Patents

Literature

34results about How to "Effective control of uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

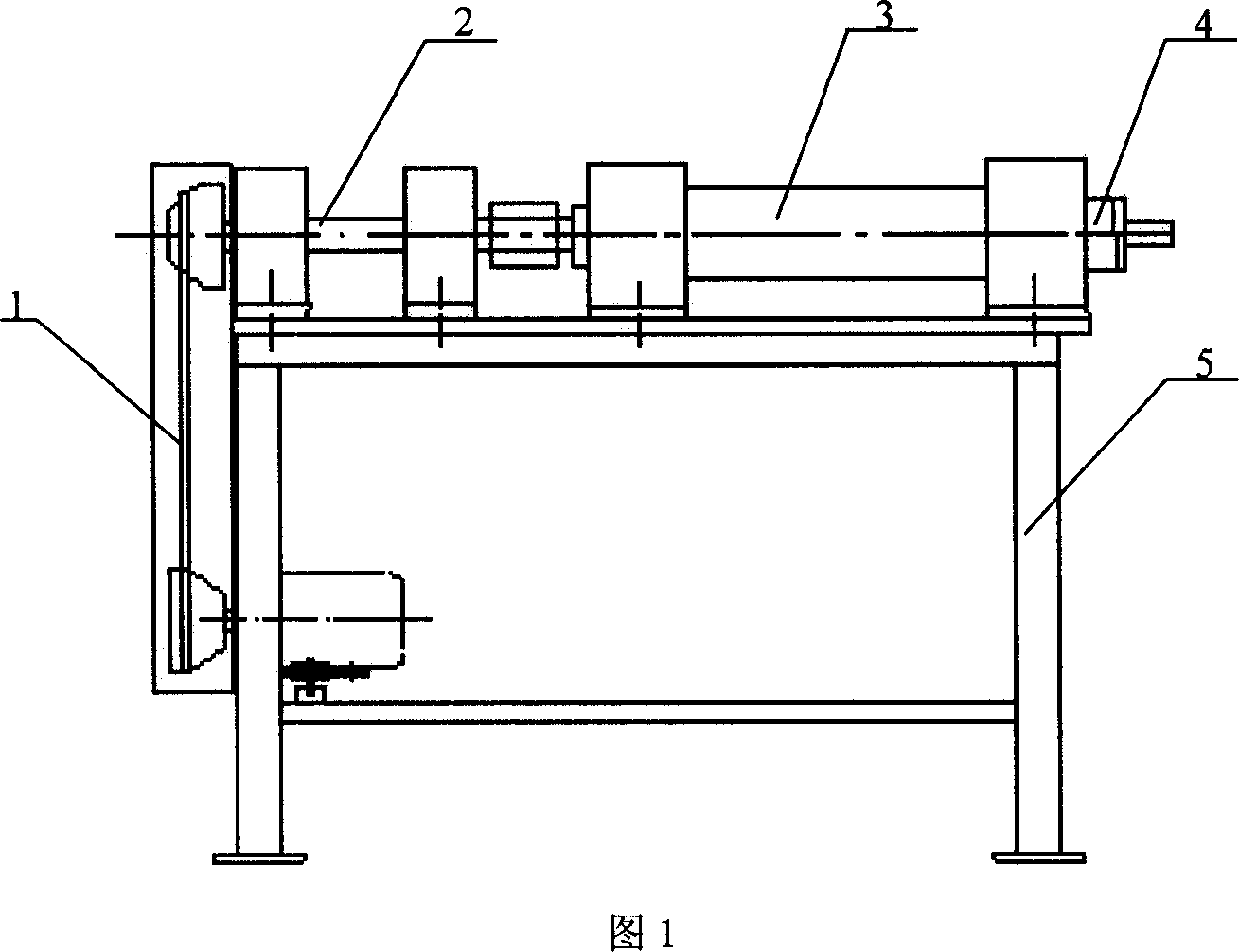

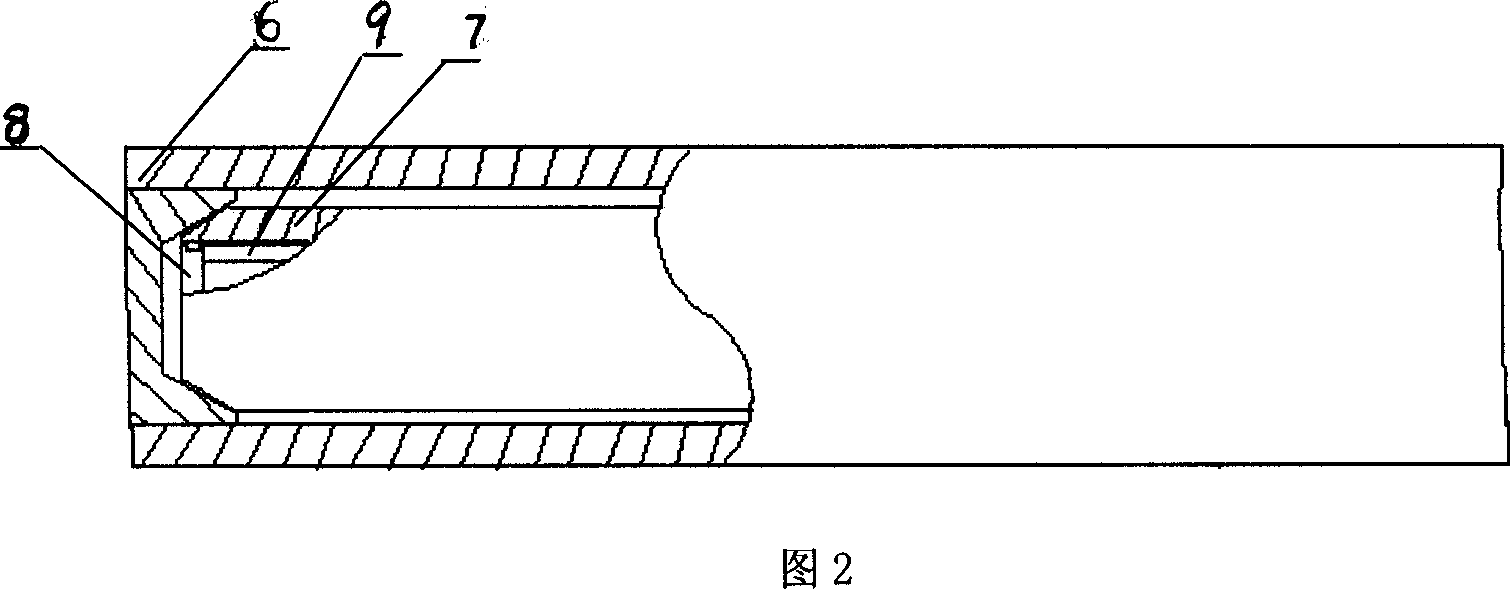

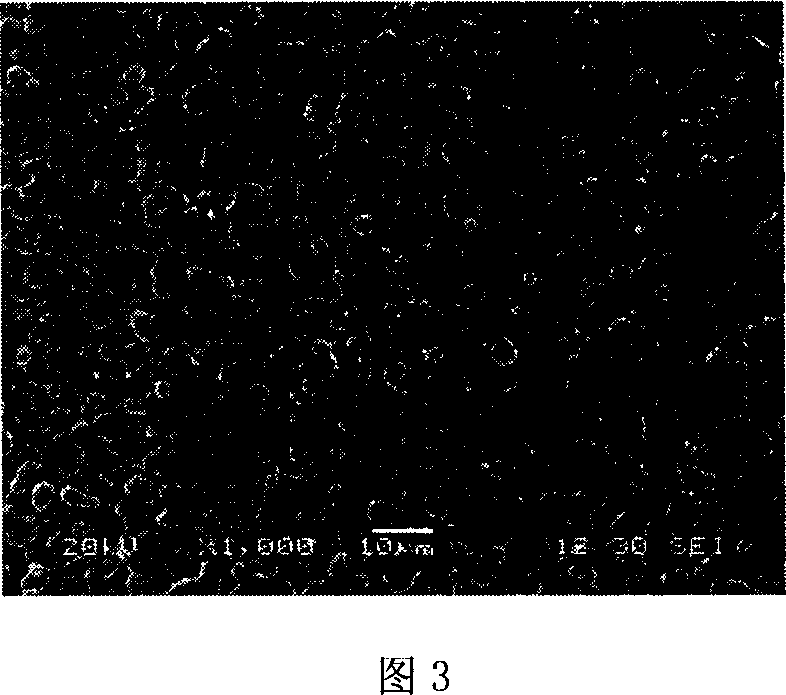

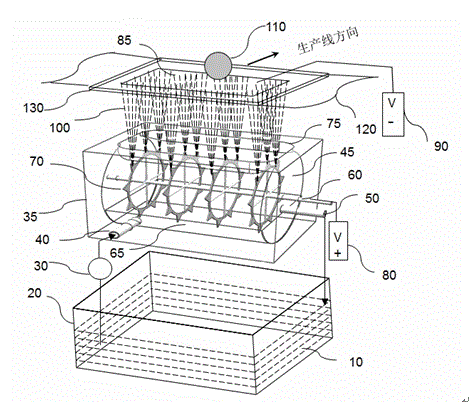

Micro-porous metal film prepn. method

InactiveCN1947861AEffective thickness controlEffective control of uniformityLiquid surface applicatorsCoatingsPorous substrateMetallurgy

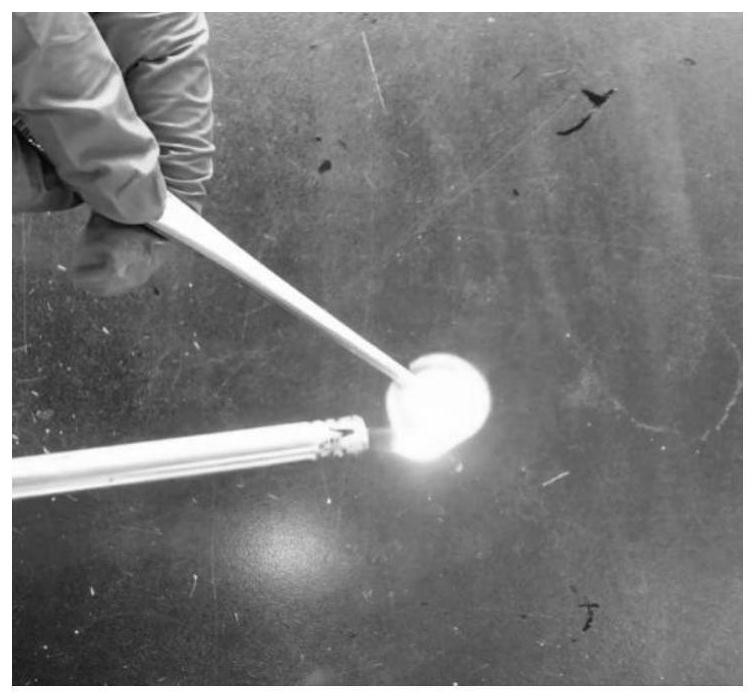

A process for preparing millipore metallic film used for filter, separator, catalyzing, fluid distributor and mass or heat transfer includes such steps as providing a centrifugal drum with a porous substrate fixed on its inner surface, preparing slurry from raw powder, loading the slurry in the centrifugal drum, and high-speed rotating to centrifugally form a gradient millipore film on the inner surface of said porous substrate.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

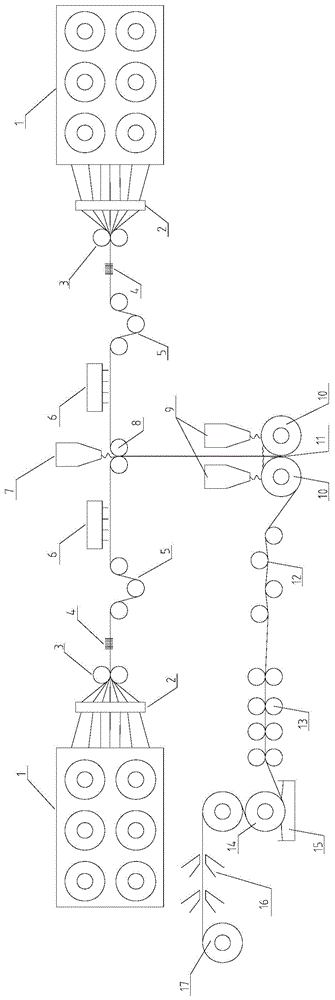

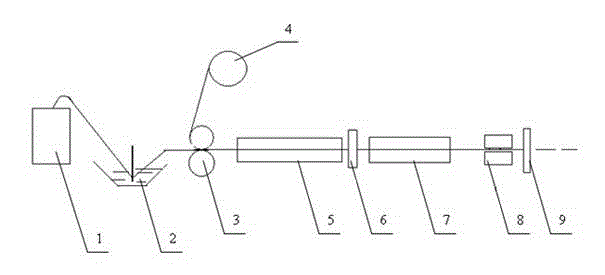

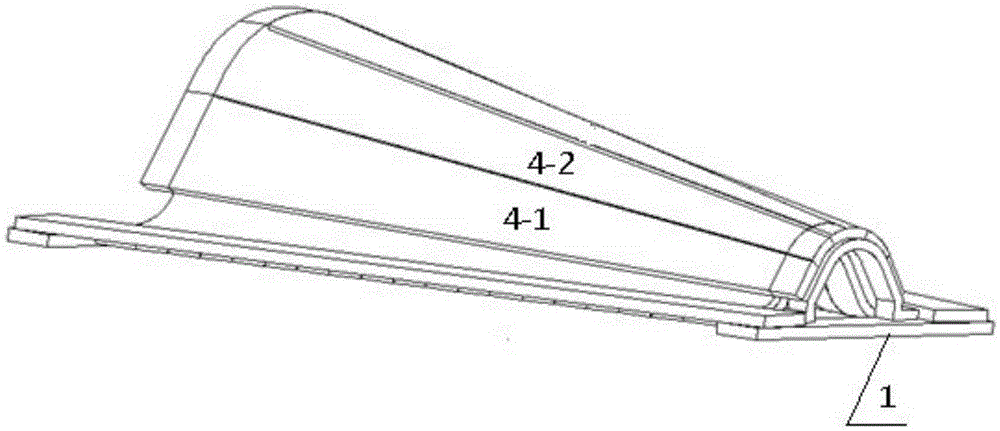

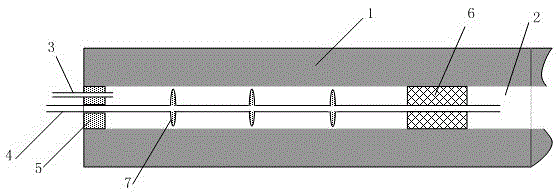

Production equipment of continuous fiber thermoplastic prepreg tape

The invention proposes production equipment of a continuous fiber thermoplastic prepreg tape, which is used for solving the problems of nonuniform coating, weak infiltration effect and high waste rate in the production process of thermoplastic continuous fibers in the prior art. The production equipment of the continuous fiber thermoplastic prepreg tape comprises two sets of yarn placing racks symmetrically arranged, a tension adjusting device and a preheating dehumidifier, and further comprises a first coating mechanism, a second double-mold head bath infiltration mechanism, a rolling cooling device and a winding device. The production equipment of the continuous fiber thermoplastic prepreg tape infiltrates the internals of fibers through a first coating roller, uses the second double-mold head bath infiltration mechanism for infiltrating the outer surfaces of the fibers, can totally presoak the fibers, and can synchronously guarantee the uniformity of the tape through adjusting a gap between the bath infiltration mechanism and the coating roller.

