Nanometer flake cerium-doped bismuth molybdate catalyst, as well as preparation method and application thereof

A nanosheet-like, cerium-doped technology, applied in chemical instruments and methods, botanical equipment and methods, catalysts for physical/chemical processes, etc., can solve the problems of thick nanosheets, cumbersome steps, poor uniformity, etc., to promote absorption , The preparation process is simple, and the effect of reducing the use of acid and alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

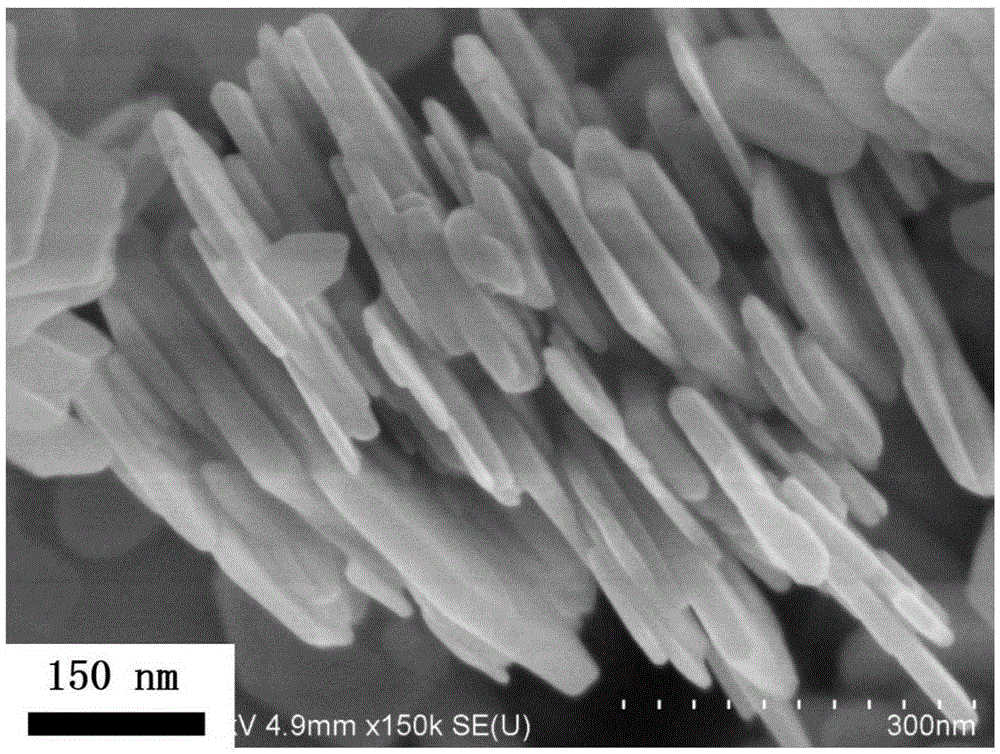

[0030] A kind of nano flake cerium doped bismuth molybdate catalyst, its preparation method comprises the steps:

[0031] 1) Add 1 mmol of bismuth nitrate pentahydrate and 0.5 mmol of sodium molybdate dihydrate to water, add 0.5 mmol of cerium nitrate hexahydrate under stirring conditions, and continue stirring for 2 hours until the raw materials are evenly mixed to obtain a reaction solution;

[0032] 2) The obtained reaction solution was placed in a stainless steel autoclave lined with polytetrafluoroethylene, heated to 180°C for 24 hours, and the obtained precipitate was centrifuged to remove residual solutes, dried and cooled to obtain the final product.

