Equipment and technology for reducing variation coefficient of threshing and redrying nicotine

A technology of variation coefficient and re-cured tobacco, applied in tobacco, tobacco preparation, application, etc., can solve the problems of large manpower and financial resources, sensory quality differences, etc., and achieve the effect of improving control ability and ensuring quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

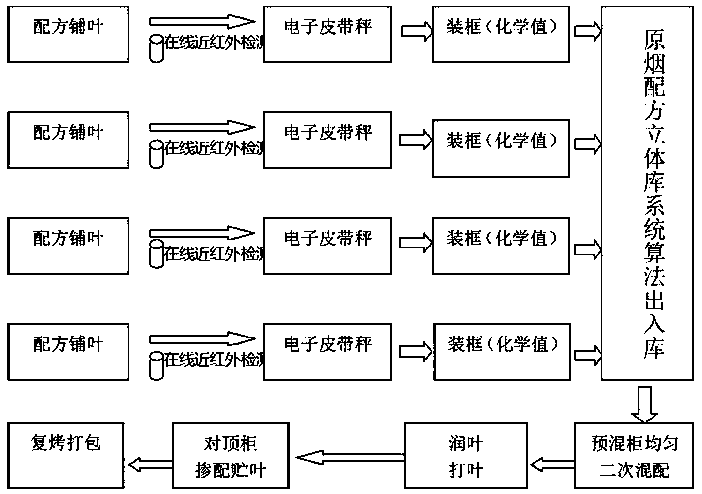

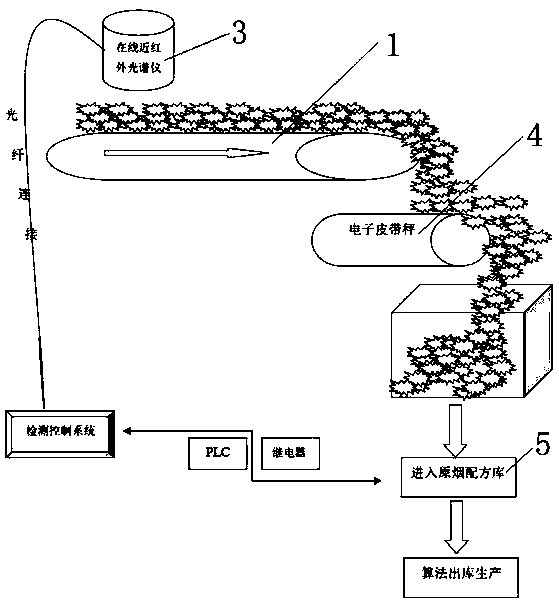

[0026] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0027] The device for reducing the coefficient of variation of threshing and redrying nicotine according to the present invention includes a conveyor belt 1 and a three-dimensional warehouse for raw tobacco formula, an online near-infrared spectrometer 3 is provided above the summary conveyor belt, and an electronic device is provided below the rear end of the conveyor belt. A belt scale 4, after the output of the belt scale is framed, the three-dimensional warehouse 5 of the original tobacco formula is carried out.

[0028] Further, the storage information of the above-mentioned raw tobacco formula three-dimensional library is connected to the detection and control system through PLC, and the online near-infrared spectrometer is connected to the data of the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com