Autogenous submerged liquid diffusion welding of titanium

a technology of submerged liquid and welding equipment, which is applied in the direction of welding equipment, manufacturing tools, other domestic objects, etc., can solve the problems of undiscovered corrosion resistance, contamination of titanium with undesirable physical and corrosion characteristics, and superior strength per unit weight of titanium, etc., to achieve high strength bonding and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

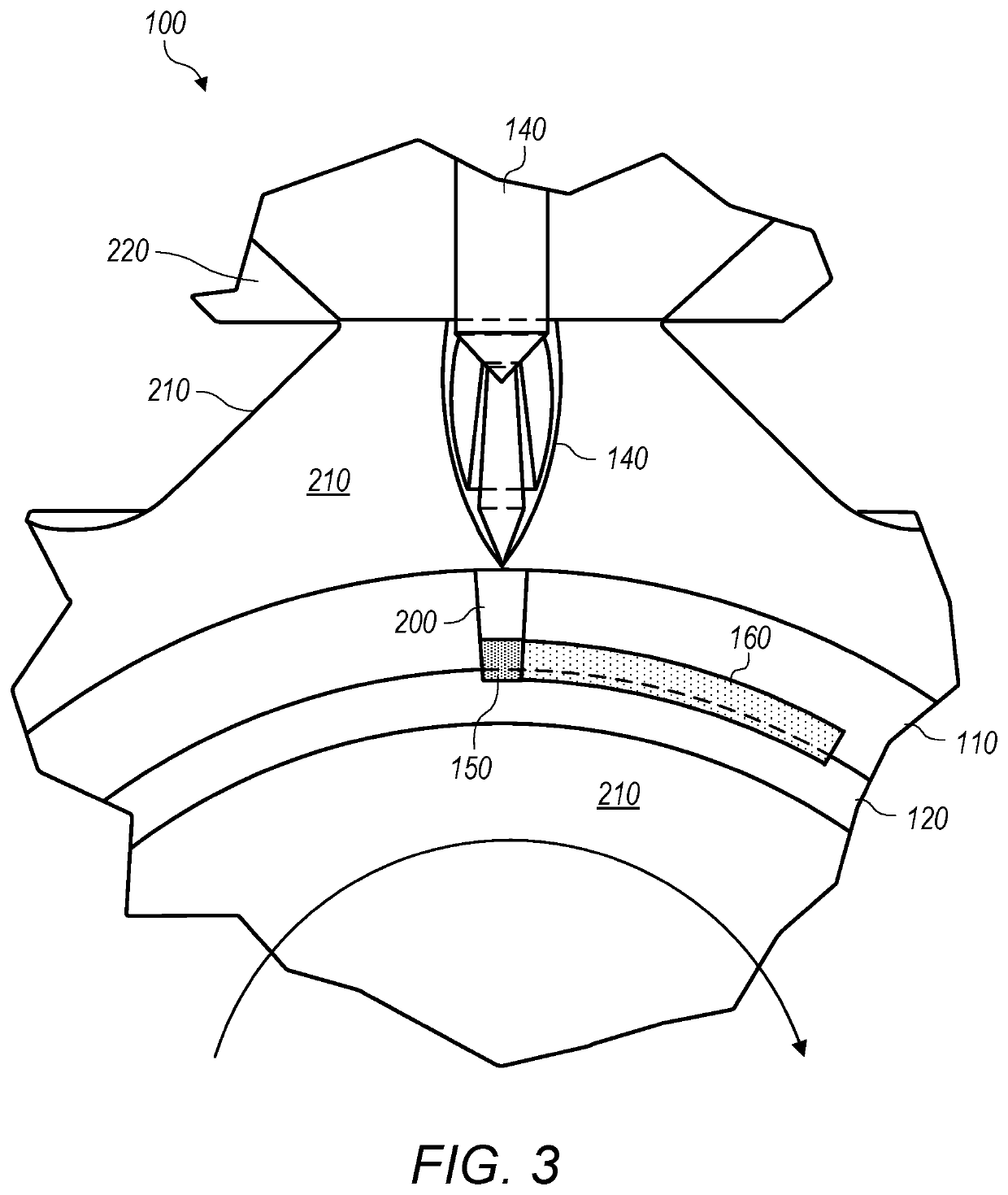

[0041]In some embodiments, the methods and systems described herein are intended to describe autogenous submerged liquid diffusion bonding of an IA to titanium. This bonding facilitates the IA as a functional composite part welded to the titanium base structure. Alternately the IA could be tasked as a bonding agent that once welded to titanium can be welded or brazed with an array of structural alloys (e.g., aluminum, steel, stainless, copper, etc.), effectively “welding” substantially dissimilar metals to titanium.