Owner:山东鸿石新材料科技有限公司

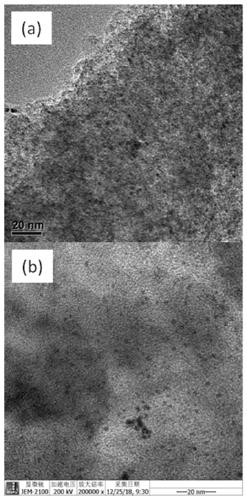

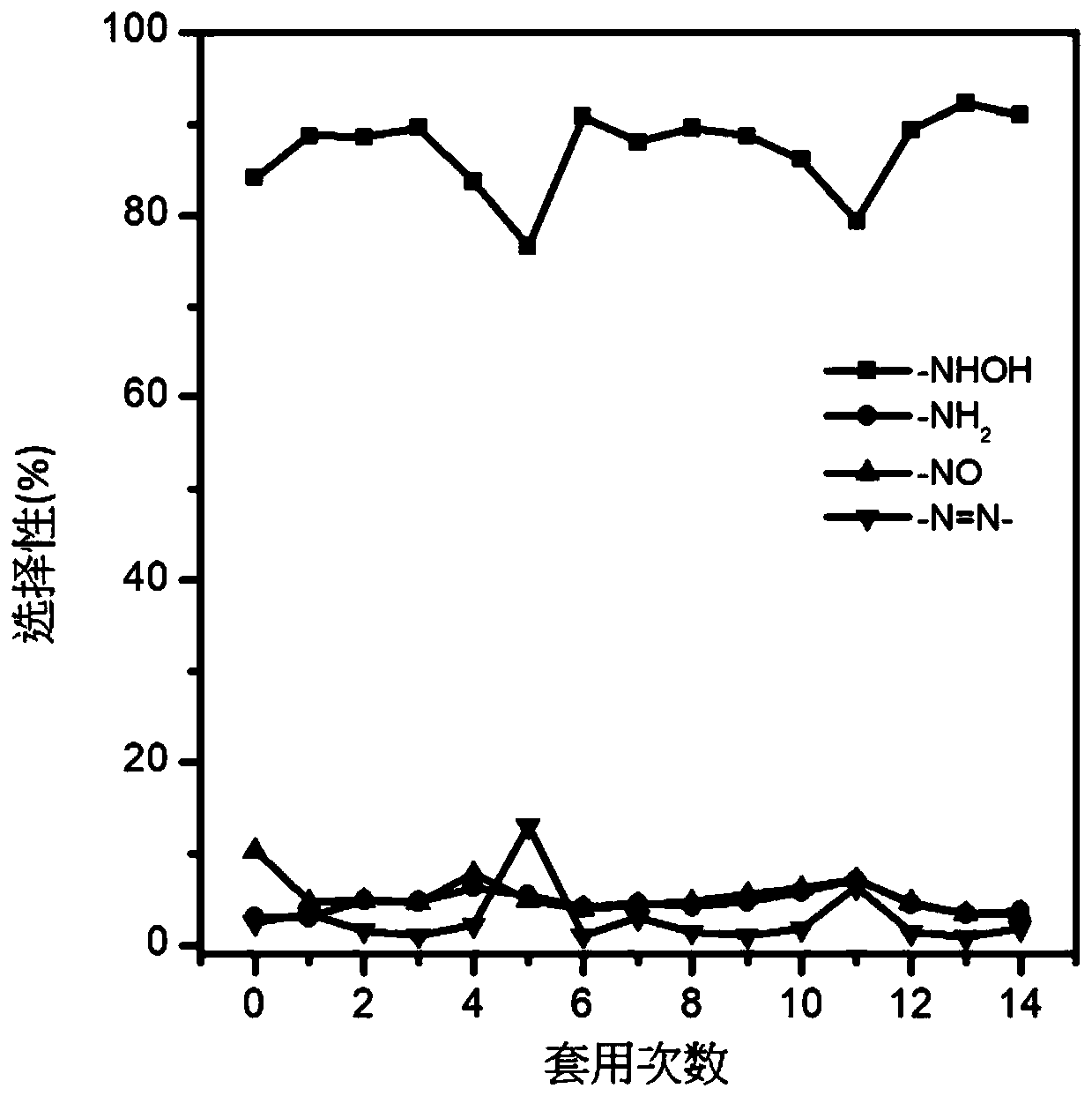

Catalyst taking nitrogen-doped carbon material as carrier and preparation method of catalyst

InactiveCN111715268AEffective control of uniformityHigh activityCatalyst carriersPreparation by halogen halide additionPtru catalystMetal catalyst

The invention relates to a catalyst taking a nitrogen-doped carbon material as a carrier and a preparation method of the catalyst, and the components of the catalyst comprise a nitrogen-doped carbon-based carrier, an ionic liquid and a non-mercury metal catalyst, and the invention relates to the method for preparing vinyl chloride by acetylene hydrochlorination. According to the catalyst, the carbon-based carrier is subjected to nitrogen doping modification, so that the stability of the loaded ionic liquid is improved, and the loss of the ionic liquid is reduced. Due to the mutual synergisticeffect of the carrier and the ionic liquid, the mercury-free metal catalyst is uniformly dispersed in the ionic liquid on the surface of the catalyst, the influence of mass transfer of a reaction substrate is reduced, and the catalyst is higher in catalytic activity and better in stability.

Owner:朱丽英

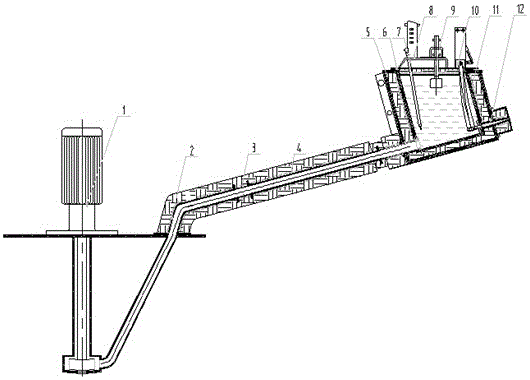

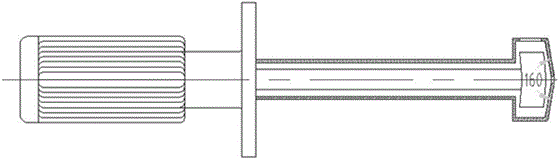

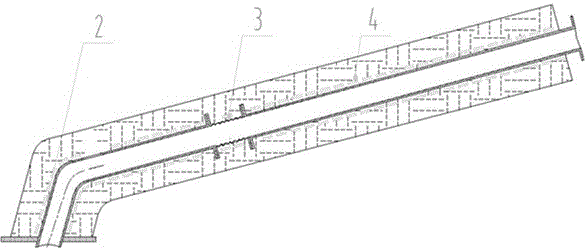

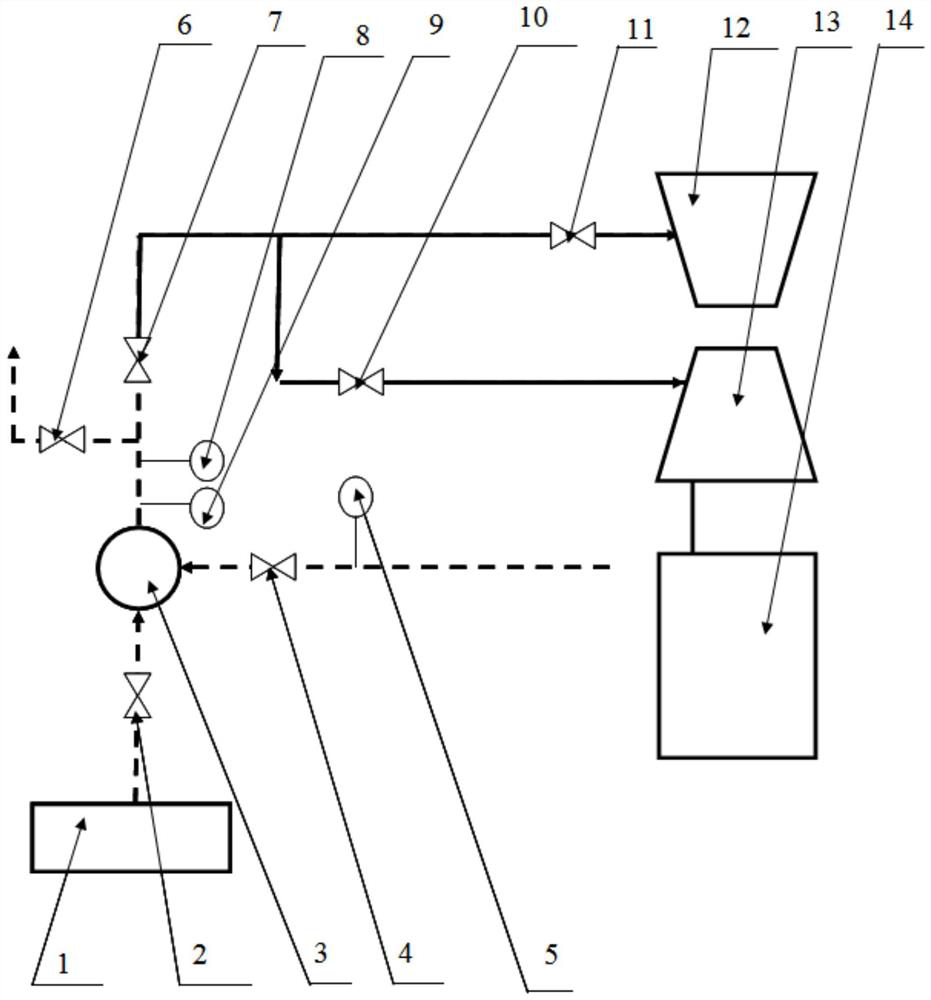

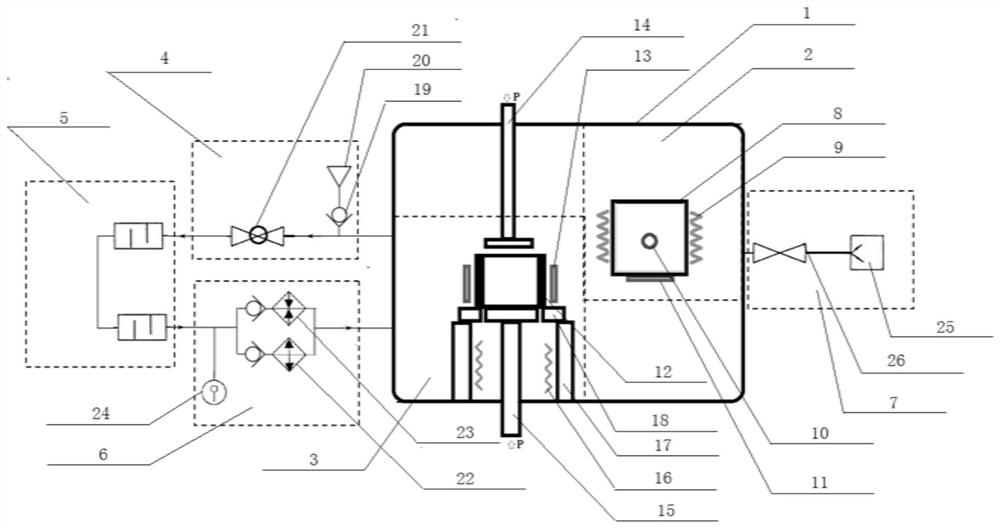

Novel magnesium alloy cast-rolling liquid transfer system device

ActiveCN106493340AEffective control of uniformityEffective control of easy to form segregationLoop controlControl system

The invention particularly relates to a novel magnesium alloy cast-rolling liquid transfer system device, and belongs to the technical field of magnesium alloy plate and strip cast-rolling unit equipment. The novel magnesium alloy cast-rolling liquid transfer system device aims at the defects that in a magnesium alloy cast-rolling liquid transfer system at present, the liquid level of a front box is instable, system temperature and flow control is inaccurate, maintenance is difficult, cast-rolling plate and strip solidification is quite prone to being uneven, and segregation, serious edge cracks, material losses and the like are prone to being formed. The system device comprises a servo liquid transfer pump with a lower-end conical hole cavity, a self-adaptive heat expansion liquid transfer pipe, a combined front box and multifunctional top cover, a flow accurate control blocking device, a liquid level and temperature closed-loop control system and the like. The magnesium alloy cast-rolling liquid transfer system device is safe, economical and convenient to maintain, the system is in butt joint with a standing furnace and an inclined cast-rolling machine conveniently and fast, and accurate control over the temperature and flow in the system is achieved. Guarantees are provided for improving the material quality and the yield of cast-rolling magnesium alloy plates and strips and reducing the cost, and wide application prospects are achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Non-combustible lithium metal battery electrolyte and preparation method thereof, lithium metal battery and preparation method thereof

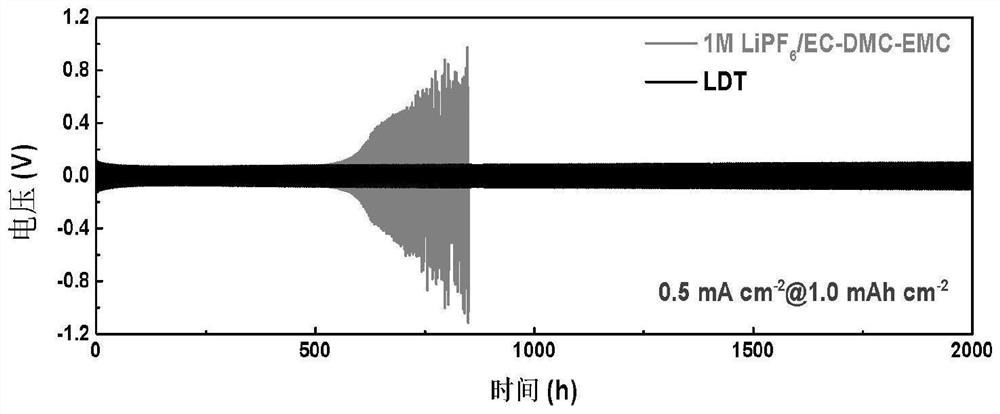

PendingCN113113670AImprove cycle stabilityImproved magnification performanceFinal product manufactureCylindrical casing cells/batteryOrganic solventElectrical battery

The invention belongs to the technical field of lithium metal batteries, and particularly relates to a non-combustible lithium metal battery electrolyte and a preparation method thereof, a lithium metal battery and a preparation method thereof. The diethyl ethyl phosphate and the hydrofluoroether solvent are adopted as the organic solvent of the lithium metal battery electrolyte, so that on one hand, the stability of a battery negative electrode material can be improved, the uniformity of lithium deposition on the surface of the negative electrode material is effectively regulated and controlled, the generation of lithium dendrites is inhibited, and the cycle life of a lithium metal battery is prolonged; and on the other hand, the electrolyte has the characteristic of incombustibility, and the safety performance of the battery is improved.

Owner:SHANDONG IND TECH RES INST OF ZHEJIANG UNIV

Air-layer suede fluff sanding technology

ActiveCN108252127AEffective control of uniformityImprove product qualityHeating/cooling textile fabricsDyeing processFiberAgricultural engineering

The invention discloses an air-layer suede fluff sanding technology. The air-layer suede fabric sanding technology comprises the following steps: (1) unwinding; (2) refining; (3) carrying out fiber opening; (4) pre-setting; (5) sanding; (6) dyeing; (7) setting a finished product; (8) brushing fluff; (9) winding. The technology disclosed by the invention has a good gigging effect and the neatness,length and density of the fluff can be effectively controlled and a technological flow is simplified.

