Procuring process of welding glue

A pre-curing and process technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of high resistance, easy short circuit, insufficient bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

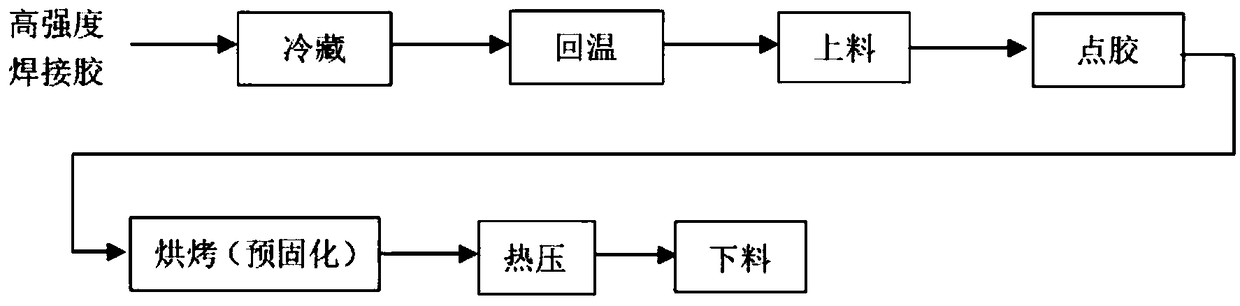

Method used

Image

Examples

Embodiment 1-10

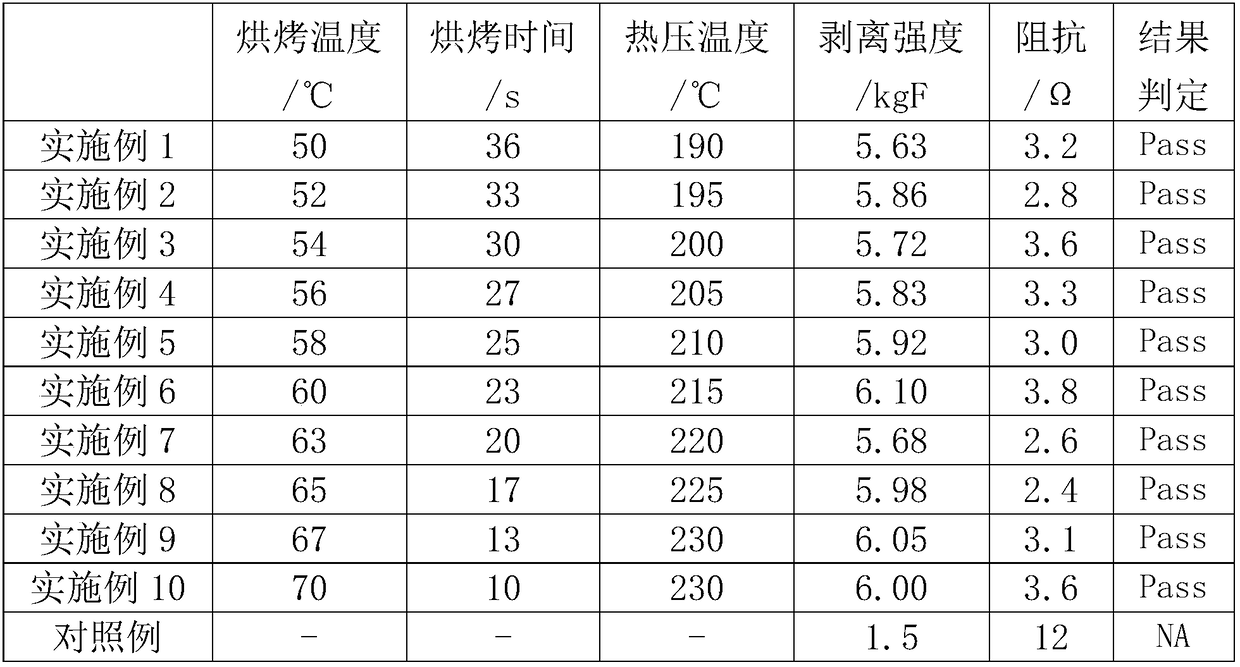

[0032] Process the product according to the conditions in Table 1, and use the product obtained by the non-pre-curing process as a control example to test the peel strength, impedance and width. If the width of the glue is not more than 0.1mm, it means pass:

[0033] Table 1

[0034]

[0035] It can be seen from Table 1 that the electronic products obtained by this process can meet the requirements of 0.1mm ultra-fine electrode spacing; and the peel strength fully meets the standard requirements of 3kgF, even above 6kgF; at the same time, the impedance is lower than the design requirements of 5Ω, even reaching 2.4Ω. It shows that this process can fully meet the requirements of conductive structure, connection and conduction.

[0036] The feature of the present invention is that the liquid glue is converted into a semi-solidified state through pre-curing, which is good for handling without splashing, can be fully filled, is good for adhesion and bonding, does not splash, is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com