LED integrated light source board and manufacturing method thereof

A technology of LED light source and manufacturing method, which is applied in the direction of light source fixing, lighting device, lighting device cooling/heating device, etc., can solve the problems of the accuracy of lens light distribution, inconsistent optical center, expensive materials, etc., to avoid all Reflection phenomenon, simple manufacturing process, and the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] like Figure 6 ~ Figure 8As shown, the LED integrated light source board of this embodiment is a flat LED integrated light source board without a lens that can simultaneously produce multiple units and can be directly connected to 220V AC mains, including a thermally conductive insulating substrate 1, six interconnected Independent and unrelated LED light source units 30, the LED light source unit 30 includes 24 LED modules 31 connected in series, and each LED module 31 is composed of four LED chips 3 connected in series. The LED module 31 can also be composed of a single LED chip 3 alone. The thermally conductive insulating substrate 1 is a metal aluminum substrate. Of course, other metal substrates such as copper substrates can also be used. The upper surface of the metal substrate is provided with a thermally conductive insulating layer. 10. The surface of the thermally conductive insulating substrate 1 is laid with a circuit connection 21 and a heat dissipation foil...

Embodiment 2

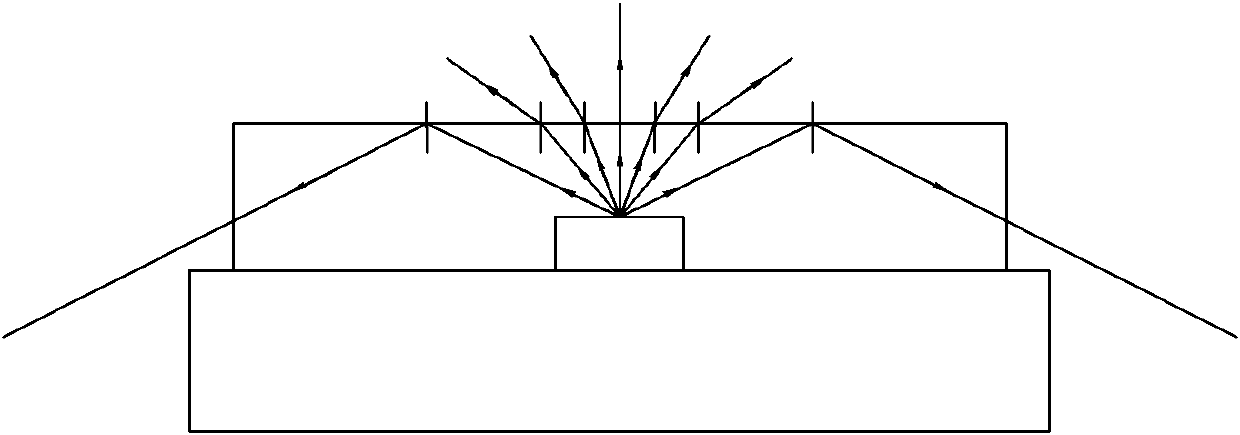

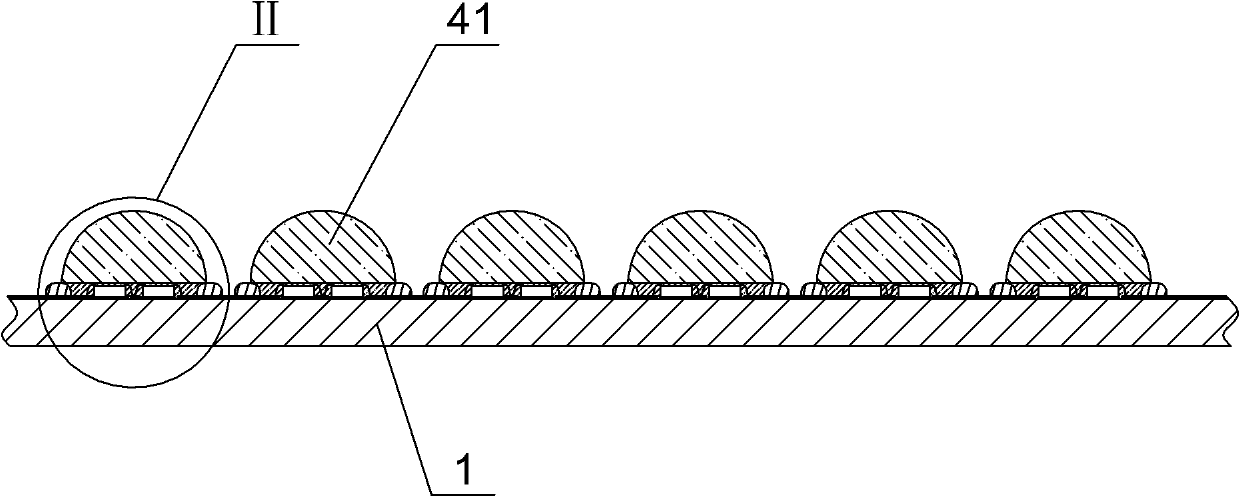

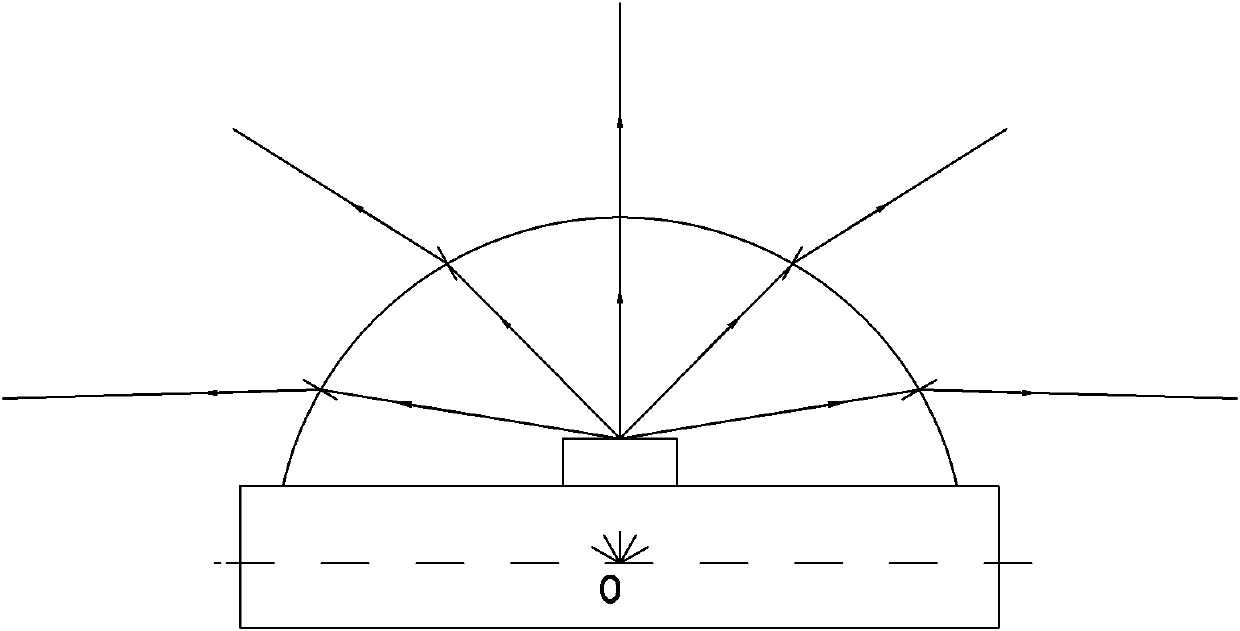

[0044] like Figure 9 , Figure 10 As shown, the difference between the LED integrated light source board of this embodiment and Embodiment 1 is that: in this embodiment, the thermally conductive and insulating substrate 1 is Al 2 o 3 Or AlN and other ceramic substrates, so the surface of the ceramic substrate does not need to be provided with a thermally conductive insulating layer; each of the LED modules 31 is covered with a spherical lens 41 in the light emitting direction, and the spherical lens 41 is cured by dispensing. Formed, the focal point of the spherical lens 41 is located in the same plane as the light emitting surface of the LED module 31, as image 3 As shown, at this time, the light emitted by the LED chip can be effectively emitted, and there will be no total reflection phenomenon. Under the same conditions, the light output rate can be increased by 5-20% compared with Embodiment 1. It is a light distribution design of a large-angle lens. When the luminous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com