A method for synthesizing soft-hard exchange coupled magnets by chemical co-precipitation molten salt method

A chemical co-precipitation and exchange coupling technology, which is applied in the field of chemical co-precipitation molten salt method to synthesize soft-hard exchange coupling magnets, can solve the problems of difficult to obtain composite magnets with good exchange coupling effects, limited mixing uniformity, and final product two-dimensionality. Solve problems such as phase composition deviation, achieve the effect of simple and easy process, and promote low-temperature synthesis of phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

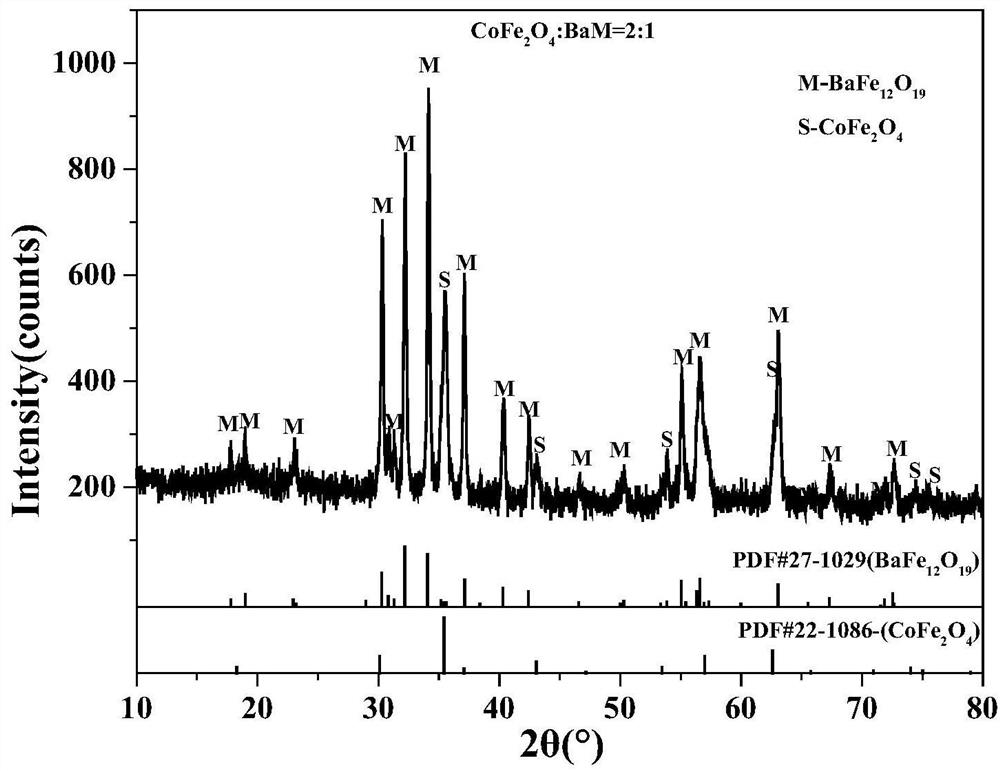

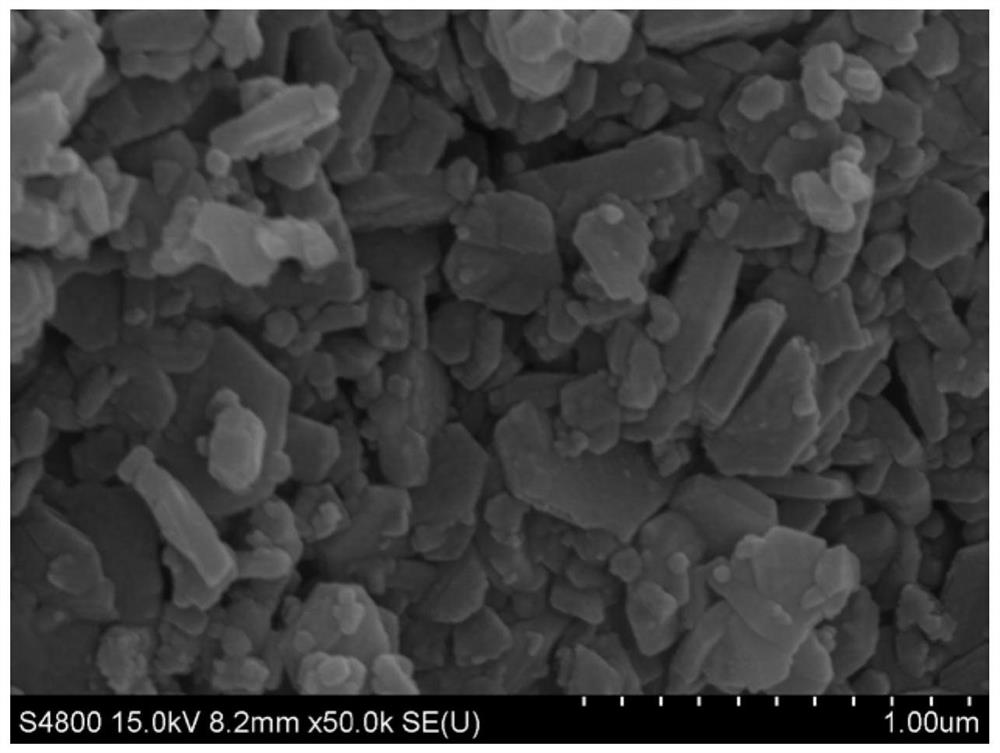

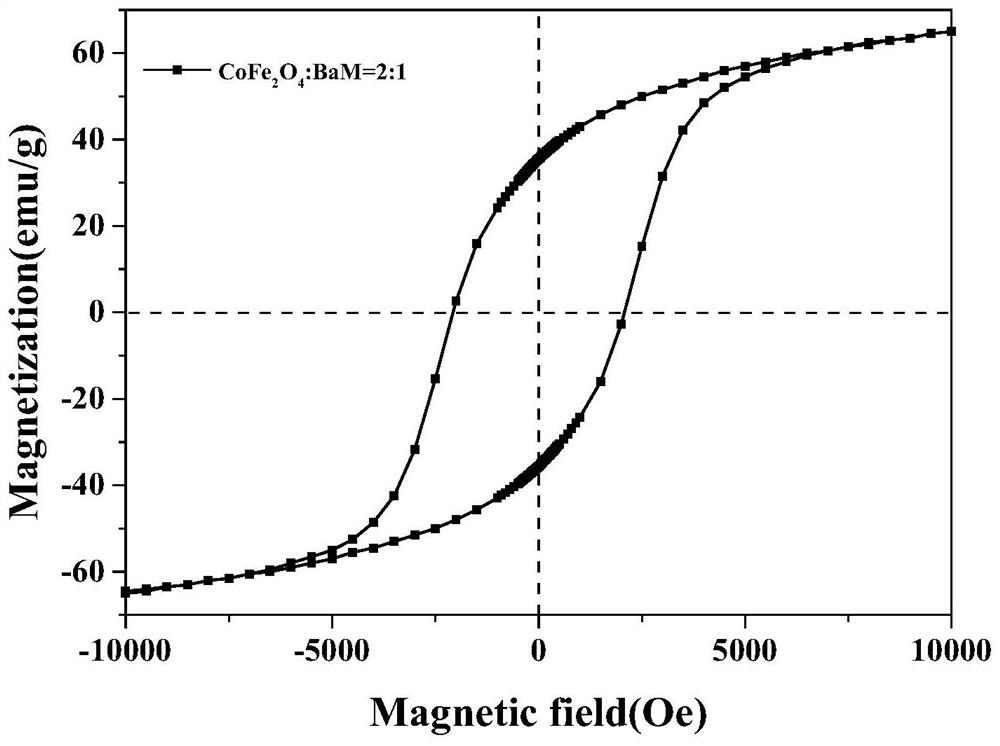

[0037] Soft-hard exchange coupled magnet xCoFe 2 o 4 CoFe in / yBaM 2 o 4 Synthesis with BaM component ratio x:y=2:1: According to the stoichiometric ratio, weigh barium nitrate, ferric nitrate nonahydrate, and cobalt nitrate hexahydrate, dissolve them in deionized water, stir and dissolve until clear and transparent, and obtain mixed metal salts Solution, wherein the iron ion concentration is 0.5mol / L; With sodium hydroxide and sodium carbonate as precipitant, add deionized water, prepare precipitant solution wherein the concentration of sodium hydroxide is 5.0mol / L, and the concentration of sodium carbonate is 0.1mol / L; and