Method for determining thickness of flexible material of roadside flexible-strength double-layer composite support in gob-side entry retaining

A double-layer composite, flexible material technology, used in earth-moving drilling, filling, safety devices, etc., to reduce errors, give play to the effect of pressure, and optimize the cost of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below by way of examples.

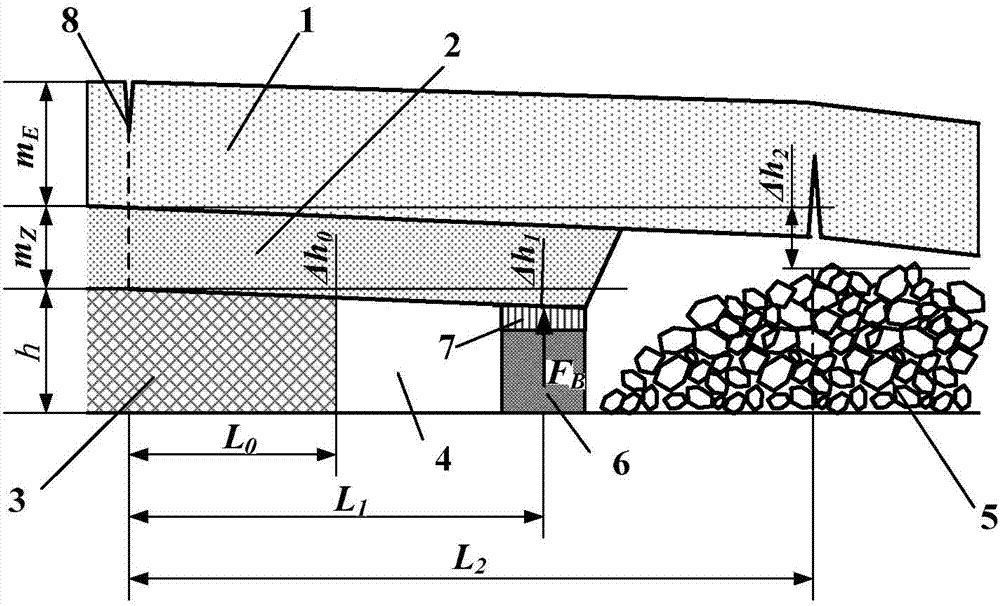

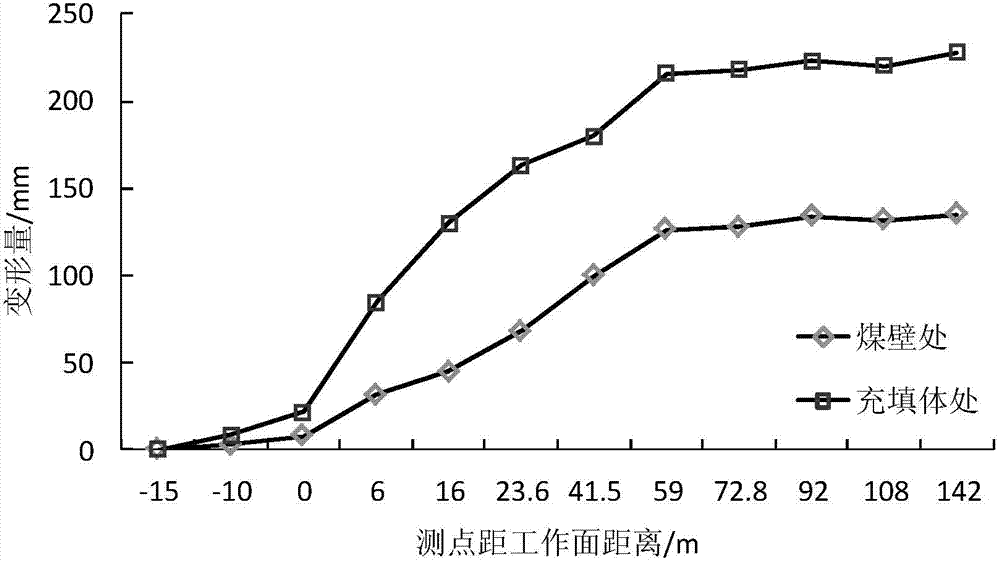

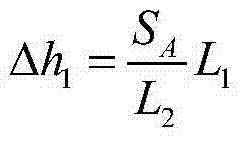

[0048] The mining height h of the 11508 working face of a certain mine is 1.7m, and the direct roof 2 is sandy mudstone, with an average thickness of m z It is 4.4m, and rises as it is mined, and generally has no suspended roof; the basic roof 1 is siltstone, and the length of the basic roof rock beam is L 2 18.0m; the distance between the basic roof fracture line 8 and the solid coal wall is 2.5m, and the width of the roadway 4 is 3.0m; when filling on site, the filling body width is 2.0m, and the upper layer adopts flexible filling material 7 with low strength and large deformation. The lower layer adopts high-strength filling material 6, among which the flexible filling material 7 adopts polymer expansion material, the high-strength filling material 6 adopts paste material, and the collapsing gangue 5 in the goaf has a broken expansion coefficient K A is 1.25.

[0049] The role of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com