Core-shell structure catalyst, preparation method thereof, and membrane electrode comprising the catalyst

A core-shell structure and catalyst technology, applied in the field of membrane electrodes containing the catalyst, can solve the problems of poor durability, less investigation of the electrochemical stability of the catalyst, etc., to improve the quality activity, improve the intrinsic reaction activity, and inhibit the electrochemical The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The embodiment of the present invention also provides a preparation method of a core-shell structure catalyst, which includes the following steps:

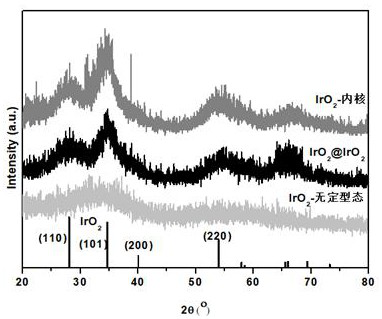

[0043] a. Add NaNO to the aqueous solution containing Ir ions 3 and NH 4 HCO 3 , stirred, evaporated, and then roasted to obtain IrO 2 kernel;

[0044] Preferably, the concentration of Ir ions in the aqueous solution containing Ir ions is 0.01-0.05mol / L, and the Ir ions: NaNO 3 :NH 4 HCO 3 The molar ratio is 1:20-40:1-20, the temperature of the roasting is 400-450°C, and the heating rate is 1-10°C / min;

[0045] B, the IrO that described step a makes 2 The inner core is added to the alkali solution containing Ir ions, stirred, and reacted;

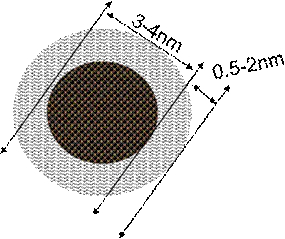

[0046] Preferably, in the alkaline solution containing Ir ions, the concentration of Ir ions is not more than 5mmol / L, the alkaline solution is KOH or NaOH, adding IrO 2 After the core, in solution Ir:IrO 2 The molar ratio is 0.3-0.5, the reaction temperature is 60-90°C, and th...

Embodiment 1

[0059] (1) Take 4.5g H 2 IrCl 6 The solution (containing iridium 35wt%) was dissolved in 300ml of high-purity water, heated and stirred at 80 degrees for 30min, the Ir ion concentration in the solution was 0.027mol / L, and then 20gNaNO 3 and 3.25gNH 4 HCO 3 , namely Ir ion: NaNO 3 :NH 4 HCO 3 The molar ratio is 1:29:5. After stirring for 1 h, the solution is evaporated to dryness to obtain a powder sample, which is roasted at 450 °C for 1 h at a heating rate of 5 °C / min. The powder sample is ground, washed, centrifuged and dried at 90 °C. Dry for 12h to get IrO 2 kernel;

[0060] (2) take 2gH 2 IrCl 6 The solution (containing iridium 35wt%) was dissolved in 1000ml of 0.5mol / L NaOH alkali solution, the temperature was controlled at 80 °C, the pH was controlled at 13, the Ir ion concentration in the solution was 0.004mmol / L, mechanically stirred for 30min, and ultrasonic treatment, the ultrasonic power is 480W, and an alkaline solution containing Ir ions is obtained, an...

Embodiment 2

[0069] The method is the same as that of Example 1, except that step (3) is to add 0.5 mol / L HCl solution dropwise to the reaction solution in step (2).

[0070] The catalyst inner core IrO that this embodiment makes 2 The specific surface area is 219m 2 / g, the grain size is 3.2-3.3nm; the shell layer thickness is 1.3-1.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com