Owner:ZHEJIANG DONGSHENG DYEING & PRINTING CO LTD

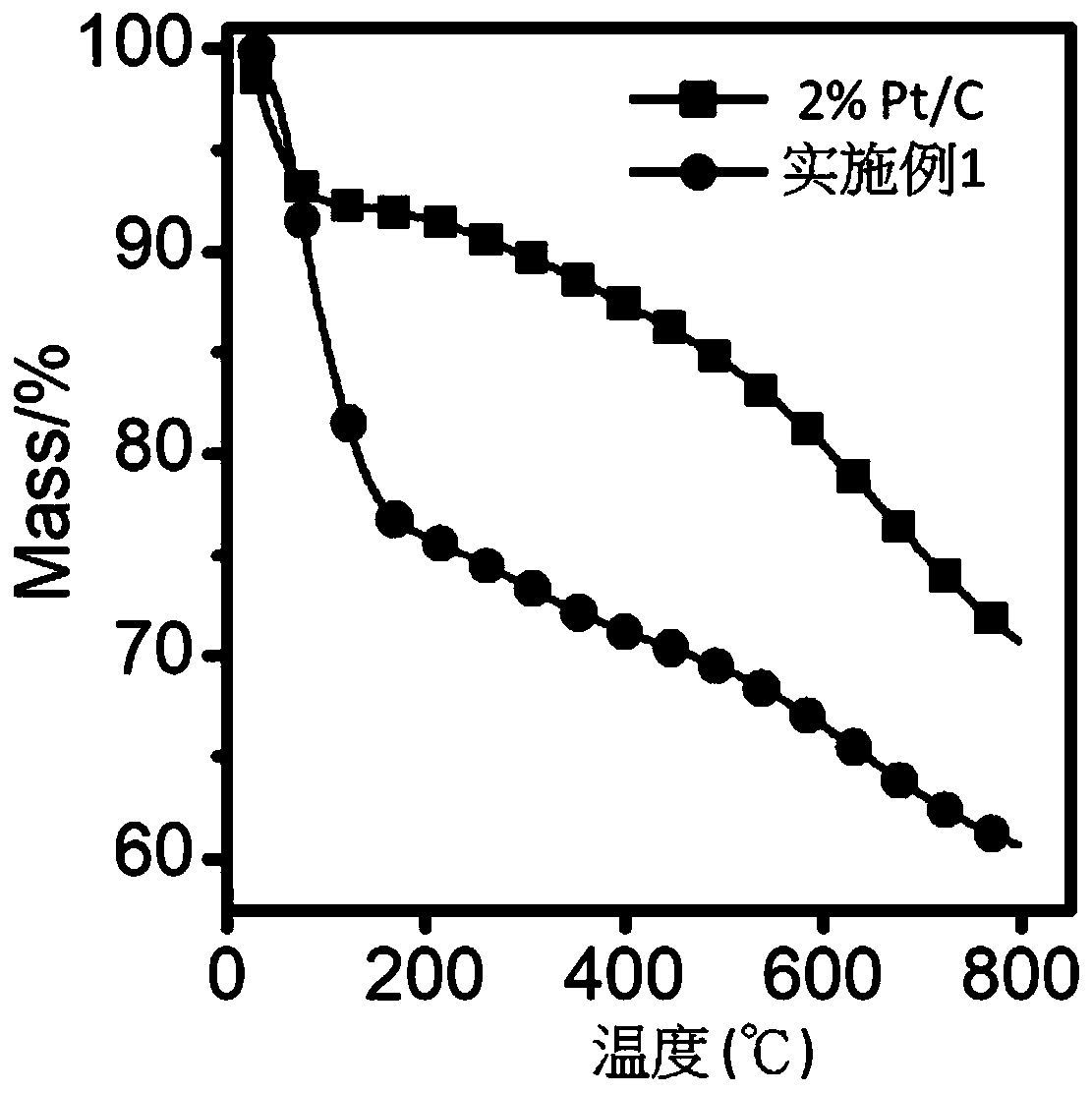

Preparation method of Pt/C catalyst, Pt/C catalyst and application of Pt/C catalyst

InactiveCN110385145AComplete shapeEffective control coverageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventMixed solution

The invention provides a method for preparing a modified Pt / C catalyst. The method comprises the steps that the Pt / C catalyst is immersed in an organic amine mixed solution to form a precursor mixture; the organic amine mixed solution comprises a component A and a component B, the component A is organic amine, and the component B is at least one solvent mutually solved with the organic amine; theprecursor mixture is stirred; and the precursor mixture is filtered through suction, a filter object is washed, and thus the modified Pt / C catalyst is obtained.

Owner:XIAMEN UNIV

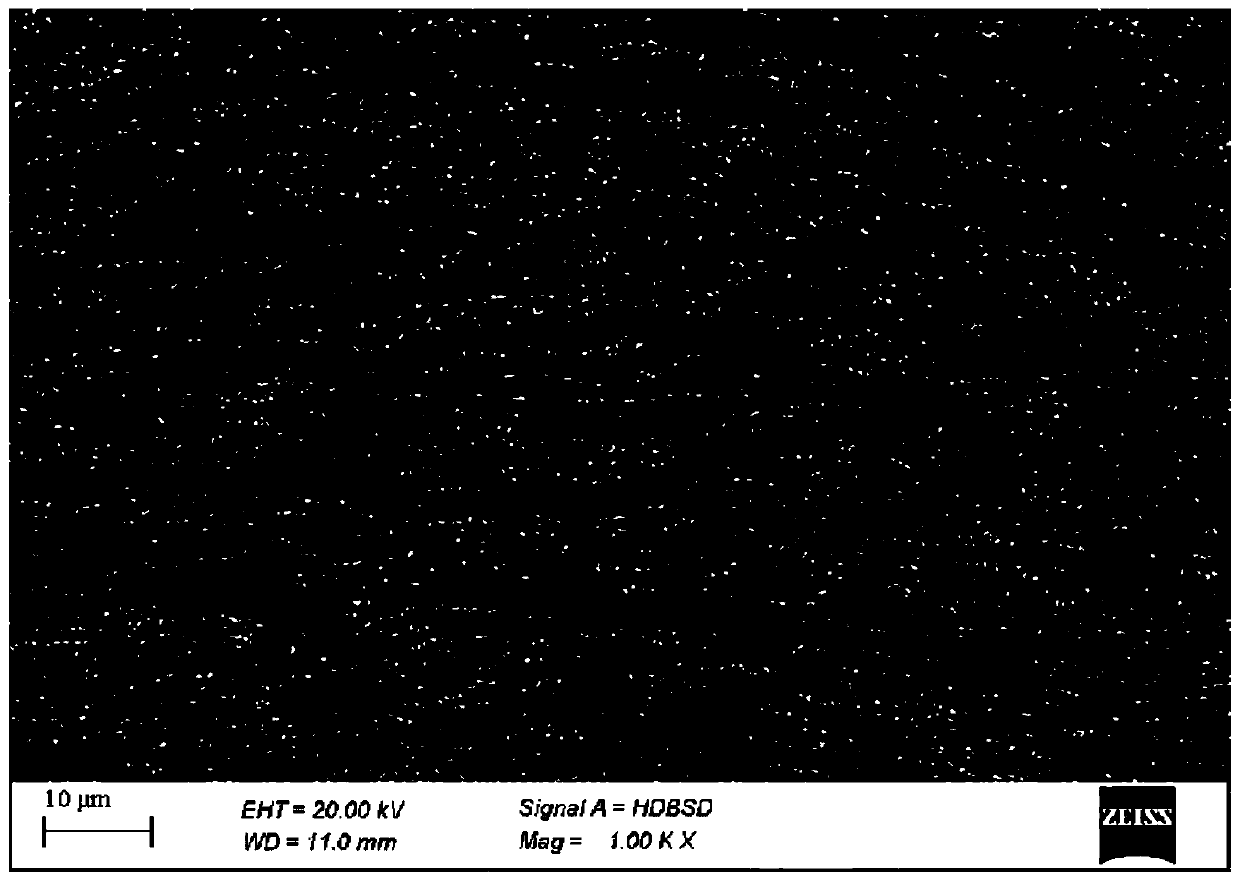

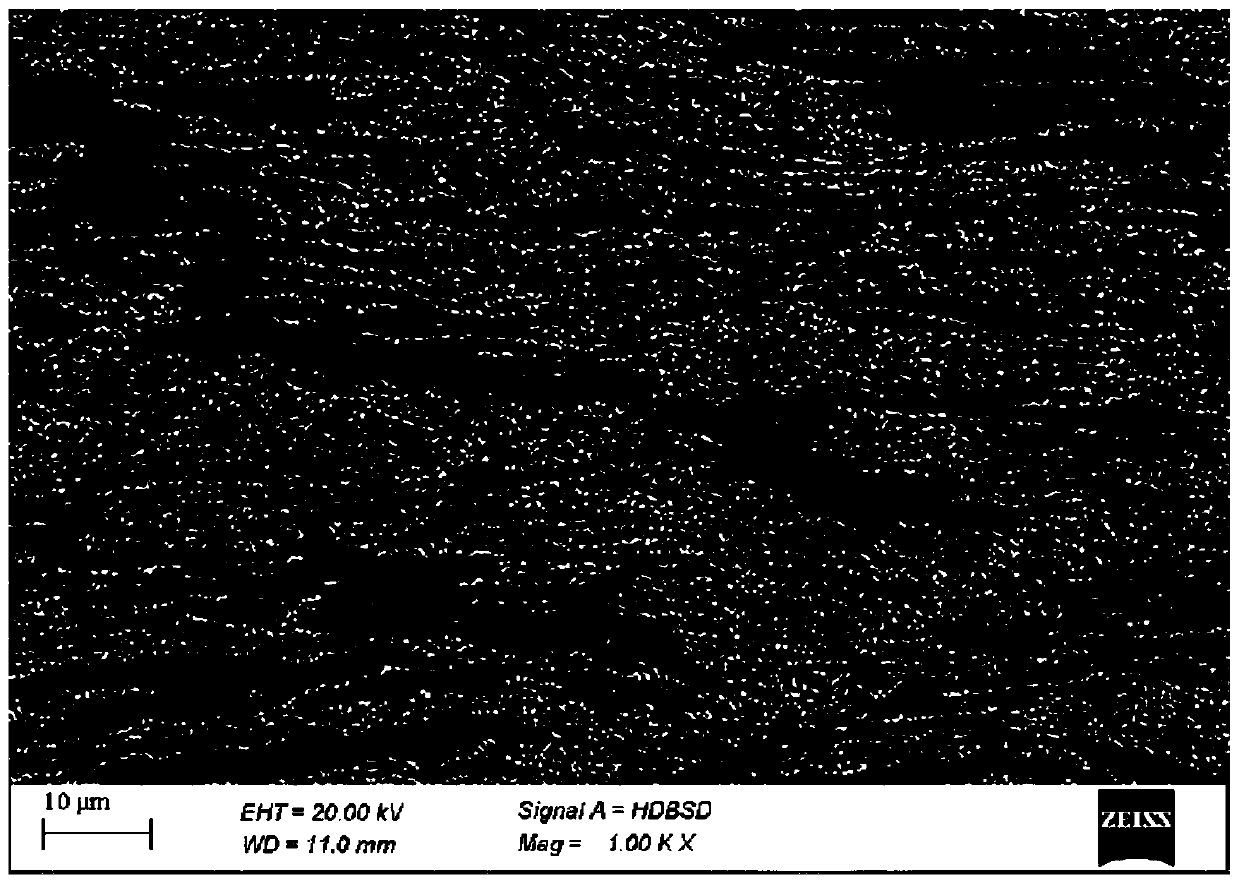

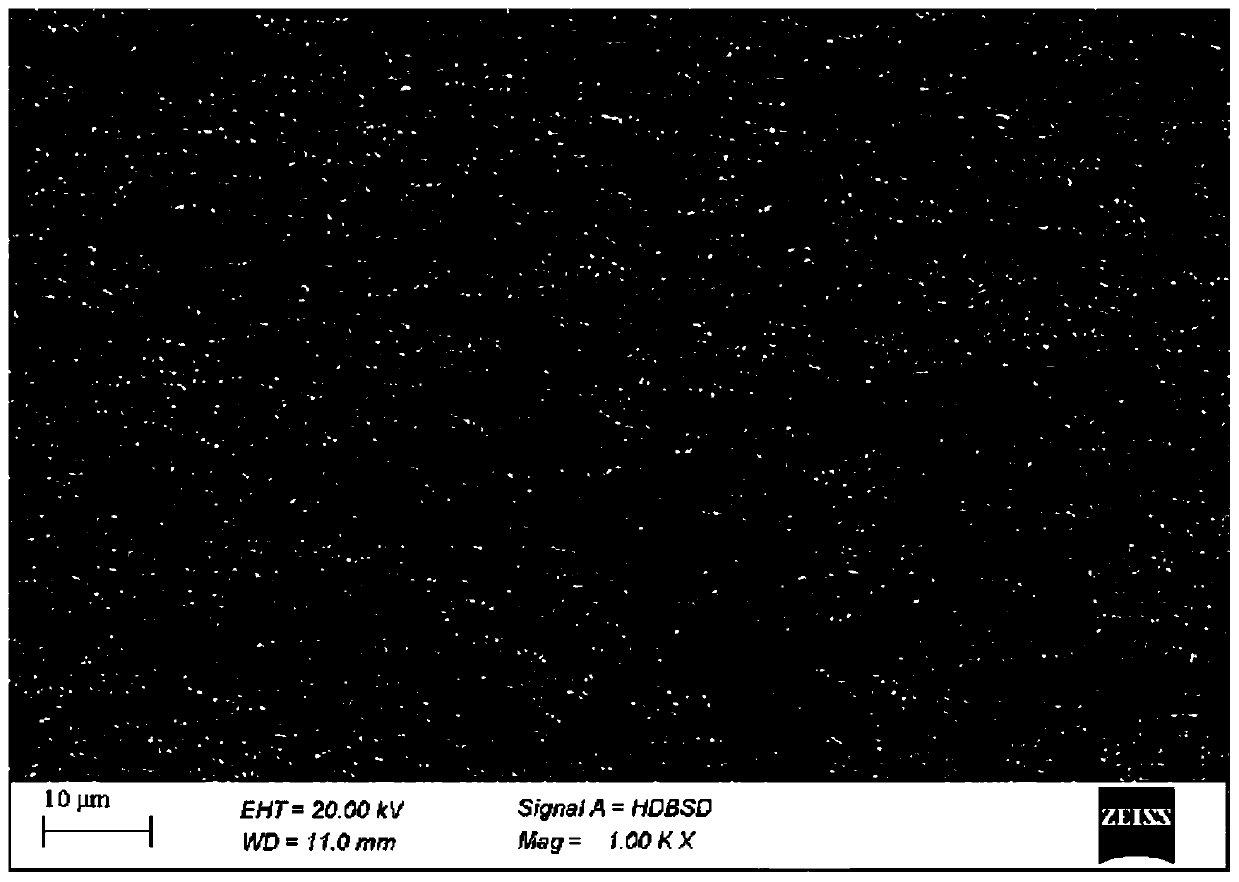

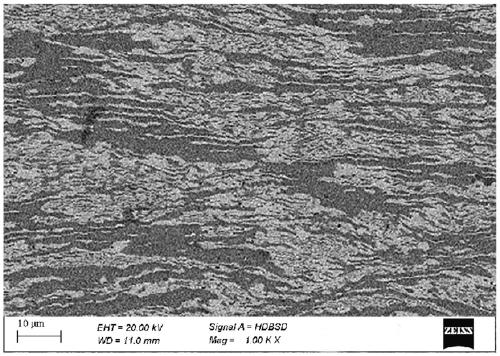

Preparing method and application of cobalt tantalum zirconium alloy target material

ActiveCN110735068AHigh purityImprove performanceMetal-working apparatusVacuum evaporation coatingThin membraneManufactured material

The invention discloses a preparing method and application of a cobalt tantalum zirconium alloy target material, and belongs to the technical field of preparation of special materials. The preparing method comprises the steps of component design, high-vacuum vertical sintering and high-vacuum electron beam melting, three-dimensional isothermal hot forging cogging, angle-varying controlled rollingand the like. In this way, the organization structure of the alloy and the performance of the target material are controlled, and the high-quality cobalt tantalum zirconium alloy target material is prepared. The oxygen content of the cobalt tantalum zirconium alloy target material is smaller than or equal to 15 ppm, the average grain size of the cobalt tantalum zirconium alloy target material is 5-20 micrometers, the phase distribution of the target material is uniform, the magnetic permeability is larger than 40%, and the heterogeneity of magnetic permeability is smaller than 2%. By means ofthe designed process, the oxygen content, organization structure heterogeneity and magnetic performance of the finished product target material can be effectively controlled, and a raw material guarantee is provided for sputtering high-quality thin films by means of the preparing method.

