Core-shell structure catalyst, preparation method thereof and membrane electrode containing catalyst

A core-shell structure, catalyst technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of poor durability and less investigation of catalyst electrochemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

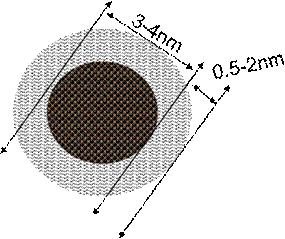

[0042] The embodiment of the present invention also provides a preparation method of a core-shell structure catalyst, which includes the following steps:

[0043] a. Add NaNO to the aqueous solution containing Ir ions 3 and NH 4 HCO 3 , stirred, evaporated, and then roasted to obtain IrO 2 kernel;

[0044] Preferably, the concentration of Ir ions in the aqueous solution containing Ir ions is 0.01-0.05mol / L, and the Ir ions: NaNO 3 :NH 4 HCO 3 The molar ratio is 1:20-40:1-20, the temperature of the roasting is 400-450°C, and the heating rate is 1-10°C / min;

[0045] B, the IrO that described step a makes 2 The inner core is added to the alkali solution containing Ir ions, stirred, and reacted;

[0046] Preferably, in the alkaline solution containing Ir ions, the concentration of Ir ions is not more than 5mmol / L, the alkaline solution is KOH or NaOH, adding IrO 2 After the core, in solution Ir:IrO 2 The molar ratio is 0.3-0.5, the reaction temperature is 60-90°C, and th...

Embodiment 1

[0059] (1) Take 4.5g H 2 IrCl 6 The solution (containing iridium 35wt%) was dissolved in 300ml of high-purity water, heated and stirred at 80 degrees for 30min, the Ir ion concentration in the solution was 0.027mol / L, and then 20gNaNO 3 and 3.25gNH 4 HCO 3 , namely Ir ion: NaNO 3 :NH 4 HCO 3 The molar ratio is 1:29:5. After stirring for 1 h, the solution is evaporated to dryness to obtain a powder sample, which is roasted at 450 °C for 1 h at a heating rate of 5 °C / min. The powder sample is ground, washed, centrifuged, and dried at 90 °C. Dry for 12h to get IrO 2 kernel;

[0060] (2) take 2gH 2 IrCl 6 The solution (35wt% iridium) was dissolved in 1000ml of 0.5mol / L NaOH alkali solution, the temperature was controlled at 80 °C, the pH was controlled at 13, the Ir ion concentration in the solution was 0.004mmol / L, mechanically stirred for 30min, and ultrasonic treatment, the ultrasonic power is 480W, and an alkaline solution containing Ir ions is obtained, and 2g of Ir...

Embodiment 2

[0069] The method is the same as that of Example 1, except that step (3) is to add 0.5 mol / L HCl solution dropwise to the reaction solution in step (2).

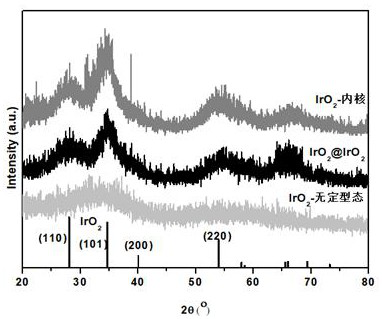

[0070] The catalyst inner core IrO that this embodiment makes 2 The specific surface area is 219m 2 / g, the grain size is 3.2-3.3nm; the shell layer thickness is 1.3-1.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com