Light high-pressure weight carrying gasbag

A technology of airbags and heavy objects, which is applied in the direction of lifting devices, etc., can solve the problems of airbag wear, cut, puncture and other safety issues, increase the proportion of skeleton materials, increase the weight of airbags, etc., and achieve superior puncture resistance, Reduced airbag weight and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

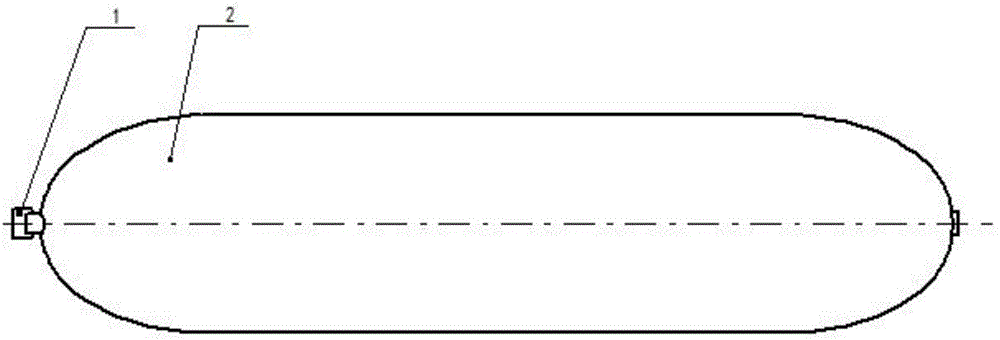

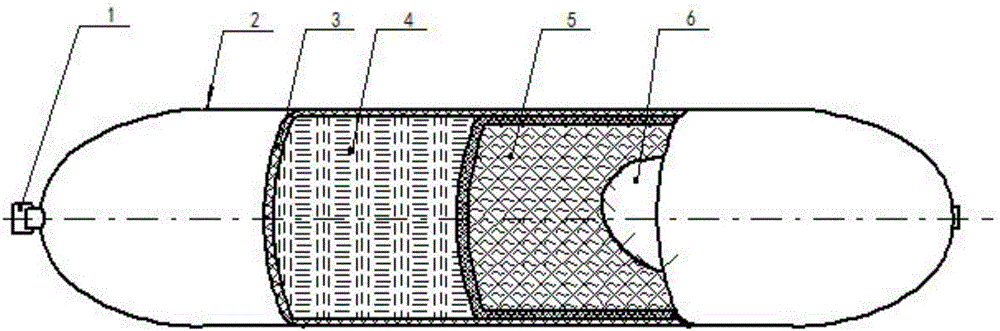

[0028] A light, high-pressure and heavy-object-carrying airbag, which is composed of an airbag body 2 and a valve 1, and a closed airbag cavity 6 is formed in the airbag body, wherein the airbag body is composed of a coaxial and tightly bonded wear-resistant layer 3 from the outside to the inside, and a puncture-resistant The layer 4 and the airtight layer 5 are formed, the adhesive is evenly applied between two adjacent rubber layers, and the angle between the winding direction is between 60-70 degrees.

[0029] The wear-resistant layer is high modulus chopped fiber filled rubber, the chopped fiber includes nylon, polyester and aramid, the diameter of the chopped fiber is 10-12 microns, and the length is 1-3 mm. The wear-resistant layer can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com