Patents

Literature

45results about How to "Improve blowback effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

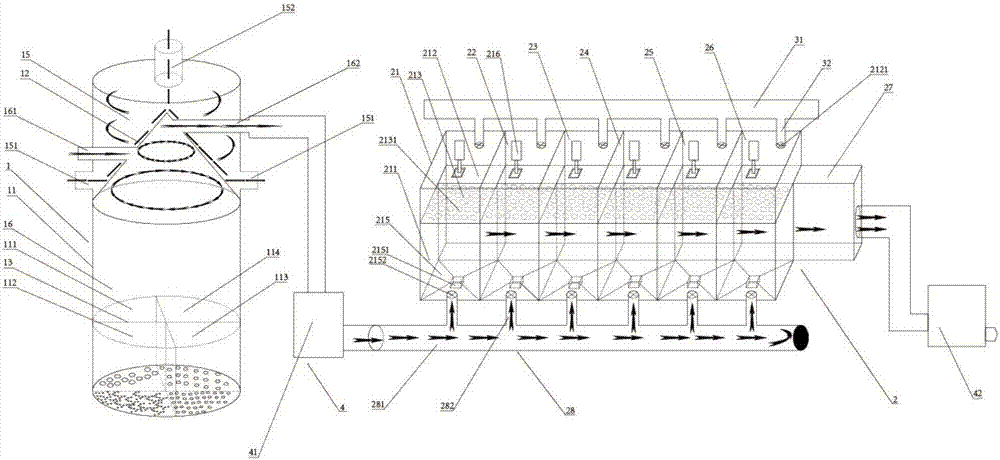

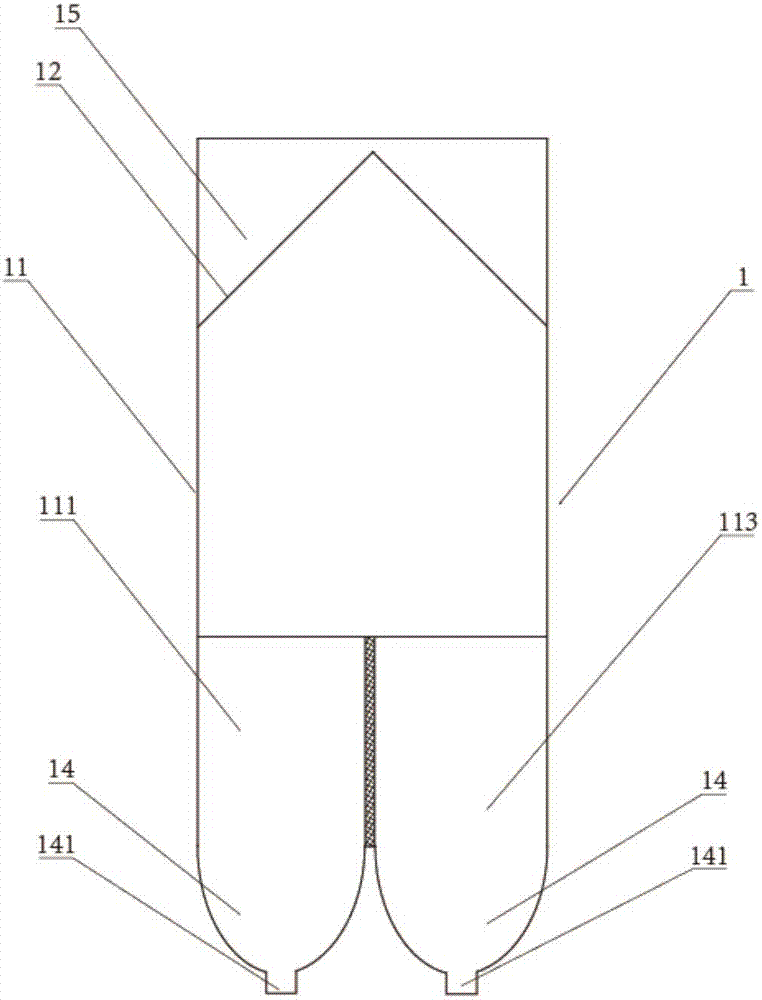

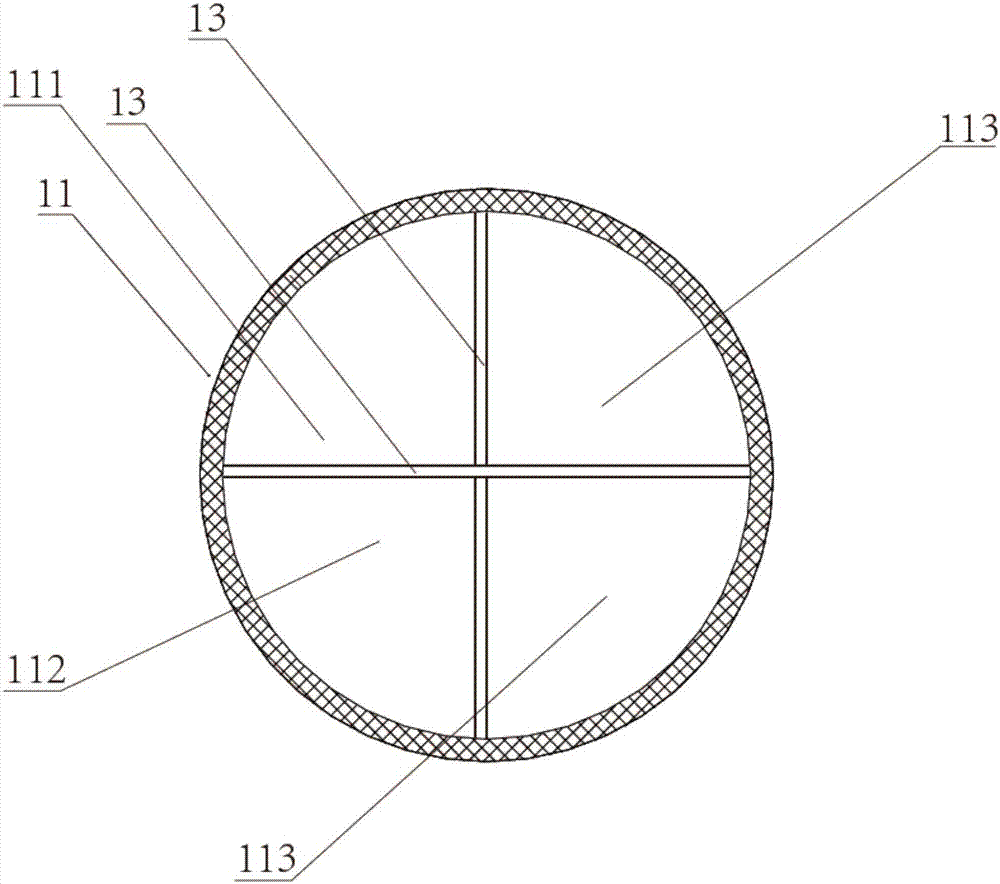

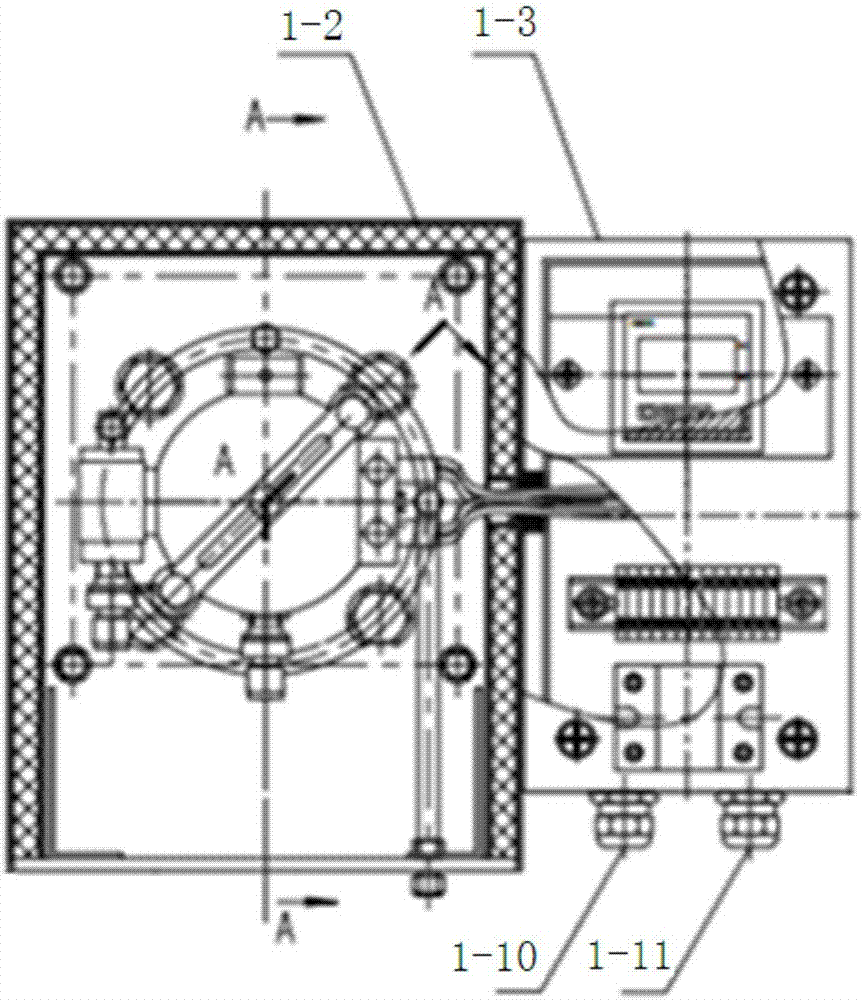

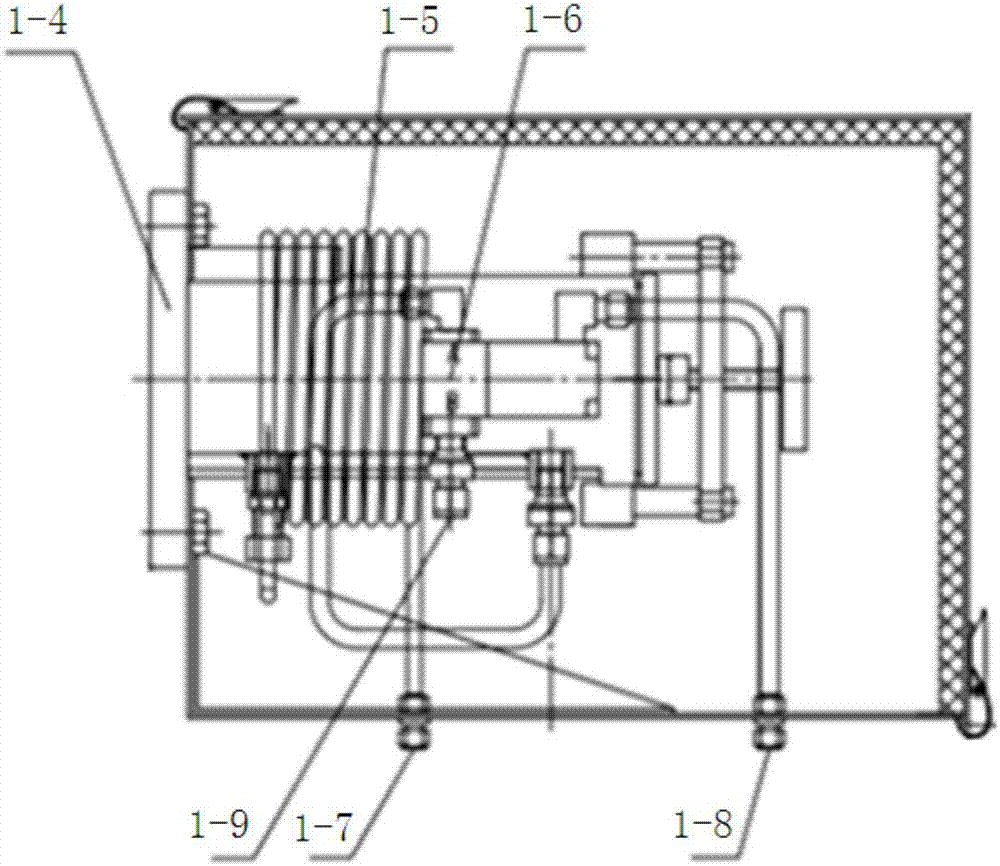

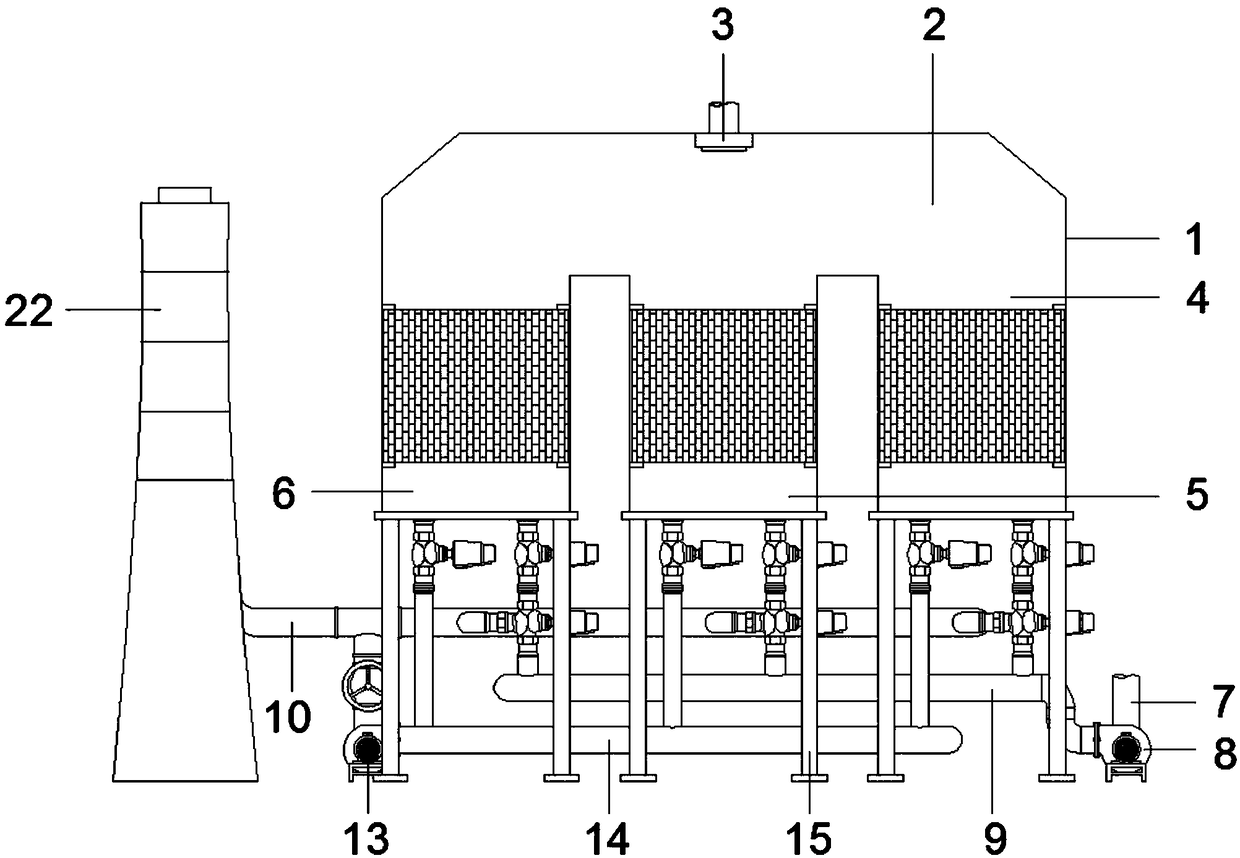

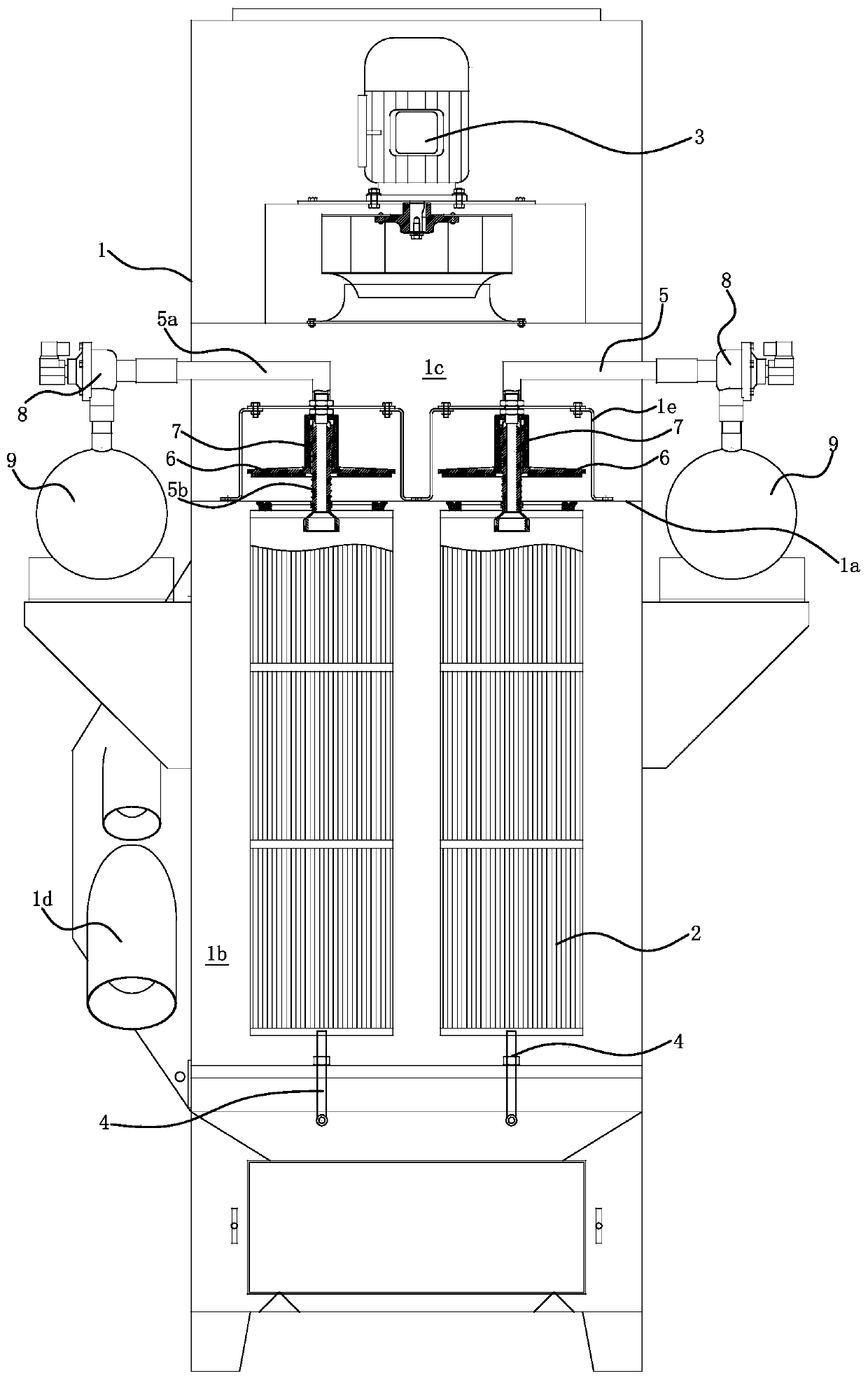

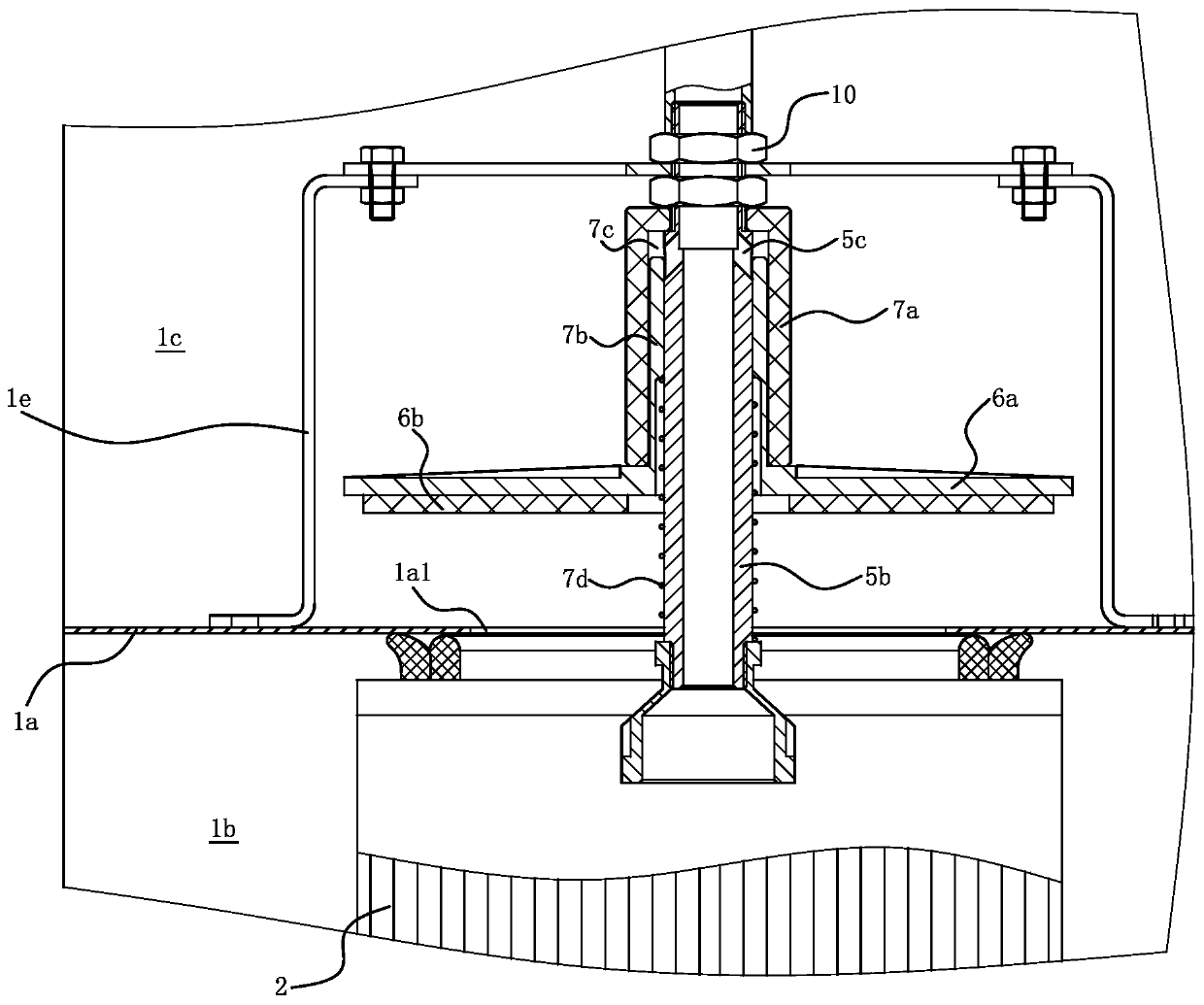

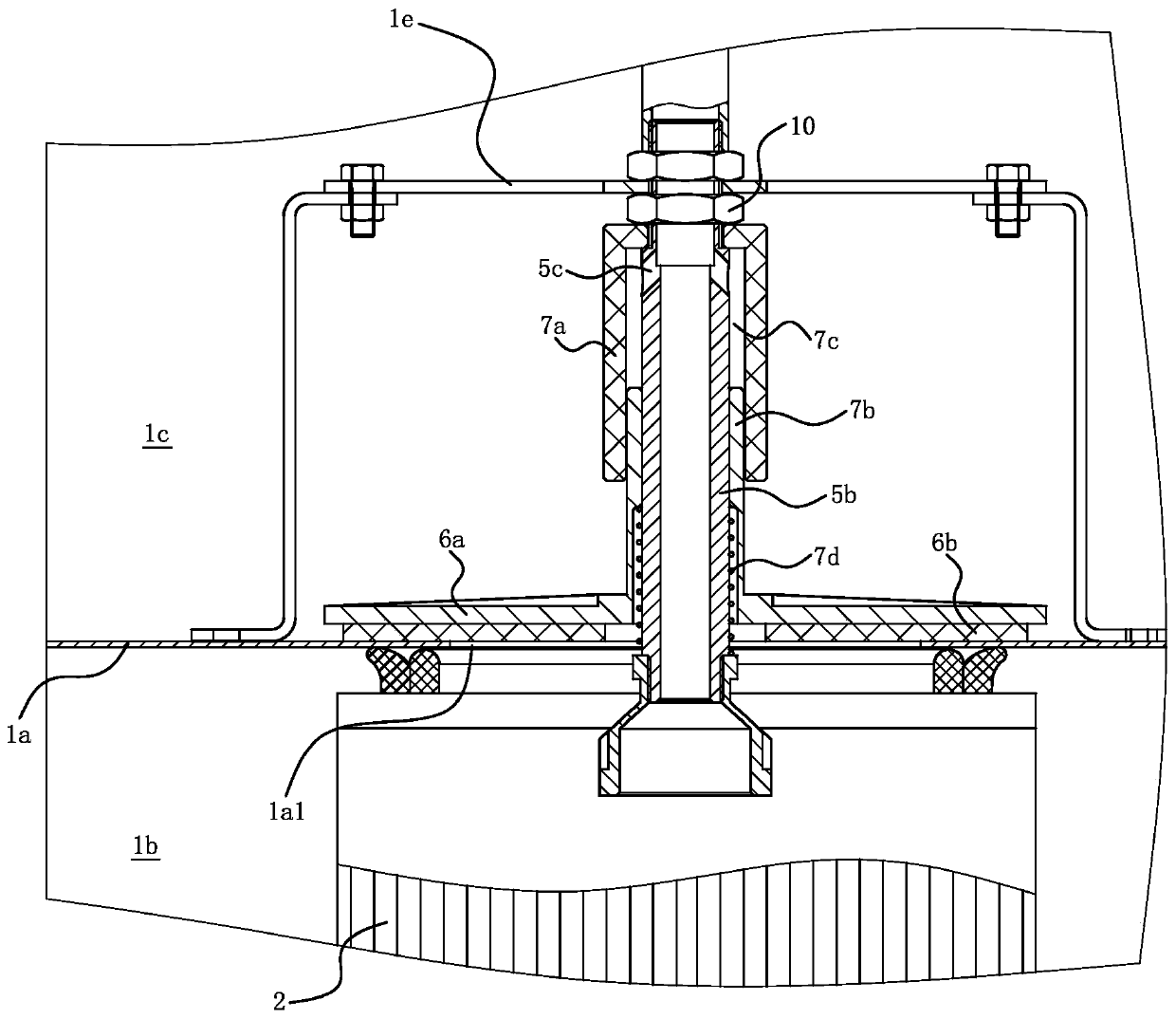

Pulsed type bag dedusting device

PendingCN107297107AImprove efficiency and effectivenessAchieving Recoil JitterDispersed particle filtrationTransportation and packagingEngineeringInlet channel

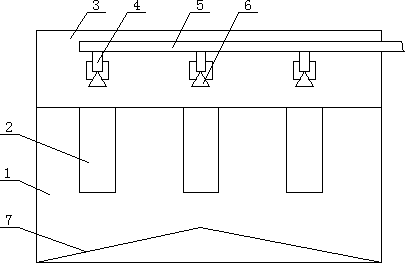

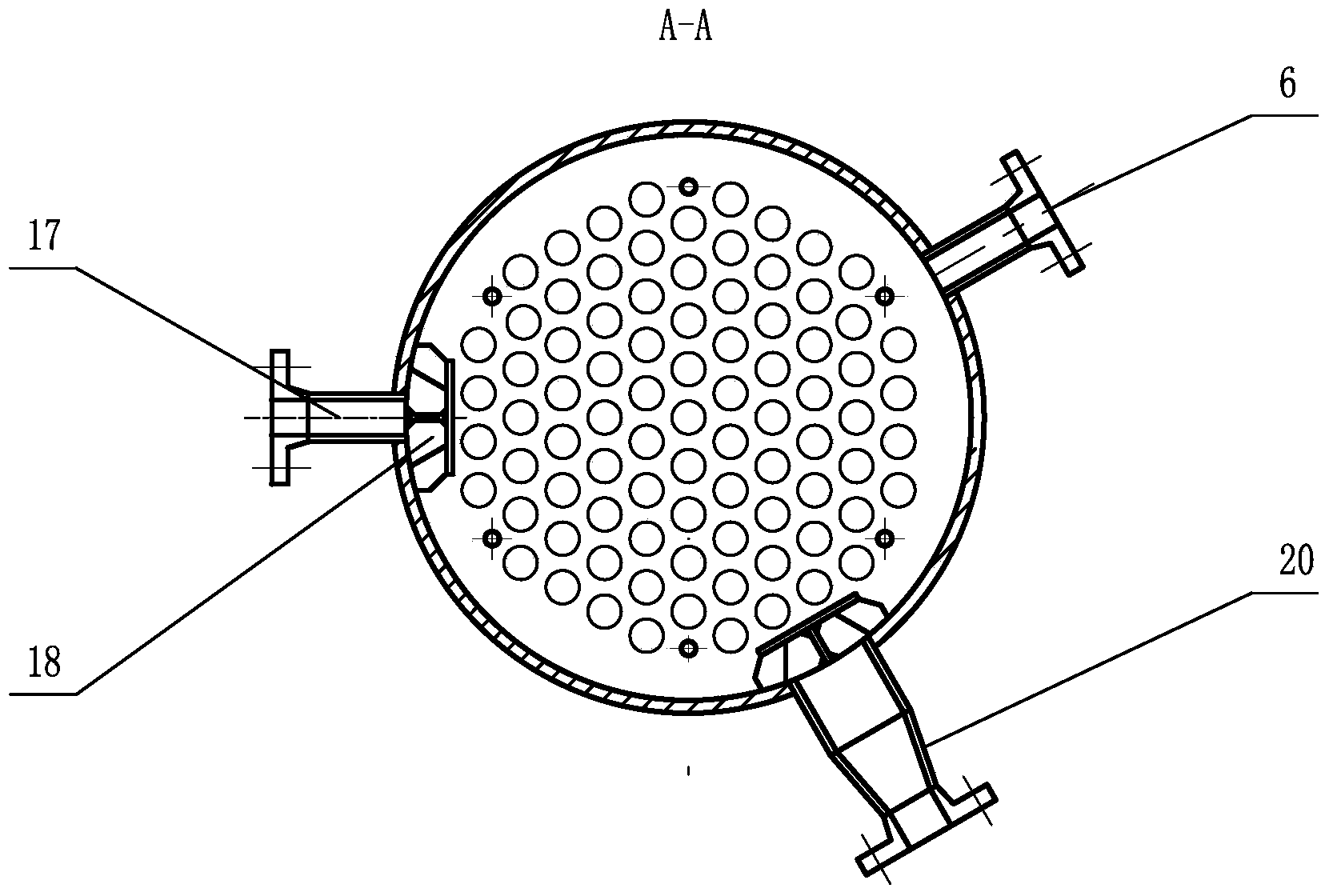

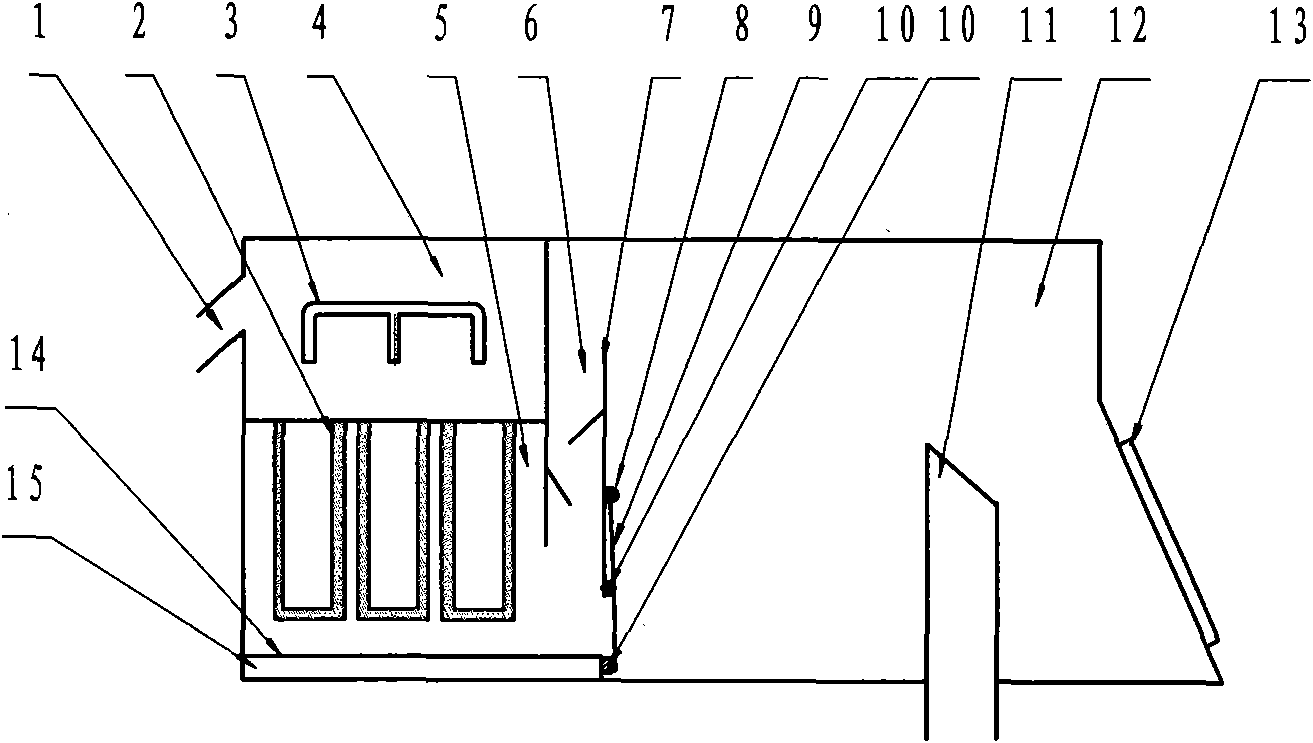

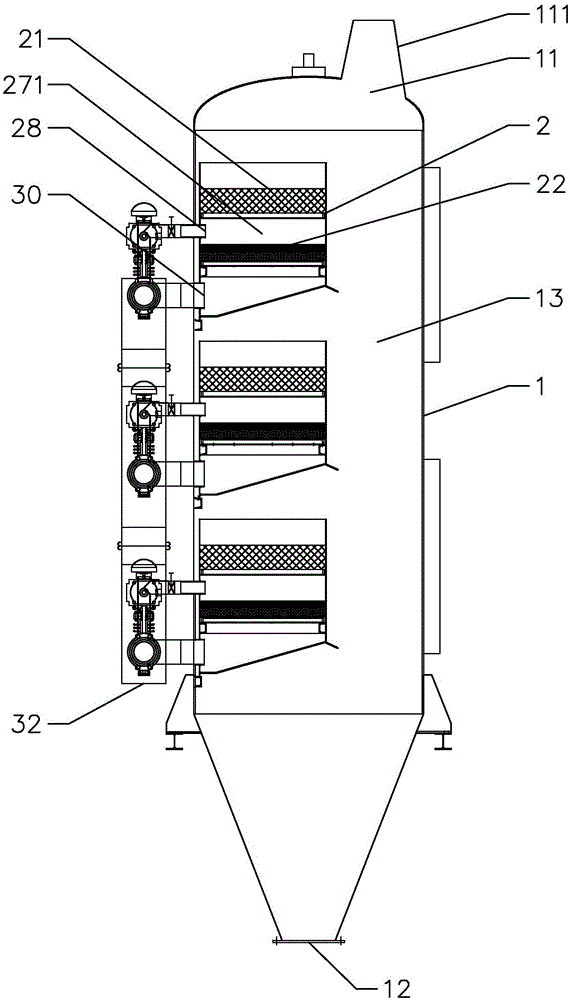

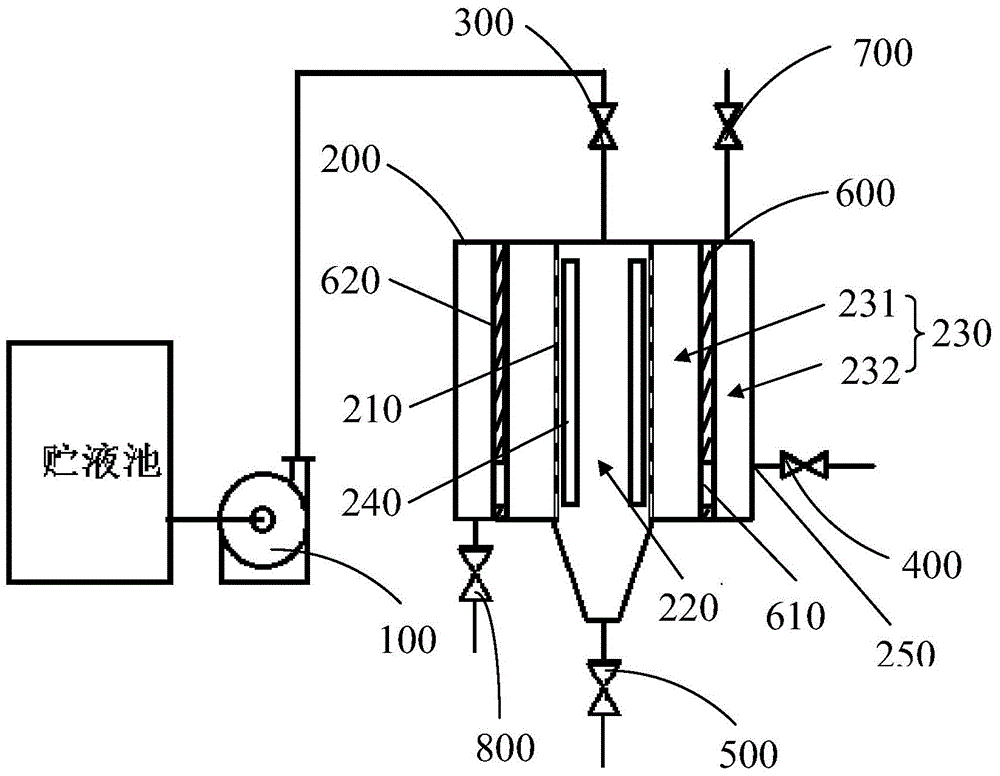

The invention discloses a pulsed type bag dedusting device which comprises a box combined type bag dust collector, a pulse airflow back-flushing cooling device and a second draught fan, wherein the pulse airflow back-flushing cooling device is arranged on the box combined type bag dust collector; the second draught fan is used for forming negative pressure suction in the pulse airflow back-flushing cooling device; the box combined type bag dust collector comprises at least two dedusting boxes, an exhausting channel, an air inlet channel and a dust collecting device; the dedusting boxes are successively arrayed from left to right; each dedusting box comprises a lower dust filtering chamber, an upper sealing air chamber, a sealing pattern plate, a cloth bag, a dust collecting hopper and a lifting valve device; the sealing pattern plate with a plurality of through holes is arranged between the lower dust filtering chamber and the upper sealing air chamber; the cloth bag is arranged on the position corresponding to the