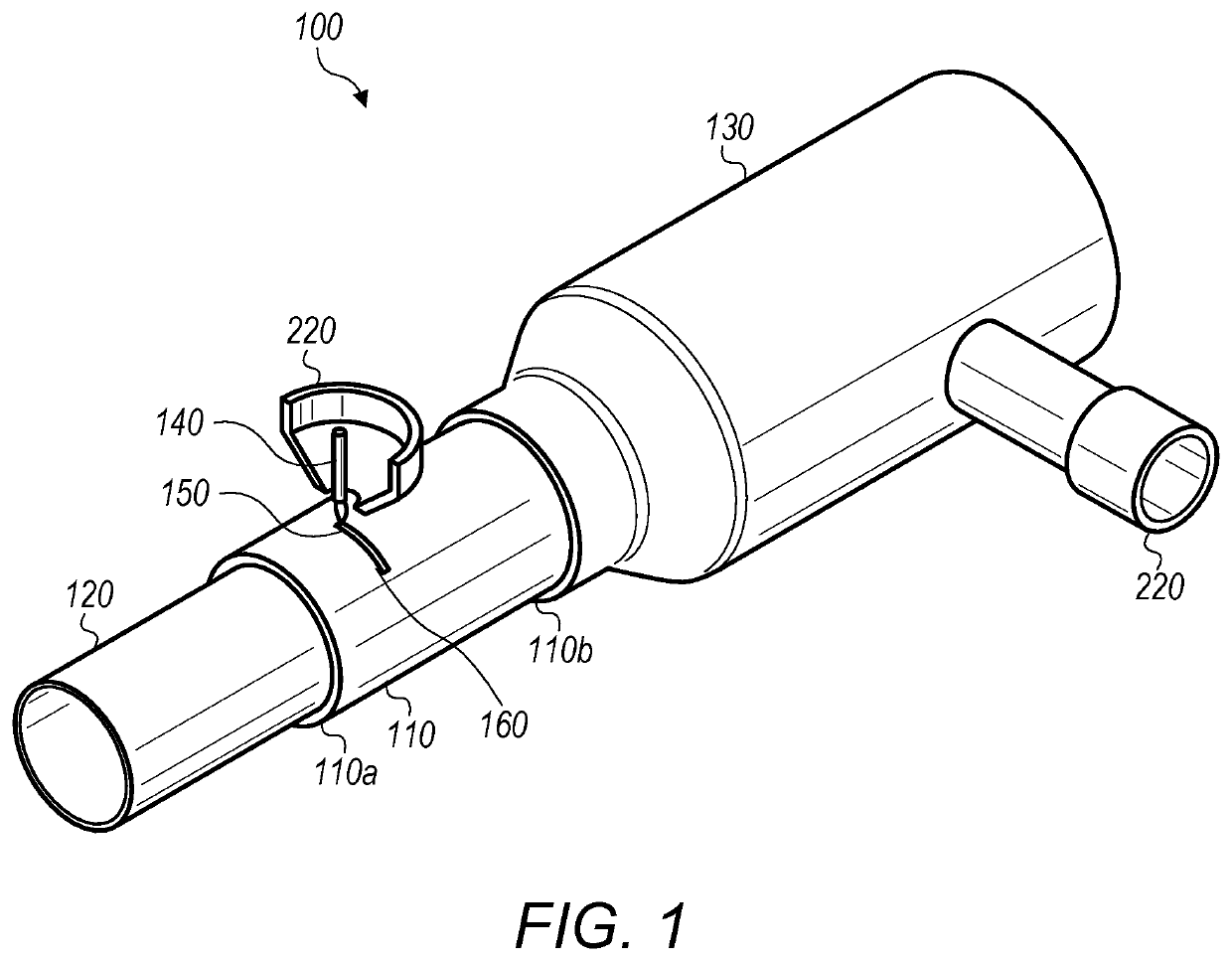

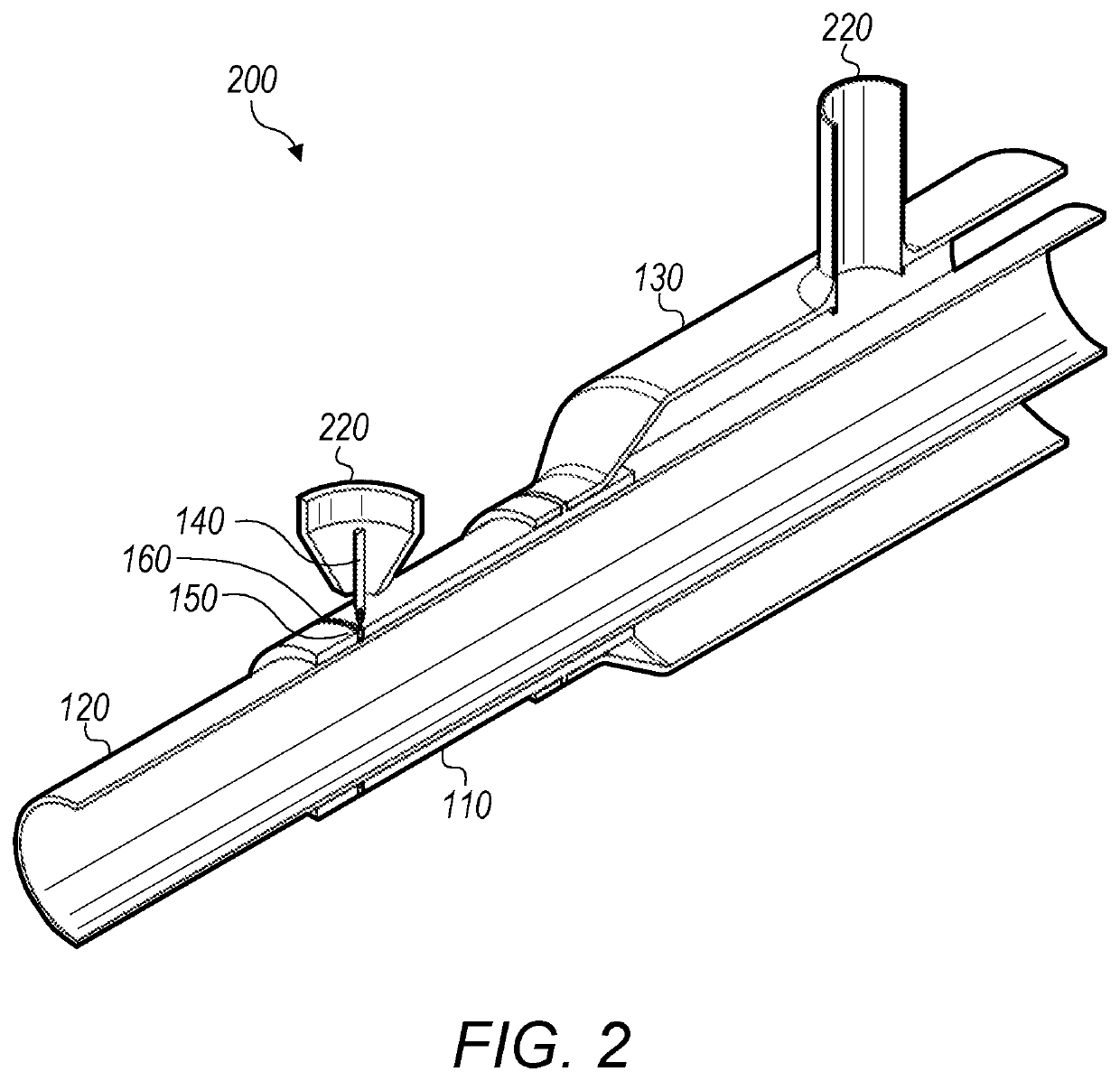

[0042]In some embodiments, autogenous submerged liquid diffusion welding of titanium involves a method and process for making a “diffusion” bond between titanium and an IA that has a substantially lower melting point than titanium that is weldable to other alloys. In some embodiments, the process layers an IA onto titanium which is passed under a pin point heat source that creates a sub meniscus sized liquidus column of the IA, wetting the titanium. The molten IA is super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transus temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com