Non-combustible lithium metal battery electrolyte and preparation method thereof, lithium metal battery and preparation method thereof

A lithium metal battery, electrolyte technology, applied in the direction of cylindrical shell battery/battery, secondary battery manufacturing, electrolyte storage battery manufacturing, etc., can solve the problem that phosphate ester is not stable enough to lithium negative electrode, battery cycle stability is not good, lithium negative electrode Poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing an electrolyte for a non-flammable lithium metal battery described in the above technical solution, comprising the following steps: uniformly mixing a lithium salt and an organic solvent for the electrolyte to obtain an electrolyte for a non-flammable lithium metal battery.

[0035] In the present invention, the lithium salt and the organic solvent of the electrolyte are the same as those in the electrolyte of the non-combustible lithium metal battery described in the aforementioned technical solution, and will not be repeated here.

[0036] In the present invention, it is preferred to firstly mix diethyl ethyl phosphate and a hydrofluoroether solvent to obtain an organic solvent for an electrolyte; then mix a lithium salt with the organic solvent for an electrolyte to obtain an electrolyte for a non-flammable lithium metal battery. The present invention has no special requirements on the mixing method, as long a...

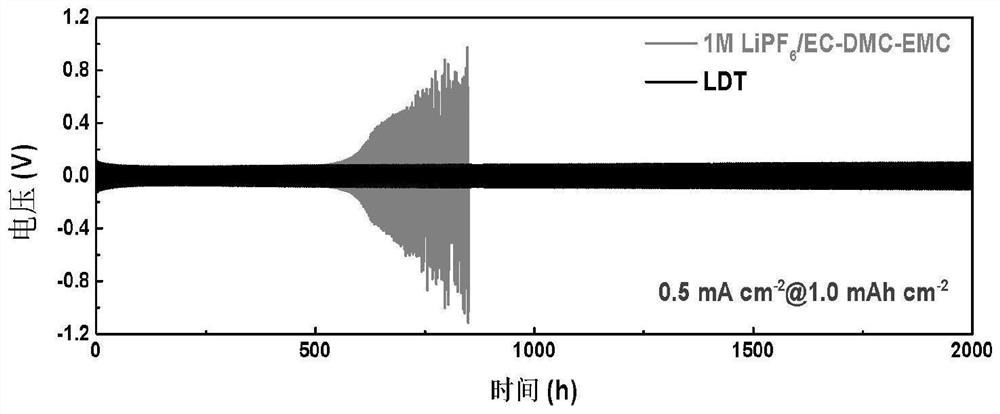

Embodiment 1

[0050] Preparation of electrolyte for non-flammable lithium metal batteries:

[0051] After mixing 2 mL of diethyl ethyl phosphate and 6.6 mL of 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether (the volume fraction of diethyl ethyl phosphate is 23 %, 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether volume fraction is 77%), add 1.61g lithium bisfluorosulfonyl imide (concentration is 1.0mol / L), obtain nonflammable lithium metal battery electrolyte (abbreviated as LDT).

[0052] Preparation of lithium metal batteries:

[0053] The lithium iron phosphate positive electrode, separator and lithium metal negative electrode are sequentially arranged to obtain the battery matrix;

[0054] A non-flammable lithium metal battery electrolyte is injected between the positive electrode and the negative electrode of the battery matrix, and the button battery is obtained by packaging.

Embodiment 2

[0056] Preparation of electrolyte for non-flammable lithium metal batteries:

[0057] After mixing 2ml diethyl ethyl phosphate and 5.8ml 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether evenly (wherein the volume fraction of diethyl ethyl phosphate is 26%, 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether volume fraction is 74%), add 1.60g bis(fluorosulfonyl)imide lithium (concentration is 1.1mol / L), obtain non-flammable lithium metal battery electrolyte.

[0058] Preparation of lithium metal batteries:

[0059] The lithium iron phosphate positive electrode, separator and lithium metal negative electrode are sequentially arranged to obtain the battery matrix;

[0060] A non-flammable lithium metal battery electrolyte is injected between the positive electrode and the negative electrode of the battery matrix, and the button battery is obtained by packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com