through holes on the sealing pattern plate; and an air inlet port of a second high temperature draught fan is communicated with an air outlet of the exhausting channel. The pulsed type bag dedusting device has the characteristics of reasonable structure design, complete function, high dedusting efficiency, safety, reliability, long service life and ultrahigh marketing value.

Owner:广东盛达穗南环保科技有限公司

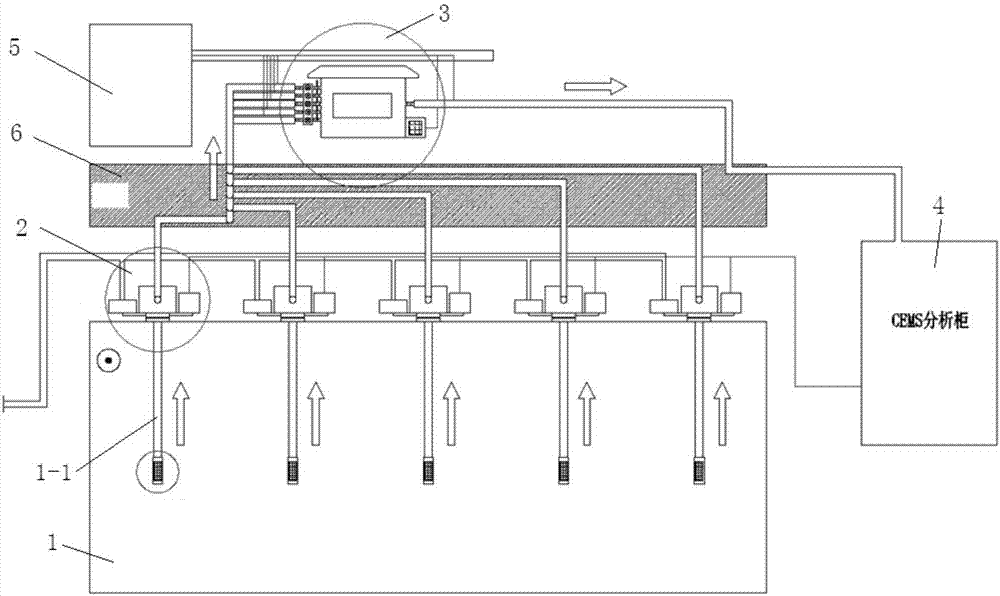

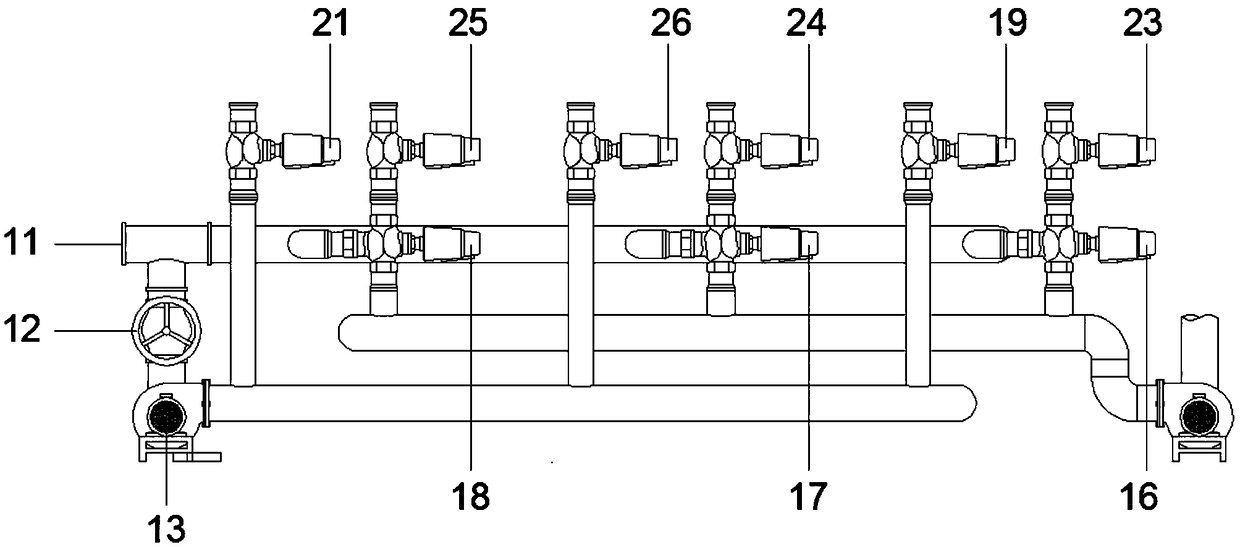

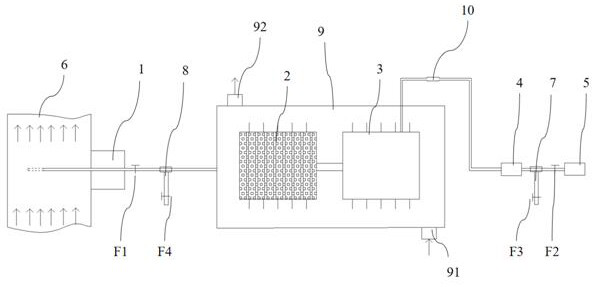

Gaseous pollutant multi-point matrix mixed sampling device, sampling method thereof and reverse blowing maintenance method

ActiveCN107421790ASolve the problem of unrepresentative samplingMixed average concentration is reasonableWithdrawing sample devicesAir quality improvementFlue gasFiltration

The invention discloses a gaseous pollutant multi-point matrix mixed sampling device, a sampling method thereof and a reverse blowing maintenance method. The device comprises a flue gas duct, a plurality of high-temperature sampling probes are uniformly arranged on the outer side of the pipe wall of the flue gas duct along the same section of a pipe, gaseous pollutants are conveyed into a rear-end mixing box by a 180-DEG C high-temperature heat tracing pipe, mixed and then conveyed into an analysis cabinet. The sampling device solves the problems that single-point flue gas sampling is non-representative, a sampling section of an existing sampling device is blocked by dust, and sampling of a sampling end does not meet standards. According to the whole multi-point matrix mixed sampling device, each probe is individually filtered, two-stage filtration is performed, namely, a front feeler lever is provided with a sintered metal filtering screen, middle high-temperature sampling probes are provided with sintered ceramic filter elements, and dust in flue gas is further prevented from entering the pipe.

