Preparation method of hollow oxide microspheres

An oxide and microsphere technology, applied in chemical instruments and methods, titanium oxide/hydroxide, zirconium oxide, etc., can solve the problems of difficult to control the thickness of the shell layer, reduce the number of homogeneous nucleation, etc., to reduce the number of , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

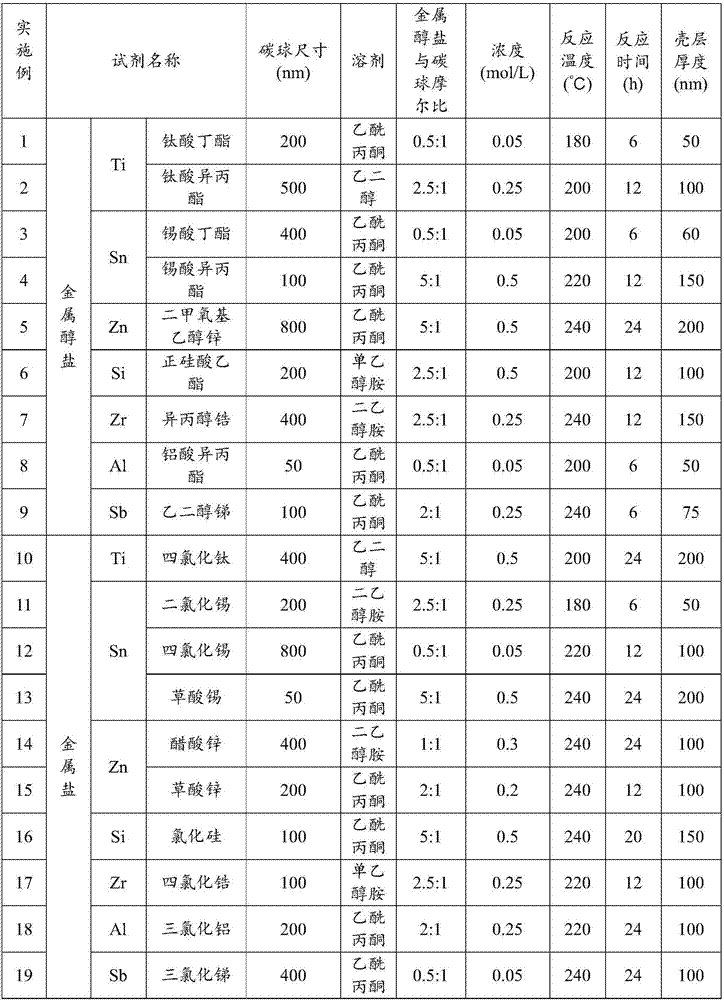

Examples

Embodiment 1

[0022] Embodiment 1 Titanium dioxide hollow microspheres——metal alkoxide

[0023] (1) Take 0.1g of carbon spheres with a size of 200nm, add deionized water at a mass ratio of 1:1, make the surface of the carbon spheres absorb water, and disperse the carbon spheres that have absorbed water in 20ml of acetylacetone;

[0024] (2) Take 1.5g of tetrabutyl titanate and add it to the above carbon sphere template suspension under high-speed stirring. The molar ratio of tetrabutyl titanate to carbon spheres is 0.5:1. Add acetylacetone to make titanate The concentration of tetrabutyl ester is 0.05mol / l, stirring and reacting for 2h;

[0025] (3) Transfer the solution obtained in step (2) into an autoclave, and conduct a hydrothermal reaction at 180° C. for 6 hours;

[0026] (4) Washing: absolute ethanol washing / centrifugation, repeated 2 to 4 times, to obtain C / oxide microspheres with a core-shell structure;

[0027] (5) The C / oxide microspheres were dried in air, and then heat-treate...

Embodiment 2

[0029] Embodiment 2 Titanium dioxide hollow microspheres——metal alkoxide

[0030] (1) Take 0.05g of carbon spheres with a size of 500nm, add deionized water at a mass ratio of 1:1, make the surface of the carbon spheres absorb water, and disperse the carbon spheres that have absorbed water in 20ml of ethylene glycol;

[0031] (2) Take 3g of isopropyl titanate and add it to the above carbon sphere template suspension under high-speed stirring. The molar ratio of isopropyl titanate to carbon spheres is 2.5:1, add ethylene glycol to make titanate The concentration of isopropyl ester is 0.25mol / l, stirring and reacting for 2h;

[0032] (3) Transfer the solution obtained in step (2) into an autoclave, and perform a hydrothermal reaction at 200° C. for 12 hours;

[0033] (4) Washing: absolute ethanol washing / centrifugation, repeated 2 to 4 times, to obtain C / oxide microspheres with a core-shell structure;

[0034] (5) The C / oxide microspheres were dried in air, and then heat-treat...

Embodiment 3 2

[0036] Embodiment 3 Tin dioxide hollow microspheres——metal alkoxide

[0037] (1) Take 0.1g of carbon spheres with a size of 400nm, add deionized water at a mass ratio of 1:1, make the surface of the carbon spheres absorb water, and disperse the carbon spheres that have absorbed water in 20ml of acetylacetone;

[0038] (2) Take 1.5g butyl stannate and add it to the above carbon sphere template suspension under high-speed stirring. The molar ratio of butyl stannate to carbon spheres is 0.5:1. Add acetylacetone to make butyl stannate Concentration of 0.05mol / l, stirring reaction 2h;

[0039] (3) Transfer the solution obtained in step (2) into an autoclave, and conduct a hydrothermal reaction at 200° C. for 6 hours;

[0040] (4) Washing: absolute ethanol washing / centrifugation, repeated 2 to 4 times, to obtain C / oxide microspheres with a core-shell structure;

[0041] (5) The C / oxide microspheres were dried in air, and then heat-treated at 450° C. for 2 h to obtain hollow oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com