Silicon nanometer wire-conductive polymer compound as well as preparation method and application thereof

A technology of conductive polymers and silicon nanowires, which is applied in the direction of silicon compounds, chemical instruments and methods, electrolysis processes, etc., can solve problems such as side reactions, increased molecular impedance, and difficult control of modification reactions, and achieve mild reaction conditions. The effect of high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

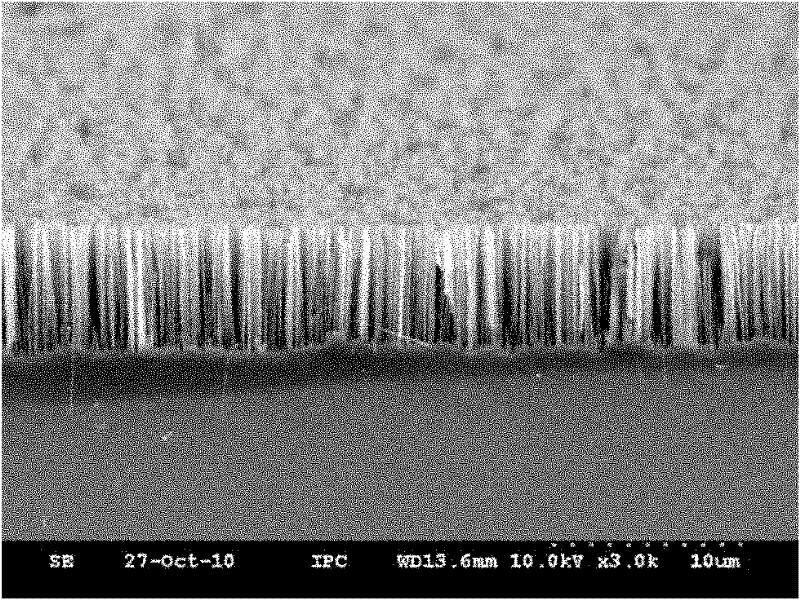

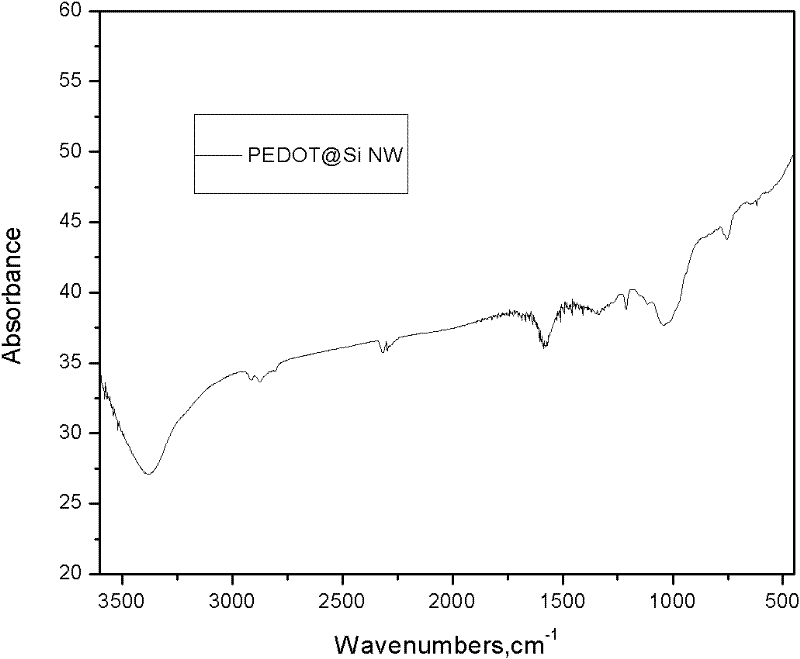

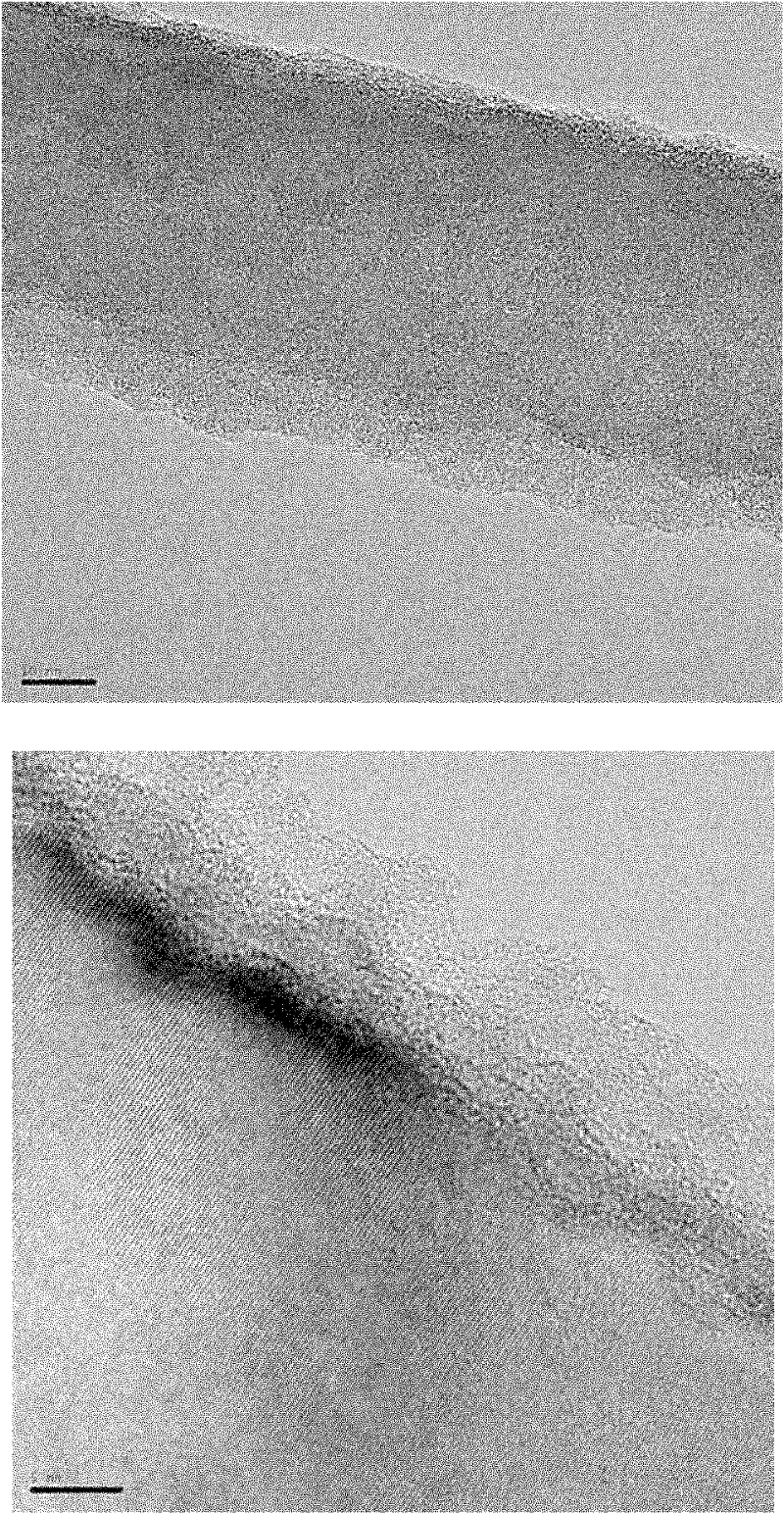

[0033] Example 1. Preparation of silicon nanowire-PEDOT composite and its iodine-doped composite

[0034] In situ polymerization of conductive polymer PEDOT on the surface of silicon nanowire array structure.

[0035]The reaction raw material is 3,4-ethylenedioxythiophene (EDOT, 3,4-ethylenedioxythiophene), and the reaction equation is as follows:

[0036]

[0037] The specific synthesis method is as follows:

[0038] Weigh 0.1173g of EDOT (0.0075M), LiClO 4 11.3g (1.0M), dissolved in 110ml of deionized water, ultrasonicated for 15 minutes to disperse EDOT, and argon gas was used for 30 minutes to remove oxygen in the solution. A three-electrode system was used. The working electrode was a silicon wafer with a silicon wire array after etching. , the counter electrode is Pt sheet (2x2cm 2 ), and the reference electrode was a saturated calomel electrode (SCE). Cyclic voltammetry was used during polymerization, the scanning potential range was: -1.0-1.2 V, and the scannin...