Owner:NANJING YOUZHI TECH CO LTD

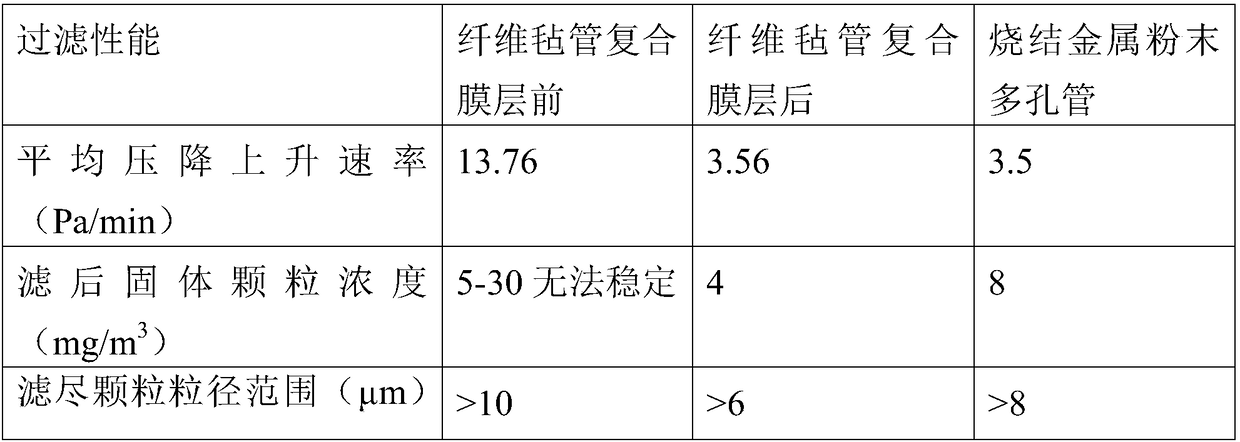

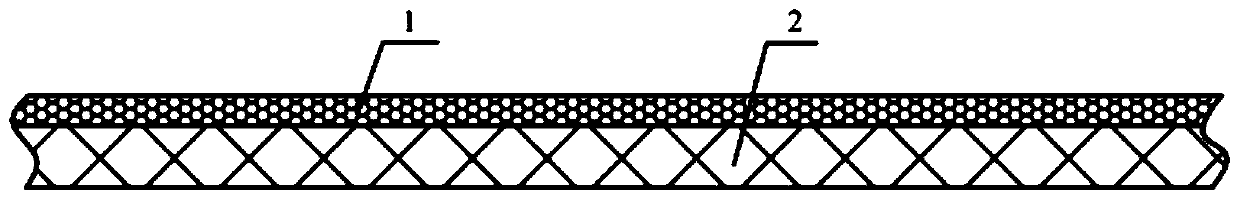

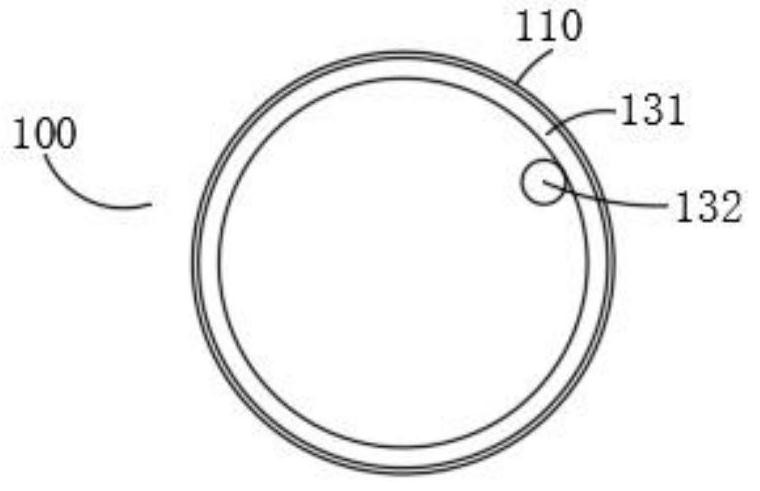

Low-resistance-drop filtering material and preparation method thereof

PendingCN108079666AImprove blowback effectMake up for the disadvantage of poor blowback performanceMembrane filtersFiltration separationFilter materialFlue gas

The invention relates to a low-resistance-drop filtering material and a preparation method thereof, and belongs to the technical field of high temperature flue gas, porous materials and high-flux filtering materials. The material is formed by compounding a metal fibrofelt base material and a metal powder film layer attached to the surface of the metal fibrofelt base material; and the metal powderfilm layer comprises the following raw materials: a Fe-Al series intermetallic compound and / or a NiCrAlFe intermetallic compound. The preparation method of the material comprises the following steps:firstly, mixing the intermetallic compound powder with a glue solution, and fully stirring to obtain metal powder suspension liquid; secondly, spraying the surface with high filtering precision of themetal fibrofelt base material with the metal powder suspension liquid to obtain a sprayed material; and finally, drying the sprayed material and then carrying out sintering treatment to obtain the low-resistance-drop filtering material finally. By the material, the problems that flux is low, resistance drop is high, high temperature resistance and sulfur attack resistance are poor, and the structural mode is single are solved, the thickness of a spraying layer and the filtering precision are controllable, and the cost is low.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD +1

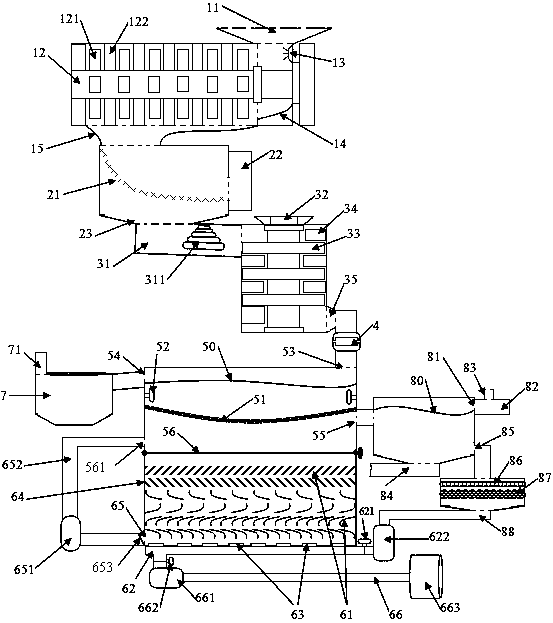

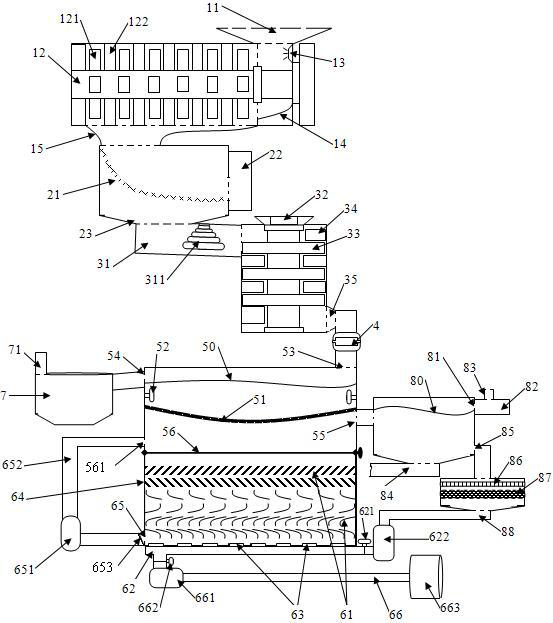

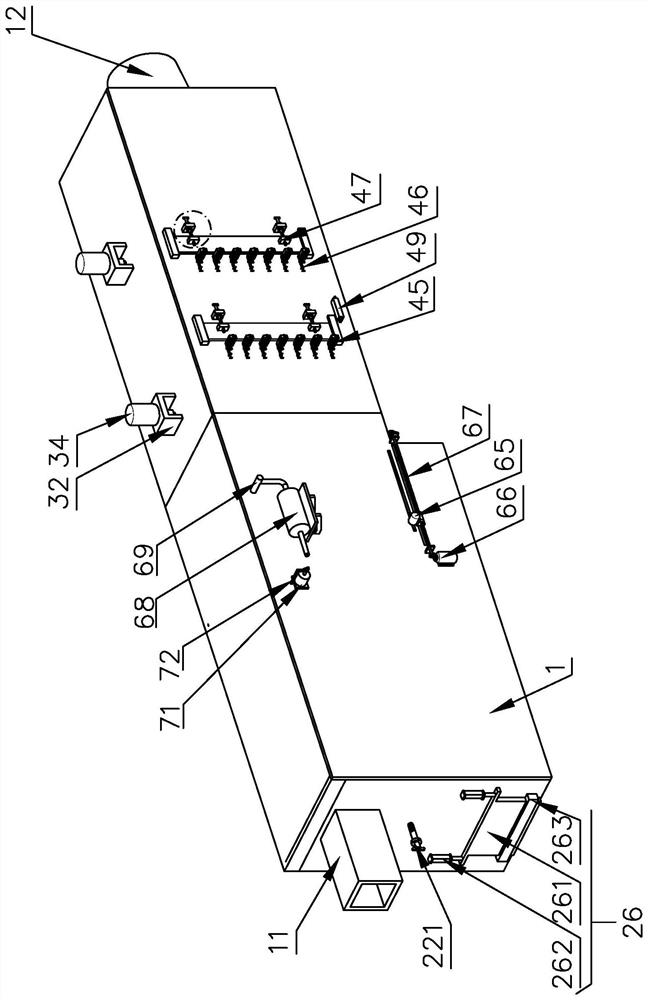

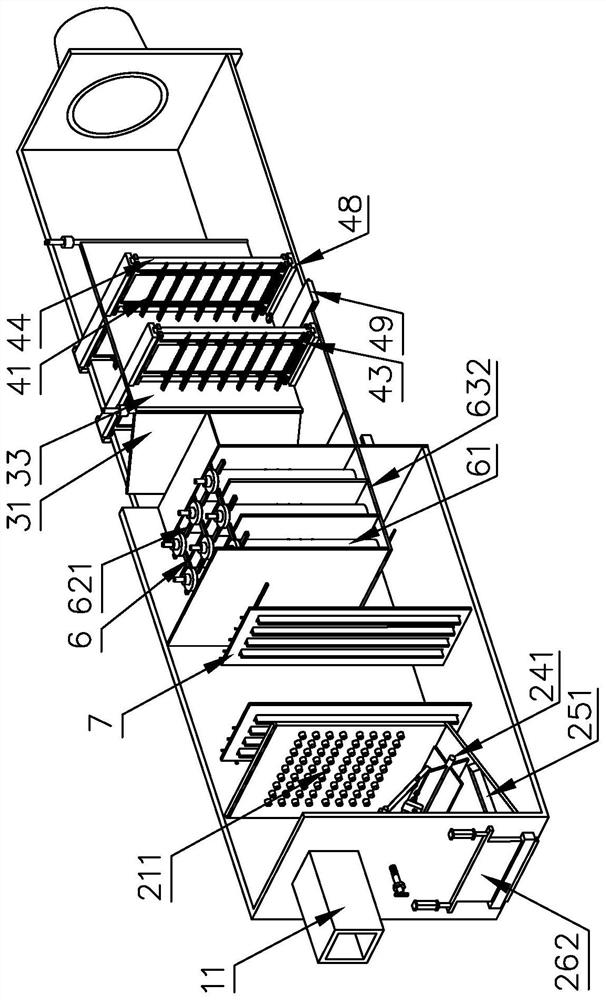

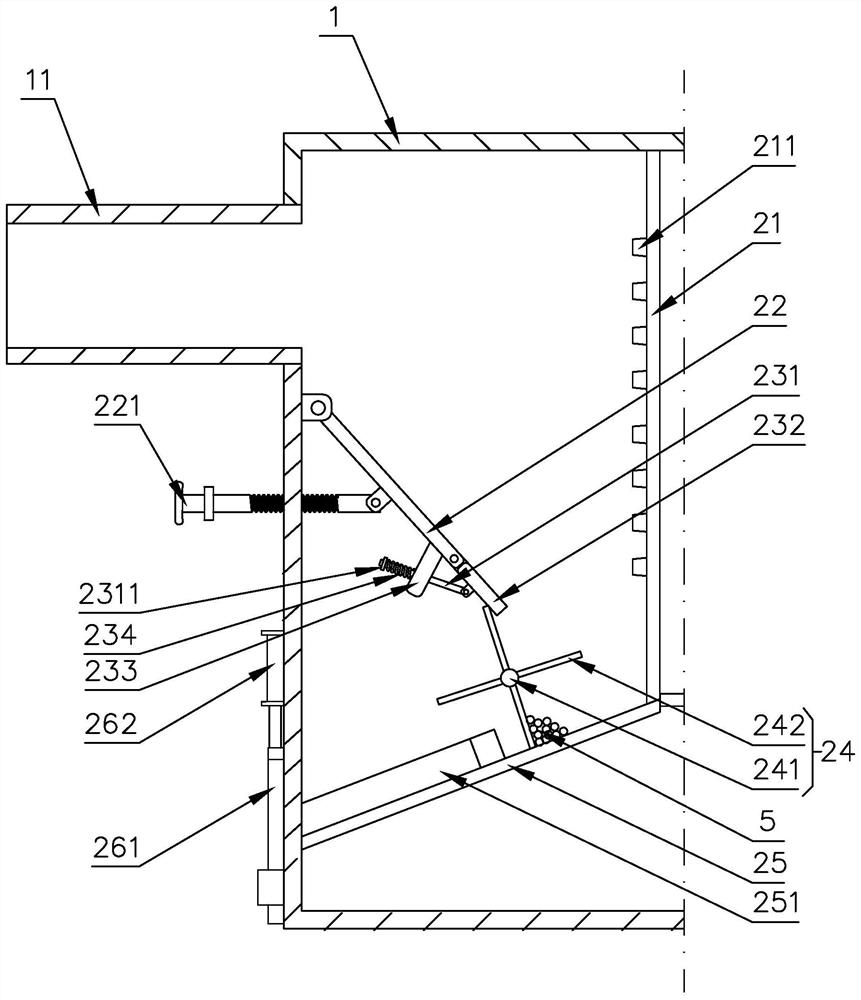

Domestic garbage comprehensive processing device

ActiveCN109663802ASpeed up the flowSmooth layeringSolid waste disposalDrying gas arrangementsWater processingDomestic waste

The invention relates to a domestic garbage comprehensive processing device. The device comprises a coarse breaking chamber, a removing block chamber, a fine breaking device, a separating chamber, a burning chamber, a backflushing device and a water treatment device. Through the specific setting of each device, the domestic garbage can be comprehensively and harmlessly processed, especially by setting the backflushing device specifically so that the cleaned solid waste can be stratified according to the specific gravity, and then the natural classification, collection and treatment of the recyclable garbage are achieved.

Owner:大唐融合(哈尔滨)生态环境科技有限公司

Three-chamber regenerative thermal oxidizer (RTO) regenerative combustion furnace with purging pipeline

The invention relates to the technical field of waste gas treatment equipment, in particular to a three-chamber regenerative thermal oxidizer (RTO) regenerative combustion furnace with a purging pipeline. The three-chamber RTO regenerative combustion furnace with the purging pipeline comprises a furnace body, a combustion chamber and a first regenerative chamber; the combustion chamber is disposedinside the furnace body; a combustor is disposed at the top of the combustion chamber and is connected with the combustion chamber in an embedded mode; the first regenerative chamber is disposed on the lower portion of one side of the combustion chamber; a second regenerative chamber is disposed in the middle of the lower portion of the combustion chamber; a third regenerative chamber is disposedon the lower portion of the other side of the combustion chamber; supporting legs are disposed at the bottom of the furnace body and connected with the furnace body in a welded mode; and a main fan is disposed on one side of the furnace body. Through the structural improvement, the three-chamber RTO regenerative combustion furnace with the purging pipeline has the advantages that the structural design is reasonable, pipeline layout is in order, an air source is clean, the back blowing effect is good, and the VOC removal rate is high.

Owner:SUZHOU HUAXI ENVIRONMENTAL TECH CO LTD

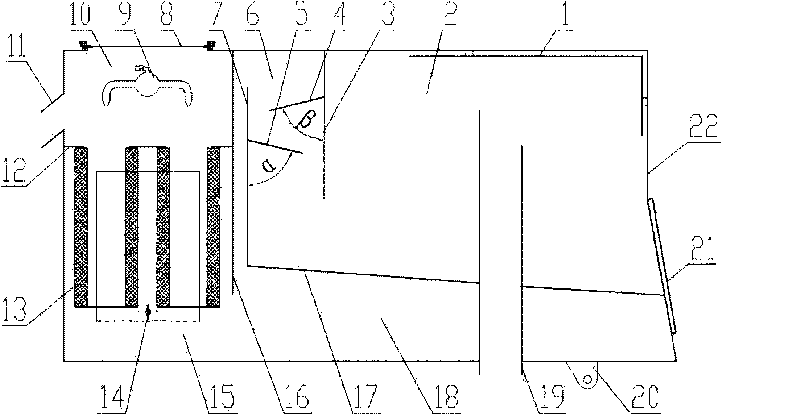

Box body of pure-suction type road sweeper

ActiveCN101718082ALarge compartment volumeGood dust separation effectRoad cleaningRoad sweeperElectric power

The invention relates to a box body of a pure-suction type road sweeper, which is used for sweeping ground surfaces and roads in the environments such as plazas, airfields, cement plants, steel plants, electric power plants, harbors and the like and maintaining cleanliness. The boxy body of the pure-suction type road sweeper has the advantages of large volume, good dust separation effect, good back flushing effect, long filter cylinder service life and the like, and belongs to the technical field of road sweepers.

Owner:SHANGHAI SHENZHOU AUTOMOBILE ENERGY SAVING ENVIRONMENTAL PROTECTION HAIAN +1

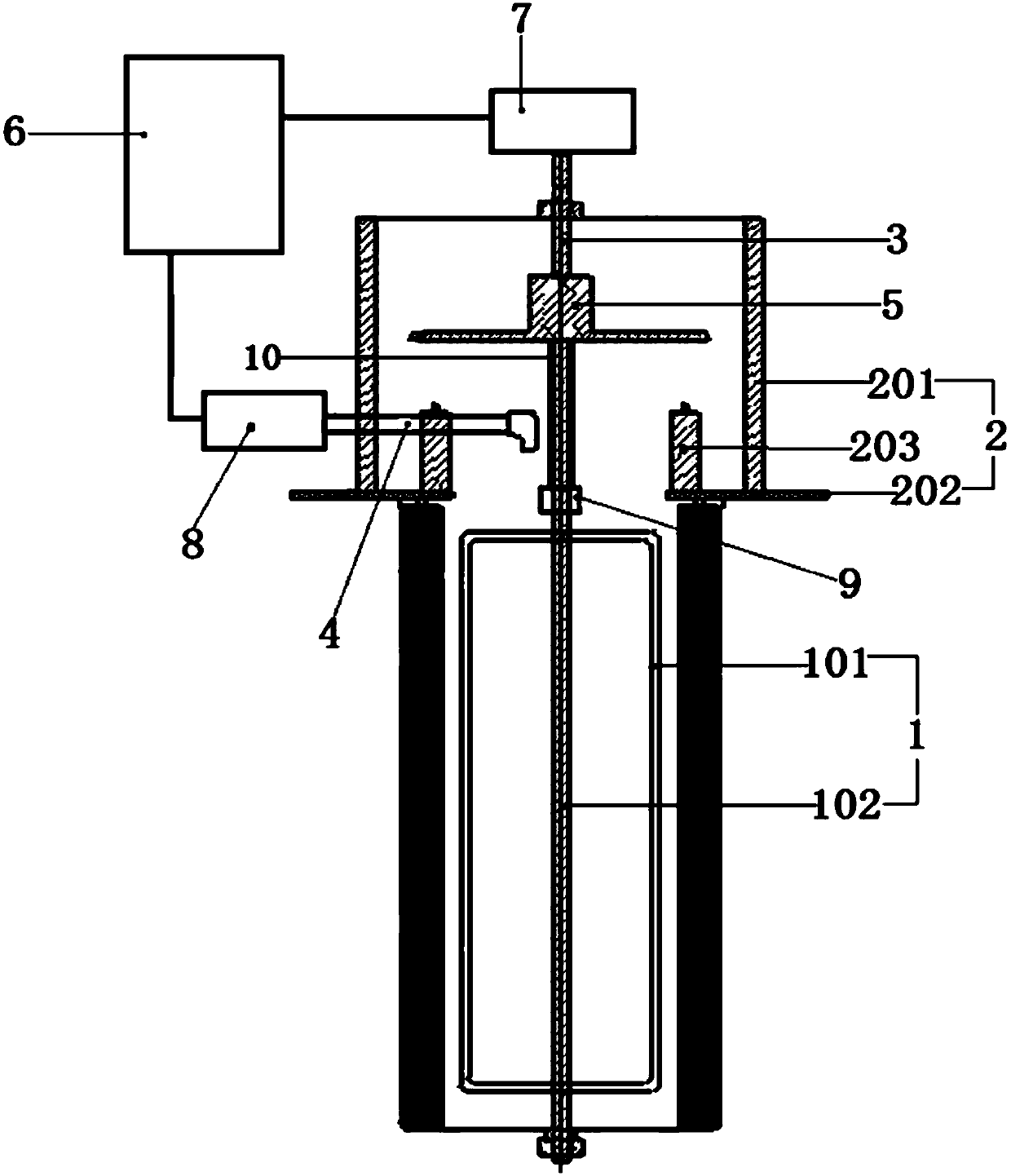

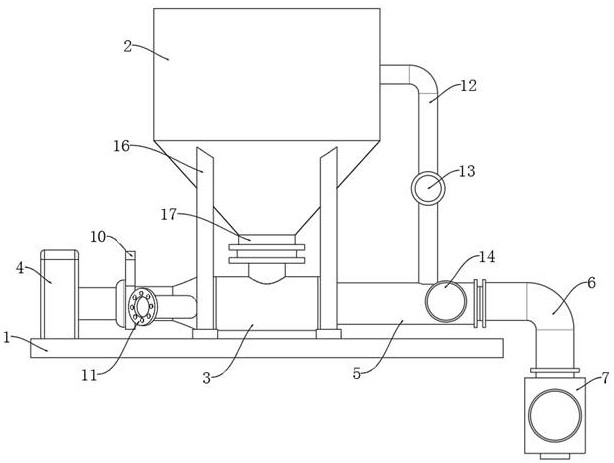

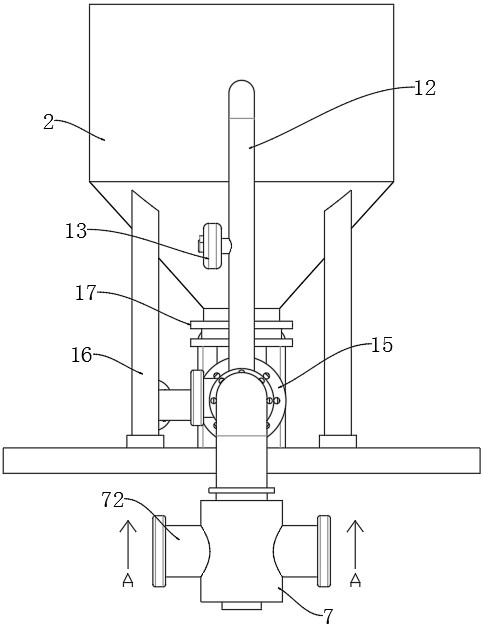

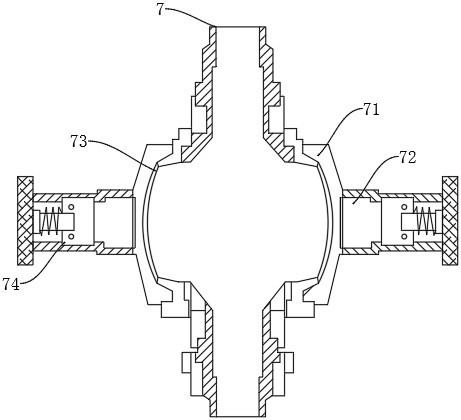

Filter element blowback device for automatic sand blasting derusting device

ActiveCN107754464AAchieve uniformityImprove blowback effectDispersed particle filtrationTransportation and packagingSand blastingEngineering

