An injection-molded zipper cloth tape and a manufacturing method thereof

A manufacturing method and tape technology, applied in the field of zipper tape, can solve problems such as inability to adapt to different chain types, unstable small holes, poor applicability, etc., achieve outstanding practicability and application value, and simple and adjustable hole distance Change and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

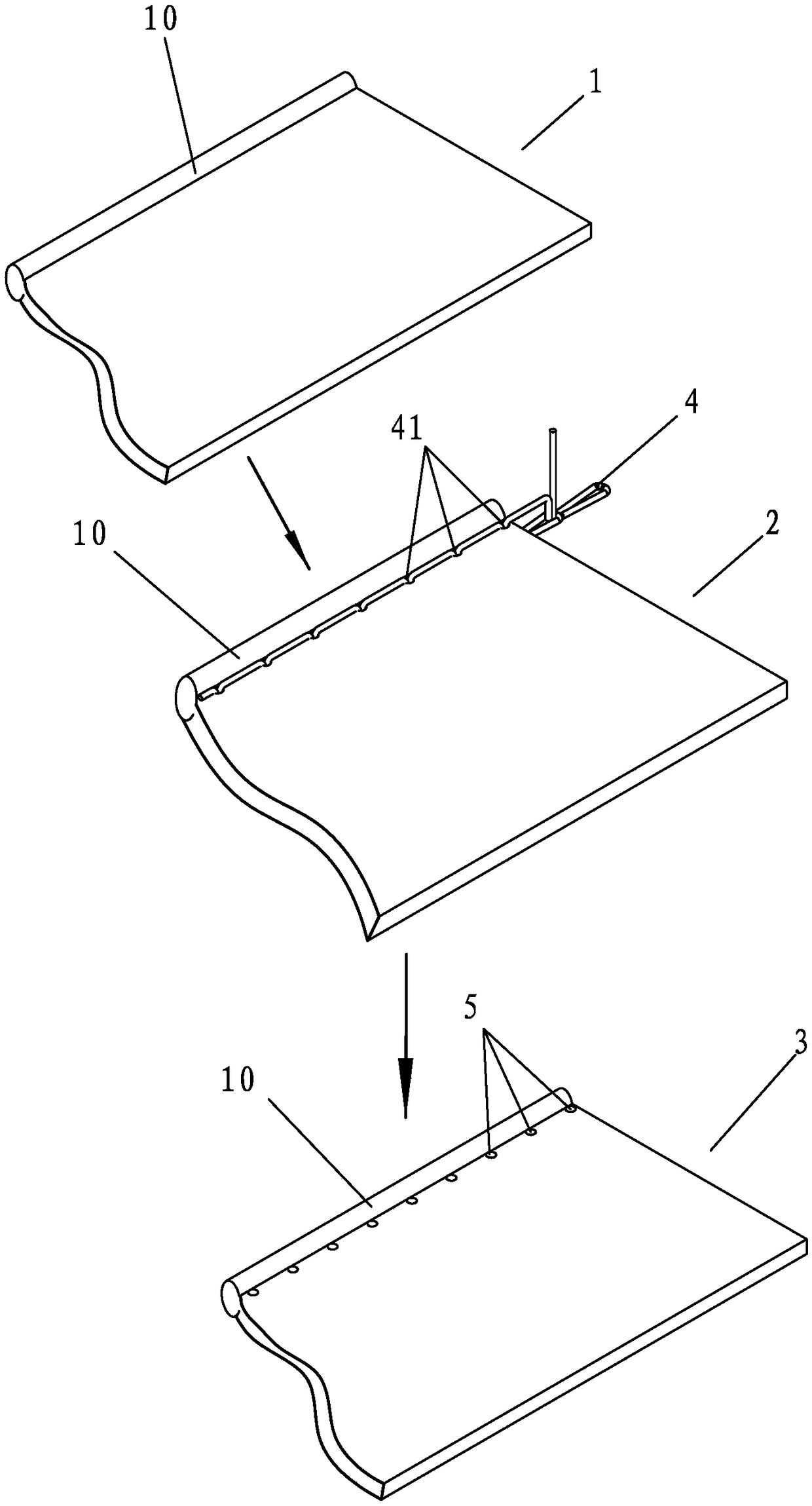

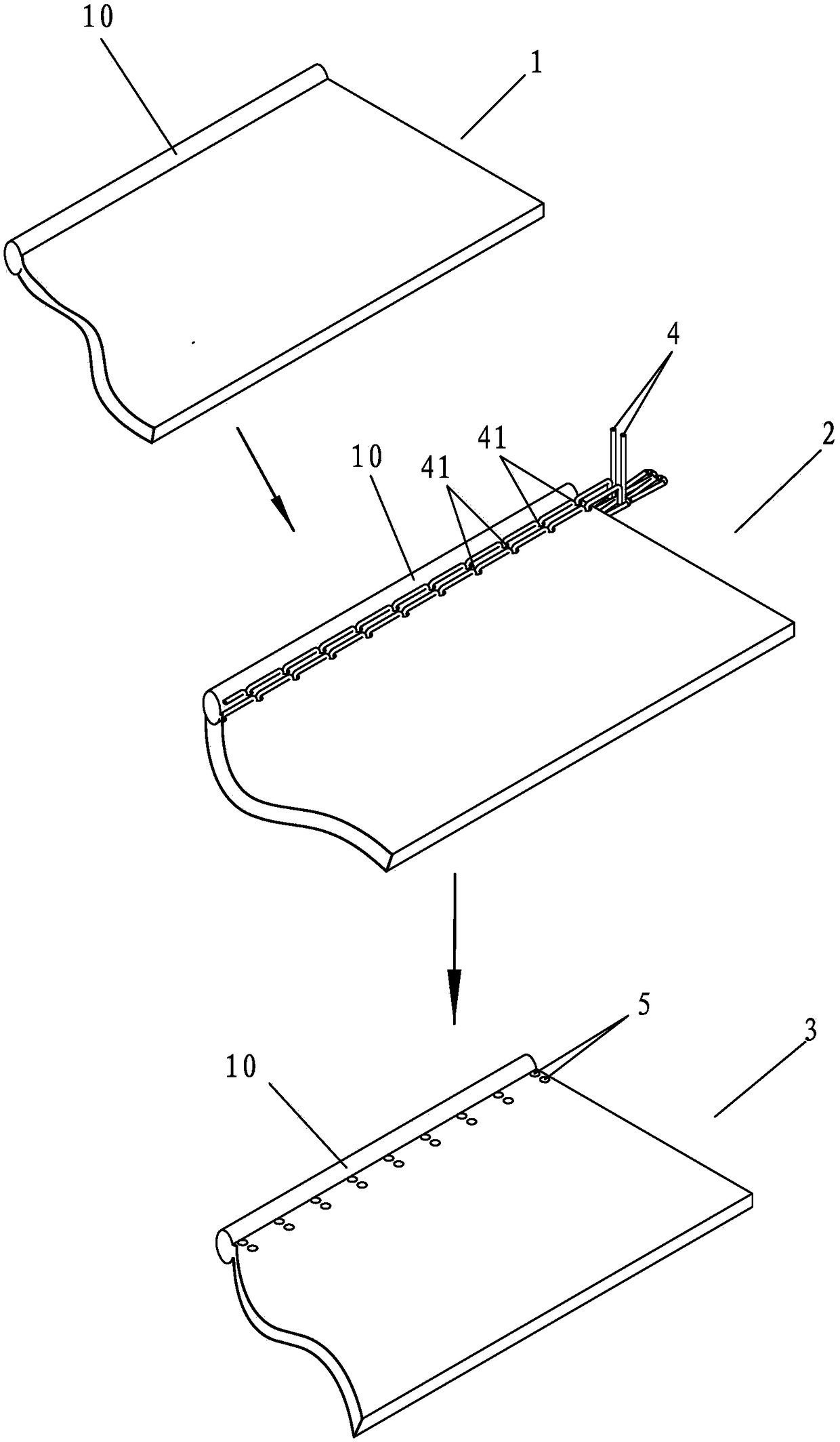

[0029] This case involves a manufacturing method of injection molded zipper tape, such as Figure 1-4 As shown, the method steps are as follows:

