High-strength, high-toughness and high-plasticity martensitic stainless steel and preparation method thereof

A martensitic stainless steel, high-strength and toughness technology, applied in the field of metallurgy to achieve the effect of improving the level of strength, toughness and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Melt molten steel in a protective atmosphere according to the set composition, and the protective atmosphere is nitrogen; then it is solidified by a mold to make a billet; its composition contains C 0.15%, Si 0.2%, Mn 0.4%, S 0.012%, P 0.016% by weight , Cr 13.0%, Ni 5.0%, Mo 2.0%, Nb 0.2%, V 0.3%, N 0.12%, the balance is Fe and unavoidable impurities;

[0026] The slab is hot-rolled into a hot-rolled slab with a thickness of 15mm, the starting rolling temperature is 1150±50°C, the final rolling temperature is 850±50°C, and the total reduction is 80%;

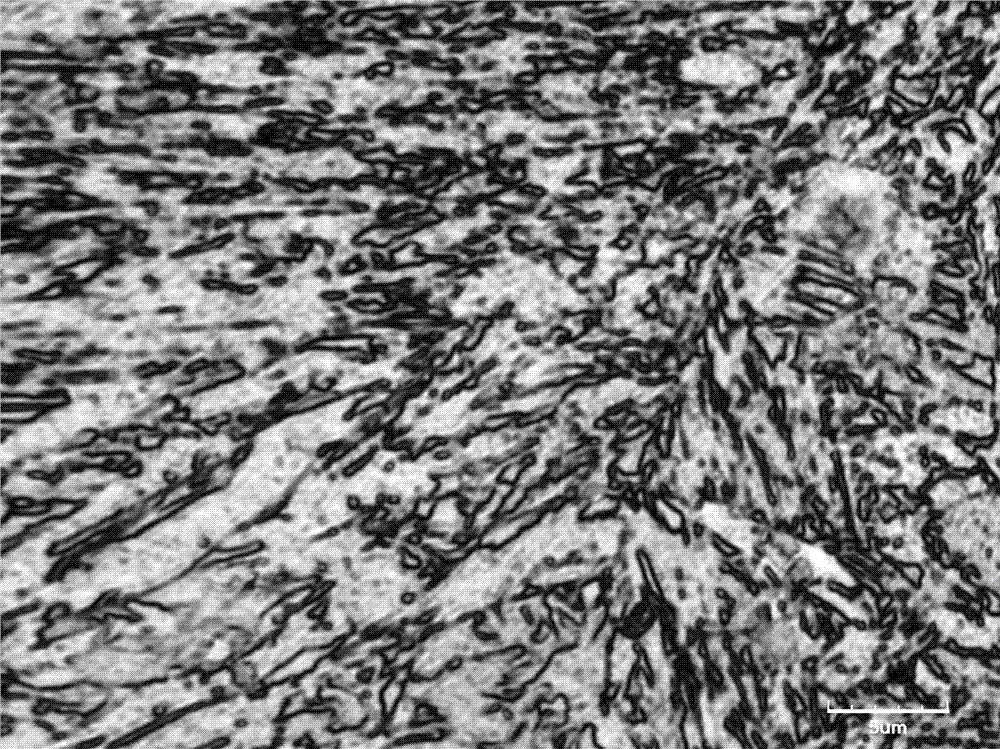

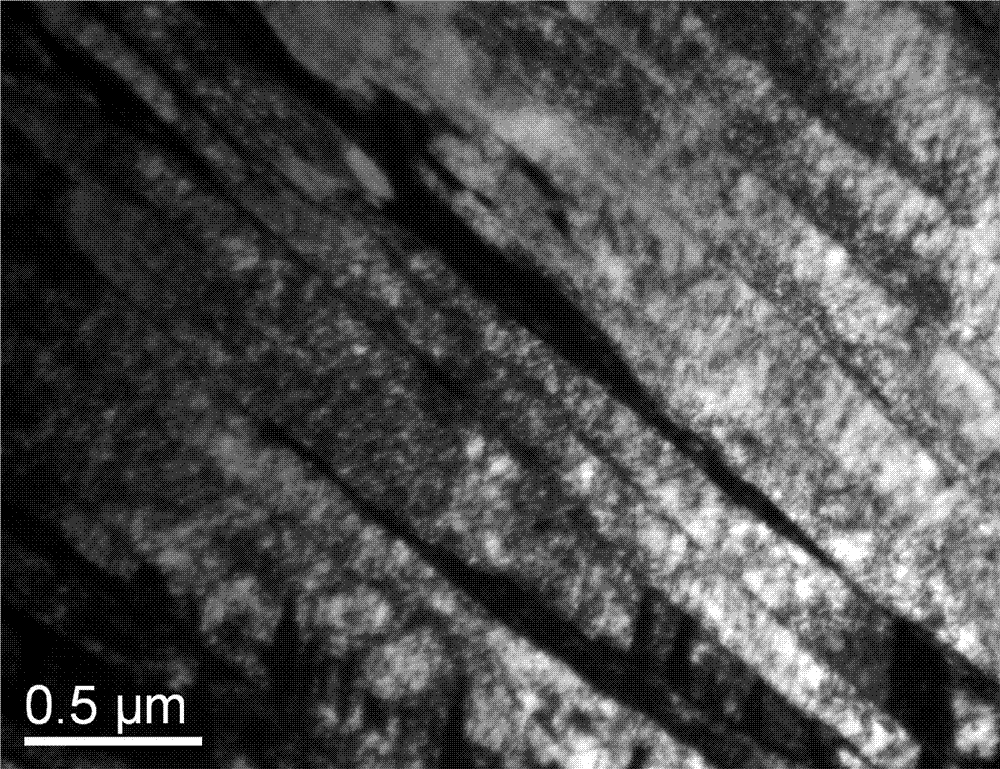

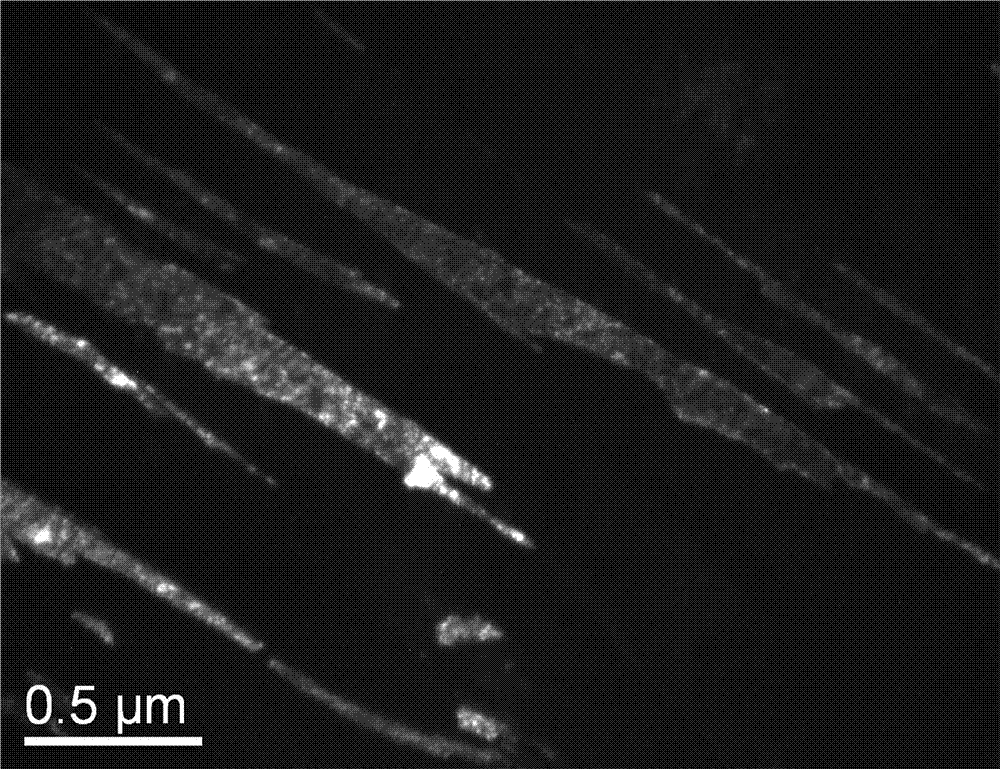

[0027] Heat the hot-rolled slab to 950°C for 2 hours, then air-cool to 150°C, heat to 450°C for 10 minutes, and air-cool to room temperature to obtain high-strength, toughness, and high-strength plastic martensitic stainless steel, with a yield strength of 873 MPa and a tensile strength of 1445MPa, elongation 22.0%, Charpy V-notch impact energy at 70J, the structure is martensite and austenite, and the volume fraction of...

Embodiment 2

[0029] Molten steel is smelted under a protective atmosphere according to the set composition, and the protective atmosphere is argon; then it is solidified by a casting mold to make a billet; its composition contains C 0.28%, Si 2.5%, Mn 3.0%, S 0.008%, P 0.019 by weight percentage %, Cr 13.0%, Al 0.8%, Mo 1.0%, Nb 0.2%, Ti 0.05%, the balance is Fe and unavoidable impurities;