The invention discloses a filter element blowback device for an automatic sand blasting derusting device, and belongs to the field of pipeline derusting. In the filter element blowback device, a blowback rotary wing component comprises a square pipe and a vertical pipe, wherein the vertical pipe is fixed and communicated with middle parts of an upper horizontal pipe and a lower horizontal pipe ofthe square pipe; and a plurality of air outlets are formed in pipe walls of a left vertical straight pipe and a right vertical straight pipe of the square pipe. A bracket comprises a cylindrical support body, an annular support plate and a cover body, wherein the cylindrical support body, the annular support plate and the cover body are arranged from inside to outside; the annular support plate isfixed at the upper part of a filter element; an air inlet pipe penetrates through the top of the cover body; the lower end of the air inlet pipe is rotationally connected with the upper end of the vertical pipe; and the lower end of the vertical pipe rotationally penetrates through the bottom of the filter element. A blasting blowback pipe sequentially penetrates through the side walls of the cover body and the cylindrical support body, and the pipe opening of the blasting blowback pipe is downwards opposite to the open end of the filter element; a sealing plate can axially and slidably sleeve the air inlet pipe to open or close the cylindrical support body; and a blowback air storage tank is connected with a first pulse valve and a second pulse valve, the first pulse valve is connected with the upper end of the air inlet pipe, and the second pulse valve is connected with the pipe opening of the blasting blowback pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

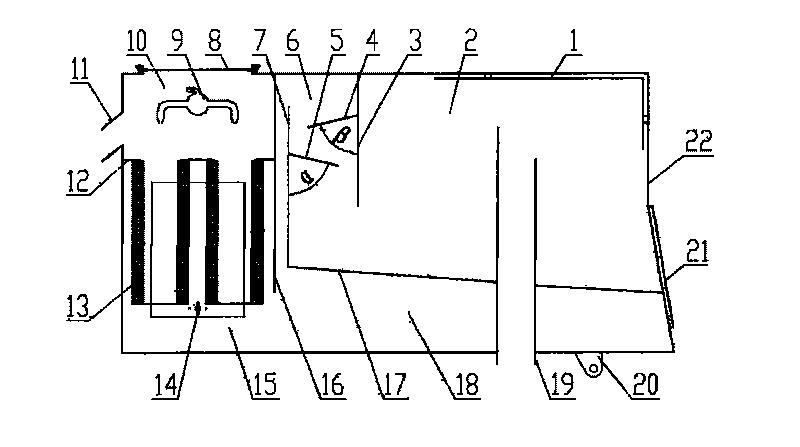

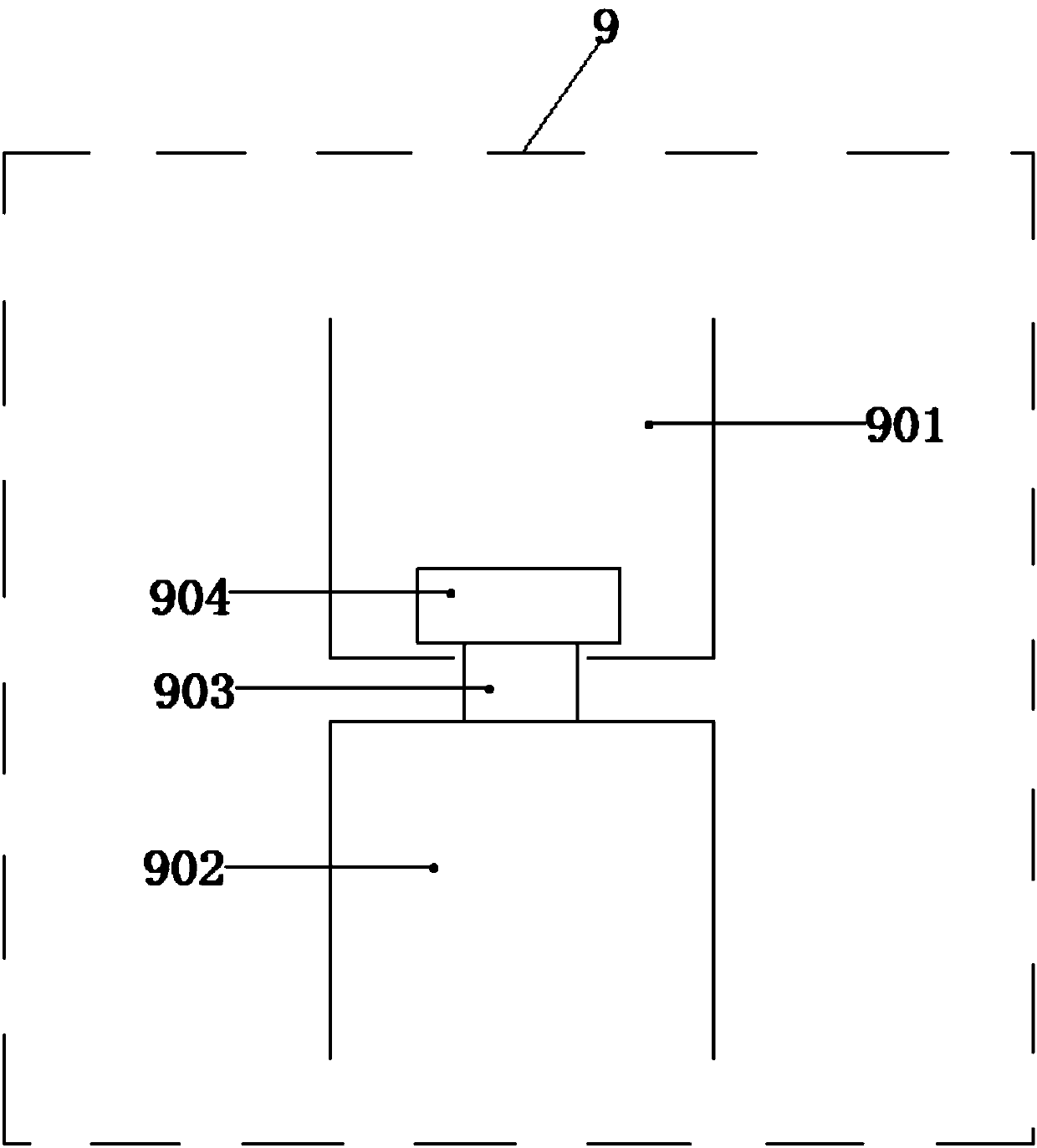

PM particle trap regeneration device

InactiveCN104533575AGood regeneration effectReduce lossExhaust apparatusSilencing apparatusProcess engineeringElectromagnetic valve

A PM particle trap regeneration device comprises a backward-blow gas generation part and a particle trap regeneration heating part. The backward-blow gas generation part comprises a gas storage tank. The input end of the gas storage tank is connected with a gas pump, and the output end of the gas storage tank is connected with the particle trap regeneration heating part through an electromagnetic valve. The particle trap regeneration heating part comprises a heater capable of containing a particle trap inside. The bottom of the heater is connected with the output end of the gas storage tank through a spoiler. A pressure transmitter for collecting gas pressure in the tank is arranged on the gas storage tank. A thermal coupler for detecting the heating temperature is installed in the heater. The pressure transmitter and the thermal coupler are connected with an external controller. The controller outputs signals to control the electromagnetic valve to be opened and closed. The temperature is monitored in the whole process through the thermal coupler; when the combustion time is long enough and the gas pressure of the gas storage tank meets the requirements, the electromagnetic valve is automatically opened, the pressure gas is released for backward blowing, operation is easy and convenient, and the combustion of the particle trap is more accurately controlled.

Owner:CHANGAN UNIV

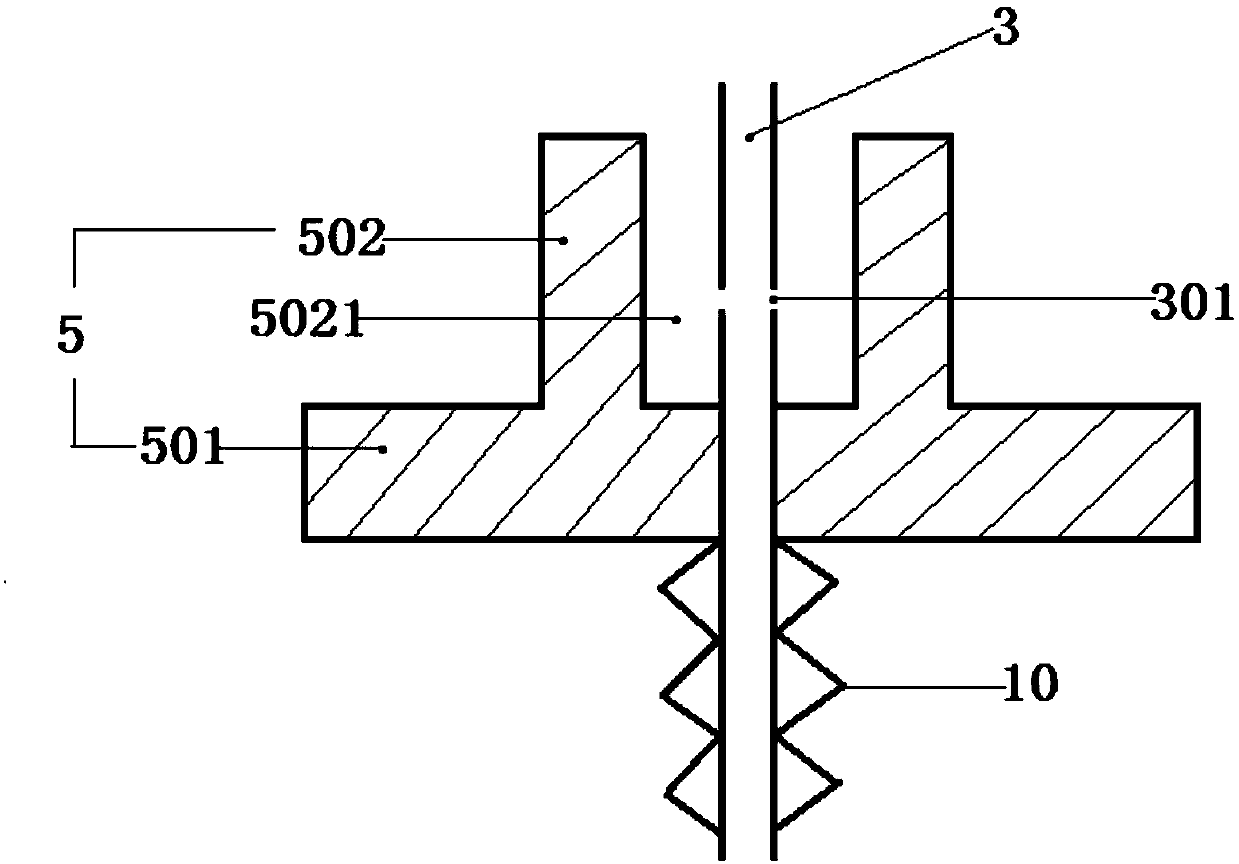

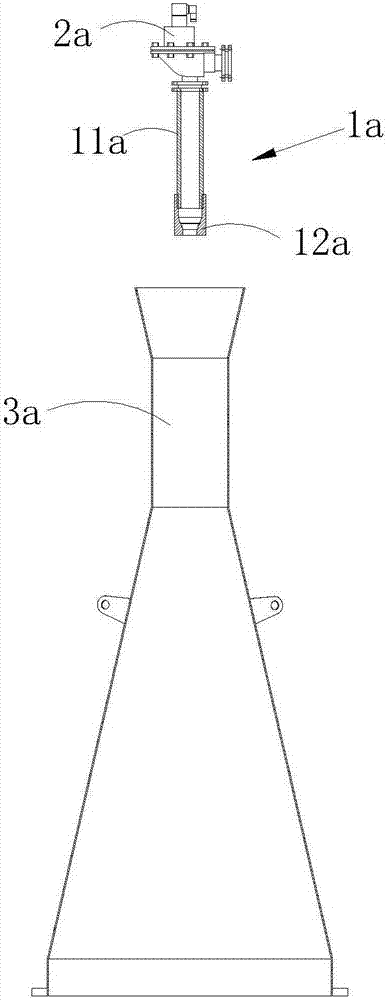

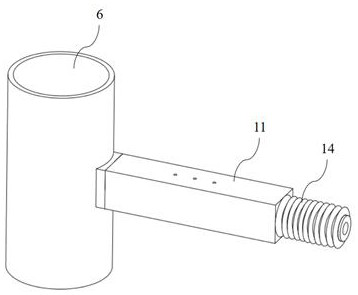

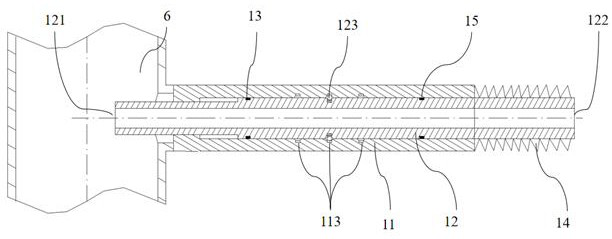

Efficient air inlet apparatus used for gas-turbine air purification

InactiveCN104524889AExtended service lifeImprove blowback effectDispersed particle filtrationGas turbine plantsAir cleaningPulp and paper industry

The invention belongs to the technical field of gas turbines, discloses an efficient air inlet apparatus used for gas-turbine air purification, and aims at solving the problem that the filter efficiency is low because a part of a filter layer in a conventional filter cylinder is not fully utilized. The efficient air inlet apparatus comprises an air inlet chamber, a filter cylinder, a back blowing chamber and a back blowing system; the filter cylinder comprises a filter cylinder frame composed of an outer metal net layer and an inner metal net layer, and the outer metal net layer and the inner metal net layer form the cylindrical filter cylinder frame surrounded on three sides a filtering layer is arranged between the outer metal net layer and the inner metal net layer; one end of the cylinder filter frame is provided with a seal end cover, and the seal end cover is provided with a breather pipe communicated with the interior of the filer cylinder frame; one end of the breather pipe penetrates through the seal end cover and stretched into the cylinder filter frame, and the bottom end of the breather pipe is connected with an air distribution disk; the bottom side and the lateral side of the air distribution disk are both provided with air distribution ports communicated with the breather pipe; and the side wall of the breather pipe is provided with an air dividing port.

