Segmented hole sealing method for bedding gas drainage

A technology of gas drainage and bedding, which is applied in the field of layered gas drainage borehole segmented sealing, which can solve the problem of poor drainage effect of bedding boreholes, affecting the effect of gas drainage, and short gas drainage time, etc. problem, to achieve the effect of improving the gas drainage effect, improving the gas drainage effect, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

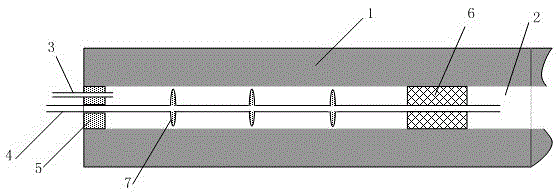

[0013] Such as figure 1 Shown, the hole sealing method of bedding gas drainage borehole of the present invention, concrete steps are as follows:

[0014] a. Firstly, construct the gas drainage borehole 2 according to the design requirements;

[0015] b. After the construction of the gas drainage borehole 2 is completed and cleaned, the front end of the sealing pipe 4 that is not less than 20m long is wrapped with a sponge and coated with polyurethane material, and elastic partitions 7 are installed in sections of the sealing pipe 4 , the elastic partition 7 adopts a special rubber plate or plastic plate that gradually becomes thinner outward along its center, and its center thickness is 5 mm, and its diameter is slightly smaller than the drilling diameter. Use 3 to 4 elastic partitions 7 to divide the middle grouting section into 4 to 5 relatively independent spaces, then quickly send the sealing pipe 4 into the gas drainage borehole 2, and wrap the front end of the sealing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com