[0030] 1) Weaving the ordinary zipper blank tape 1 for injection molding according to the normal process; specifically, the center line, warp yarn and weft yarn are woven into the ordinary zipper blank tape 1 for injection molding according to the normal process by the loom, and the corresponding preferably formed There is a center line 10 .

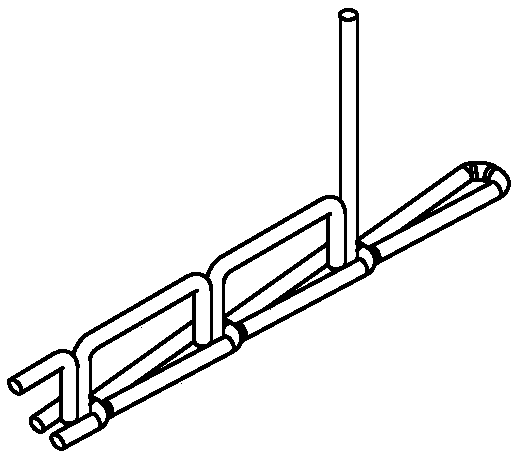

[0031] 2) Sew the sutures 4 penetrating the blank tape 1 on the blank tape 1, and the suture holes 41 of the stitches 4 penetrating the blank tape are correspondingly distributed according to the small holes of the injection molded fastener elements to be provided on the zipper tape. A centerline 10 is formed corresponding to the zipper blank, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com