Owner:CHENGDU BOOST ENERGY TECH

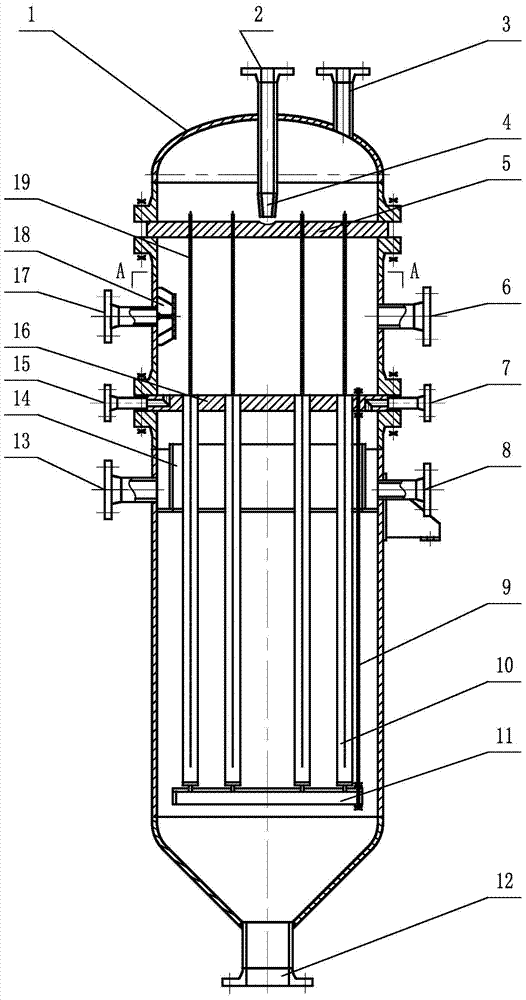

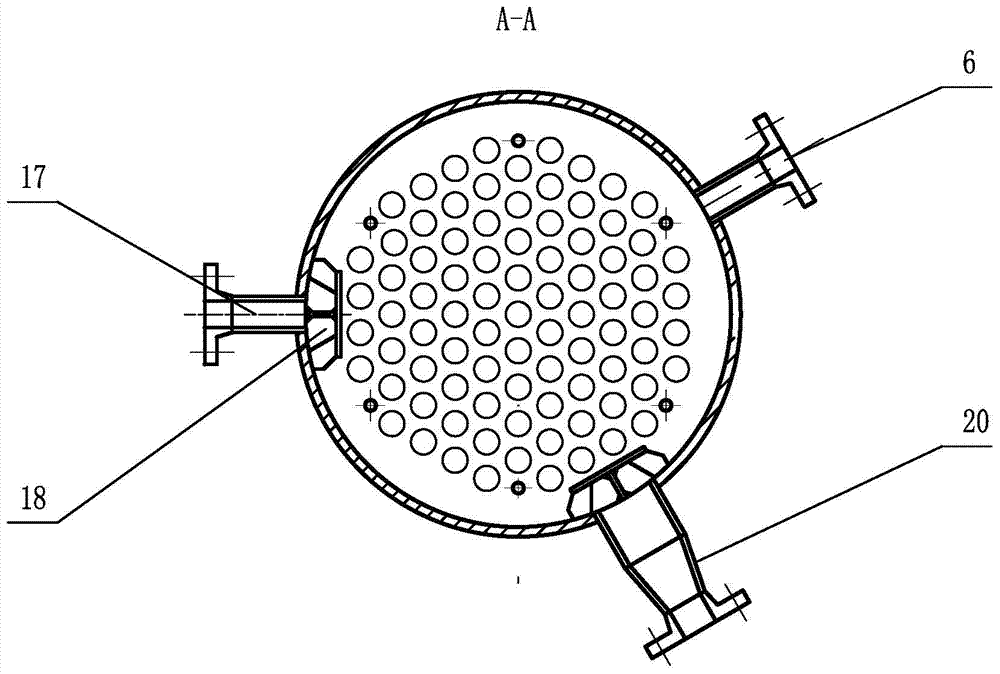

Coal tar filtering device and method

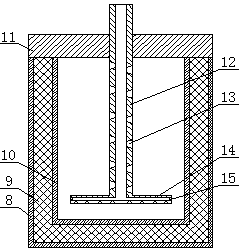

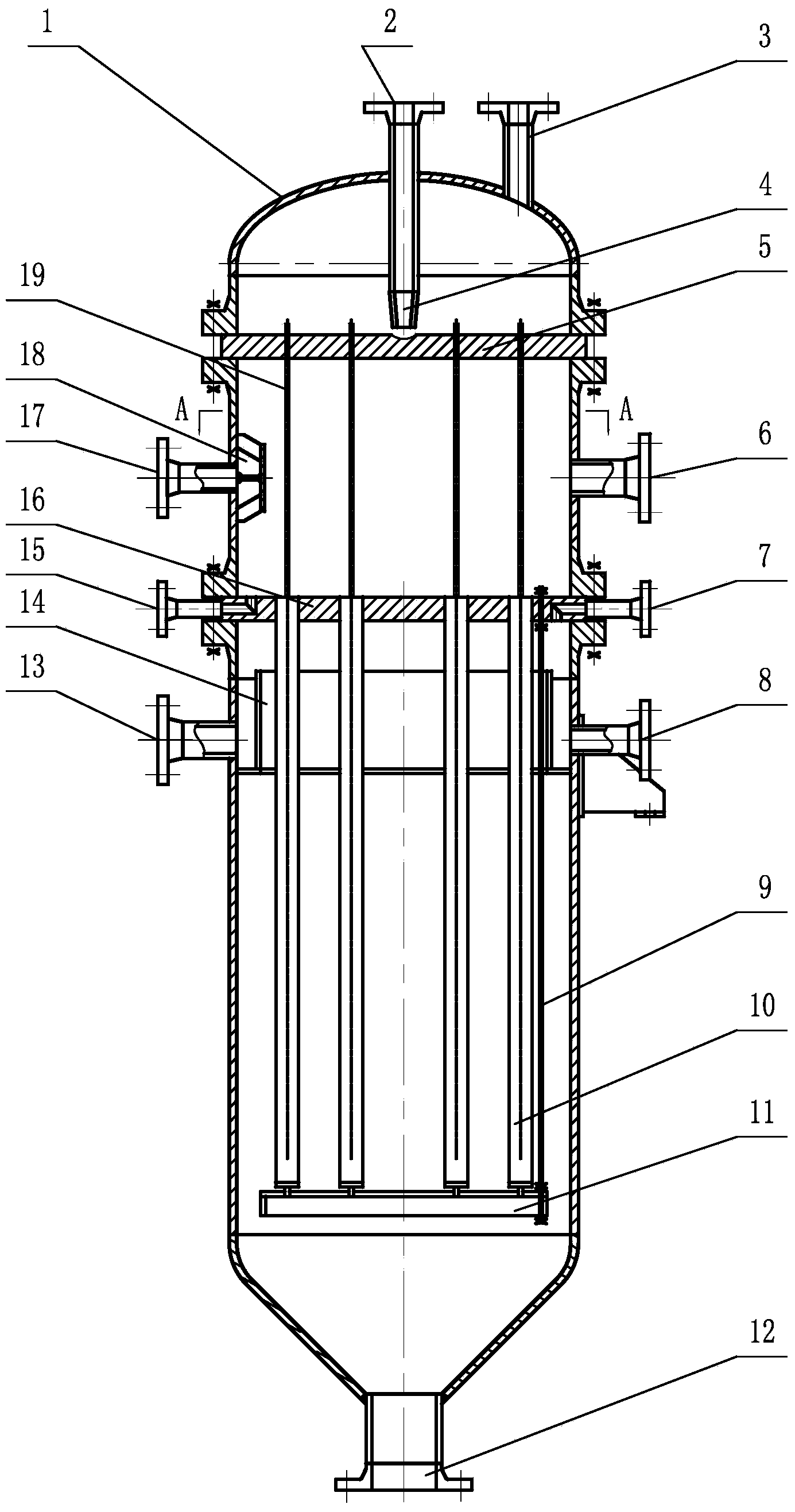

The invention relates to a coal tar filtering device and method. The device comprises at least one can-type filter, wherein the can-type filter is internally divided into an after-filtration residual oil collecting chamber, a filter liquor collecting chamber and a filtering chamber from top to bottom; a residual oil leading-out tube plate is arranged between the after-filtration residual oil collecting chamber and the filter liquor collecting chamber; a residual oil leading-out tube is arranged above the residual oil leading-out tube plate, an after-filtration residual oil guide tube is arranged in the filter liquor collecting chamber, an upper filter element fixing plate is arranged between the filter liquor collecting chamber and the filtering chamber, and filter elements and a raw oil distributor as well as a lower filter element fixing plate are arranged in the filtering chamber; the lower filter element fixing plate is connected with the upper filter element fixing plate by a connecting rod, and the upper and lower ends of the filter elements are fixed on the upper filter element fixing plate and the lower filter element fixing plate respectively. According to the invention, the sump oil quantity can be greatly reduced, the filtering precision of the device is improved, the equipment runs stably, the filtering method is relatively simple, the coal tar recovery rate is high, environmental pollution is less, the filtering efficiency is high, and the coal tar filtering device and method are suitable for industrialized application.

Owner:SHENMUFUYOU ENERGY TECH

Road sweeper carriage with single-cabin structure

The invention provides a road sweeper carriage with a single-cabin structure, which omits an independent passage of a filtering dust room. The invention has the advantages of large carriage volume, good dust separation effect, good back-flushing effect, long service life of a filter cylinder and the like and also improves the service performance of the road sweeper.

Owner:SHANGHAI SHENZHOU AUTOMOBILE ENERGY SAVING ENVIRONMENTAL PROTECTION HAIAN +1

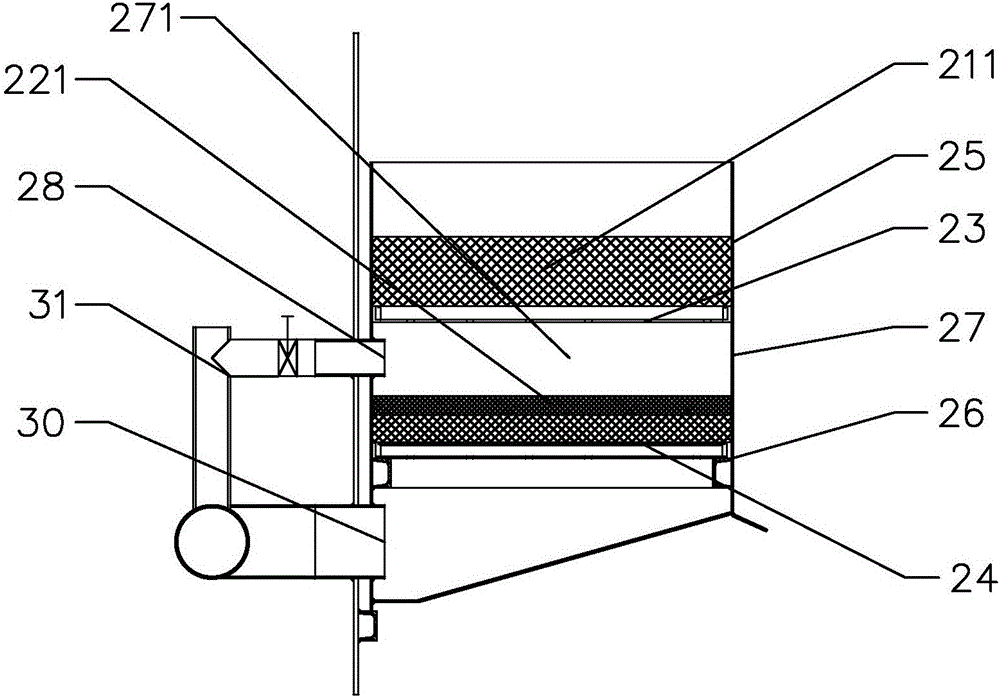

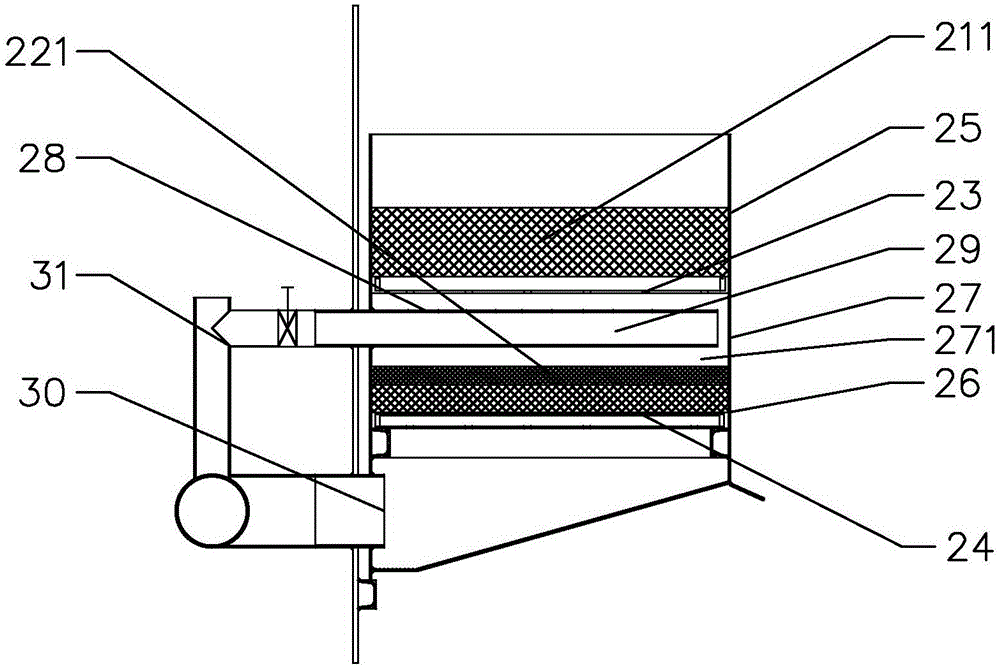

Gas filtration and dust removal device

InactiveCN106362504AImprove clearanceImprove filtration efficiency and filtration effectGas treatmentDispersed particle filtrationEngineeringFilter effect

The invention provides a gas filtration and dust removal device which comprises a shell and a filtering device arranged inside the shell. The filtering device comprises a first filtering layer and a second filtering layer. The first filtering layer is located above the second filtering layer. The bottom of the filtering device is provided with a reverse blowing gas inlet, and a pressurizing layer for enhancing reverse blowing wind pressure of the first filtering layer is arranged between the first filtering layer and the second filtering layer. Due to the fact that the pressurizing layer for enhancing the reverse blowing wind pressure of the first filtering layer is arranged between the first filtering layer and the second filtering layer, the first filtering layer can obtain the good reverse flowing wind pressure during reverse blowing, the reverse blowing wind capacity of the first filtering layer is increased, and it is ensured that dust on the first filtering layer can be removed completely so as to improve the filtering effect and the filtering efficiency.

Owner:江阴远帆环保科技有限公司

Blowback device for filter cartridges of dust remover

PendingCN110180271ACommission hermeticityLess quantityDispersed particle filtrationTransportation and packagingHigh pressurePiston

Owner:安徽正义研磨环保科技有限公司

Quantitative feeding device for metal powder machining

The invention relates to the technical field of metal powder processing, in particular to a quantitative feeding device for metal powder processing, which comprises a stock bin mounted on a bottom plate and further comprises a feeding pipe arranged below the stock bin, an air pump is arranged at one end of the feeding pipe, a conveying pipe is arranged at the other end of the feeding pipe, and one end, far away from the feeding pipe, of the conveying pipe is connected with an arc-shaped pipe. A feeding cavity is formed in the end, away from the conveying pipe, of the arc-shaped pipe and comprises an inner wall and an outer wall, a gap is formed between the inner wall and the outer wall and used for installing an external expansion connector, an external expansion cavity is formed in the outer wall of the feeding cavity and penetrates through the outer wall of the feeding cavity to be connected with the external expansion connector in a penetrating mode, and the inner wall of the feeding cavity is of a smooth flexible shrinkage film structure. The shrink film, the external expansion connector and the external expansion cavity jointly form a closed space, a piston and a pushing mechanism connected with the piston are arranged in the external expansion cavity, metal powder can be prevented from being blocked in the feeding cavity, and quantitative feeding can be achieved so that it can be guaranteed that the amount of the metal powder in a pressed blank is within a reasonable range.

