Method for preparing metallized ceramic substrate by low-temperature sintering

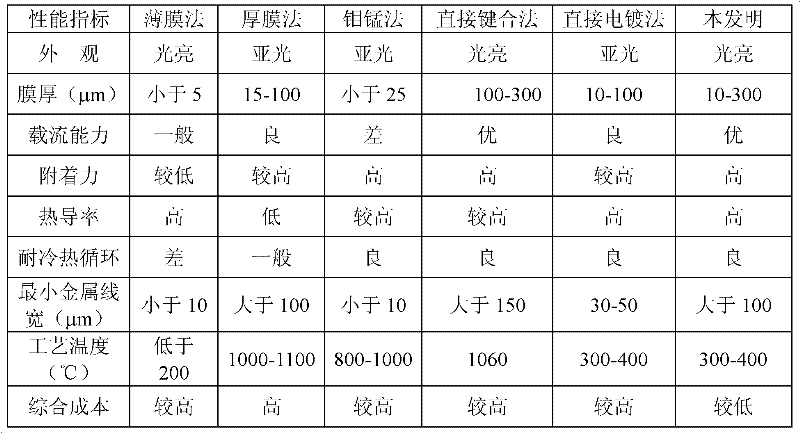

A metallized ceramic and low-temperature sintering technology, which is applied in the field of electronic manufacturing, can solve the problems of low bonding strength, slow deposition speed, and low reliability, and achieve the effects of small thermal stress, low production cost, and high substrate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