Embodiment 2

[0046] Example 2. Preparation of silicon nanowire-PEDOT composite and its iodine-doped composite

[0047] The composite of silicon nanowire-PEDOT was prepared according to the method in Example 1, except that the scanning rate during polymerization in this example was 0.3 v / s.

[0048] Doping the prepared silicon nanowire-PEDOT composite with iodine elemental substance and depositing co-catalyst titanium bronze on the surface of the iodine-doped PEDOT film are the same as those in Example 1.

[0049] The electrochemical performance test of photocatalytic hydrogen production was carried out on the sample silicon nanowire-iodine-doped PEDOT-CuPc. The test method is the same as Example 1, and the results are shown in Figure 5 .

Embodiment 3

[0051] Example 3. Preparation of silicon nanowire-PEDOT composite and its iodine-doped composite

[0052] The composite of silicon nanowire-PEDOT was prepared according to the method in Example 1, except that the scanning rate during polymerization was 0.4 v / s in this example.

[0053] Doping the prepared silicon nanowire-PEDOT composite with iodine elemental substance and depositing co-catalyst titanium bronze on the surface of the iodine-doped PEDOT film are the same as those in Example 1.

[0054] The electrochemical performance test of photocatalytic hydrogen production was carried out on the sample silicon nanowire-iodine-doped PEDOT-CuPc. The test method is the same as Example 1, and the results are shown in Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com