Owner:CENT SOUTH UNIV

Pultrusion process and pultrusion device of phenolic resin composite

The invention discloses a pultrusion process and a pultrusion device of phenolic resin composite. The device is sequentially provided with a yarn releasing device, an impregnating vessel, a felt releasing device, a pre-pultrusion template, a mold, a traction device and a cutting device from front to back, and is characterized in that double driven rollers and a drying device are additionally arranged between the impregnating vessel and the pre-pultrusion device; the pultrusion process which is implemented by using the above devices comprises an impregnating step, a pre-pultrusion template guiding step and a mold solidifying step, wherein a double driven rollers extruding step and a drying step are added between the impregnating step and the pre-pultrusion template guiding step; the impregnated yarn and the felt released by the felt releasing device are extruded in the double driven rollers, the glue solution on the yarn is redistributed, and the felt is impregnated; the yarn and the felt are discharged by the double driven rollers, the discharged yarn and felt are delivered into the drying device for being dried, and finally the dried yarn and felt are delivered into the mould forbeing solidified. The process is simple, the content and the homogeneity of phenolic resin can be effectively controlled, volatile matters can be removed, the performances are improved, and popularization and application of the composite are favored.

Owner:北京玻钢院复合材料有限公司

Washing system and washing method for accumulated salt of power station steam turbine

PendingCN111810257AEffective control of uniformityEffective control of steam intakeEngine componentsSteam engine plantsExhaust valveInlet valve

The invention discloses a washing system and washing method for accumulated salt of a power station steam turbine. The system comprises an auxiliary steam header or a start boiler steam source which communicates with a parallel connection inlet of temporary steam valves of a high-pressure cylinder and a medium-pressure cylinder through a temporary steam pipe, and a steam inlet which communicates with a buffer tank through an outlet valve of the auxiliary steam header or the start boiler steam source, and the temporary steam pipe, wherein a steam outlet of the buffer tank communicates with theparallel connection inlet of the temporary steam valves of the high-pressure cylinder and the medium-pressure cylinder through a temporary steam inlet valve; a temperature gauge and a pressure gauge are arranged on the temporary steam pipe of the steam outlet of the buffer tank, the temporary steam pipe of the steam outlet of the buffer tank further communicates with a temporary steam exhaust pipe, and a temporary steam exhaust valve is arranged on the temporary steam exhaust pipe; and a desuperheating water inlet of the buffer tank communicates with a desuperheating water pipe, and a desuperheating water valve and a desuperheating water pressure gauge are arranged on the desuperheating water pipe. The invention further discloses a washing method of the system. The system is simple in design, reliable and easy to realize, and solves the problems that salt accumulation of a steam turbine is caused due to leakage of a steam condenser and a unit cannot be loaded, of a coastal power plant.

Owner:XIAN THERMAL POWER RES INST CO LTD

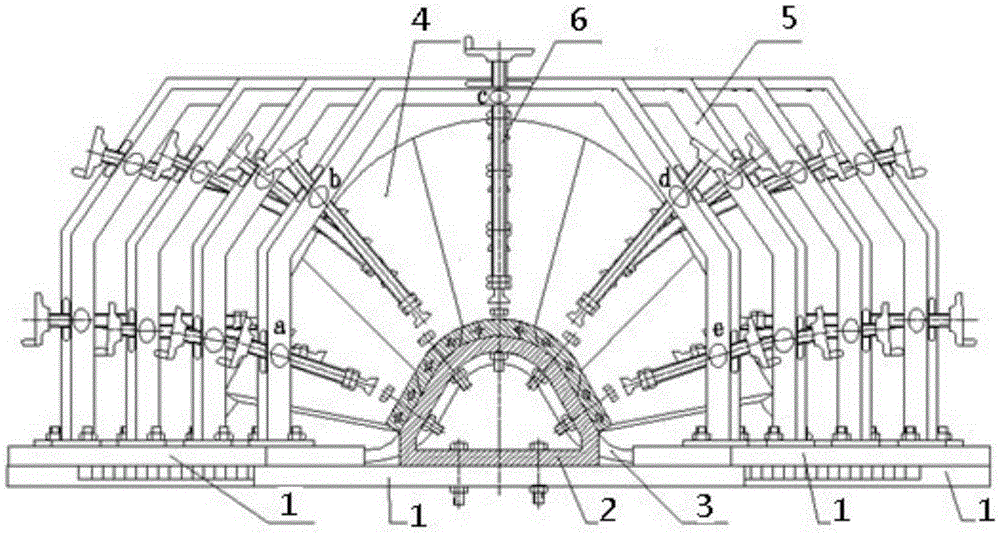

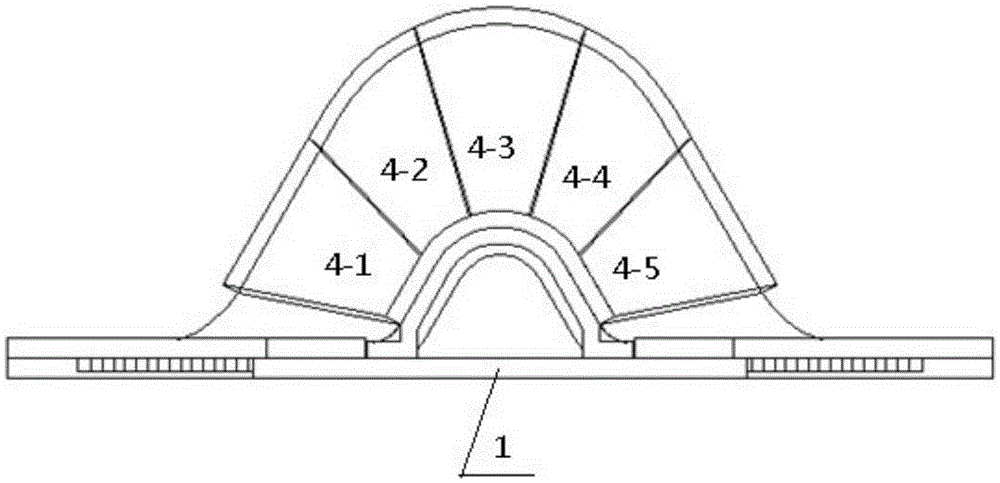

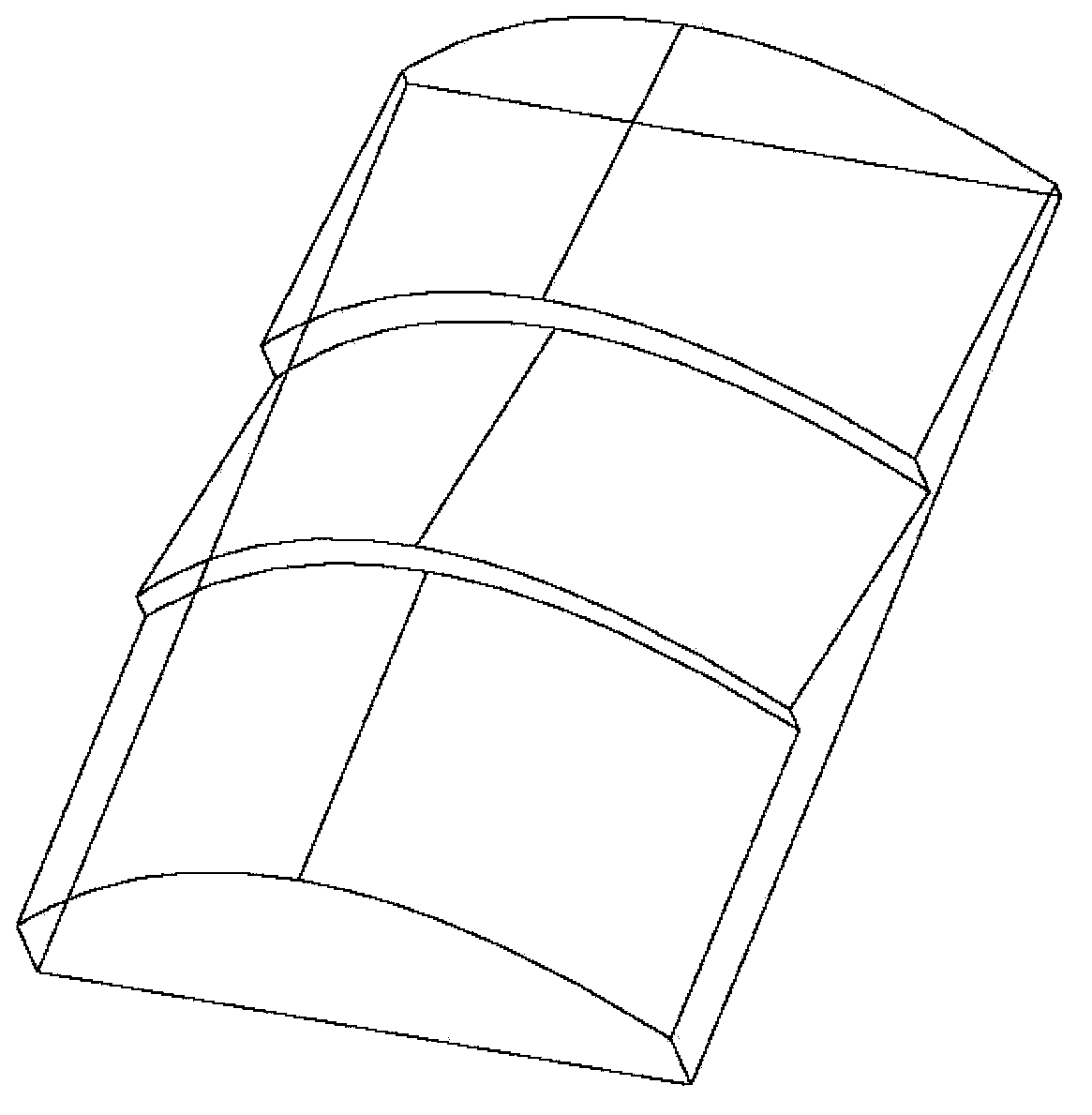

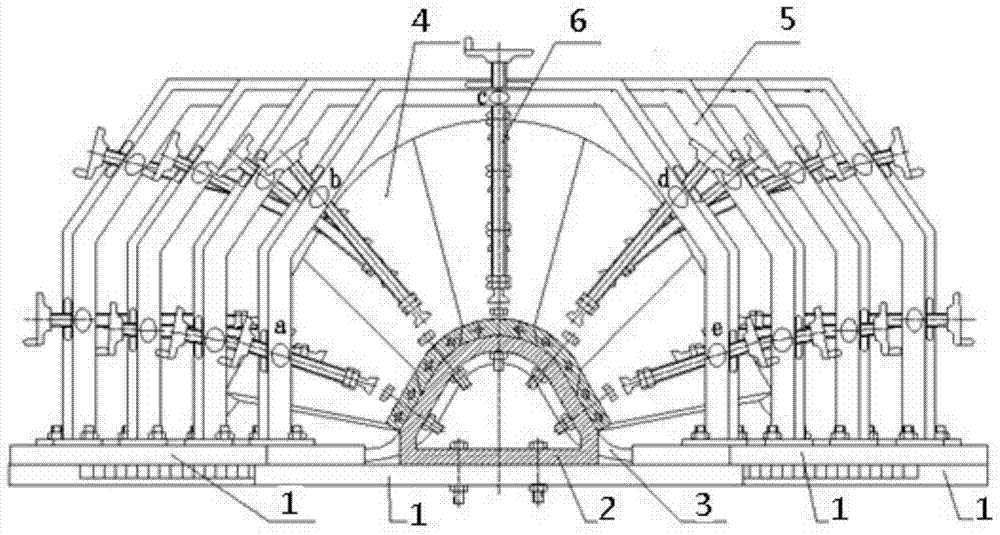

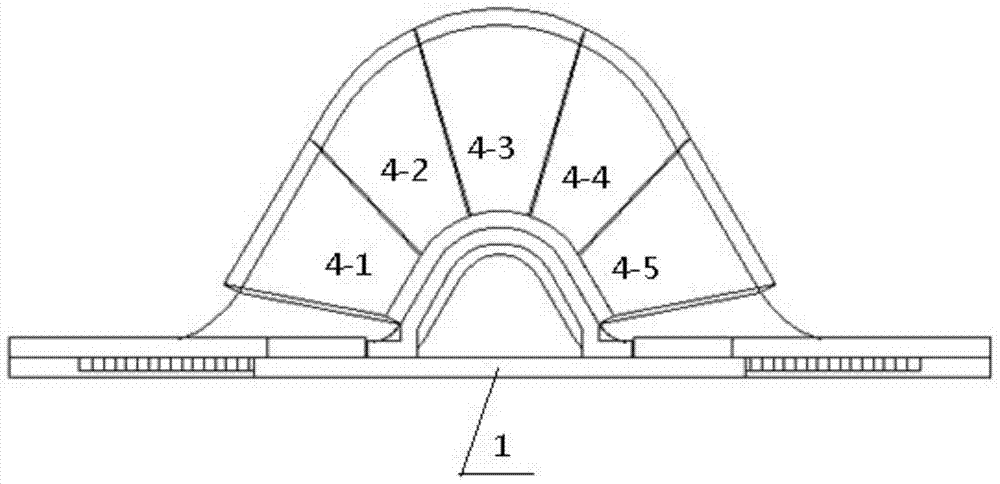

Multi-point pressurizing device for controlling layer density and uniformity of complex surface stitched fabric

The invention discloses a multi-point pressurizing device for controlling layer density and uniformity of a complex surface stitched fabric. The device comprises a male mold, a female mold and a multi-point pressurizing component, wherein the multi-point pressurizing component comprises an arched bracket and a pressurizing component; the arched bracket is arranged at the outer periphery of the female mold; the pressurizing component comprises a screw rod, a rotating handle and a rubber pad; the screw rod is in threaded connection to the arched bracket; one end of the screw rod penetrates through the arched bracket to extend to the outer surface of the female mold, and the other end is left outside the arched bracket; the rotating handle is connected to one end, left outside the arched bracket, of the screw rod; and the rubber pad is arranged at the end part of one end, extending to the outer surface of the female mold, of the screw rod. The multi-point pressurizing device for controlling the layer density and the uniformity of the complex surface stitched fabric is simple in structure, is easy to be machined and assembled, is convenient for use, and can effectively control the layer density and the uniformity of the complex surface three-dimensional fabric to improve the quality of the complex surface stitched fabric.

