Material flow system feeding crude tobaccos according to ratio in crude tobacco production and transportation method thereof

A logistics system and raw tobacco technology, applied in the field of logistics systems, can solve problems such as production and processing control traps, information islands, complex and changeable information, etc., and achieve the effects of reducing labor intensity, improving formula precision, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

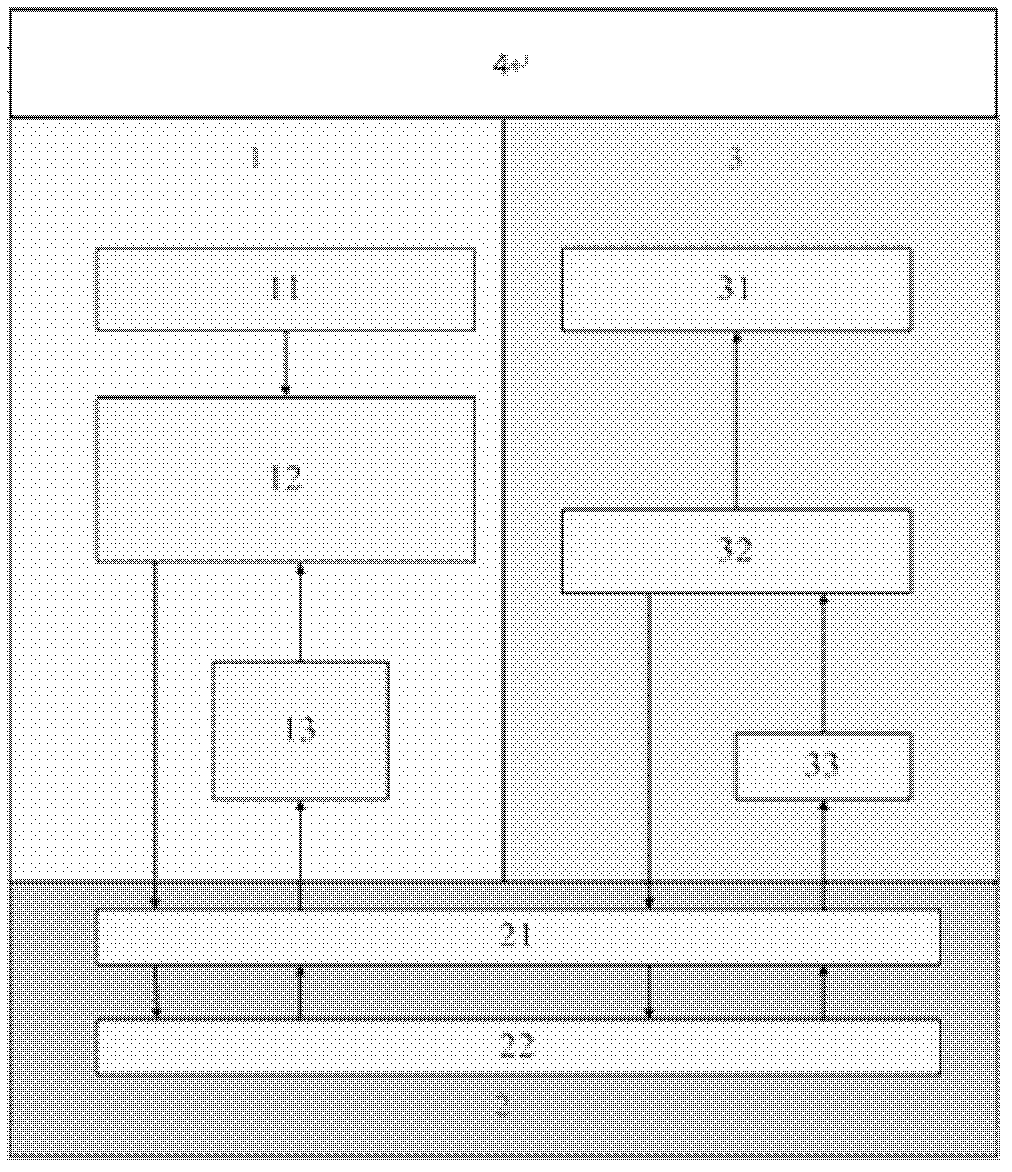

[0045] as attached figure 1 As shown, the logistics system specifically includes: the original cigarette packing area 1, the three-dimensional warehouse storage area 2, the box turning feeding area 3 and the logistics central control system 4. In order to reduce the logistics transportation path, the three-dimensional warehouse storage area is used as the turnover center of the logistics system, and the three units form an interrelated and organically connected whole.

[0046] Among them, the raw cigarette packing area includes a packing area 12 and an empty case buffer area 13, the main function of the packing area 12 is to pack materials, and the main function of the empty case buffer area 13 is to place empty cases. The empty case buffer area 13 stores the empty case after feeding from the unloading buffer station 32 to the feeding station 31, and the packing area 12 uses the empty case transported out from the empty case buffer area 13 and cleared by the RFID reader. Rack...

Embodiment 2

[0052] as attached figure 1 As shown, the logistics system of Example 1 operates independently in the packing area and the feeding area, and in the case of no direct feeding, regardless of whether the blade body and the handle are classified and processed, the process is as follows:

[0053] Solid box storage process: materials are boxed in the boxing area 12, and the tobacco leaves of the same variety are boxed separately, and the tobacco leaf information is recorded by RFID. The capacity of each box system is 6000 kg / hour. Each cigarette box stores 300 kg of tobacco leaves. The electronic belt scale without weighing frame and easy to maintain is selected for packing measurement. Each electronic belt scale is equipped with an independent control cabinet, and the frequency converter is placed in the cabinet. The display screen is installed on the belt scale control cabinet, the quantitative function data is input by the automatic control program of the process section, and th...

Embodiment 3

[0059] as attached figure 1 As shown, the logistics system of embodiment 1 is under the situation of direct feeding, regardless of whether the blade body and the handle are classified and processed, the flow process is as follows:

[0060] After the materials are packed in the boxing area 12, the information is entered into the logistics central control system 4 through the RFID reader, and the material boxes are transported to the outbound platform 21; the logistics central control system 4 enters the material boxes that need to be dampened into the dampening station 33 After regaining moisture, enter the discharge buffer station 32 according to the feeding order set by the logistics central control system. After the writer confirms the material, the material box on the unloading buffer station 32 is transported to the feeding station 31 for feeding.

[0061] Packing and feeding process: the solid boxes produced after boxing, including leaf body boxes, stem boxes, wrapping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com