Owner:徐州威德金属制品有限公司

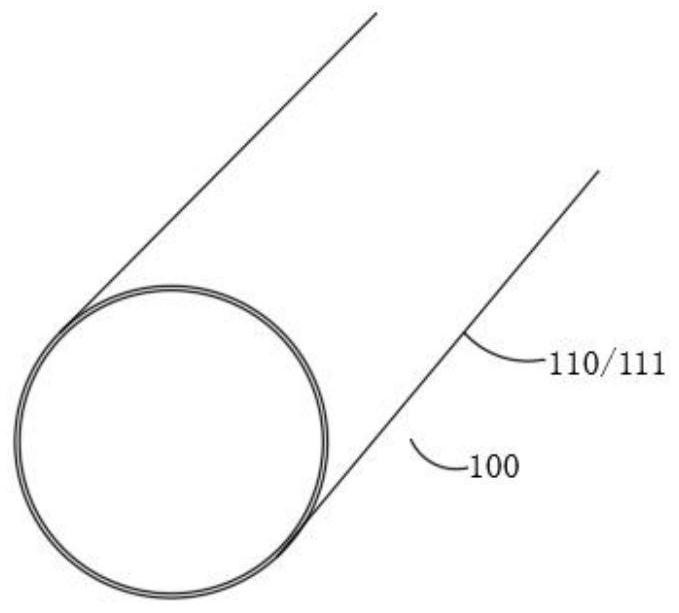

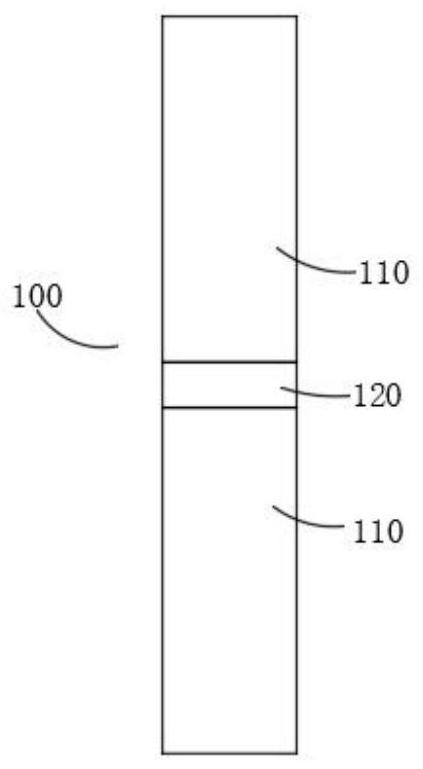

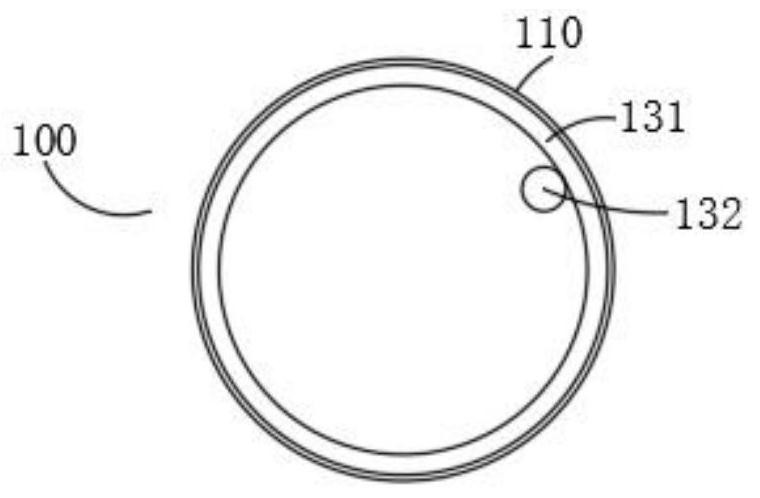

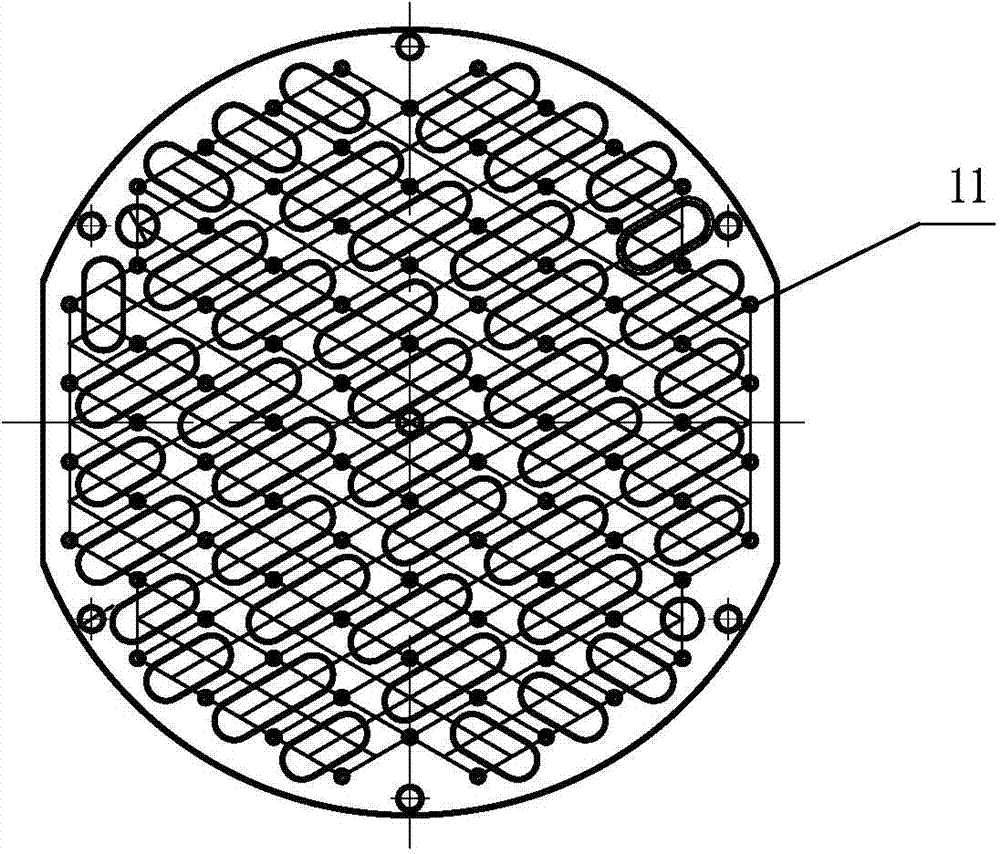

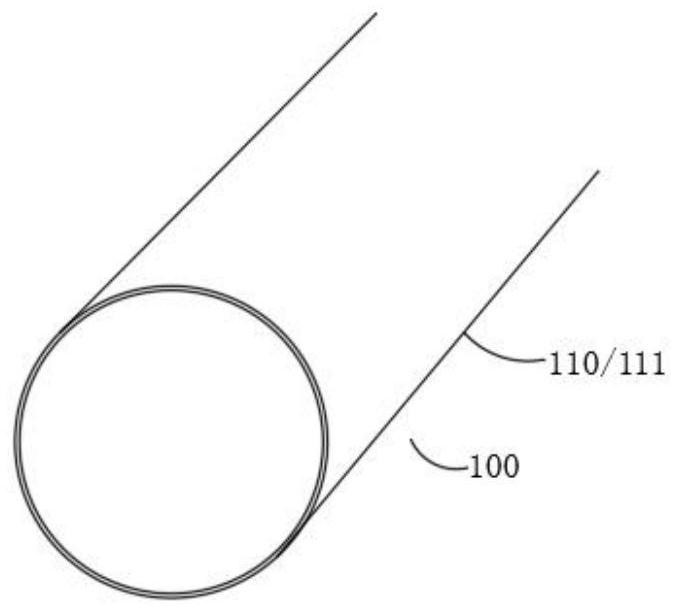

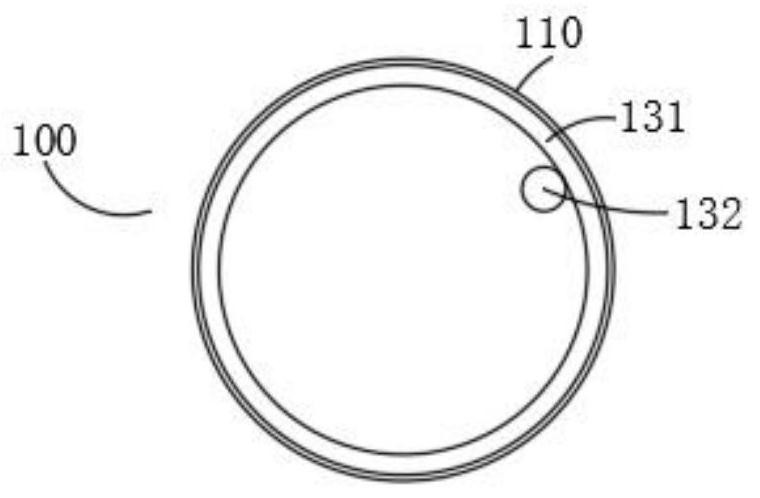

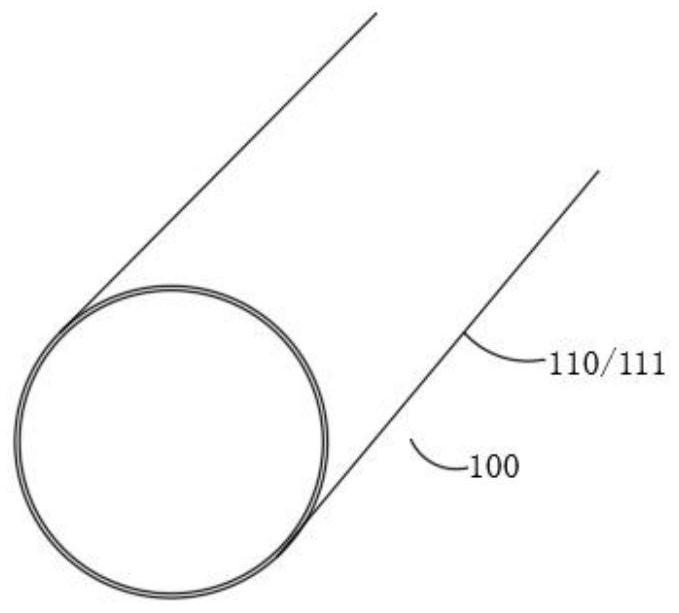

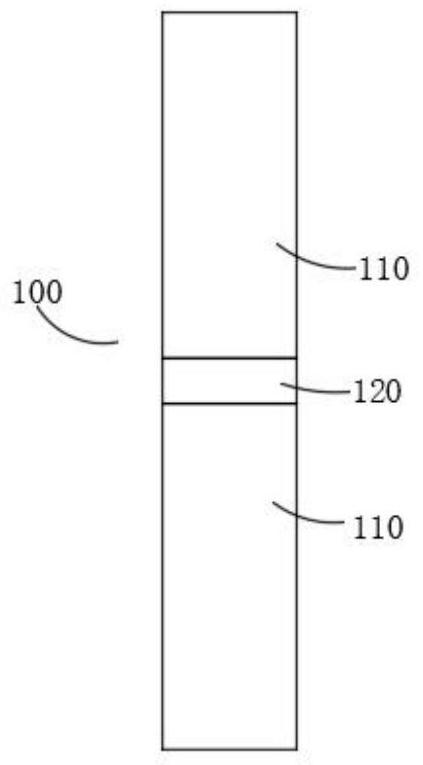

Filter element

PendingCN112237811AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

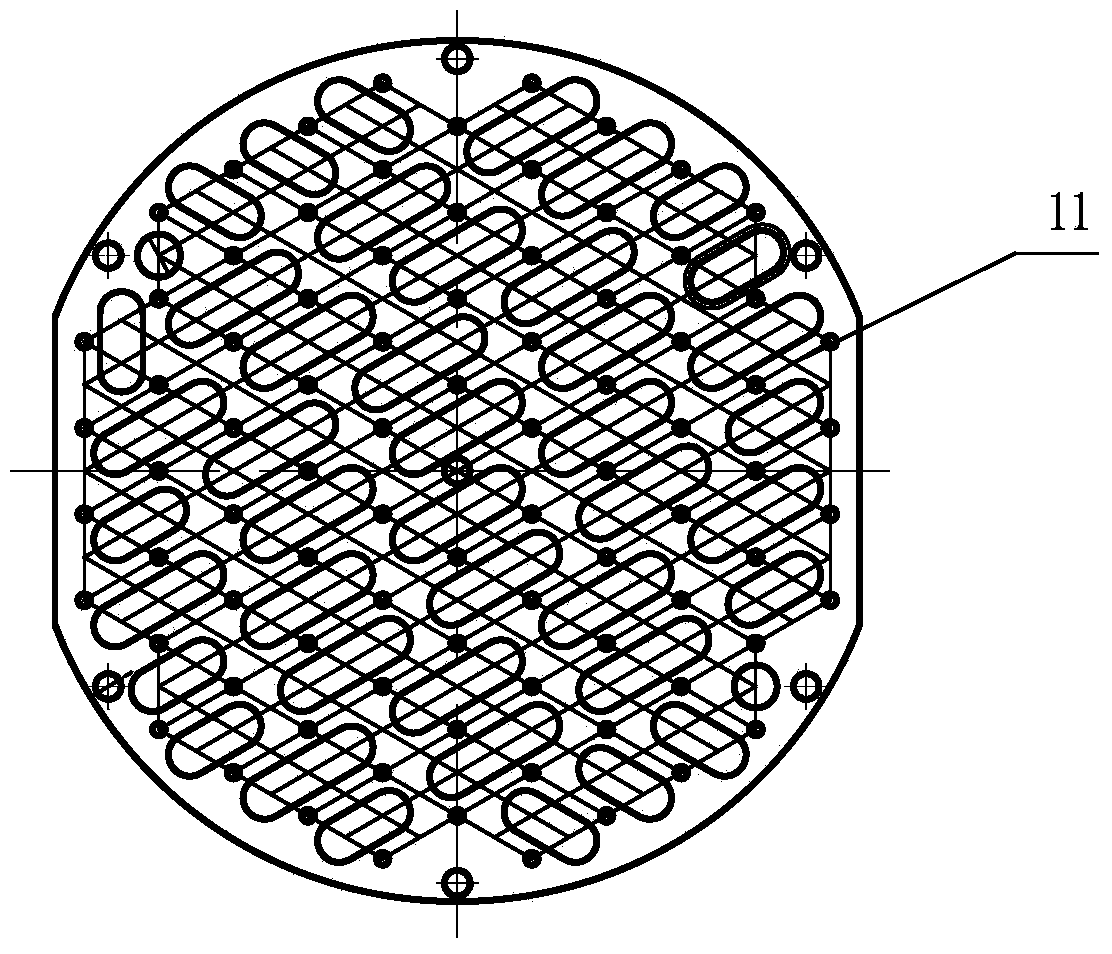

The invention discloses a filter element. The filter element is placed in a filter to be used for carrying out gas-solid separation filtration and / or liquid-solid separation filtration on an object tobe filtered during use; the filter element comprises at least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or sheet-shaped materials taking the metal as a base body in a rolled mode and carrying out sealing processing on joints; the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm, furtherpreferably 20-60 mm, and further preferably 25-50 mm, and the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm; the lengths of the filter tubes range from 100mm to 5000 mm, preferably range from 100 mm to 3000 mm, further preferably range from 100 mm to 2000 mm, and further preferably range from 200 mm to 1500 mm. A plurality of small-diameter filter tubesare bundled, so the filtering area can be remarkably increased in a limited mounting space; the length of the filter element is reduced, so the blowback effect can be more uniformly distributed in the axial direction of the filter tubes. Therefore, the technical problems that in the prior art, a filter element is small in filtering area and poor in back flushing effectiveness are effectively solved.

Owner:CHENGDU INTERMENT TECH

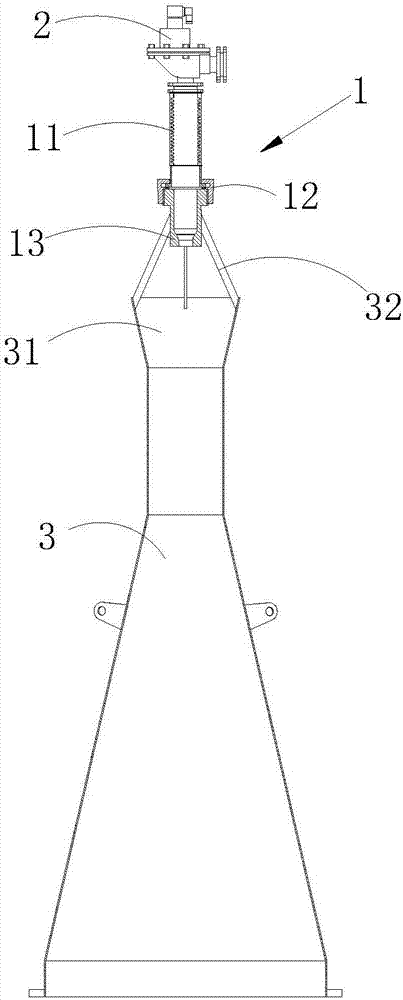

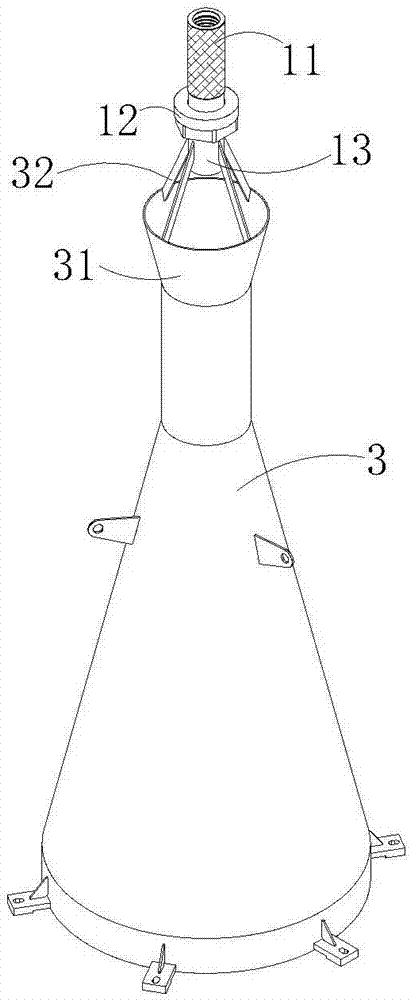

Reverse blowing component

PendingCN107029480AMaintain alignment accuracyEasy to disassemble and installDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

The invention discloses a reverse blowing component which comprises a pulse valve and a spraying and blowing structure connected with the pulse valve. A venturi tube is oppositely arranged an outlet of the spraying and blowing structure, the spraying and blowing structure comprises a spraying and blowing pipe and a nozzle connected with the spraying and blowing pipe, the spraying and blowing pipe is a heat compensation pipe body, heat compensation of the pipe body can be achieved under the high-temperature reverse blowing condition through the heat compensation pipe body, the spraying and blowing pipe can effectively keep alignment accuracy when the spraying and blowing structure is used, so that the nozzle is easily disassembled and assembled, and the reverse blowing effect of a gas filtering device is better.

Owner:CHENGDU INTERMENT TECH

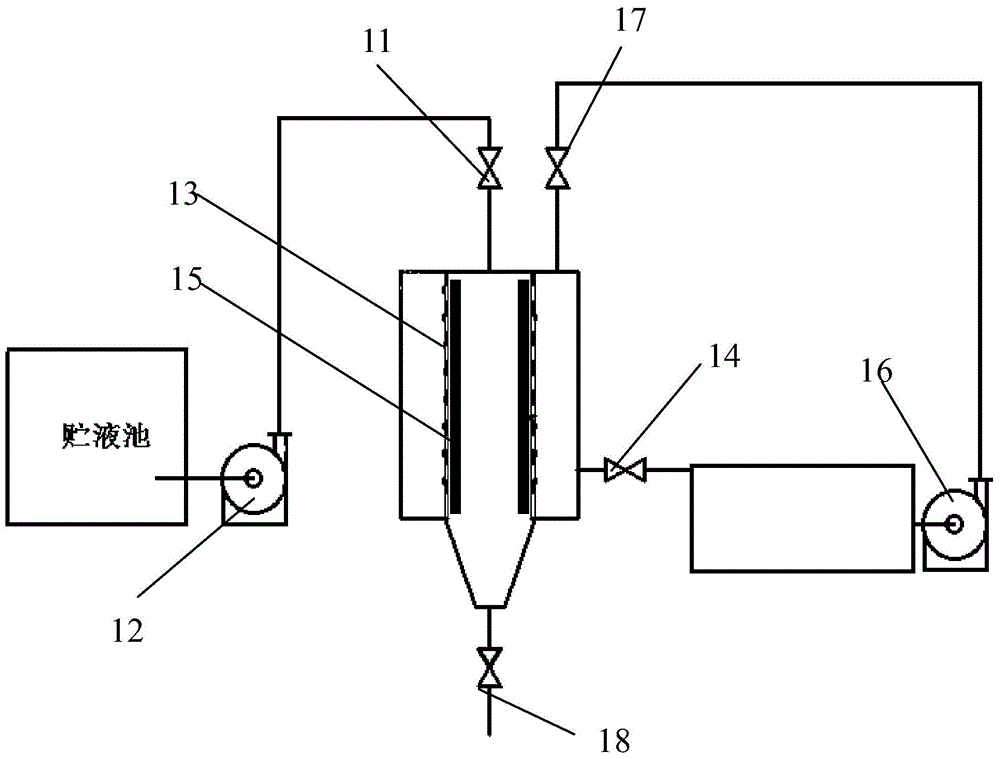

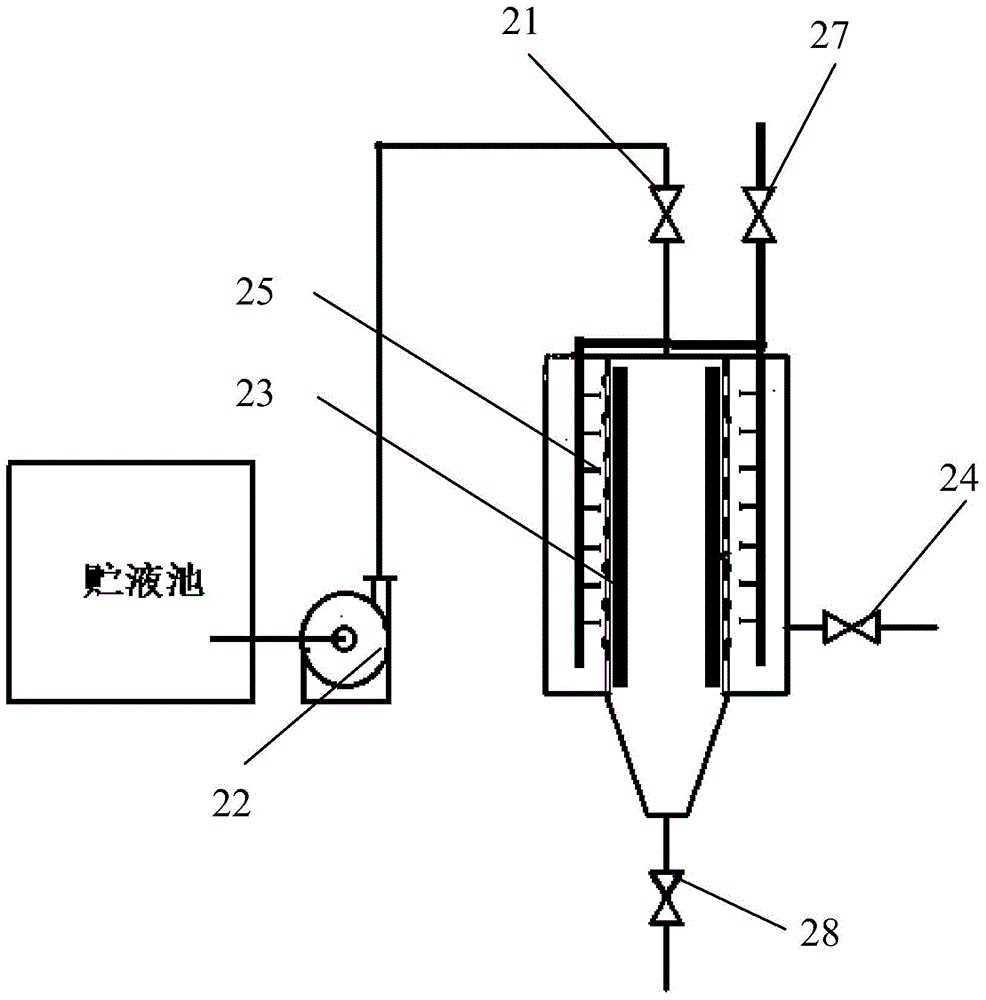

Energy-storage backblowing filter, and filtration and filtration-regeneration method thereof

ActiveCN105080196ALow costLow running costStationary filtering element filtersAir compressionInlet valve

The invention discloses an energy-storage backblowing filter and a filtration and filtration-regeneration method thereof. The energy-storage backblowing filter comprises a body, and an original liquid inlet valve, a filtration clear liquid outlet valve and a filter cake outlet valve which are correspondingly connected with the body, wherein a filter screen is arranged inside the body and divides the interior of the energy-storage backblowing filter into an original liquid space and a filtration clear liquid space; a power supply device is connected with the original liquid inlet valve; the original liquid inlet valve and the filter cake outlet valve communicate the original liquid space; the filtration clear liquid outlet valve communicates the filtration clear liquid space; meanwhile, the filter also comprises an air compression energy-storage member which is arranged on and connected with the body; the filter cake outlet valve is opened before filtration so as to naturally fill air into the interior of the energy-storage backblowing filter; the air compression energy-storage member forms an energy-storage space in individual or in cooperation with the body; and the air filled in the interior of the energy-storage backblowing filter undergoes compression and energy storage and is enclosed in the energy-storage space when filtration. The energy-storage backblowing filter provided by the invention has the advantages of simple structure, simple and convenient operation, and low equipment and operation costs.

Owner:CHINA IPPR INT ENG

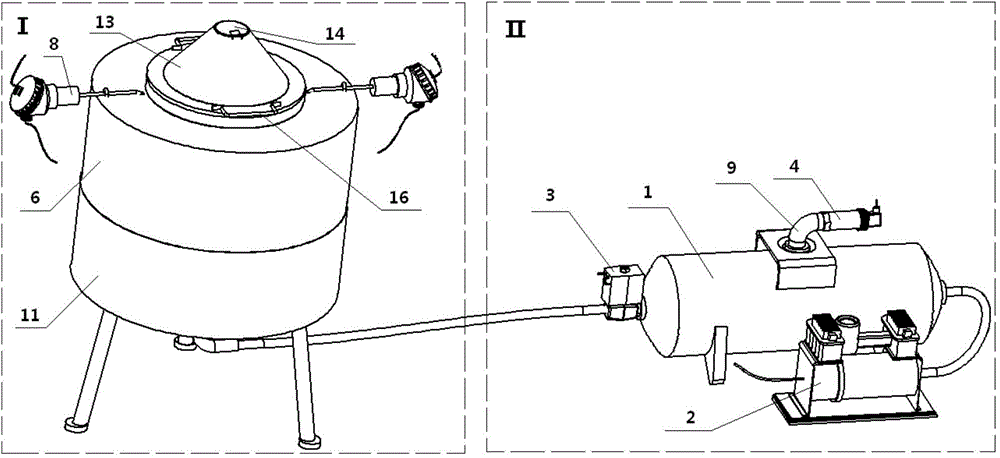

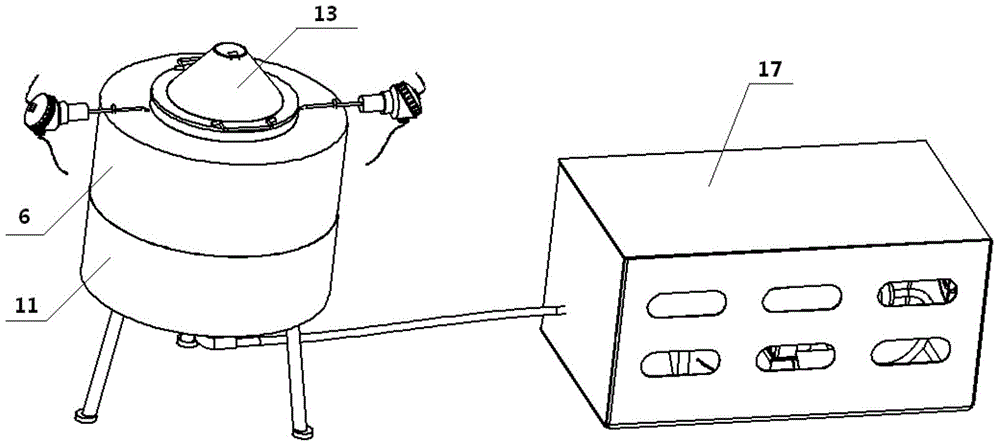

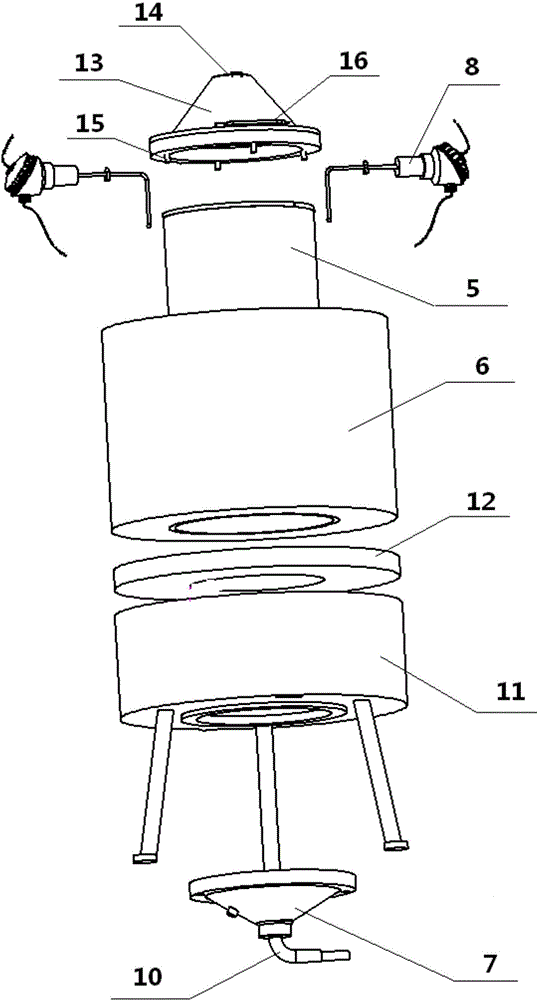

High-temperature garbage pyrolysis gas online monitoring system and method

PendingCN114002388ARealize multi-point continuous automatic detectionEasy to operatePreparing sample for investigationGas analyser construction detailsPeristaltic pumpControl engineering

The invention is suitable for gas online monitoring, and particularly relates to a high-temperature garbage pyrolysis gas online monitoring system and method. The system comprises a multi-point gas collecting device, a filtering device, a buffering device, a two-way peristaltic pump and a gas sensor which are sequentially communicated through a communicating pipeline. The multi-point gas collecting device can extend into a plurality of positions in the garbage pyrolysis gas pipeline to carry out multi-point continuous automatic detection. During use, the first switch valve and the second switch valve (other valves are in a closed state) are opened, and the bidirectional peristaltic pump is opened in the forward direction so that the detection passage is communicated. The multi-point gas collecting device extends into the garbage pyrolysis gas pipeline to carry out gas collection and analysis at multiple positions, compared with a traditional single-point collection mode, the scheme can realize multi-point continuous automatic detection of different areas in the pipeline, and the obtained result is closer to the actual working condition.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

