Foaming agent injecting device of shoe sole foaming machine

A technology of injecting foaming agent and foaming shoe machine, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of difficulty in control, waste of foaming materials, affecting the quality of shoemaking, etc., so as to improve production efficiency and improve production efficiency. Production quality, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in conjunction with accompanying drawing and embodiment:

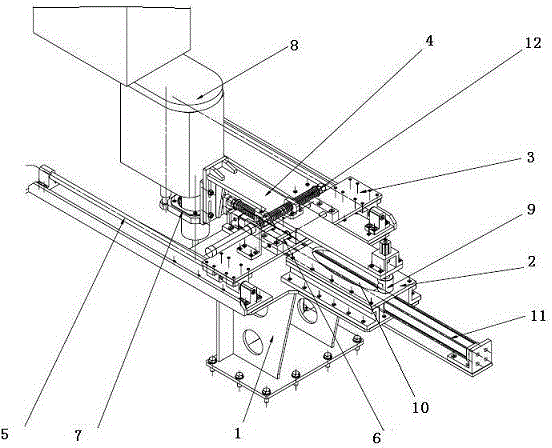

[0012] like figure 1 As shown, a foaming agent injection device for a foaming shoe machine, the foaming agent injection device includes a frame 1, a nozzle 8, a plate I3 and a plate II4 that drive the nozzle to move; the nozzle 8 is located at the nozzle on the fixing frame 7, and is located above the bottom mold of the shoe mold that needs to inject foaming agent into it; the nozzle fixing frame 7 is connected to the plate II4; the plate II4 is located at the bottom of the plate I3 The slide rail II6 is set vertically with the plate I3, the plate I3 is set parallel to the production line of the foam shoe machine, and the plate I3 is set on the slide rail I5 on the frame through the slider, so that the The plate I3 moves along the slide rail I5; corresponding to the plate I3 and the plate II4, there are drive mechanisms respectively, and the plate I3 is a structure that moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com