Composite double-layer filter cartridge with built-in parabolic airflow guide cone and method

A parabolic and composite technology, applied in separation methods, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems of insufficient dust removal strength of filter cartridges, shortening the service life of filter cartridges, and incomplete dust removal, etc., to achieve improved reaction Blowing effect, improving dust cleaning effect, improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

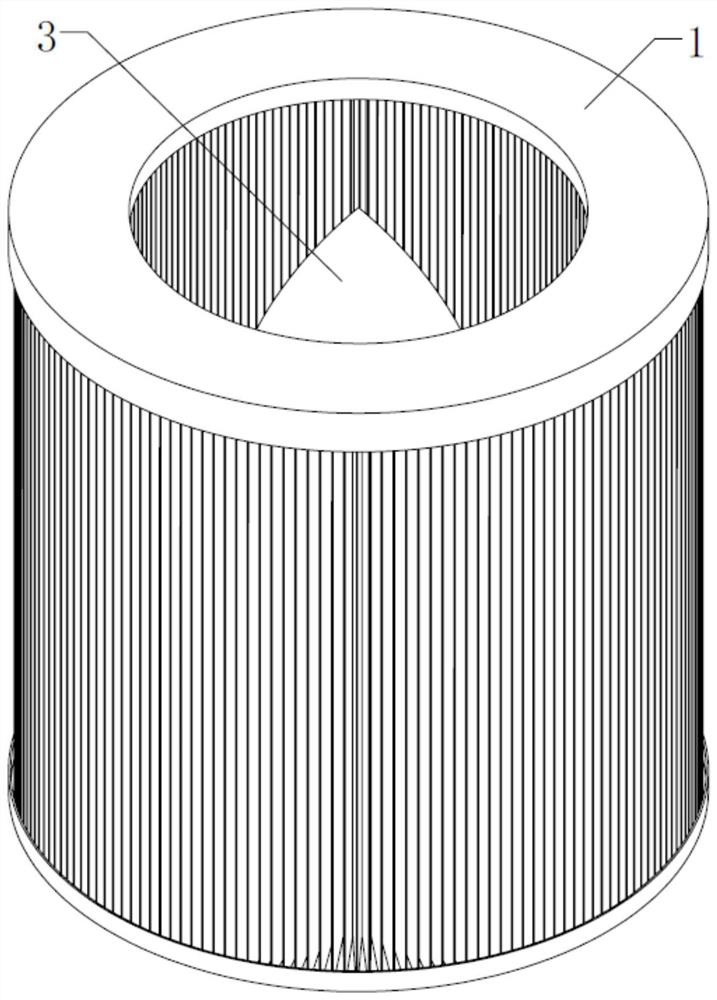

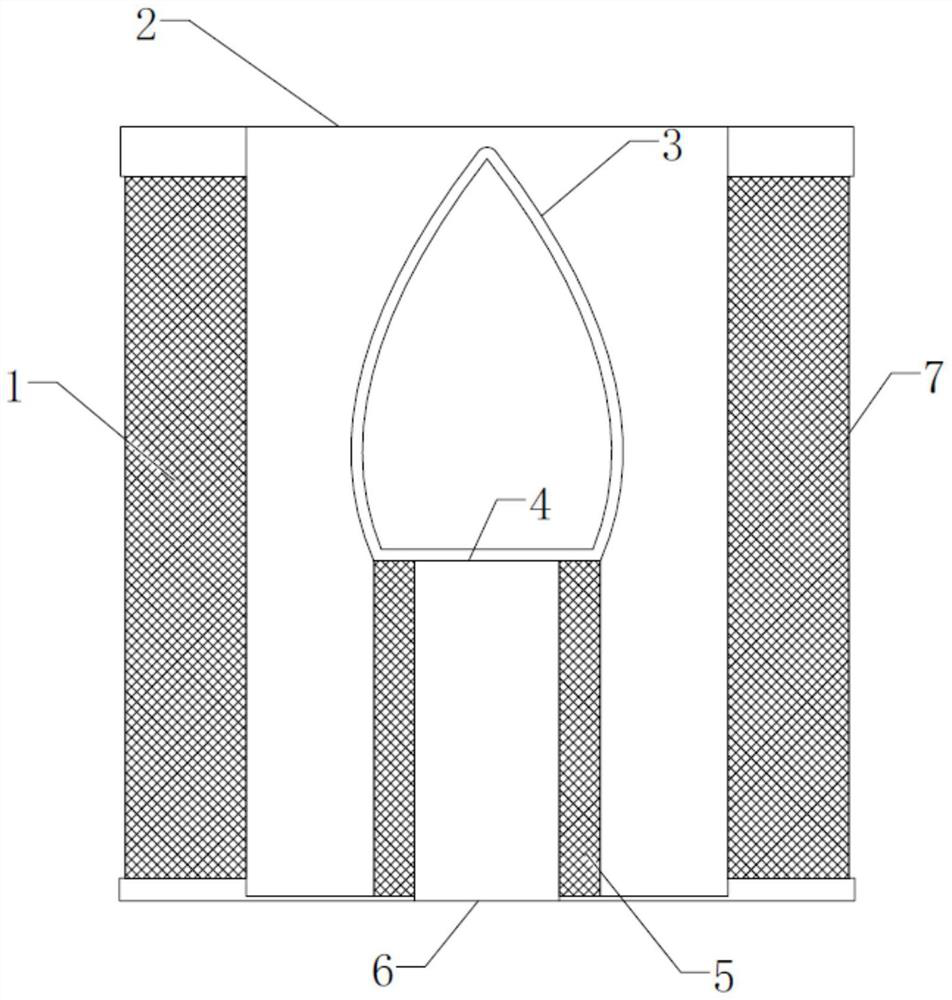

[0038] like Figure 1-3 shown. The invention discloses a composite double-layer filter cartridge with a built-in parabolic airflow guide cone, comprising