Owner:SINOMA SCI & TECH

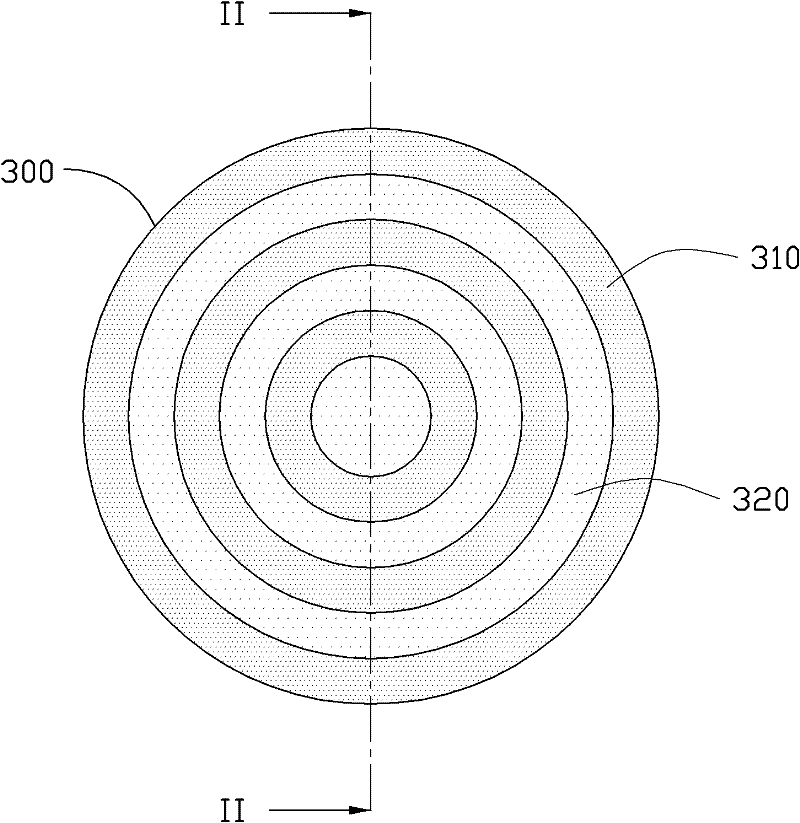

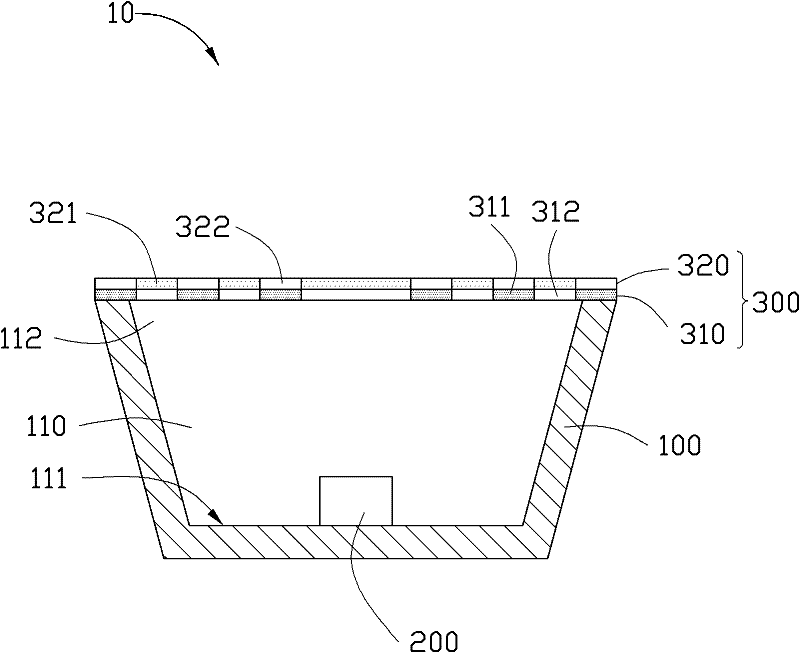

Phosphor layer structure, method for forming same, and light-emitting diode packaging structure

ActiveCN102270732AImprove lighting efficiencyEffective control of uniformityThin material handlingSemiconductor devicesFluorescencePhosphor

The invention provides a fluorescent layer structure comprising a first fluorescent layer and a second fluorescent layer which are stacked, wherein the first fluorescent layer comprises a plurality of first phosphor powder strips which are spaced from one another, the second fluorescent layer comprises a plurality of second phosphor powder strips which are spaced from one another, and the maximum distance between two adjacent first phosphor powder strips and the maximum distance between two adjacent second phosphor powder strips are both less than 1 mm. Compared with the prior art, in the fluorescent layer structure provided by the invention, the phosphor powder strips are spaced to achieve the purpose of controlling the uniformity of phosphor powders in the fluorescent layer structure, so as to ensure more uniform mixing of light from a light emitting diode and better light output efficiency. The invention also provides a forming method of the fluorescent layer structure and a light emitting diode package structure having the fluorescent layer structure.

Owner:XUYU OPTOELECTRONICSSHENZHEN CO LTD

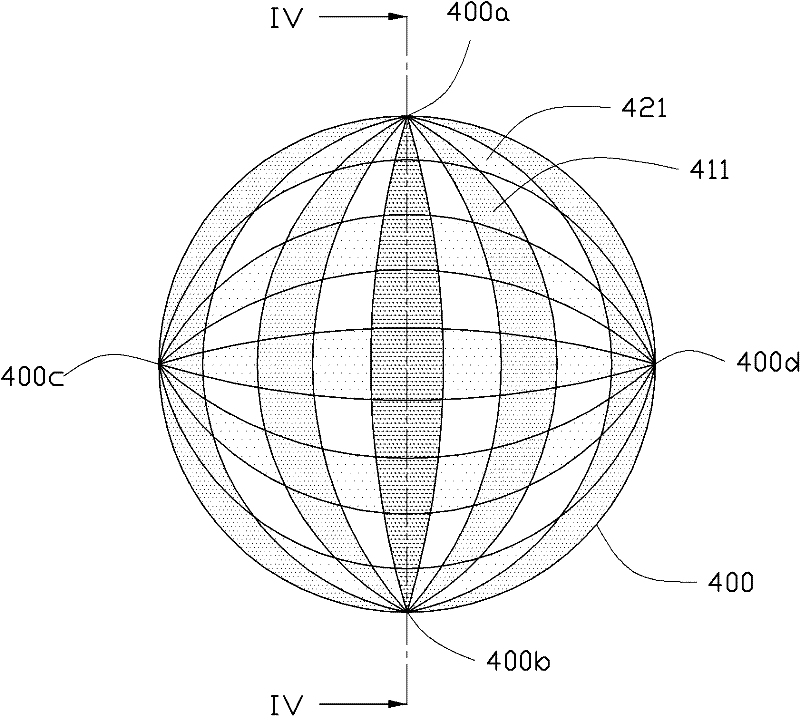

Banded LED lamp optical cover with free-form surface

InactiveCN103851533AEffective control of spot distributionEffective control of uniformityPoint-like light sourceGlobesBand shapeFree form

The invention belongs to the technical field of lamp covers and particularly relates to a banded LED lamp optical cover with a free-form surface. The banded LED lamp optical cover with the free-form surface is formed by jointing a plurality of optical cover units; each optical cover unit is formed by jointing one or multiple free-form surface polyhedrons at different angles. The banded LED lamp optical cover with the free-form surface has the advantages that flux of LED light sources can be reasonably allocated, flux availability is improved, and LED lamp lighting quality is improved.

Owner:SOUTHWESTERN INST OF PHYSICS +1

Salt bath heat treatment method for tool and mould steel

InactiveCN108531694AOvercoming the slow coolingHigh thermal conductivityHeat treatment bathsAir coolingMaterials science

The invention relates to a salt bath heat treatment method for tool and mould steel, in particular to a salt bath annealing method for the tool and mould steel. The method has the advantages that thequality and the performance of the annealed structure of materials can be improved. The method comprises the following steps that 1) high-temperature salt bath treatment is carried out, specifically,the tool and mould steel is put in a salt bath with the temperature of 840-920 DEG C for heat preservation so as to enable the temperature of the tool and mould steel to be uniform; 2) isothermal saltbath treatment is carried out, specifically, the tool and mould steel subjected to high-temperature salt bath treatment in the step 1) in put in a salt bath with the temperature of 710-780 DEG C forisothermal treatment; and 3) air cooling is carried out, specifically, air cooling is carried out on the tool and mould steel subjected to isothermal salt bath treatment in the step 2) to reach the room temperature so as to obtain the tool and mould steel with the uniform structure. The tool and mould steel prepared through the method has the advantages of being uniform in structure, uniform in grain size and good in machining performance and using performance.

Owner:SOUTHEAST UNIV +1

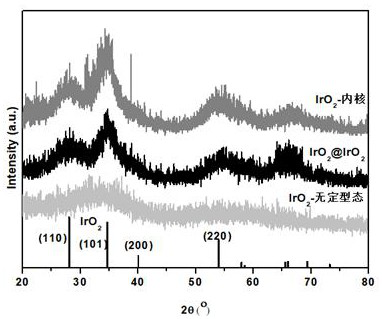

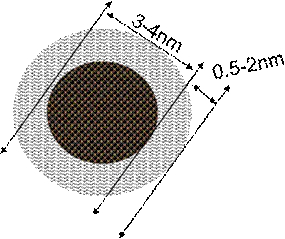

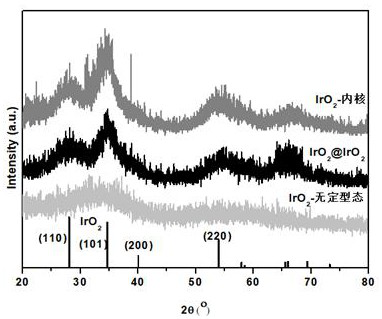

Core-shell structure catalyst, preparation method thereof and membrane electrode containing catalyst

ActiveCN113355695AIncrease active areaEffective exposureElectrode shape/formsPtru catalystHigh activity

The invention discloses a core-shell structure catalyst, a preparation method of the core-shell structure catalyst and a membrane electrode containing the core-shell structure catalyst. The core-shell structure catalyst can be used for PEM hydrogen production but is not limited to the PEM hydrogen production. The core-shell structure catalyst is characterized in that IrxMyOz is used as an inner core, and the inner core is in a crystalline state; IrxMyOz is a shell layer, and the shell layer is of a dispersed amorphous structure; wherein M is selected from at least one of Pt, Pd, Au, Sn, Sb, Ti, Mn, Ru, Ni, W, Mo, Nb, Zr, Zn, Ta and Sr, in the formula, x / (x + y + z) is 31.6%-33.3%, and y / (x + y + z) is 0-1.6%. According to the core-shell structure catalyst, an outer shell layer structure is constructed on the surface of the noble metal oxide core through a deposition method that ultrasonic treatment cooperates with pH value control, and the core-shell structure catalyst has appropriate outer layer thickness and a synergistic effect of the inner layer and the outer layer, so the catalyst has high activity and high stability.

Owner:国家电投集团氢能科技发展有限公司

Segmented hole sealing method for bedding gas drainage

InactiveCN103362542BImprove the extraction effectEffective control of uniformityGas removalSealing/packingEngineeringCoal

Provided is a sectionalized hole sealing method for bedding gas extraction drilled holes. After gas extraction drilling construction is completed, sponge wraps the front ends of hole sealing tubes with the lengths not less than 20m in a winding mode and then polyurethane materials coat the sponge, elastic partition plates are arranged on the tube sections of each hole sealing tube in a sectionalized mode, then, the hole sealing tubes are sent into gas extraction drilled holes, quick-drying cement plugs are adopted to seal the hole openings of the gas extraction drilled holes, and the grouted cement materials are injected in hole sealing spaces through grouting tubes. Under the action of grouting pressure, each section of relatively independent hole sealing space is filled with the grouted cement materials, and the grouted cement materials enter gaps of media around the drilled holes to the maximum extent so that the drilled holes can be sealed. Due to the fact that the method is characterized in that each sealed hole is long and the partition plates are used for dividing grouted sections into a plurality of hole sealing spaces, sedimentation and uneven solidification of the grouted cement materials in the hole sealing spaces can be effectively controlled, sealing of the gaps of the media around the drilled holes is facilitated, the hole sealing effect is good, concentration of gas extracted after the hole drilling can be kept in a high level for a long time, and the coal bed gas extraction effect can be obviously improved.

Owner:CHINA UNIV OF MINING & TECH

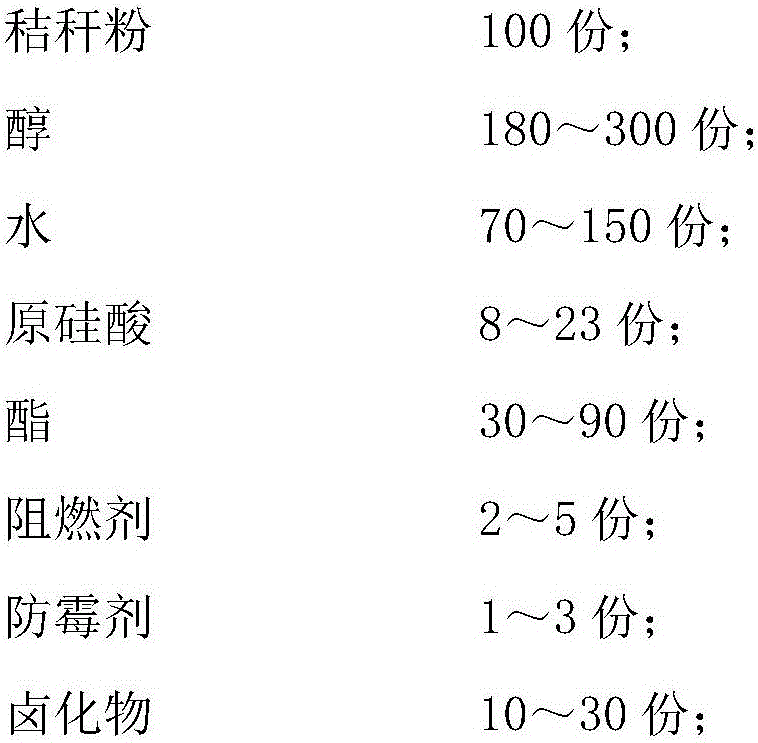

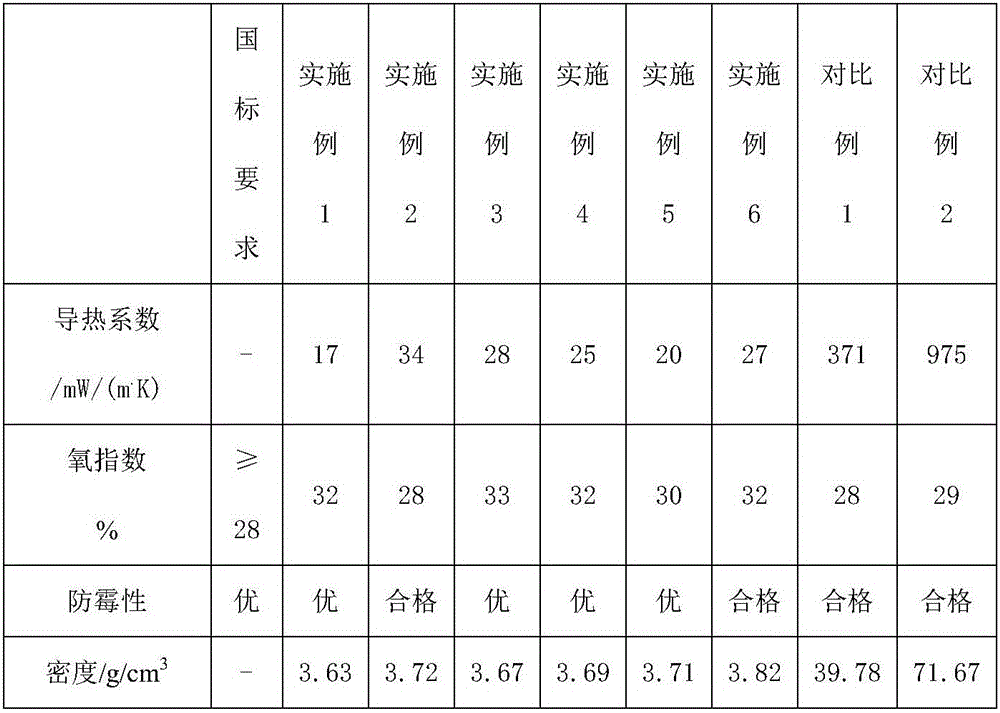

Low-heat-conductivity thermal insulation material and preparation method and application thereof

The invention discloses a low-heat-conductivity thermal insulation material and a preparation method and application thereof. The low-heat-conductivity thermal insulation material is prepared from the following components in parts by weight: 100 parts of straw powder, 180-300 parts of alcohol, 70-150 parts of water, 8-23 parts of orthosilicic acid, 30-90 parts of ester, 2-5 parts of a fire retardant, 1-3 parts of a mildew preventive, 10-30 parts of halide and 3-13 parts of oxalate. The low-heat-conductivity thermal insulation material has excellent low density, low heat conductivity coefficient, mold resistance and fire resistance; the preparation method has the advantages of being simple and feasible in production technology, low in production cost, abundant and cheap in raw materials and stable in process; the low-heat-conductivity thermal insulation material can be processed into a sheet, a panel or a filling body.