under the condition of rapid stirring, the initial metal ion solution obtained in 1) is added to the precipitant solution, and the flow rate is controlled at 200~500ml / min; after stirring and reacting for 2~6 hours, separate by suction filtration, and use Wash with deionized water until the filtrate is neutral to obtain a filter cake; the obtained filt...

Embodiment 2

[0040] Soft-hard exchange coupled magnet xCoFe 2 o 4 CoFe in / yBaM 2 o 4 Synthesis with BaM component ratio x:y=1:2: According to the stoichiometric ratio, weigh barium nitrate, ferric nitrate nonahydrate, and cobalt nitrate hexahydrate and dissolve them in deionized water, stir and dissolve until clear and transparent, and obtain mixed metal salts Solution, wherein the iron ion concentration is 0.5mol / L; With sodium hydroxide and sodium carbonate as precipitant, add deionized water, prepare precipitant solution wherein the concentration of sodium hydroxide is 5.0mol / L, and the concentration of sodium carbonate is 0.2mol / L; and under the condition of rapid stirring, the initial metal ion solution obtained in 1) is added to the precipitant solution, and the flow rate is controlled at 200~500ml / min; after stirring and reacting for 2~6 hours, separate by suction filtration, and use Wash with deionized water until the filtrate is neutral to obtain a filter cake; the obtained f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com