[0030] The slab is hot-rolled into a hot-rolled slab with a thickness of 20mm, the starting rolling temperature is 1150±50°C, the final rolling temperature is 850±50°C, and the total reduction is 80%;

[0031] Heat the hot-rolled slab to 1050°C for 2 hours, then air-cool to 25°C, then heat to 500°C and hold for 60 minutes, then air-cool to room temperature to obtain high-strength, toughness, and high-strength plastic martensitic stainless steel with a yield strength of 650MPa and a tensile strength of 1695MPa , the elongation rate is 25.0%, the Charpy V-notch impact energy is 56J, the structure is mart...

Embodiment 3

[0033] Molten steel is smelted under a protective atmosphere according to the set composition, and the protective atmosphere is argon; then it is made into a billet through a continuous casting machine; its composition contains C 0.4%, Si 0.6%, Mn 0.4%, S 0.015%, P 0.013 by weight percentage %, Cr 17.0%, Mo 1.0%, V 0.3%, Ni 2.8%, the balance is Fe and unavoidable impurities;

[0034] The slab is hot-rolled into a hot-rolled slab with a thickness of 25mm, the starting rolling temperature is 1150±50°C, the final rolling temperature is 850±50°C, and the total reduction is 70%;

[0035] Since the total weight content of C and N in the slab is ≥0.3%, annealing treatment is carried out after hot rolling. During annealing treatment, it is heated to 900°C for 2 hours, then cooled to 500°C with the furnace, and then air-cooled to room temperature;

[0036]Heat the annealed hot-rolled slab to 1050°C for 0.5 hours, then cool it to 100°C with industrial quenching oil, heat it to 350°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com