Continuous laminating and rolling method for corrugated interface double-metal composite board

A composite plate and bimetal technology, applied in metal rolling and other directions, can solve problems such as unevenness, edge crack product thickness, warpage, etc., and achieve the effect of improving bonding strength, high bonding strength, and good plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

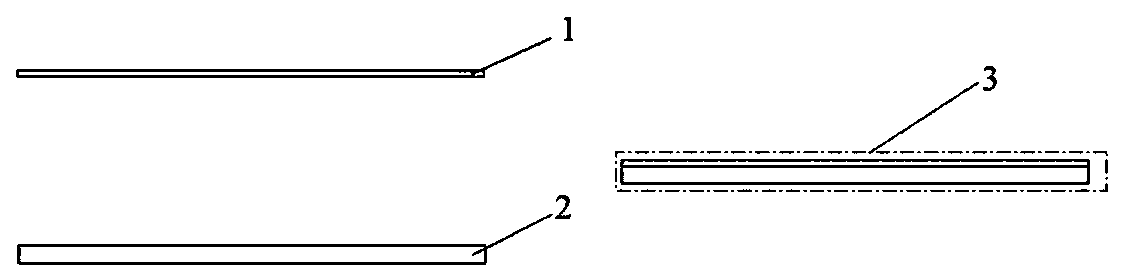

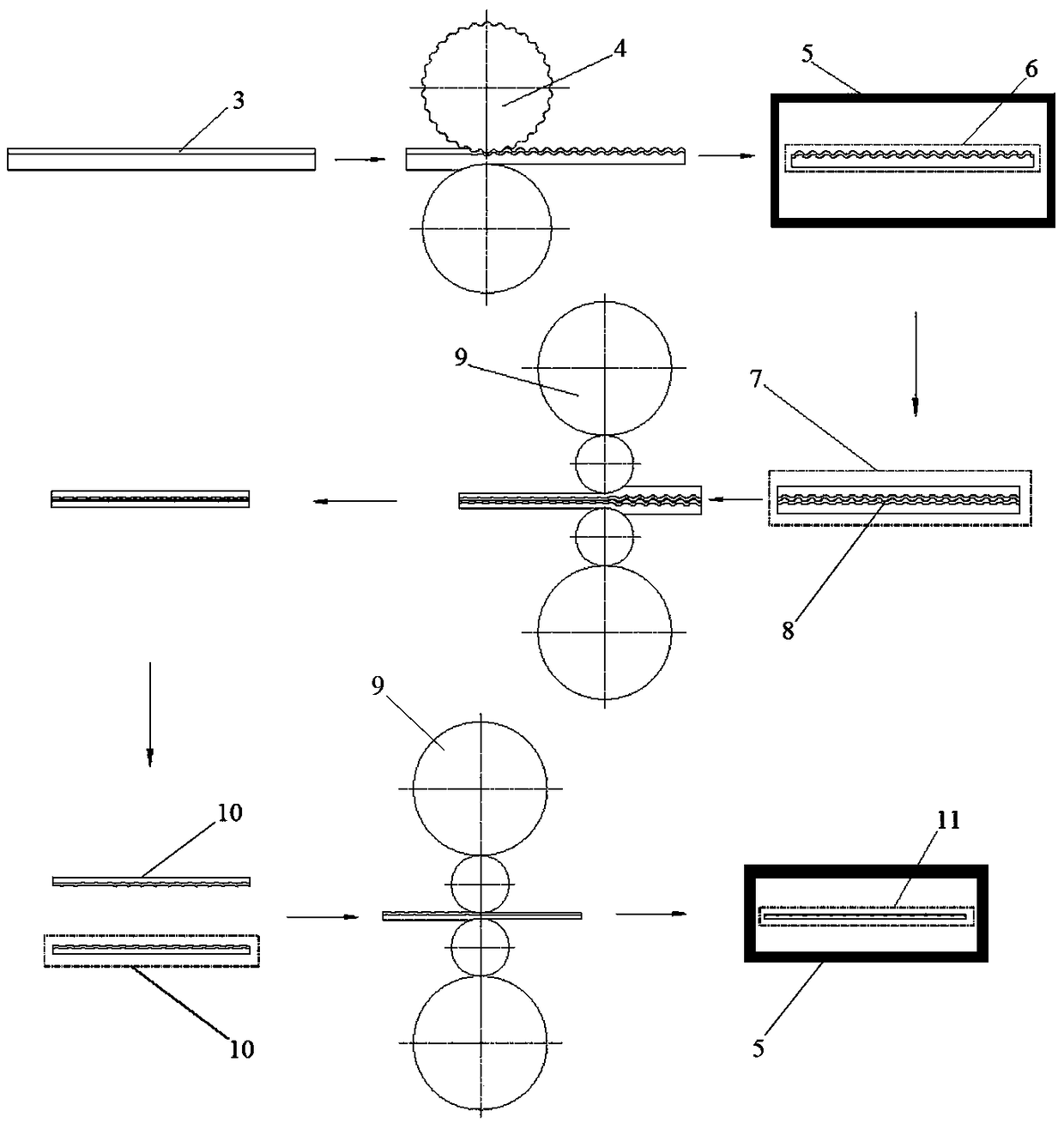

[0062] with attached figure 1 , 2 The copper-aluminum composite panel was prepared by the method shown:

[0063] 1) Billet making: select pure aluminum plate as the cladding plate 1, the plate size is 200mm (length) × 50mm (width) × 2mm (height), and the pure copper plate is used as the base plate 2, and the plate size is 200mm (length) × 50mm (width) × 8mm (height). Use a grinding tool equipped with a wire brush to grind the surfaces to be combined between the pure copper and pure aluminum plates to a "sand surface" effect to remove oxides on the surface of the slab and create favorable conditions for copper-aluminum composite. The heads and tails of the plates are stacked and riveted to ensure that the base-complex plate is smoothly and synchronously bitten, and that it will not deviate during the rolling process, and the composite plate blank 3 is obtained.

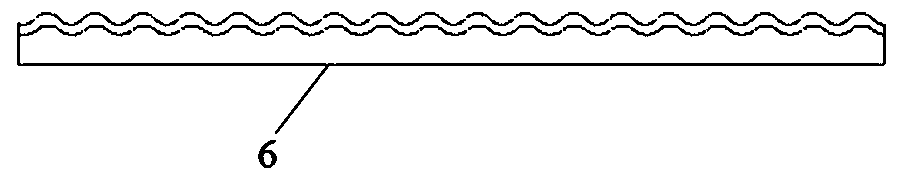

[0064] 2) Rolling: The upper roll is corrugated roll 4 and the lower roll is ordinary flat roll for rolling, and ...

Embodiment 2

[0073] with attached figure 1 , 2 The carbon steel-stainless steel clad plate was prepared by the method shown:

[0074] 1) For billet making, select the s316L plate as the cladding plate 1, the plate size is 200mm (length) × 50mm (width) × 2mm (height), the Q345R carbon steel plate is used as the base plate 2, and the plate size is 200mm (length) × 50mm (width) ×8mm (height). Use a grinding tool equipped with a wire brush to grind the joint surfaces of the pure copper plate and pure aluminum plate after stress relief annealing to a "sand surface" effect, so as to remove oxides on the surface of the slab and create favorable conditions for the composite of carbon steel and stainless steel. , and then stack the polished surfaces of the carbon steel and stainless steel plates, weld the carbon steel and stainless steel around, and weld a vacuum tube at the interface of the billet head to be joined, and use a vacuum pump to vacuum the billet to prevent the joint interface. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com