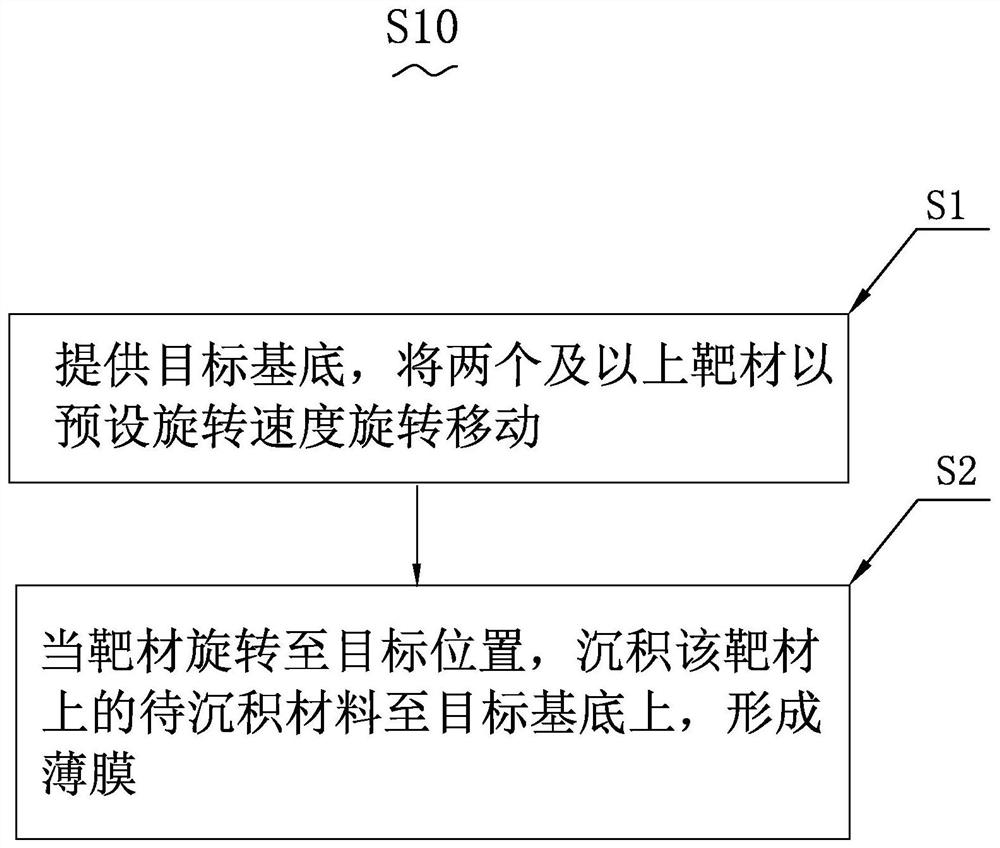

Thin film preparation method, high-throughput combined material chip preparation method and system thereof

A technology for the preparation of composite material chips and thin films, which can be used in metal material coating processes, semiconductor/solid-state device manufacturing, ion implantation and plating, etc., and can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

