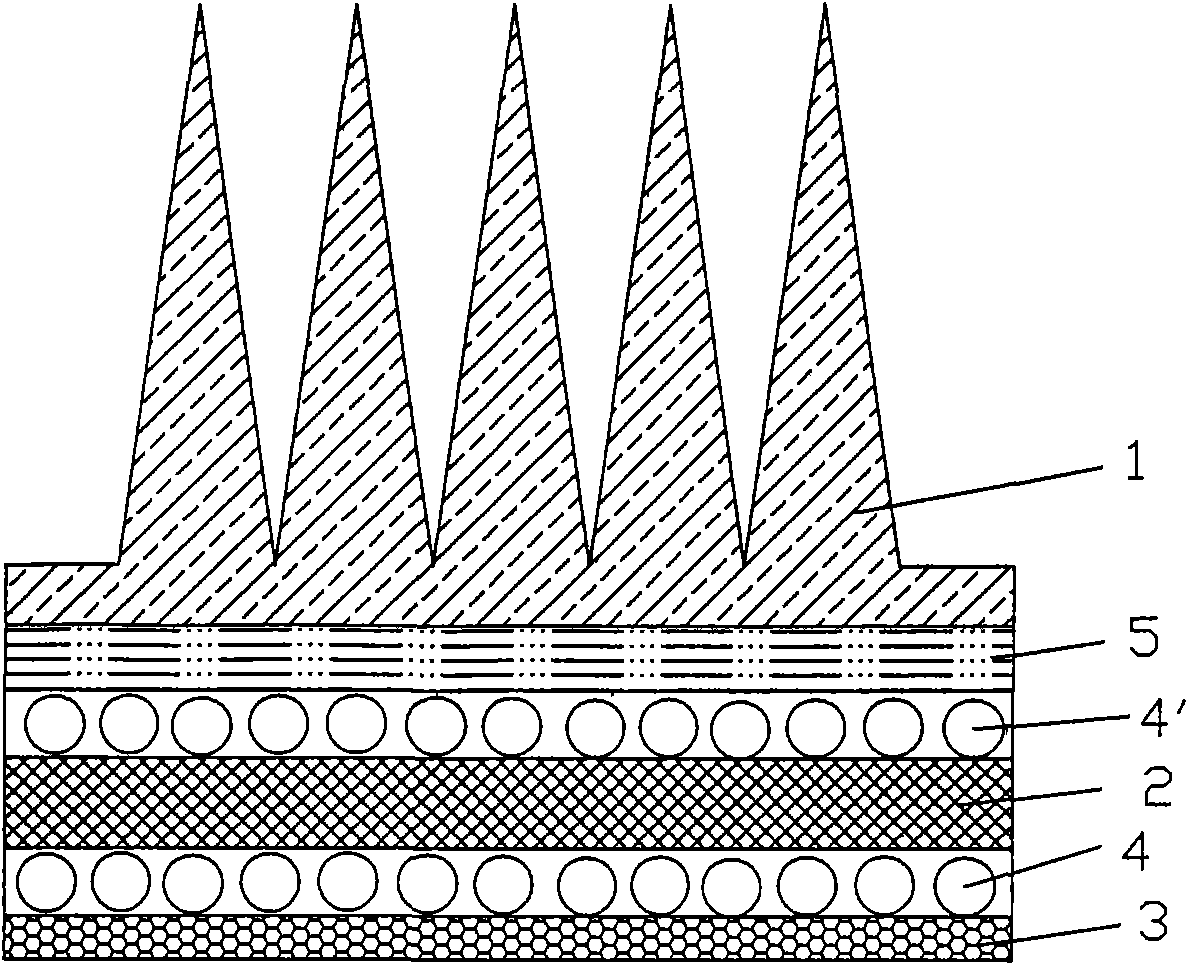

[0063] figure 2 As shown, in this embodiment, the composite film 5 is bonded on the upper surface of the release film 3 through the adhesive 4 , and the tongue coating elastic body 1 is bonded on the upper surface of the composite film 5 .

[0064] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com