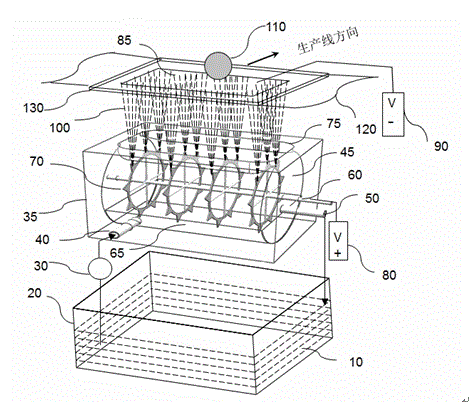

Saw tooth type needle-free electrostatic spinning device

An electrospinning, needle-free technology, applied in textiles and papermaking, spinneret assemblies, filament/thread forming, etc., can solve problems such as electrostatic interference, needle blockage, inconvenient cleaning, etc., to reduce impact and reduce electric energy Loss, the effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A rack with an isosceles triangle at the top of the teeth is used as the electrospinning unit, which is combined into a single rack helical electrospinning assembly (see figure 2 ) for needle-free multi-jet tip electrospinning. The spin pack was 30 cm long and 20 cm in diameter. The rotating speed of the spinning assembly is 5rev / min, the voltage is 20kV+2kV (the output voltage of the positive high-voltage power supply is 20kV, and the output voltage of the negative high-voltage power supply is 2kV), the receiving distance is 15cm, and the PVA nanometer with an average diameter of 115nm and CV=12% is obtained. Fiber film.

Embodiment 2

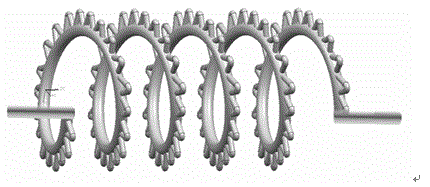

[0030] A rack with an isosceles triangle at the tooth top is bent into a circle with a diameter of 20 cm as the electrospinning unit, and combined into a serial circular rack electrospinning assembly (see Figure 5 ) for needle-free multi-jet electrospinning. The length of the spinning assembly is 30cm, the speed is 5rev / min, there are 5 circular rack spinning heads evenly distributed, the spinning voltage is 26kV, the receiving distance is 15cm, and the average diameter is 98nm, CV=10% PVA nano fiber.

Embodiment 3

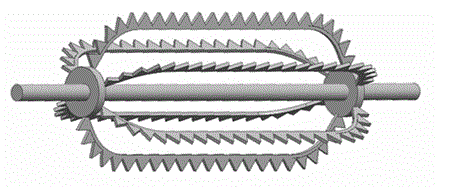

[0032] A rack with an isosceles triangular tooth top is used as the electrospinning unit, and a parallel multi-rack electrospinning assembly with a separated central axis is adopted (see Figure 4 ) for multi-jet electrospinning. The length of the spinning assembly is 30cm, and there are 6 metal racks on it, which are arranged parallel to each other and equidistant from the center line. The spinneret diameter was 20 cm. Two synchronous motors are used to drive the spinning assembly to rotate slowly at a speed of 5 rev / min. The voltage is 28kV, the receiving distance is 15cm, and the PVA nanofibers with an average diameter of 105nm and CV=9% are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com