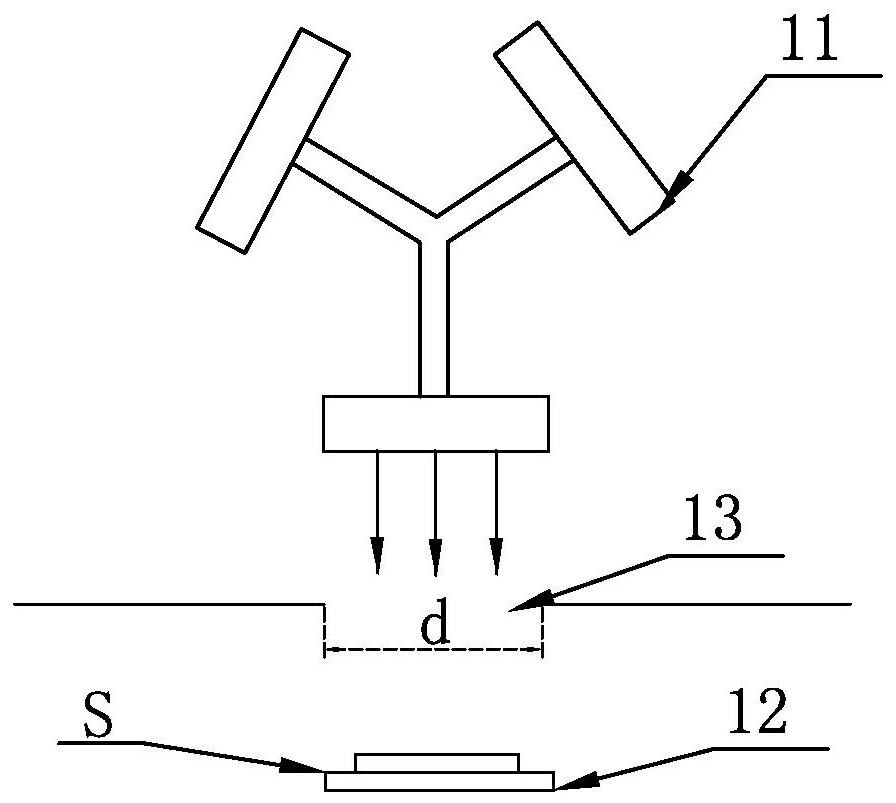

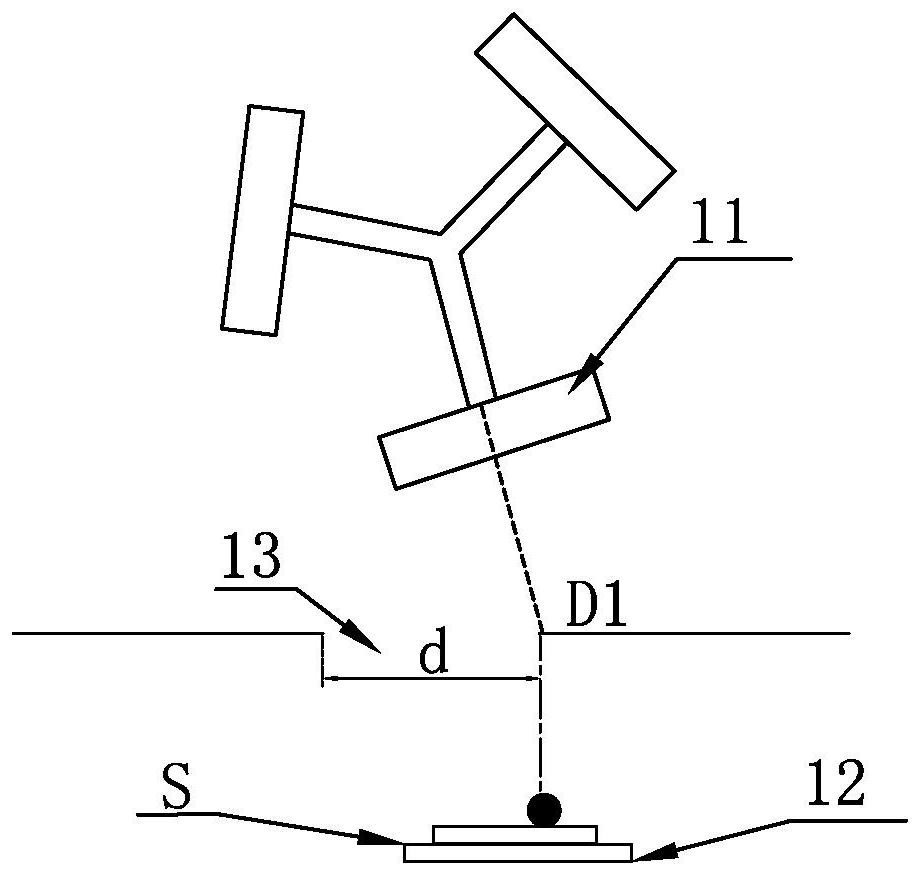

Embodiment Construction

[0047] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0048] "One embodiment", "preferred embodiment", "embodiment" or "multiple embodiments" mentioned in this specification means that the specific features, structures, characteristics or functions described in conjunction with the embodiments are included in the present invention In at least one embodiment and may be in more than one embodiment. The appearances of the phrases "in one embodiment," "in an embodiment," or "in multiple embodiments" in various places in this specification are not necessarily all referring to the same embodiment or the same multiple embodiments.

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com