Fabrication method of dual-polarity solid-state lithium secondary battery

A secondary battery and bipolar electrode technology, applied in secondary batteries, battery electrodes, electrode carriers/collectors, etc., can solve problems such as limiting battery applications, achieve high safety, controllable voltage, and easy large-scale The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

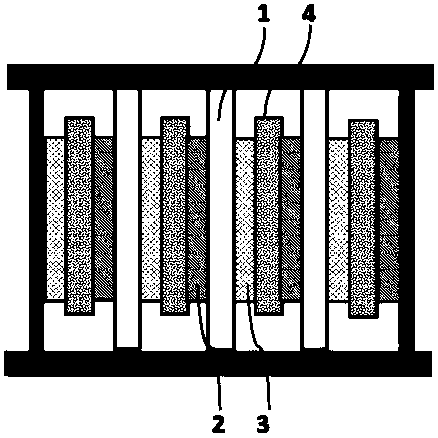

Image

Examples

Embodiment 1

[0027] A method for preparing a bipolar solid-state lithium secondary battery comprises stacking and assembling a bipolar electrode, a solid electrolyte layer, and a unipolar electrode in sequence to form a solid-state battery. Specific preparation process:

[0028] (1) Preparation of bipolar current collector

[0029] Cu was deposited on the surface of the aluminum foil by atomic layer deposition (ALD) to form a bipolar current collector.

[0030] Concrete preparation steps are as follows:

[0031] a) Place the aluminum foil pre-cut into 10cm×10cm in the vacuum reaction chamber of the atomic layer deposition equipment, and vacuumize the reaction chamber;

[0032] b) Copper hexafluoroacetylacetone complex (Cu(hfac) 2 ) and methanol as a prepolymer, in an inert gas Ar atmosphere, carry out atomic layer deposition cycle, the deposition temperature is set to 220 ° C, the pressure in the reaction chamber is maintained at 10 Pa, and the deposition thickness is 1 μm;

[0033] c)...

Embodiment 2

[0049] A method for preparing a bipolar solid-state lithium secondary battery comprises stacking and assembling a bipolar electrode, a solid electrolyte layer, and a unipolar electrode in sequence to form a solid-state battery. Specific preparation process:

[0050] 1) Preparation of bipolar current collector

[0051] Cu is deposited on the surface of the aluminum foil by magnetron sputtering to form a bipolar current collector.

[0052] Concrete preparation steps are as follows:

[0053] a) Place the aluminum foil pre-cut into 10cm×10cm in the vacuum reaction chamber of the magnetron sputtering equipment, and vacuumize the reaction chamber;

[0054] b) A copper target is used to carry out a sputtering reaction in an inert gas Ar atmosphere, the reaction temperature is set to normal temperature, the pressure in the reaction chamber is kept at 0.2 Pa, and the deposition thickness is 1 μm;

[0055] c) After the sputtering is finished, fill the vacuum reaction chamber with an ...

Embodiment 3

[0058] A method for preparing a bipolar solid-state lithium secondary battery comprises stacking and assembling a bipolar electrode, a solid electrolyte layer, and a unipolar electrode in sequence to form a solid-state battery. Specific preparation process:

[0059] 1) Preparation of bipolar current collector

[0060] Cu is deposited on the surface of the aluminum foil by physical vapor deposition to form a bipolar current collector.

[0061] Concrete preparation steps are as follows:

[0062] a) Place the aluminum foil pre-cut into 10cm×10cm in the vacuum reaction chamber of the evaporation equipment, and vacuumize the reaction chamber;

[0063] b) Using metal copper as the reaction source, in an inert gas Ar atmosphere, perform physical vapor deposition, the reaction temperature is 1100 ° C, the pressure in the reaction chamber is kept at 0.001 Pa, and the deposition thickness is 2 μm;

[0064] c) After the vapor deposition is finished, fill the vacuum reaction chamber wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com