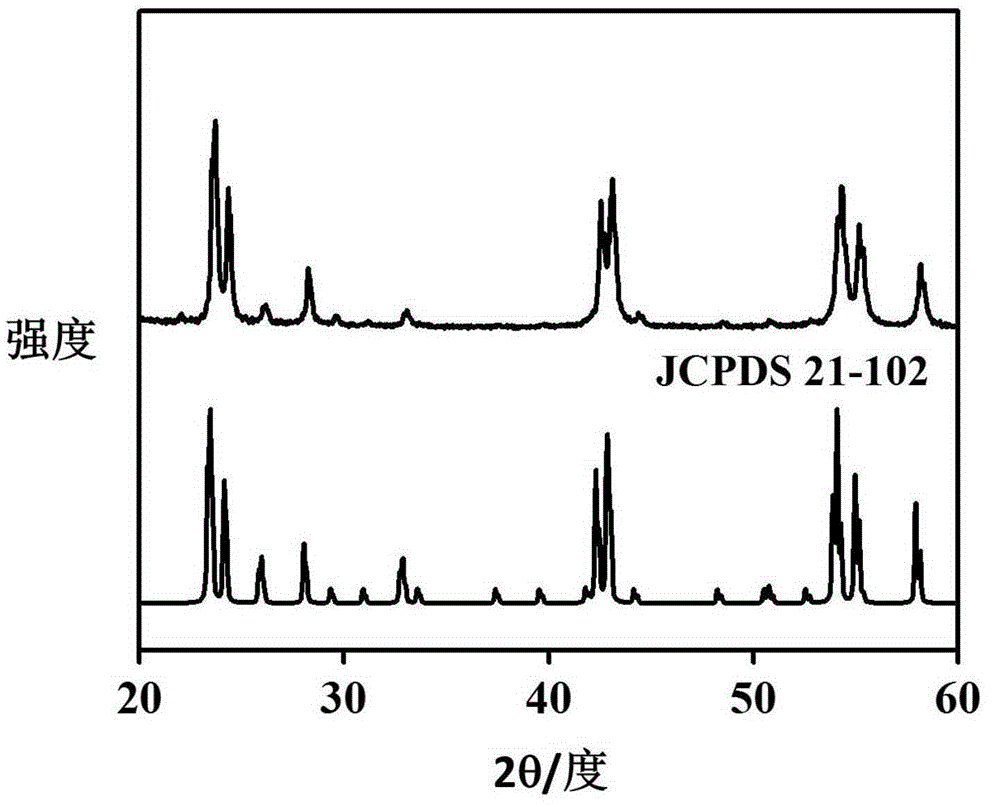

[0033] The product obtained in this embodiment is analyzed by X-ray diffraction, the results are shown in figure 1 , the main peak in the figure is consistent with the standard spectrum JCPDS10-221 of the orthorhombic phase, and no other impurity peaks appear, but the positions of the peaks are all shifted to high angles...

Embodiment 2

[0048] A kind of nano flake cerium doped bismuth molybdate catalyst, its preparation method comprises the steps:

[0049] 1) Add 1 mmol of bismuth nitrate pentahydrate and 0.5 mmol of sodium molybdate dihydrate to water, add 0.75 mmol of cerium nitrate hexahydrate under stirring conditions, and continue stirring for 2 hours until the raw materials are evenly mixed to obtain a reaction solution;

[0050] 2) Place the obtained reaction solution in a stainless steel autoclave lined with polytetrafluoroethylene, heat it to 170°C for 20 hours, and then carry out centrifugal washing to remove the residual solute, and dry and cool to obtain the nanosheet Cerium doped bismuth molybdate catalyst.

Embodiment 3

[0052] A kind of nano flake cerium doped bismuth molybdate catalyst, its preparation method comprises the steps:

[0053] 1) Add 1.5 mmol of bismuth nitrate pentahydrate and 0.5 mmol of sodium molybdate dihydrate into water, add 0.25 mmol of cerium nitrate hexahydrate under stirring conditions, and continue stirring for 2 hours until the raw materials are evenly mixed to obtain a reaction solution;

[0054] 2) Place the obtained reaction solution in a stainless steel autoclave lined with polytetrafluoroethylene, heat it to 160°C and react for 20 hours, then carry out centrifugal washing to remove the residual solute, and dry and cool to obtain the nanosheet Cerium doped bismuth molybdate catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com