Low-heat-conductivity thermal insulation material and preparation method and application thereof

A technology of thermal insulation materials and low thermal conductivity, applied in the field of thermal insulation materials, it can solve problems such as low density, achieve low thermal conductivity and density, excellent grinding effect, and improve the softening degree and internal void ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

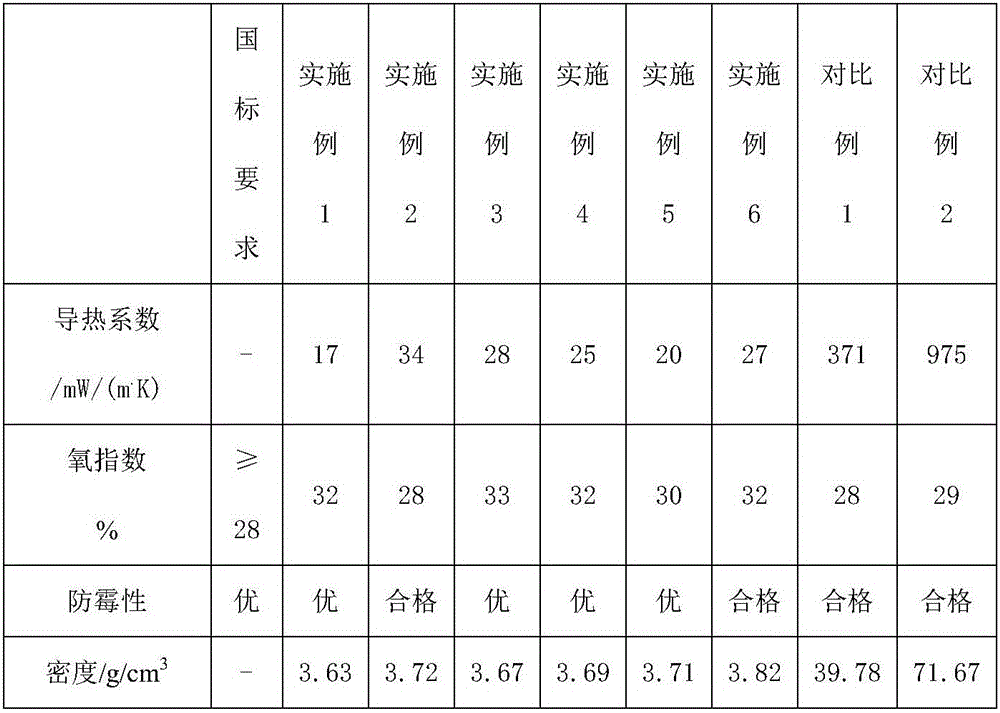

Embodiment 1

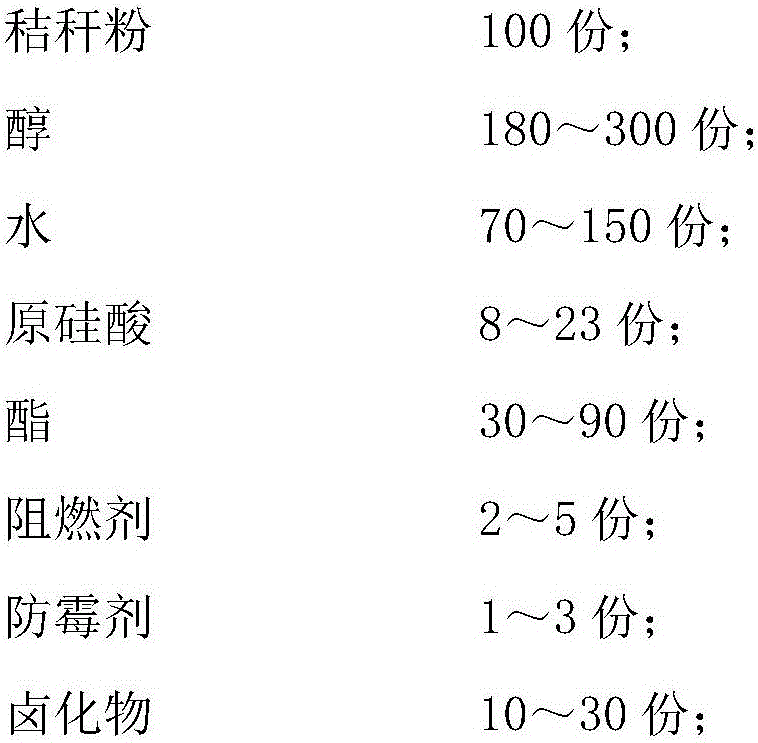

[0036] A kind of low thermal conductivity insulation material, its preparation method comprises the following steps:

[0037] (1) Add 100 parts of corn stalk powder, 230 parts of ethanol, 90 parts of water, and 50 parts of ethyl acetate into the reaction kettle, and react for 20 minutes at a reaction temperature of 27 ° C and a stirring speed of 95 r / min to obtain a mixture ;

[0038] (2), the mixed material is transferred to the freezer, and the temperature is controlled to be frozen at -45°C for 3 hours to obtain the frozen mixed material;

[0039] (3), put into ball mill after freezing mixture pulverization, cylinder rotating speed is 50r / min reaction 15min, crosses 8000 mesh sieves, obtains freezing mixture powder;

[0040] (4), 470 parts of frozen mixture powder, 12 parts of orthosilicic acid, 4 parts of ammonium polyphosphate (manufacturer: Yunnan Tianyao Chemical Co., Ltd., model: TY-1324), 3 parts of sodium benzoate, 21 parts of chloride Ammonium and 10 parts of ammo...

Embodiment 2

[0045] A kind of low thermal conductivity insulation material, its preparation method comprises the following steps:

[0046](1) Add 100 parts of wheat straw powder, 180 parts of isopropanol, 70 parts of water, and 30 parts of butyl acetate into the reaction kettle, and react for 10 minutes at a reaction temperature of 3°C and a stirring speed of 85r / min to obtain Mixture;

[0047] (2), the mixed material is transferred to the freezer, and the temperature is controlled to be frozen at -15°C for 5 hours to obtain the frozen mixed material;

[0048] (3), pulverize the frozen mixture and put it into a ball mill, the rotating speed of the cylinder is 37r / min and react for 20min, and pass through a 8000 mesh screen to obtain the frozen mixture powder;

[0049] (4) Add 380 parts of frozen mixture powder, 8 parts of orthosilicic acid, 2 parts of magnesium hydroxide, 1 part of sodium benzoate, 10 parts of hydrochloric acid, and 3 parts of potassium oxalate into the reaction kettle, a...

Embodiment 3

[0054] A kind of low thermal conductivity insulation material, its preparation method comprises the following steps:

[0055] (1), 100 parts of branch powder, 300 parts of ethanol, 150 parts of water, and 90 parts of ethyl acetate were added to the reaction kettle, and reacted for 10 minutes at a reaction temperature of 45 ° C and a stirring speed of 120 r / min to obtain a mixture;

[0056] (2), the mixed material is transferred to the freezer, and the temperature is controlled to be frozen at -80°C for 0.5h to obtain the frozen mixed material;

[0057] (3), put into ball mill after freezing mixture pulverization, cylinder rotating speed is 60r / min reaction 5min, crosses 8000 mesh sieves, obtains freezing mixture powder;

[0058] (4), 640 parts of frozen mixture powder, 23 parts of orthosilicic acid, 5 parts of magnesium hydroxide, 3 parts of sodium pentachlorophenate (manufacturer: Guangzhou Sanchang Chemical Co., Ltd.), 30 parts of ammonium chloride, 13 parts Add one part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com