pvb film and laminated glass

A technology of laminated glass and composition, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve problems such as easy agglomeration and poor mechanical properties of PVB films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] An embodiment of the present invention also provides a method for preparing the PVB film, which includes: heating and extruding the PVB composition at 140°C to 150°C.

[0032] Extrusion is a common method for preparing PVB films, and the uniform mixing of polyvinyl butyral with other film components is a key issue that limits the production of high-performance and high-quality PVB films by extrusion. The cross-linking agent system in the PVB composition of the embodiment of the present invention makes the PVB composition uniformly dispersed by dispersing the acid anhydride into the polyvinyl butyral more easily, strengthens the cross-linking of the polyvinyl butyral, and improves the preparation process of the PVB film. stability and crosslinking controllability and uniformity.

[0033] The embodiment of the present invention further provides a laminated glass, the intermediate film of the laminated glass includes the PVB film of the above-mentioned embodiment or the PV...

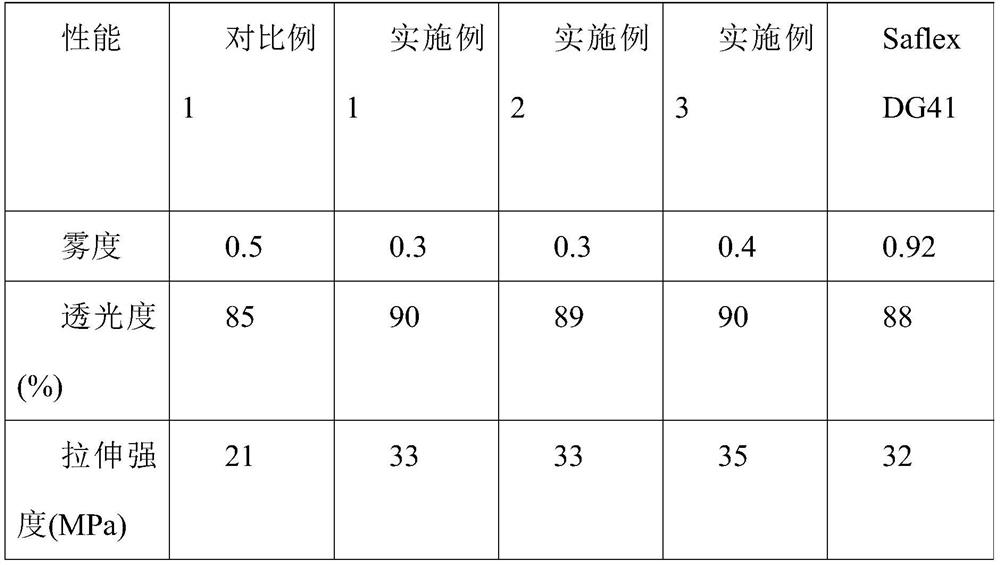

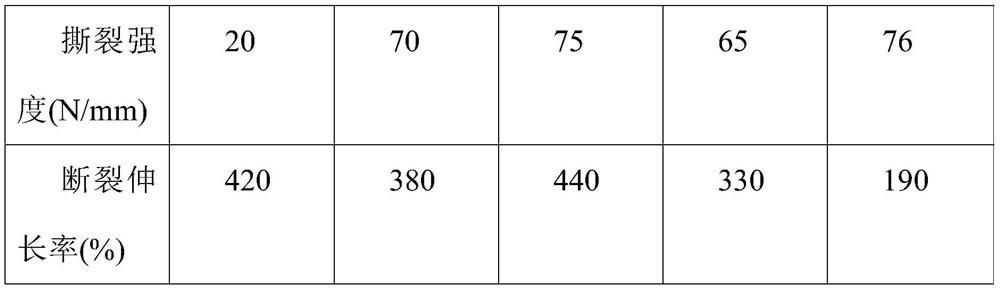

Embodiment 1

[0035] A mixture was obtained by blending 90 parts by weight of polyvinyl butyral resin with 8 parts by weight of 3GO, 25 parts by weight of crosslinking agent system, 0.26 parts by weight of antioxidant BHT and 0.13 parts by weight of UV326 agent. The cross-linking agent system is composed of 10% by mass of maleic anhydride, 50% of bis(2-ethylhexyl) phthalate and 40% of alkylphenol deoxyethylene ether. The mixture was mixed for 5 minutes using a mixing roll at a speed of 50 rpm and a set temperature of 130° C. to obtain a PVB composition. The PVB composition was extruded through an extruder to obtain a PVB film with a thickness of 0.76 mm. The PVB film can be used as a single-layer interlayer film for laminated glass.

Embodiment 2

[0037] A mixture was obtained by blending 90 parts by weight of polyvinyl butyral resin with 10 parts by weight of 3GO and 23 parts by weight of a crosslinking agent system, 0.26 parts by weight of antioxidant BHT and 0.13 parts by weight of UV326. The crosslinking agent system is composed of 5% by mass of maleic anhydride, 45% of dioctyl terephthalate and 55% of alkylsulfonate phenol. The mixture was mixed for 5 minutes using a mixing roll at a speed of 50 rpm and a set temperature of 130° C. to obtain a PVB composition. The PVB composition was extruded through an extruder to obtain a PVB film having a thickness of 0.76 mm. The PVB film can be used as a single-layer interlayer film for laminated glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com