Owner:泰州精展金属制品有限公司

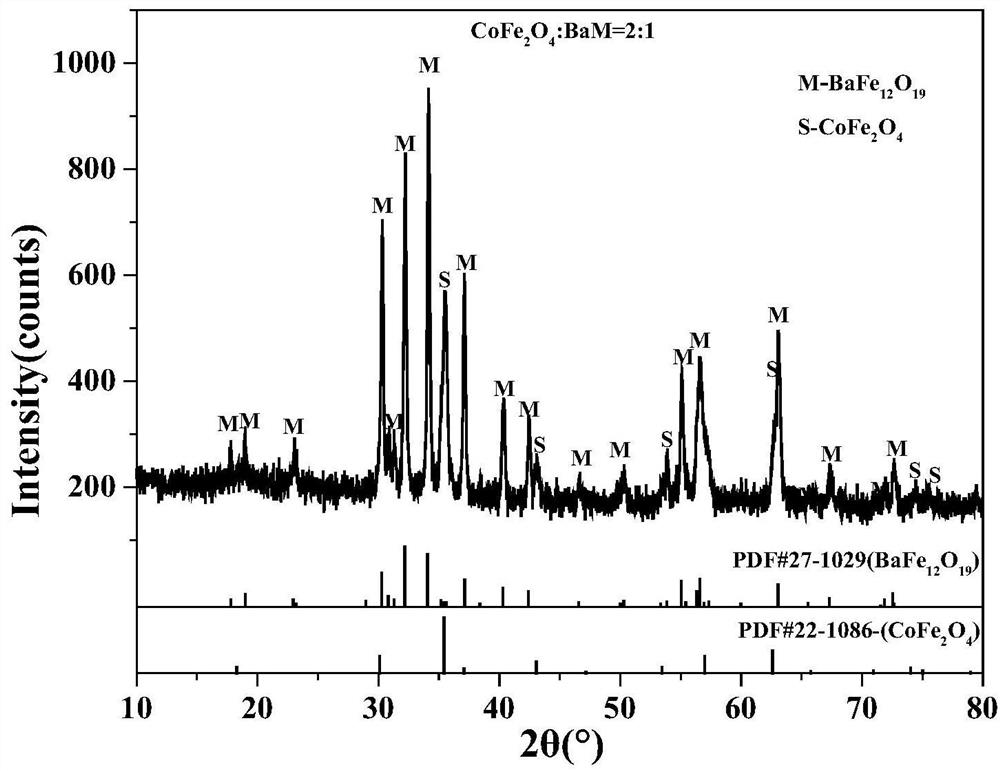

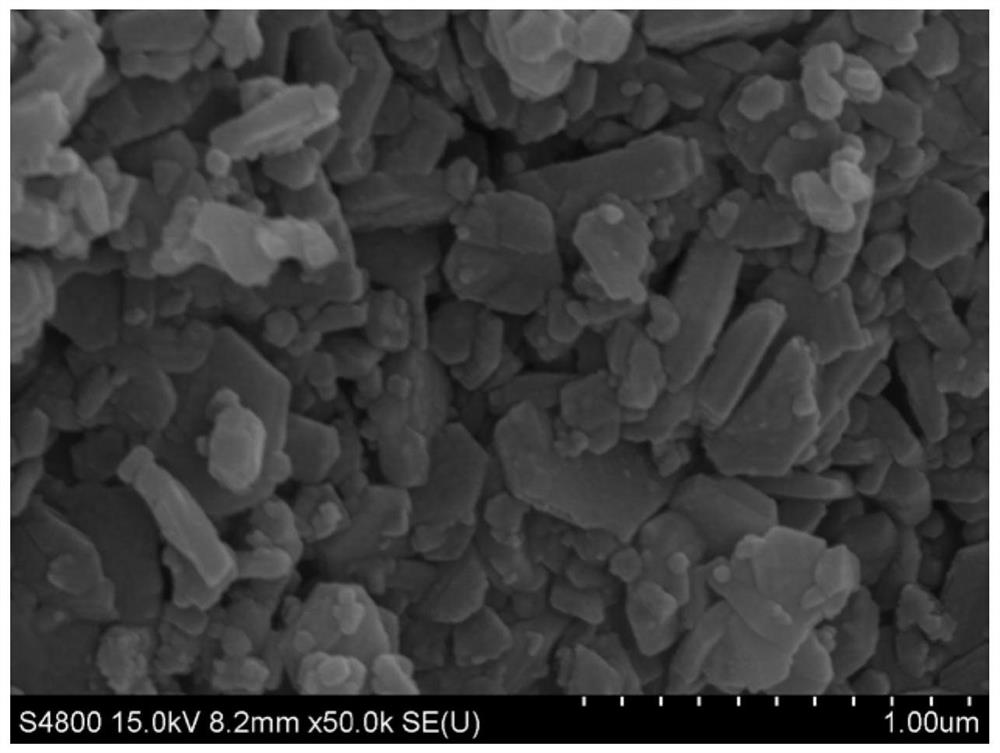

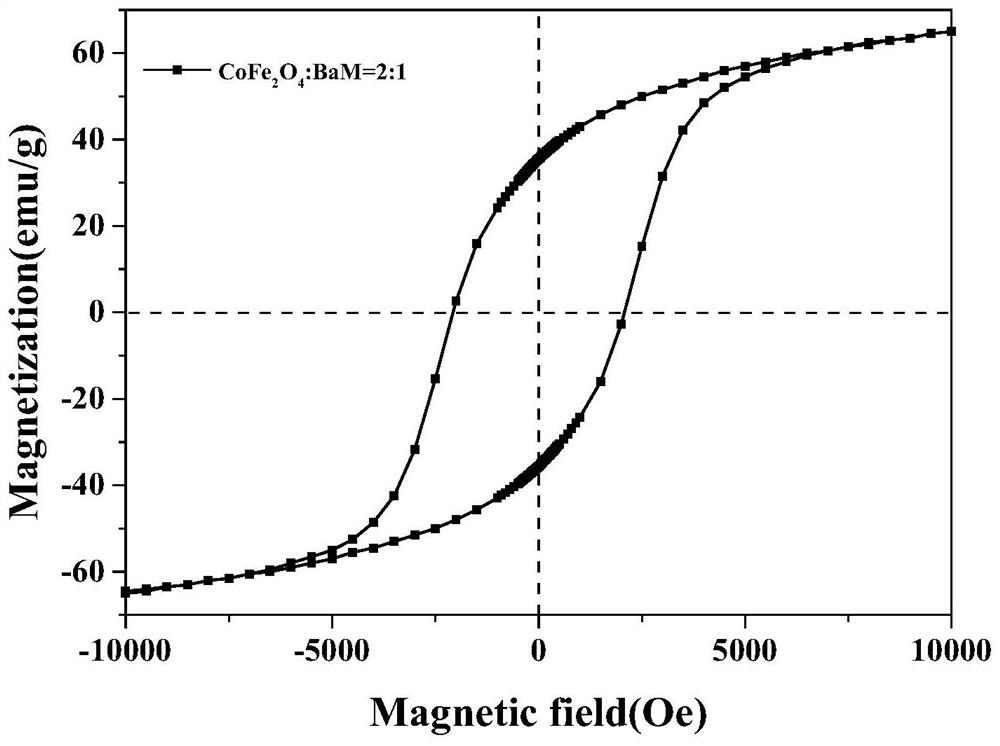

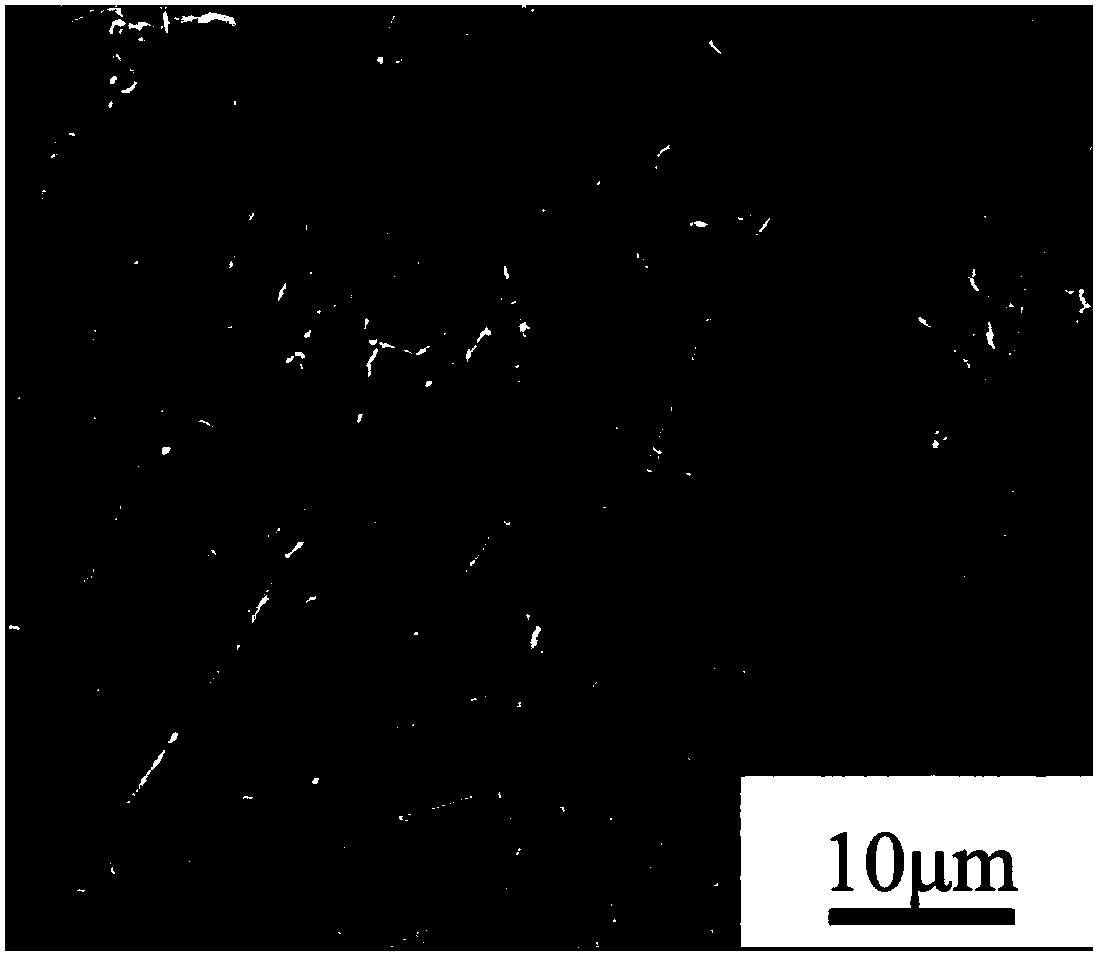

A method for synthesizing soft-hard exchange coupled magnets by chemical co-precipitation molten salt method

ActiveCN110182852BPrecise SynthesisSolve precision synthesisIron compoundsCobalt compoundsPhysical chemistryFerrite powder

The invention relates to the technical field of functional materials, in particular to a method for synthesizing a soft-hard exchange coupling magnet by a chemical co-precipitation molten salt method; comprising the following steps: according to xCoFe 2 o 4 CoFe in / yBaM 2 o 4 According to the stoichiometric ratio of the BaM component, the raw materials were weighed to prepare a mixed metal salt solution; to prepare a precipitant, the mixed metal salt solution was added to the precipitant, stirred and reacted for a period of time, and separated by suction filtration to obtain a filter cake; the filter cake was baked Dry to constant weight, crush and grind to obtain precursor powder, mix with salt, and ball mill to obtain mixed product; heat treat the mixed product, filter the product after cleaning, and dry the filtered product to obtain ferrite powder; The invention combines the uniform mixing of chemical co-precipitation metal ions and the crystal growth control of molten salt heat treatment, and realizes the two-component compounding of soft-hard exchange coupling magnets through technical means such as component adjustment, optimization of composite precipitant, and molten salt heat treatment instead of traditional heat treatment. Precise synthesis of ferrite and control of particle structure.