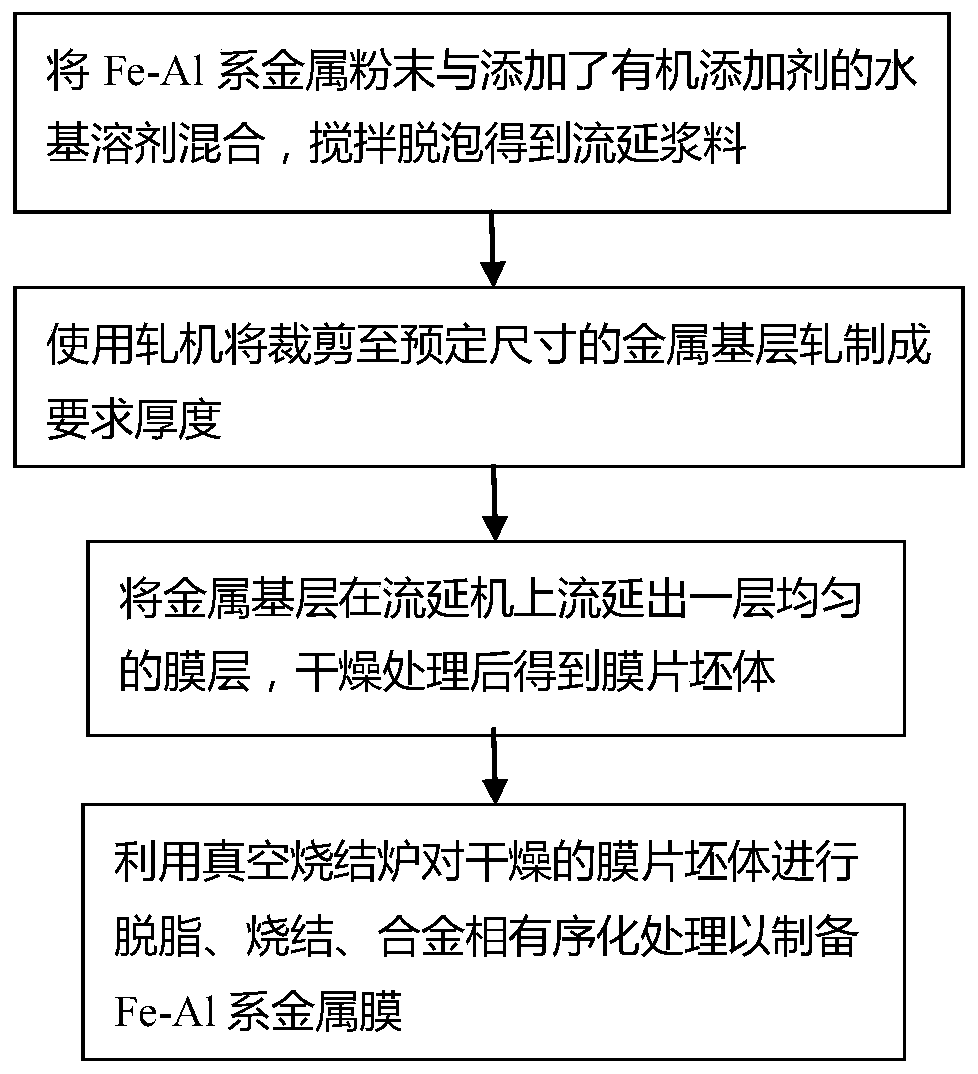

Fe-Al-series metal film and preparation method thereof

PendingCN111249922AHigh filtration precisionPromote circulationSemi-permeable membranesDispersed particle filtrationHigh fluxWorking environment

The invention discloses a Fe-Al-series metal film and a preparation method thereof, belonging to the related technical field of gas-solid separation under high-temperature and low-pressure working conditions. The invention mainly aims to overcome the defect that a traditional metal filter element is large in filtering resistance, low in flux and the like in a low-pressure working environment in the prior art. The preparation method comprises the steps: subjecting Fe-Al-series metal powder and a water-based solvent added with an organic additive to stirring and defoaming to obtain tape castingslurry; carrying out tape casting on a metal base layer with a desired thickness by using a tape casting machine to obtain a uniform film layer, and drying the uniform film layer to obtain a film blank; and subjecting the dried film blank to degreasing, sintering and alloy phase ordering treatment in a sintering furnace to prepare the Fe-Al-series metal film, wherein the degreasing treatment refers to treatment for removing the organic additive. Therefore, the Fe-Al-series metal film prepared by the method has high flux and can be applied under the working conditions of high operation temperature, low working pressure and low outlet solid content.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

Coal tar filtering device and method

The invention relates to a coal tar filtering device and method. The device comprises at least one can-type filter, wherein the can-type filter is internally divided into an after-filtration residual oil collecting chamber, a filter liquor collecting chamber and a filtering chamber from top to bottom; a residual oil leading-out tube plate is arranged between the after-filtration residual oil collecting chamber and the filter liquor collecting chamber; a residual oil leading-out tube is arranged above the residual oil leading-out tube plate, an after-filtration residual oil guide tube is arranged in the filter liquor collecting chamber, an upper filter element fixing plate is arranged between the filter liquor collecting chamber and the filtering chamber, and filter elements and a raw oil distributor as well as a lower filter element fixing plate are arranged in the filtering chamber; the lower filter element fixing plate is connected with the upper filter element fixing plate by a connecting rod, and the upper and lower ends of the filter elements are fixed on the upper filter element fixing plate and the lower filter element fixing plate respectively. According to the invention, the sump oil quantity can be greatly reduced, the filtering precision of the device is improved, the equipment runs stably, the filtering method is relatively simple, the coal tar recovery rate is high, environmental pollution is less, the filtering efficiency is high, and the coal tar filtering device and method are suitable for industrialized application.

Owner:SHENMUFUYOU ENERGY TECH

A comprehensive treatment equipment for domestic waste

ActiveCN109663802BImprove blowback effectAvoid Environmentally Unfriendly DefectsSolid waste disposalDrying gas arrangementsProcess engineeringDomestic waste

The invention relates to a domestic garbage comprehensive processing device. The device comprises a coarse breaking chamber, a removing block chamber, a fine breaking device, a separating chamber, a burning chamber, a backflushing device and a water treatment device. Through the specific setting of each device, the domestic garbage can be comprehensively and harmlessly processed, especially by setting the backflushing device specifically so that the cleaned solid waste can be stratified according to the specific gravity, and then the natural classification, collection and treatment of the recyclable garbage are achieved.

Owner:大唐融合(哈尔滨)生态环境科技有限公司

Filter

PendingCN112237810AReduce areaSolve the costCombination devicesDispersed particle filtrationProcess engineeringControl theory

The invention discloses a filter. The filter comprises a filter structure, and the filter structure comprises at least two filter elements which are arranged at intervals; the filter element comprisesat least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking the metal as a base body in a rolling manner and performing sealing processing on joints; and the outer diameter of the pipe body formed by rolling is only 20-200 mm. The bundled filter element formed by bundling a plurality of small-diameterfilter tubes is adopted, so that the filtering area can be remarkably increased; for a filter with a large size, the weight of a single filter element can be reduced by adopting a plurality of cluster type filter elements while a high filtering area is ensured, and the installation is simplified; for a filtering structure needing a large number of filter tubes, a plurality of cluster type filterelements are respectively mounted, so that a relatively uniform blowback effect can be ensured. Therefore, compared with the prior art, the filter has the advantages that a larger filter area can be achieved, and the problems of installation and blowback after the filter pipes are bundled are solved.

Owner:CHENGDU INTERMENT TECH

Treatment device for dust and waste gas in building material industry

ActiveCN113457289AReduce damage rateReduce impact forceDispersed particle filtrationDust controlProcess engineering

The invention discloses a treatment device for dust and waste gas in the building material industry. The treatment device comprises a box body, a particle filtering mechanism, an air duct adjusting mechanism, a cloth bag dust removal mechanism, a speed reduction mechanism and an acid-alkali washing mechanism; the particle filtering mechanism, the air duct adjusting mechanism, the cloth bag dust removal mechanism, the speed reduction mechanism and the acid-alkali washing mechanism are arranged in the box body; the particle filtering mechanism is arranged at one end of the box; the acid-alkali washing mechanism is arranged at the other end of the box body; the speed reducing mechanism is positioned between the particle filtering mechanism and the cloth bag dust removing mechanism; the cloth bag dust removal mechanism is positioned between the speed reduction mechanism and the acid-alkali washing mechanism; and the particle filtering mechanism comprises a filtering plate, a control plate, a buffering mechanism, a material guiding mechanism, a material guiding plate and a discharging mechanism. Large particles can be independently filtered, and the damage rate of a cloth bag in cloth bag dust removal is reduced; meanwhile, in the cloth bag dust removal mechanism, sticking substances attached to the surfaces of the cloth bags can be loosened through vibration, so that the cleaning effect of back flushing of the cloth bags is improved.

Owner:深圳博奥环境技术有限公司

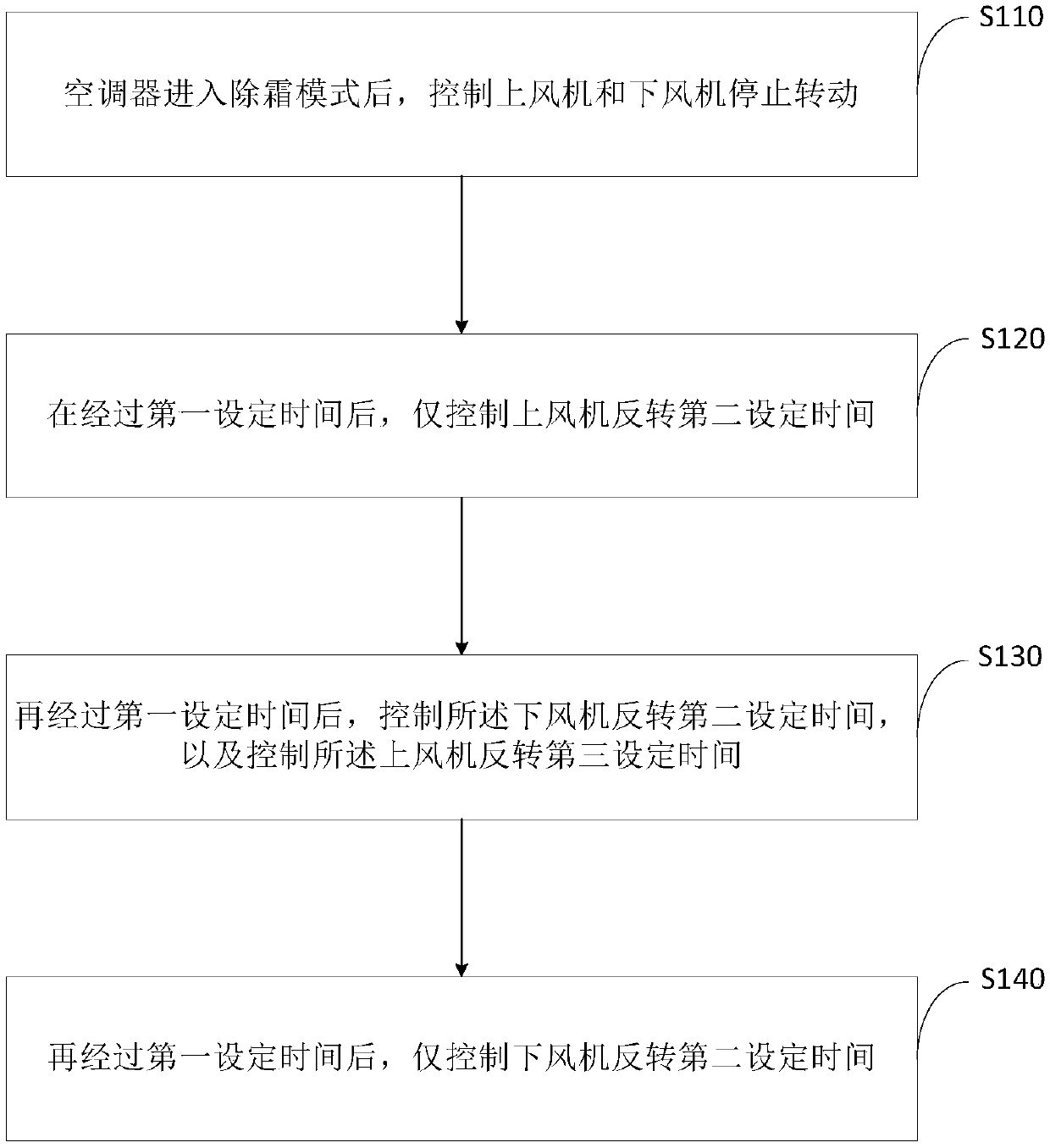

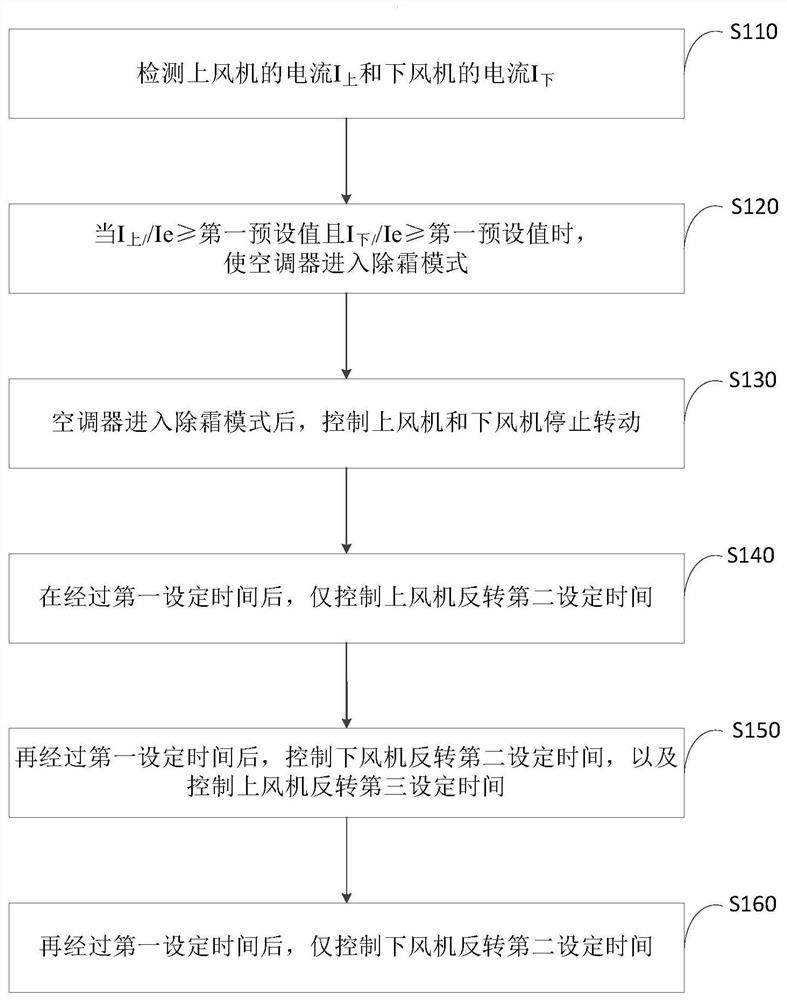

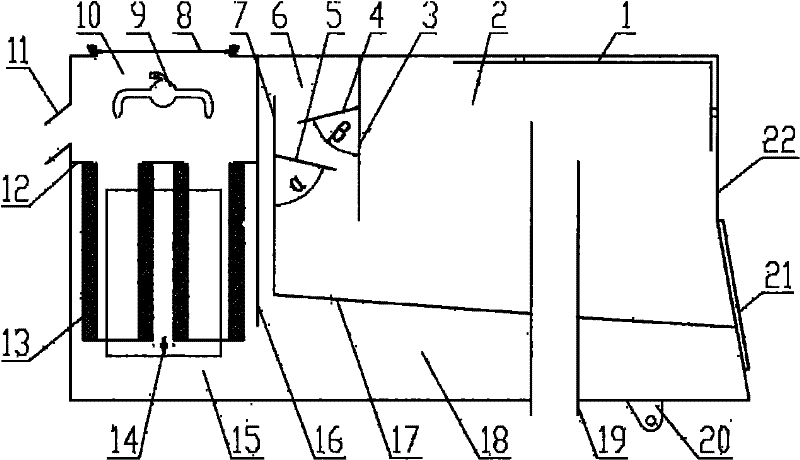

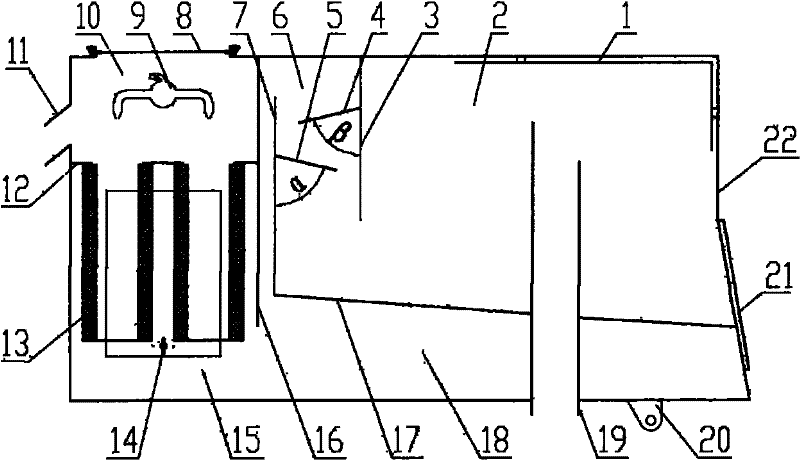

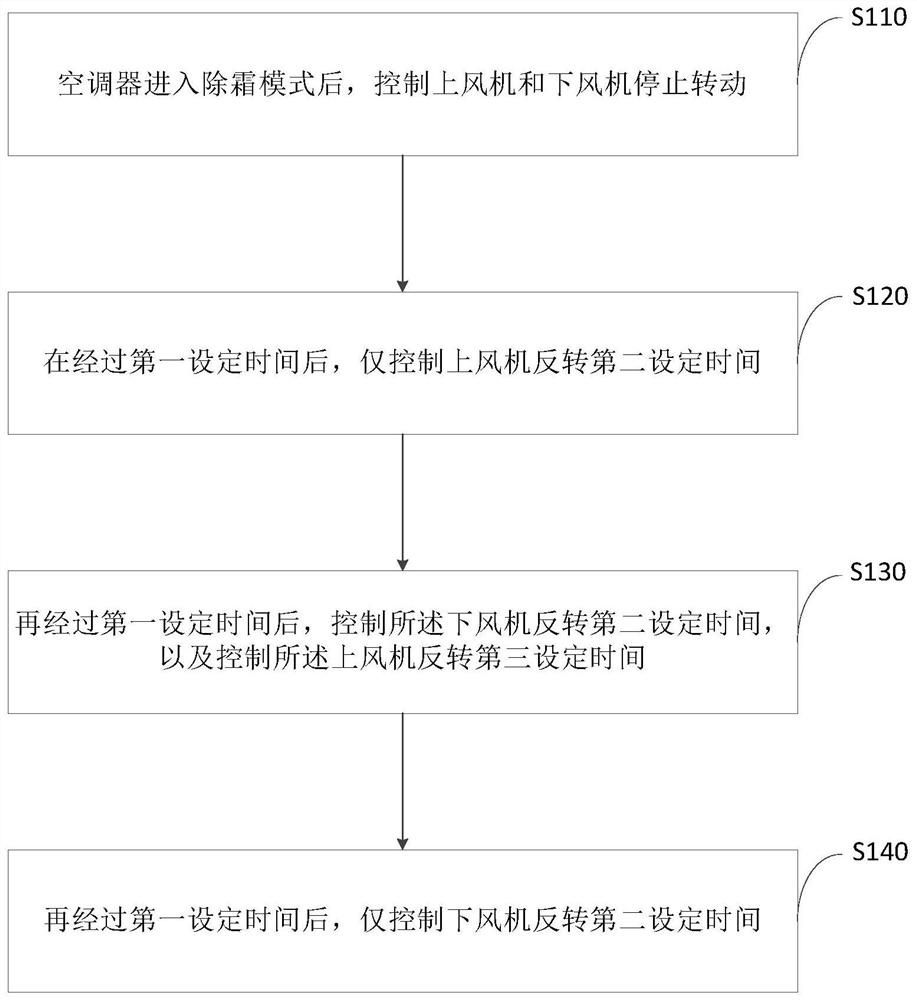

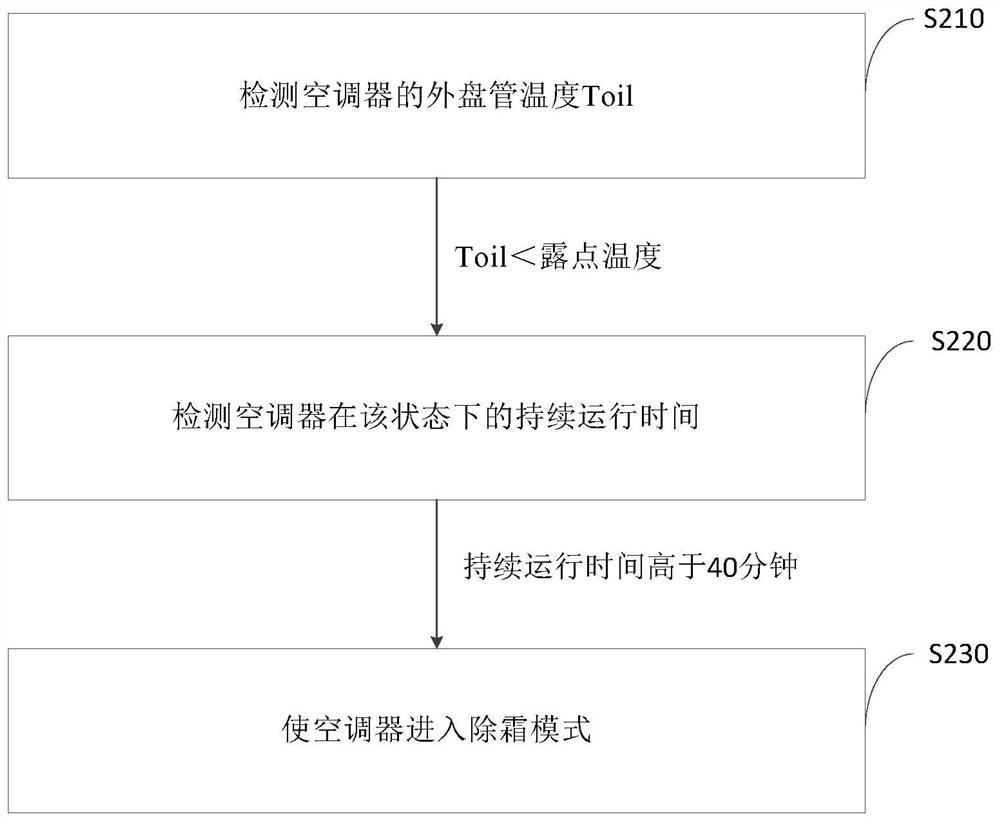

Defrosting control method of air conditioner

ActiveCN110836501AImprove defrosting efficiencyBlow off accuratelyMechanical apparatusSpace heating and ventilation safety systemsControl engineeringControl theory

The invention belongs to the technical field of air conditioners, and particularly relates to a defrosting control method of an air conditioner. The defrosting control method of the air conditioner isapplied to the air conditioner with double fans arranged on an outdoor unit so as to improve the defrosting efficiency of the air conditioner. The method includes the following steps that after the air conditioner enables the defrosting mode, an upper fan and a lower fan are controlled to stop rotation; after the first set time, only the upper fan is controlled to rotate reversely for the secondset time; after the first set time, the lower fan is controlled to rotate reversely for the second set time, and the upper fan is controlled to rotate reversely for the third set time; and after the second set time, only the lower fan is controlled to rotate reversely for the second set time. According to the method, the fans in the corresponding positions are controlled in a matched manner to rotate reversely according to the thawing sequence of frost, so that frost layers are blown off accurately, and the defrosting efficiency of the air conditioner is greatly improved.

