Pultrusion process and pultrusion device of phenolic resin composite

A technology of pultrusion and composite materials, which is applied in the field of phenolic resin composite material pultrusion molding process and its forming device, which can solve the problem of non-uniform dipping, small molecule volatile substances, complicated dipping process, and no phenolic resin and other problems, to achieve the effect of improving the uniformity of dipping, simple process and dense material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

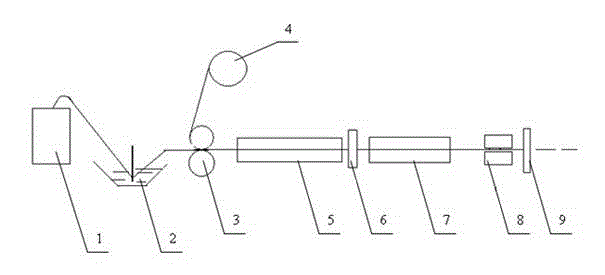

[0018] Such as figure 1 As shown, a phenolic resin composite material pultrusion molding device of the present invention includes a frame and a pultrusion machine arranged horizontally from front to back, and a yarn release frame is arranged in front of the frame, and a yarn release device 1 is installed on it. ; The frame is sequentially installed with passive double rollers 3, drying device 5, and preformed template 6 from front to back; dipping tank 2 is placed on the front end of the frame; The side is fixedly connected to the bracket, and a felt device 4 is installed on the bracket; the mold 7 is installed on the pultrusion machine, and the traction device 8 is the equipment that the pultrusion machine comes with, and the traction device 8 is driven by a motor; cutting device 9;

[0019] The felting device 4 is located above the passive double rollers 3; the end of the fiber reinforced material released by the yarn releasing device 1 is impregnated with the phenolic resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com