Owner:南京睿磐内尔环保复合新材料有限公司

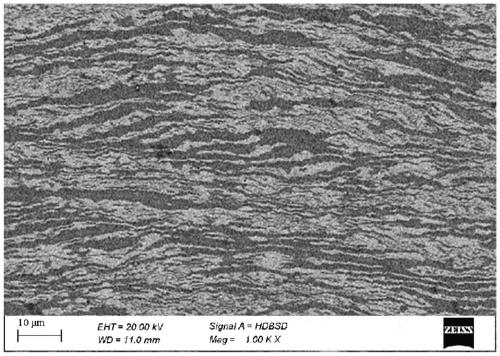

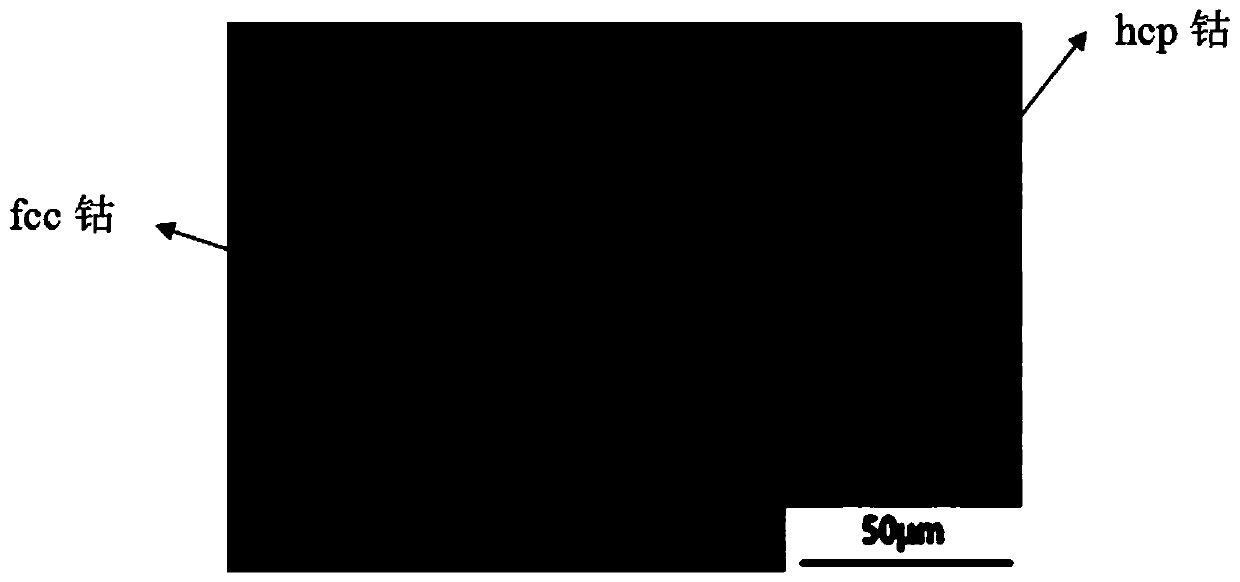

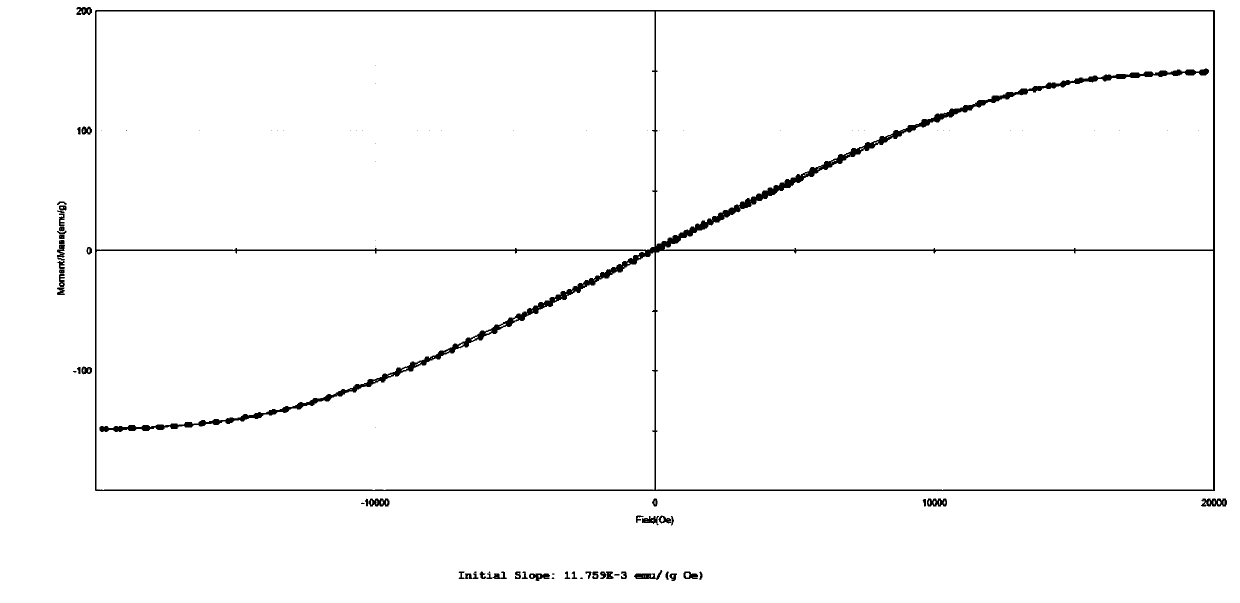

Preparation method and application of a cobalt-tantalum-zirconium alloy target

ActiveCN110735068BHigh purityImprove performanceVacuum evaporation coatingMetal-working apparatusThin membraneManufactured material

The invention discloses a preparing method and application of a cobalt tantalum zirconium alloy target material, and belongs to the technical field of preparation of special materials. The preparing method comprises the steps of component design, high-vacuum vertical sintering and high-vacuum electron beam melting, three-dimensional isothermal hot forging cogging, angle-varying controlled rollingand the like. In this way, the organization structure of the alloy and the performance of the target material are controlled, and the high-quality cobalt tantalum zirconium alloy target material is prepared. The oxygen content of the cobalt tantalum zirconium alloy target material is smaller than or equal to 15 ppm, the average grain size of the cobalt tantalum zirconium alloy target material is 5-20 micrometers, the phase distribution of the target material is uniform, the magnetic permeability is larger than 40%, and the heterogeneity of magnetic permeability is smaller than 2%. By means ofthe designed process, the oxygen content, organization structure heterogeneity and magnetic performance of the finished product target material can be effectively controlled, and a raw material guarantee is provided for sputtering high-quality thin films by means of the preparing method.

Owner:CENT SOUTH UNIV

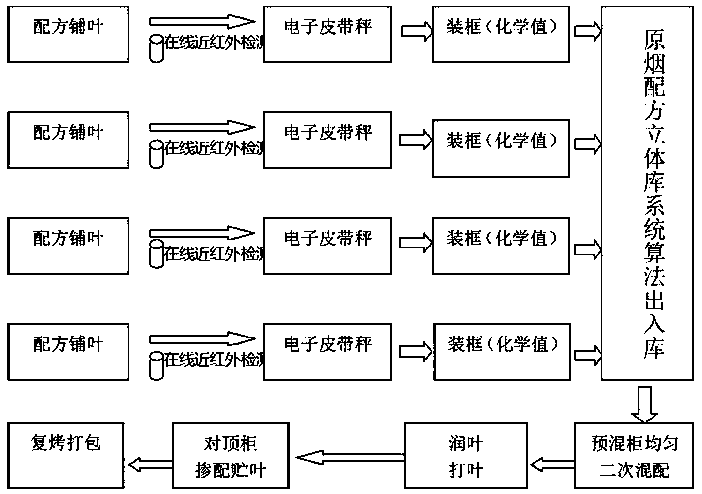

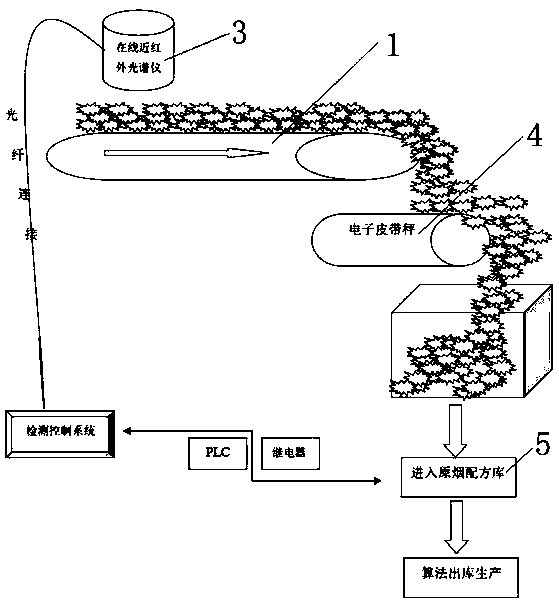

Equipment and technology for reducing variation coefficient of threshing and redrying nicotine

ActiveCN106418635BSolve the problem of manual material selection and feedingImprove controlTobacco preparationEngineeringCoefficient of variation

The invention relates to equipment and a process for reducing a threshing and redrying nicotine variation coefficient. The equipment for reducing the threshing and redrying nicotine variation coefficient is characterized in that the equipment comprises a conveying belt and a warehouse, an online near-infrared spectrograph is arranged above the conveying belt, an electronic belt scale is arranged below the rear end of the conveying belt, and the output end of the belt scale leads to the raw-tobacco formula stereoscopic warehouse. The equipment and the process have the advantages that manual material selecting and feeding in a preparation area are realized, uniformity of tobacco leaves in the preparation area before formula threshing and redrying is regulated effectively, and the nicotine variation coefficient of the preparation area for formula threshing and redrying production is reduced, so that the control capability for formula threshing homogenization level is improved, and product quality stability is guaranteed.

Owner:FUJIAN WUYI TOBACCO +1

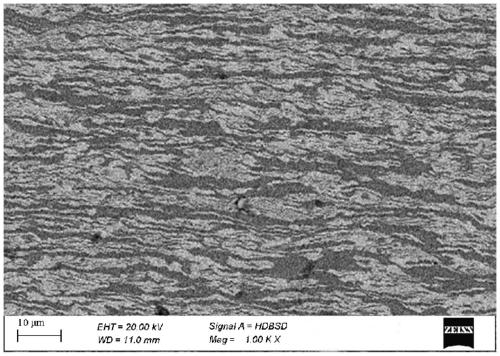

Preparation method and application of tissue-controllable ultrahigh-purity cobalt plate

ActiveCN110923645AImprove performanceImprove qualityVacuum evaporation coatingSputtering coatingManufactured materialCobalt

The invention discloses a preparation method and application of a tissue-controllable ultrahigh-purity cobalt plate. The preparation method comprises the following steps of cold-pressing molding, high-vacuum-degree vertical melting, high-vacuum-degree electron beam smelting furnace, argon chamber stainless steel wrapping, pass forging deformation amount and total deformation amount coordinately-controlled three-dimensional high-speed equal-temperature hot forging cogging, variable-angle cross-control rolling and heat treatment, turning machining, packaging and the like. The prepared ultrahigh-purity cobalt purity is greater than or equal to 99.995%, the average grain size is 10-40 microns, the beta-Co content of the fcc structure in the plate is more than 50%, the magnetic permeability isgreater than 70%, and the magnetic permeability non-uniformity is less than 1%. According to the preparation method, the grain size and the grain size distribution of the finished product can be effectively controlled, and the tissue distribution of the finished product is regulated and controlled, so that the raw material guarantee is provided for the finished product to be used as the high-quality target material.

Owner:CENT SOUTH UNIV

Preparation equipment and preparation method of sputtering target material

ActiveCN112962070APrevent impurity pollutionGood processing conditionsCasting plantsStirring devicesMoulding deviceClosed cavity

The invention discloses preparation equipment and a preparation method of a sputtering target material. The preparation equipment comprises a closed cavity, a smelting and pouring device, a casting and forming device and an atmosphere treatment device; the smelting and pouring device and the casting and forming device are positioned in the closed cavity; the atmosphere treatment device is connected with the closed cavity through a pipeline; and a protective atmosphere is conveyed to the closed cavity. Through the combined action of the smelting device, the casting and forming device and the atmosphere cleaning device, unnecessary pollution caused by processing links in the smelting, stirring, cooling and molding processes is reduced, good conditions such as proper temperature, cooling speed, pressure and atmosphere are provided for material preparation, the impurity content of the prepared high-purity material can be effectively controlled in the whole preparation process, and the high-purity material can be uniformly fused and controllably cooled and formed.

Owner:CHANGSHA HUAISHI NEW MATERIAL TECH CO LTD

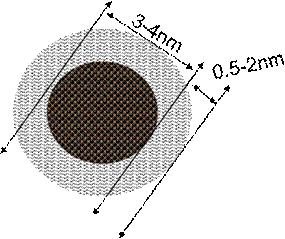

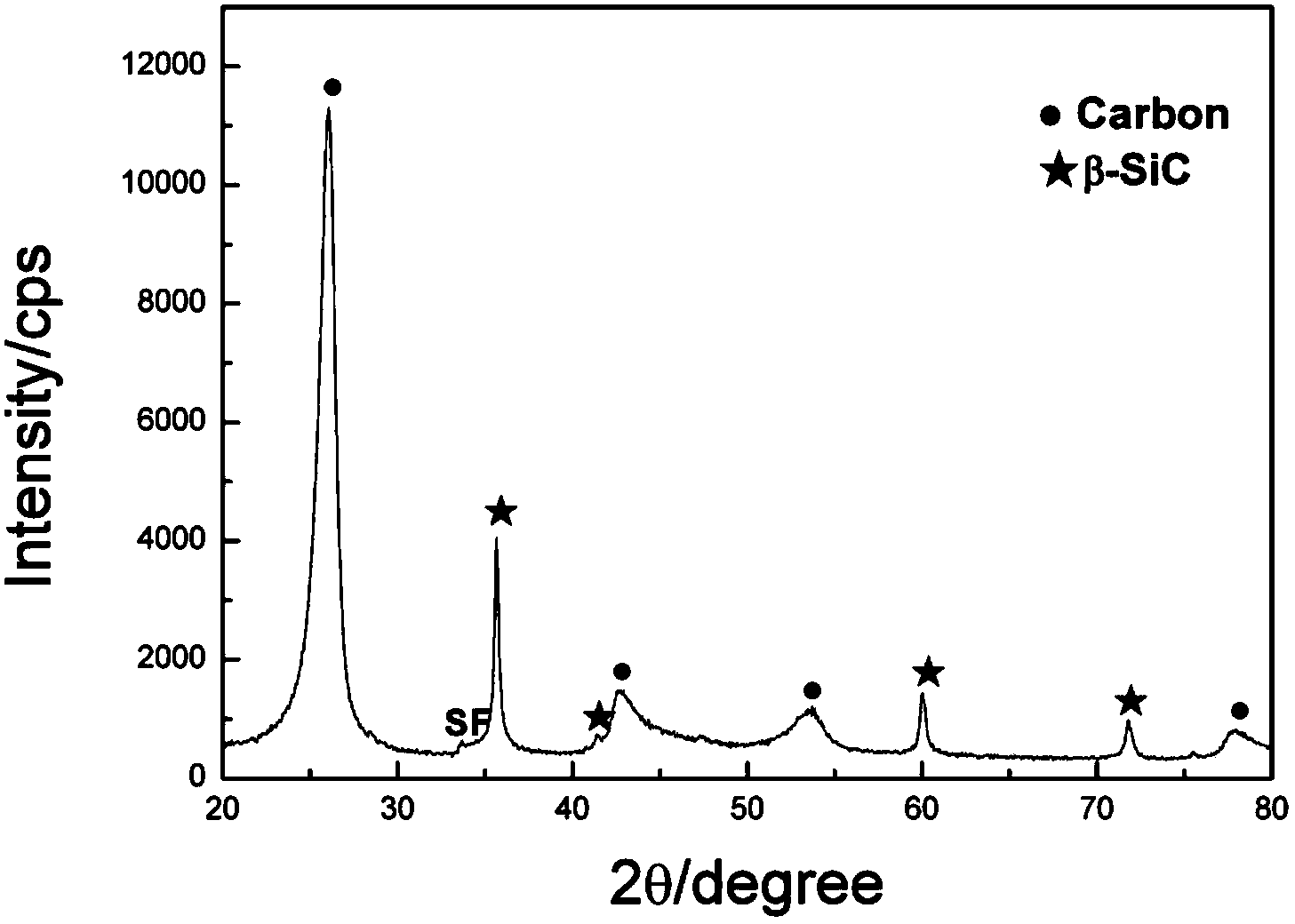

Method for manufacturing coaxial silicon carbide/silicon dioxide nanocable with chemical vapor deposition method

ActiveCN102810359BThe synthesis process is simpleLower requirementChemical vapor deposition coatingCable/conductor manufactureDeposition temperatureCarbon composites

The invention relates to a method for manufacturing a coaxial silicon carbide / silicon dioxide nanocable with a chemical vapor deposition method. The method comprises the following steps of: putting a soaked carbon / carbon compound material into a deposition furnace; vacuumizing and introducing argon till the normal pressure is reached; introducing hydrogen gas serving as carrier gas into a bubbling bottle loaded with methyl trichlorosilane; introducing methyl trichlorosilane serving as a reaction gas resource into a hearth; and meanwhile, introducing diluted argon and diluted hydrogen for reacting. The method has a simple synthesizing process, and a pre-synthesizing process is not required; the silicon carbide / silicon dioxide (inner core / outer layer) coaxial nanocable is manufactured under the normal pressure, and the requirement on equipment is low; the deposition temperature is low, and the manufacturing cost is lowered; and moreover, the method has another outstanding characteristic that the purity and uniformity of the silicon carbide / silicon dioxide (inner core / outer layer) coaxial nanocable can be effectively controlled by adjusting deposition process parameters. According to the advantages, large-scale industrial production of the silicon carbide / silicon dioxide (inner core / outer layer) coaxial nanocable becomes possible.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

