LED (Light-Emitting Diode) chip and manufacturing method of LED chip

A technology of LED chips and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem that the current in the LED chip cannot be evenly distributed, and achieve the effects of good luminous efficiency, uniform light emitting rate, and uniform current distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

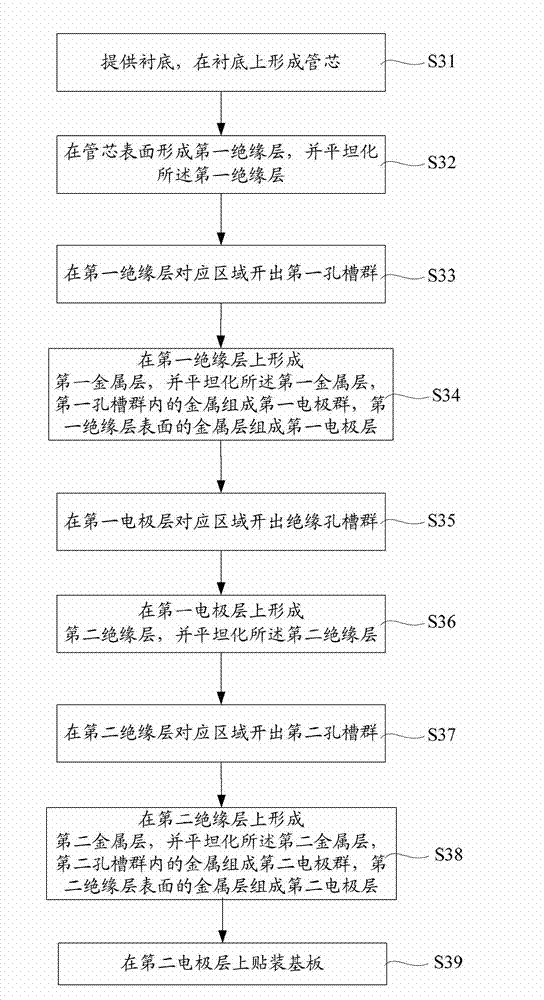

[0032] It has been mentioned in the background technology that the traditional LED chip flip-chip manufacturing method increases the process steps and difficulty, and limits the further development of the LED chip in thickness and size. At the same time, the electrode structure of the existing LED chip can only obtain A certain degree of current expansion makes the current evenly distributed, which cannot meet the needs of further increase in chip size.

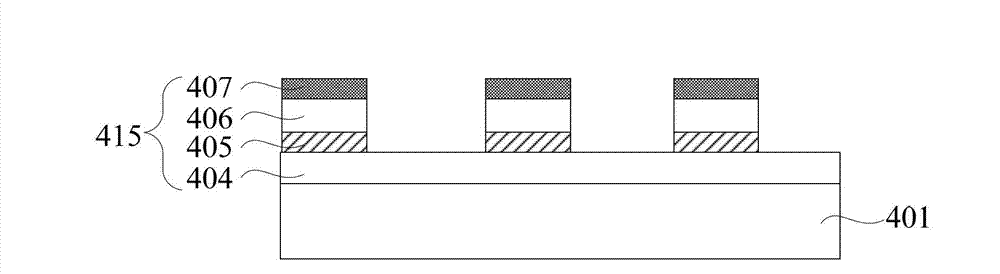

[0033] To this end, the present invention provides an LED chip and a manufacturing method thereof. The manufacturing method of the LED chip optimizes the traditional flip-chip process. Device thickness.

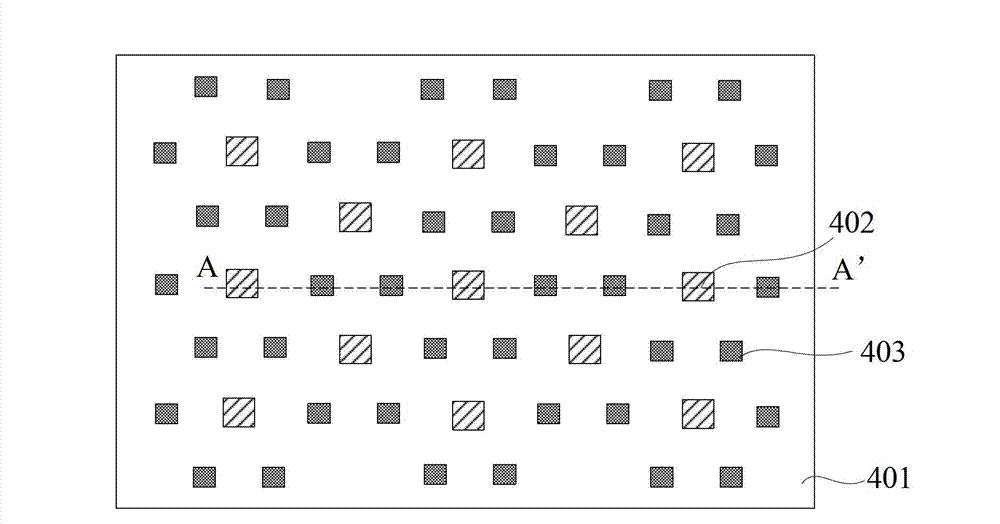

[0034] Further, the N electrode and the P electrode are separated into the first electrode group and the second electrode group, which are distributed on the corresponding area of the die. Such a structure can obtain sufficient current expansion to make the current evenly distributed, so that the device can obtain good lum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com