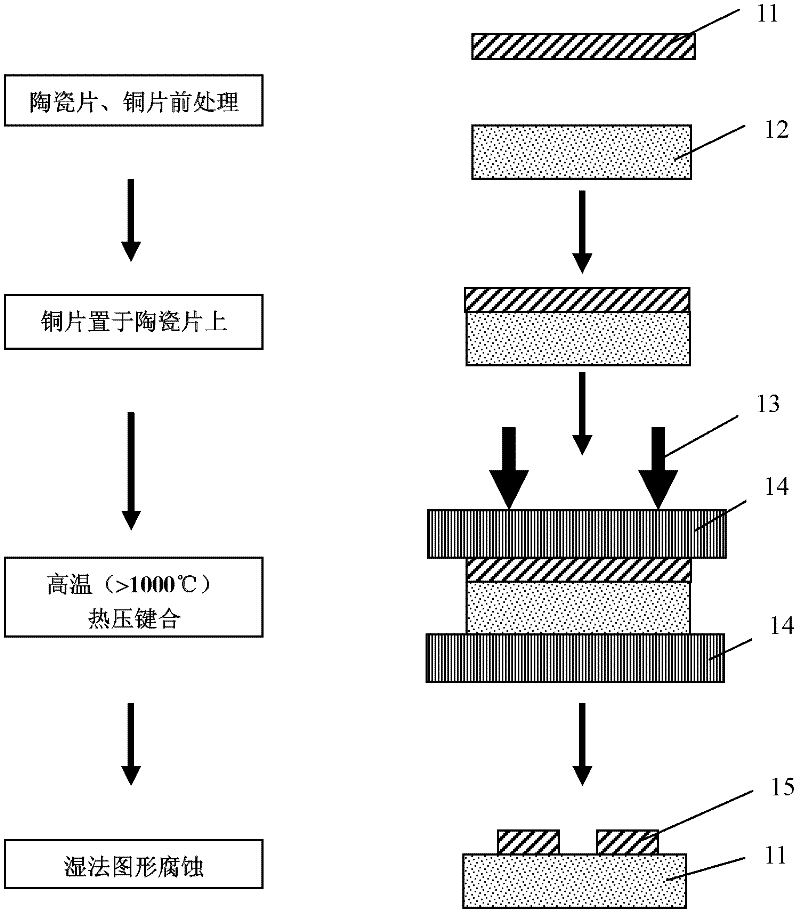

Method used

Image

Examples

Embodiment 1

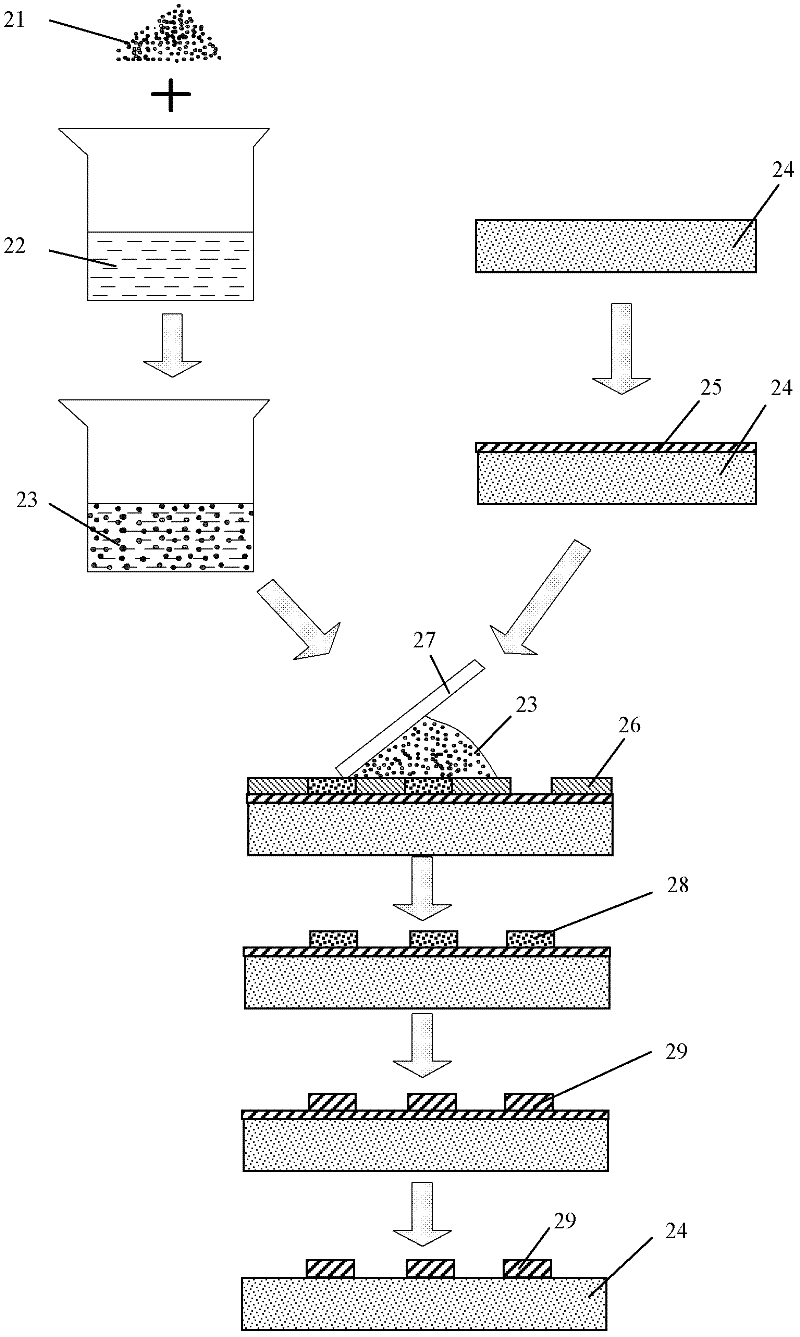

[0017] Material preparation: copper powder: particle size 5-30nm, spherical in appearance; organic compound formula (mass ratio): 5% ethyl cellulose, 1% triethanolamine, fully dissolved with the balance of terpineol.

[0018] The production process is:

[0019] (1) Mix and stir the nano-copper powder and the organic matter in a mass ratio of 70:30 to make a nano-copper paste;

[0020] (2) Metallization of ceramic sheets: Ultrasonic cleaning of 96% alumina substrates with acetone for 10 minutes, and drying; using a multi-target sputtering machine to deposit 30nm titanium films and 50nm copper films on alumina ceramic sheets;

[0021] (3) Printing and coating conductor patterns: using a stainless steel orifice plate and a manual screen printing machine to form nano-copper paste patterns on the alumina substrate; dry at 100°C for 30 minutes to obtain a copper paste layer with a thickness of 100 microns;

[0022] (4) Sintering: Place the alumina ceramic substrate with copper past...

Embodiment 2

[0027] Material preparation: copper powder: particle size 2-20nm, spherical appearance; organic formula (mass ratio): 8% ethyl cellulose, 2% triethanolamine, fully dissolved with the balance of terpineol.

[0028] The production process is:

[0029] (1) Mix and stir the nano-copper powder and the organic matter in a mass ratio of 80:20 to prepare a nano-copper paste;

[0030] (2) Metallization of ceramic sheets: ultrasonically clean the aluminum nitride substrate with acetone for 10 minutes, and dry it; use a multi-target sputtering machine to deposit a 20nm titanium film and a 50nm copper film on the aluminum nitride ceramic sheet;

[0031] (3) Printing and coating conductor graphics: using a stainless steel orifice plate and a manual screen printing machine to prepare nano-copper paste graphics on an aluminum nitride substrate; dry at 100°C for 30 minutes to obtain a copper paste layer with a thickness of 300 microns ; Turn over the aluminum nitride substrate, repeat the sc...

Embodiment 3

[0037]Material preparation: silver powder: particle size 2-20nm, spherical appearance; organic formula (mass ratio): 6% ethyl cellulose, 2% triethanolamine, fully dissolved with the balance of terpineol.

[0038] The production process is:

[0039] (1) Mix and stir the nano-silver powder and the organic matter in a mass ratio of 70:30 to prepare a nano-silver paste;

[0040] (2) Metallization of ceramic sheets: Ultrasonic cleaning of 99% alumina substrate with acetone for 10 minutes, drying; deposition of 20nm titanium film and 50nm silver film on alumina ceramic sheet by multi-target sputtering machine;

[0041] (3) Printing and coating conductor graphics: using a stainless steel orifice plate and a manual screen printing machine to form nano-silver paste graphics on the alumina substrate; dry at 100°C for 30 minutes to obtain a silver paste layer with a thickness of 200 microns;

[0042] (4) Sintering: place the alumina ceramic substrate with silver paste layer in a sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com