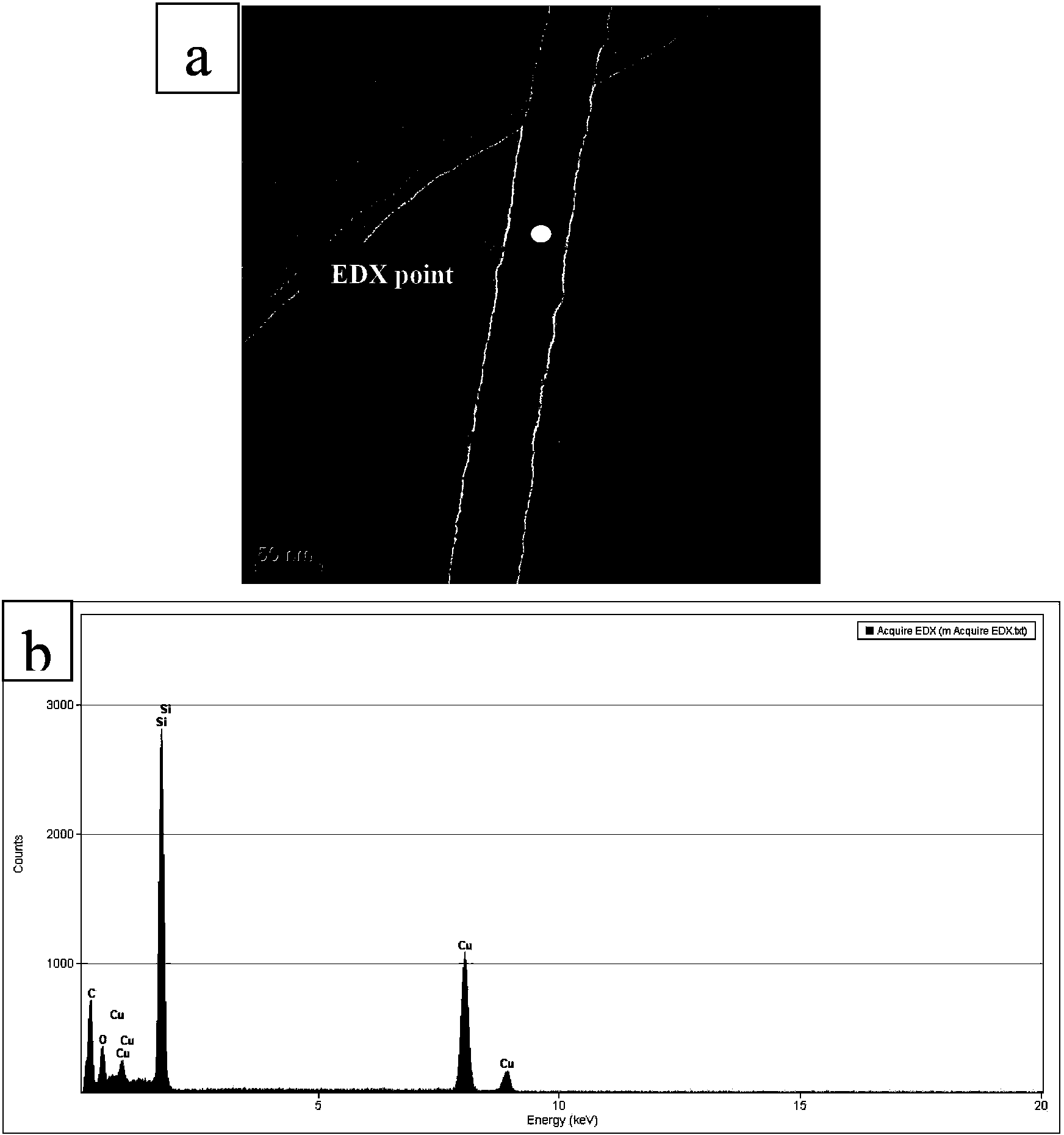

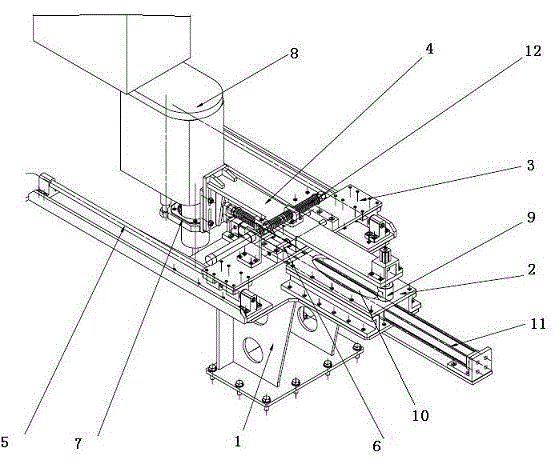

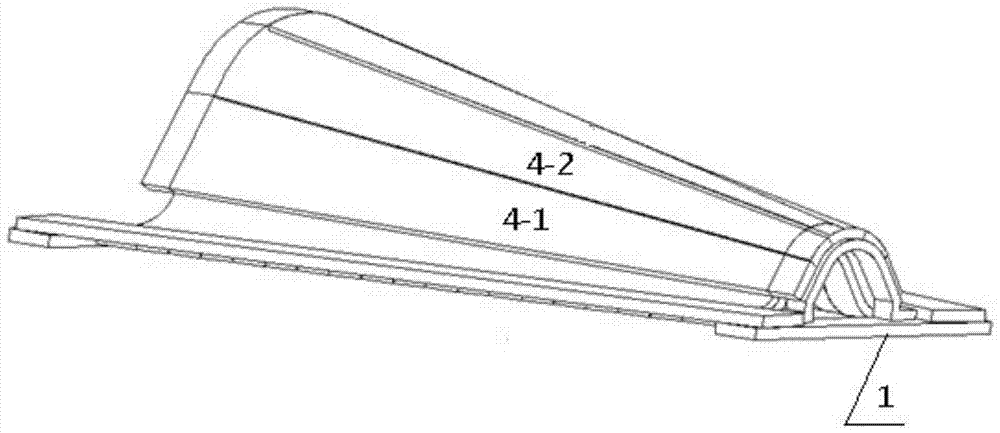

Foaming agent injecting device of shoe sole foaming machine

InactiveCN102744824AEffective control of injection flowInjection flow controlDomestic articlesFoaming agentEngineering

The invention belongs to the technical field of shoe manufacturing, and provides a foaming agent injecting device of a shoe sole foaming machine. The agent injecting device comprises a frame (1), a nozzle (8), and a plate I (3) and a plate II (4) for driving the nozzle to move, wherein the nozzle (8) is located on a nozzle fixed mount (7); the nozzle fixed mount (7) is connected with the plate II (4); the plate II (4) is located on a slide rail II (6) of the plate I (1) and arranged vertically to the plate I (3); a guide wheel (9) arranged on one end of the plate II (4) is located in a mold hole (16) of a mold board (2) and elastically props against the wall of the mold hole of the mold board; and the guide wheel (9) is driven by the plate I (3) and the plate II (4) to perform horizontal and vertical composite motions along the motion trail limited by the inner wall of the mold hole of the mold board (2). By the foaming agent injecting device, the foaming agent nozzle can inject a foaming agent to a bottom mold along the motion trail limited by the mold hole of the mold board, so that the production efficiency and the production quality can be improved, and the waste of materials can be reduced to a certain extent.

Owner:LUOYANG XINSILU ELECTRIC

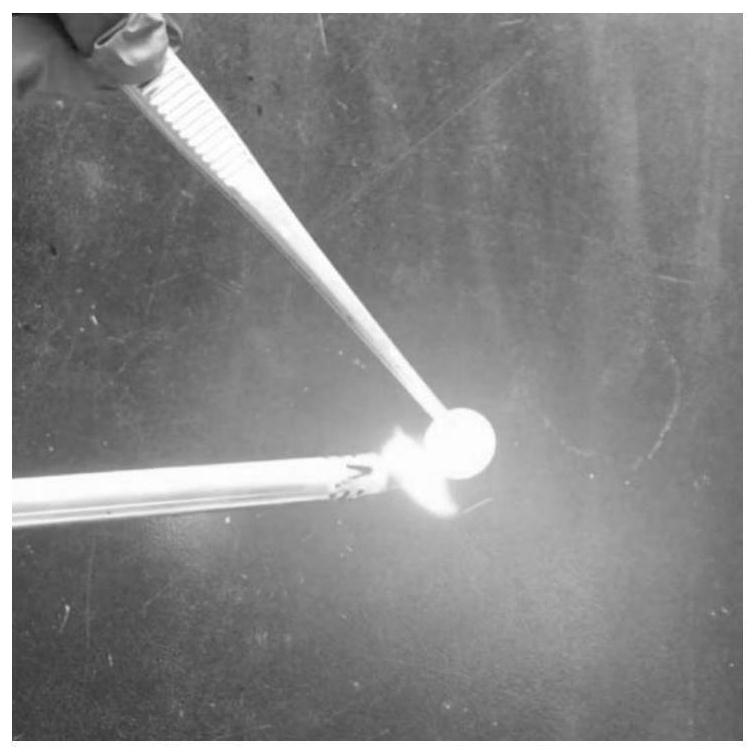

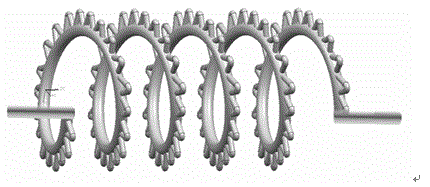

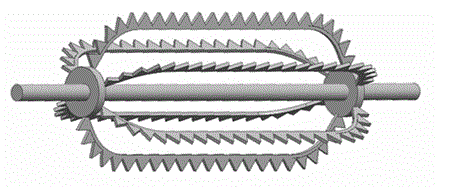

Saw tooth type needle-free electrostatic spinning device

ActiveCN102828259BAvoid cloggingAvoid cleaningSpinnerette packsArtificial thread manufacturing machinesNeedle freeElectrospinning

The invention discloses a saw tooth type needle-free electrostatic spinning device, which comprises a liquid supply system, a spinning system, a power supply system, a receiving system, a transmission system and a control system. The device is characterized in that the spinning system comprises a spinning manifold body, a spinning component and a center shaft; the exterior of the spinning manifold body has a horizontal cuboidal shape, and a horizontal cylindrical cavity is formed in the spinning manifold body; a main body of the center shaft is arranged in the cavity, and the two ends of the center shaft extend from the spinning manifold body, and are connected with the transmission system; the spinning component has an axially continuous or parallel thin rack structure, and points of a rack are outwards arranged on the center shaft, and can be driven by the center shaft to rotate; distances of 1 to 3mm are reserved between the points and the inner wall of the spinning manifold body; a liquid inlet pipe orifice of the spinning manifold body is communicated with a spinning metering pump of the liquid supply system, and an overflow port of the spinning manifold body is connected to a liquid storage device of the liquid supply system through a pipe, and is reserved between the bottom of the spinning component and the center shaft; and rectangular spinning openings are reserved in positions opposite to the highest parts of the spinning component on the upper surface of the spinning manifold body.

Owner:TIANJIN POLYTECHNIC UNIV

Conical LED lamp optical mask

InactiveCN103851536AEffective control of spot distributionEffective control of uniformityPoint-like light sourceSemiconductor devices for light sourcesEngineeringLuminous flux

The invention belongs to the technical field of lamp masks, and particularly relates to a conical LED lamp optical mask which comprises one or multiple optical mask units. Each optical mask unit comprises a cone and a plurality of circular truncated cones, each cone is stacked at the top, the circular truncated cones are erected and stacked below the corresponding cone according to undersurface radius from small to big, the undersurface of each cone is identical with the upper undersurface of the circular truncated cone adjacent to the cone in radius, and the lower undersurface of each circular truncated cone is identical with the upper undersurface of the circular truncated cone below in radius. By the conical LED lamp optical mask, luminous flux of an LED light source can be reasonably distributed, so that luminous flux utilization rate is increased, and lighting quality of an LED lamp is improved.

Owner:SOUTHWESTERN INST OF PHYSICS +1

Core-shell structure catalyst, preparation method thereof, and membrane electrode comprising the catalyst

ActiveCN113355695BIncrease active areaEffective exposureElectrode shape/formsPtru catalystPhysical chemistry

The invention discloses a catalyst with a core-shell structure, a preparation method thereof and a membrane electrode containing the catalyst. The catalyst of the invention can be used for PEM hydrogen production but is not limited thereto. The core-shell structure catalyst of the present invention comprises: Ir x m y o z is the core, the core is crystalline; Ir x m y o z is the shell layer, and the shell layer is a dispersed amorphous structure; wherein, M is selected from Pt, Pd, Au, Sn, Sb, Ti, Mn, Ru, Ni, W, Mo, Nb, Zr, Zn, Ta, Sr elements At least one of them, where x / (x+y+z) is 31.6%-33.3%, and y / (x+y+z) is 0-1.6%. The core-shell structure catalyst of the present invention constructs a shell layer structure on the surface of the noble metal oxide core through the deposition method of ultrasonic treatment to control the pH value, and has a suitable outer layer thickness, and the inner and outer layers work together to make the catalyst have high activity and high stability. .

Owner:国家电投集团氢能科技发展有限公司

A multi-point pressurization device for controlling the density and uniformity of fabric layers stitched on complex curved surfaces

Owner:SINOMA SCI & TECH

Foaming agent injecting device of shoe sole foaming machine

InactiveCN102744824BEffective control of injection flowInjection flow controlDomestic articlesFoaming agentEngineering

The invention belongs to the technical field of shoe manufacturing, and provides a foaming agent injecting device of a shoe sole foaming machine. The agent injecting device comprises a frame (1), a nozzle (8), and a plate I (3) and a plate II (4) for driving the nozzle to move, wherein the nozzle (8) is located on a nozzle fixed mount (7); the nozzle fixed mount (7) is connected with the plate II (4); the plate II (4) is located on a slide rail II (6) of the plate I (1) and arranged vertically to the plate I (3); a guide wheel (9) arranged on one end of the plate II (4) is located in a mold hole (16) of a mold board (2) and elastically props against the wall of the mold hole of the mold board; and the guide wheel (9) is driven by the plate I (3) and the plate II (4) to perform horizontal and vertical composite motions along the motion trail limited by the inner wall of the mold hole of the mold board (2). By the foaming agent injecting device, the foaming agent nozzle can inject a foaming agent to a bottom mold along the motion trail limited by the mold hole of the mold board, so that the production efficiency and the production quality can be improved, and the waste of materials can be reduced to a certain extent.

Owner:LUOYANG XINSILU ELECTRIC

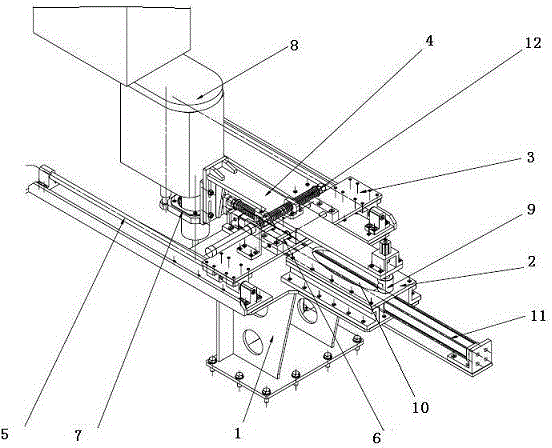

pvb film and laminated glass

ActiveCN110655336BHigh mechanical strengthImprove mechanical propertiesSynthetic resin layered productsGlass/slag layered productsPolyvinyl butyralBenzoic acid

The invention discloses a PVB film, which is prepared from a PVB composition. In parts by weight, the PVB composition includes 60-90 parts of polyvinyl butyral, 1-30 parts of a crosslinking agent system and a plasticizer 1-40 parts, the cross-linking agent system includes benzoic acid or benzoic acid analogues, alkylphenols and acid anhydrides in a mass ratio of (30-50):(40-60):(5-10) in sequence. The invention also discloses a laminated glass.

Owner:怀德创建有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com