Owner:ZHENGZHOU HAIER AIR CONDITIONER CO LTD +2

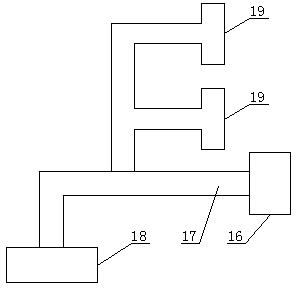

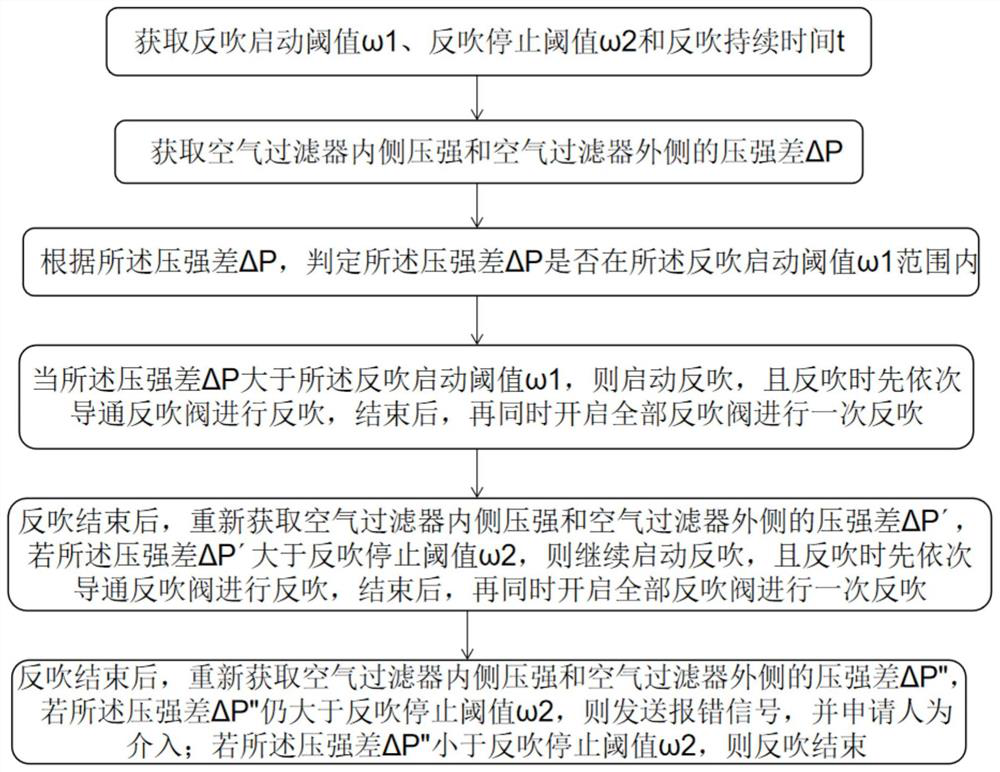

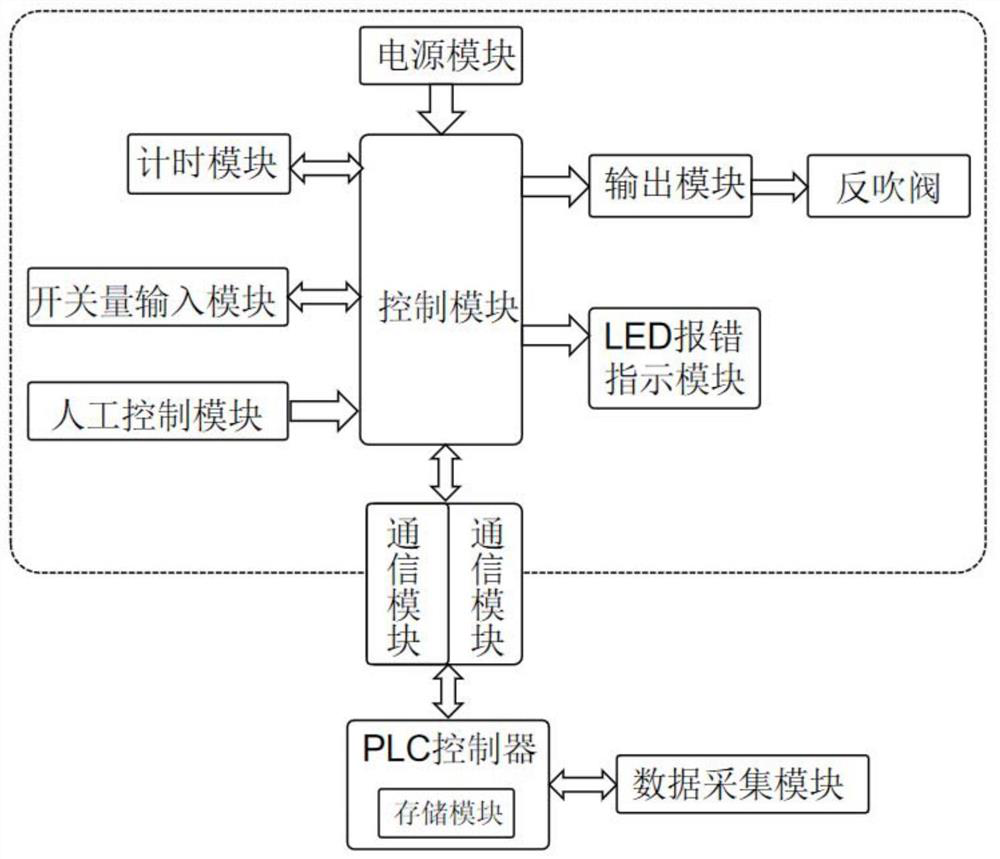

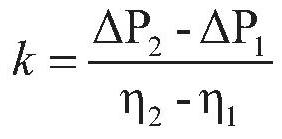

Gas turbine intake blowback control method, system and computer readable medium

ActiveCN111946463BImprove blowback effectLow blowback costGas turbine plantsJet propulsion plantsThermodynamicsAir filter

The invention discloses a gas turbine intake blowback control method, system and computer-readable medium. The gas turbine intake blowback control method includes: obtaining the blowback startup threshold ω 1 , Blowback stop threshold ω 2 and back-blowing duration t; obtain the pressure difference ΔP between the inside and outside of the air filter and determine whether the pressure difference ΔP is greater than the back-blowing start threshold ω 1 , when it is greater than , the blowback will be started, and when the blowback is performed, the blowback valves will be turned on one by one to carry out the blowback, and then all the blowback valves will be turned on at the same time for a blowback; the pressure difference ΔP′ will be obtained again, if it is greater than the blowback stop threshold ω 2 , repeat the backflushing of the above steps; after the backflushing is over, obtain the pressure difference ΔP″ again, if it is greater than the backflushing stop threshold ω 2 , send an error signal, and the applicant will intervene; if it is less than the blowback stop threshold ω 2 , the blowback ends. The present invention can achieve a better back blowing effect on the gas turbine filter by adopting the method of coordinating two back blows, and the cost of back blowing is low.

Owner:管网集团(新疆)联合管道有限责任公司 +1

Filter element

PendingCN112237809AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

Owner:CHENGDU INTERMENT TECH

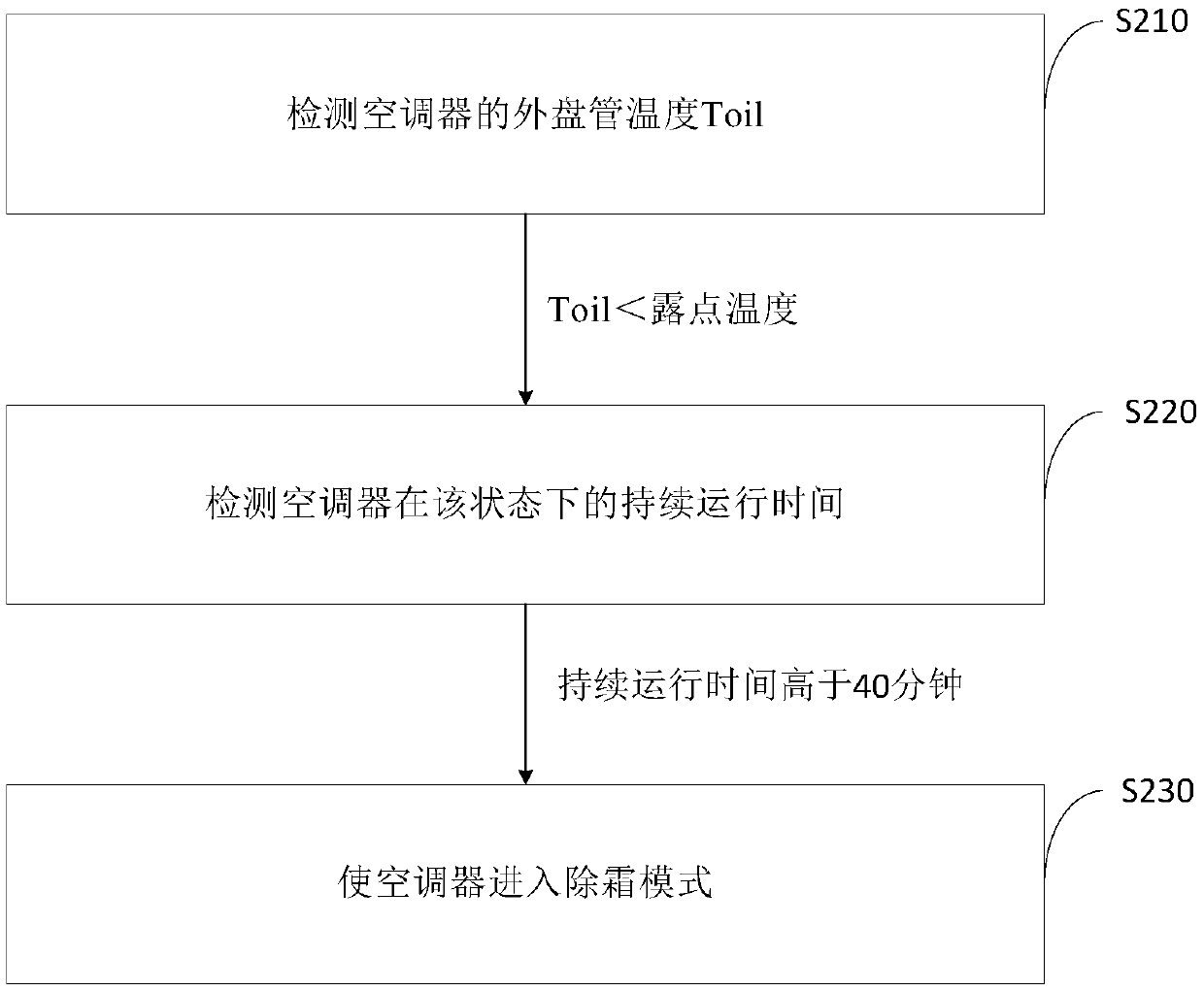

Air conditioner defrosting control method

ActiveCN110836499BImprove defrosting efficiencyBlow off accuratelyMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention belongs to the technical field of air conditioners, and in particular relates to an air conditioner defrosting control method. In order to improve the defrosting efficiency of the air conditioner, the air conditioner defrosting control method proposed in the present invention is aimed at an air conditioner with dual fans installed on the outdoor unit. The method includes: detecting the current I of the upper fan 上 and the current I of the lower fan 下 ; when I 上 / / Ie≥the first preset value and I 下 / When / Ie≥the first preset value, the air conditioner enters the defrosting mode; after the air conditioner enters the defrosting mode, the upper fan and the lower fan are controlled to stop rotating; after the first set time, only the upper fan is controlled to reverse for the second time 2. Set the time; after the first set time, control the reverse of the lower fan for the second set time, and control the reverse of the upper fan for the third set time; after the second set time, only control the lower fan Reverse the second set time. The present invention matches and controls the reverse rotation of the fan at the corresponding position according to the melting sequence of the frost, thereby accurately blowing off the frost layer and greatly improving the defrosting efficiency of the air conditioner.

Owner:CHONGQING HAIER AIR CONDITIONER CO LTD +2

Box body of pure-suction type road sweeper

ActiveCN101718082BLarge compartment volumeGood dust separation effectRoad cleaningRoad sweeperElectric power

Owner:SHANGHAI SHENZHOU AUTOMOBILE ENERGY SAVING ENVIRONMENTAL PROTECTION HAIAN +1

Air conditioner defrosting control method

ActiveCN110836501BImprove defrosting efficiencyBlow off accuratelyMechanical apparatusSpace heating and ventilation safety systemsFrostControl engineering

The invention belongs to the technical field of air conditioners, and in particular relates to a defrosting control method for an air conditioner. In order to improve the defrosting efficiency of the air conditioner, the defrosting control method for the air conditioner proposed by the present invention is aimed at the air conditioner with dual fans on the outdoor unit. The method includes the following steps: after the air conditioner enters the defrosting mode, control the upper fan and all The lower fan stops rotating; after the first set time, only the upper fan is controlled to reverse for the second set time; after the first set time, the lower fan is controlled to reverse for the second set time, and controlling the upper fan to reverse for a third set time; and after the second set time passes, only control the down fan to reverse for the second set time. The invention controls the reverse rotation of the fans at the corresponding positions in a matched manner according to the melting sequence of the frost, thereby accurately blowing off the frost layer and greatly improving the defrosting efficiency of the air conditioner.

Owner:ZHENGZHOU HAIER AIR CONDITIONER CO LTD +2

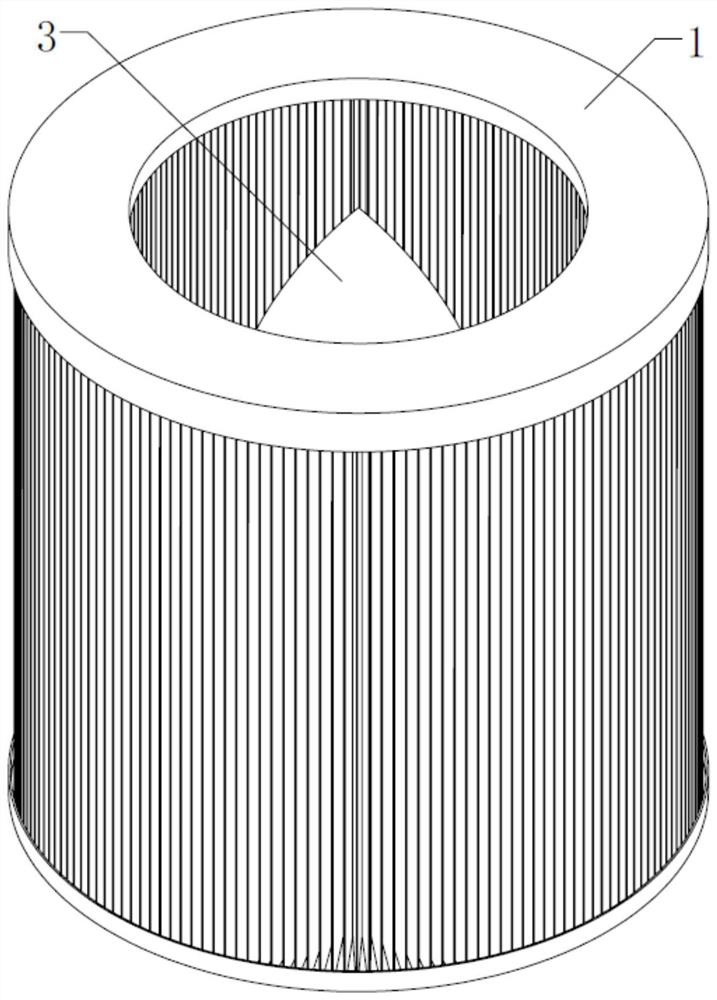

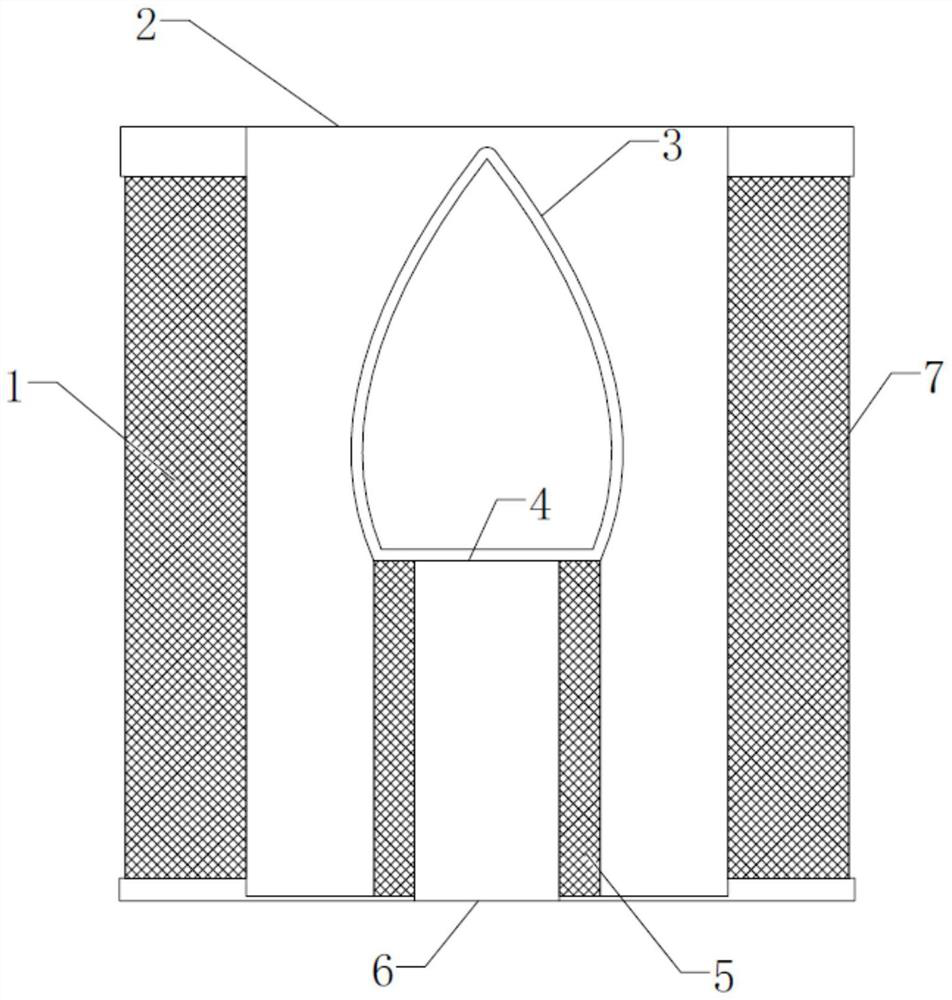

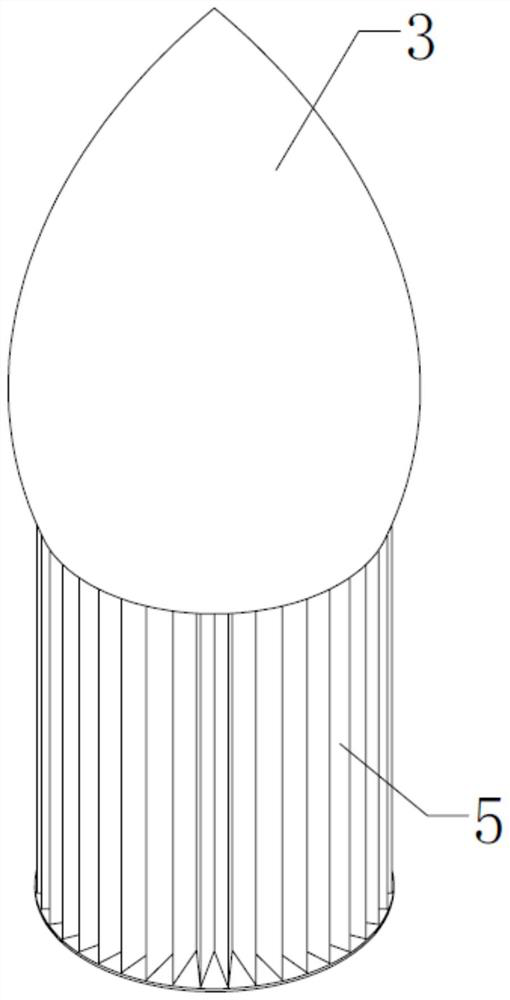

Composite double-layer filter cartridge with built-in parabolic airflow guide cone and method

PendingCN114699858AReduce lossesInjection pressure increasesDispersed particle filtrationTransportation and packagingDust controlStructural engineering

The invention discloses a composite double-layer filter cartridge with a built-in parabolic airflow guide cone and a method. Comprising an outer filter element and an inner filter element, the inner filter element is coaxially sleeved with the outer filter element; a space between the outer filter element and the inner filter element forms a filter cartridge cavity; the axial length of the inner filter element is smaller than that of the outer filter element; one axial end of the outer filter element is an air outlet, and the other axial end of the outer filter element is an air inlet; one end of the inner filter element is arranged at the air inlet end of the outer filter element, and an airflow guide cone is mounted at the other end of the inner filter element; the top end of the airflow guide cone is arranged towards the air outlet; according to the composite double-layer filter cartridge provided by the invention, the flow field of blowback dust removal airflow is changed through the airflow guide cone, so that the blowback pressure acting on the inner wall of the filter element is more uniform in the axial direction, and meanwhile, the filter area of the filter cartridge is increased due to the existence of the inner filter element, so that the dust removal effect is improved, the dust removal efficiency is improved, and the service life is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com