an outer filter element 1 and an inner filter element 5; the inner filter element 5 is coaxially sleeved inside the outer filter element 1;

[0039] The space between the outer filter element 1 and the inner filter element 5 constitutes a filter cartridge cavity;

[0040] The peripheral wall of the outer filter element 1 is the air intake surface 7;

[0041] The axial length of the inner filter element 5 is less than the axial length of the outer filter element 1;

[0042] One axial end of the outer filter element 1 is the air outlet 2, and the other axial end is the air inlet 6;

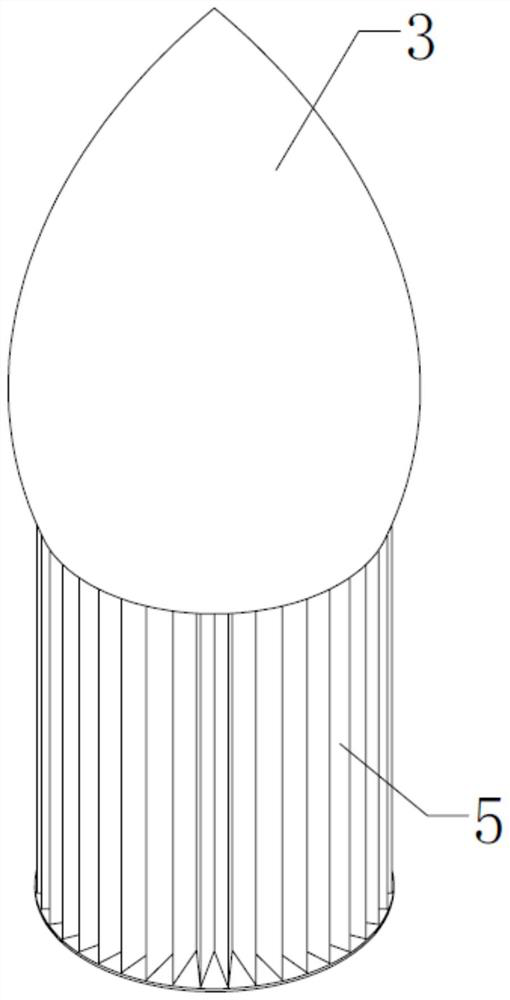

[0043] One end of the inner filter element 5 is arranged at the end of the air inlet 6 of the outer filter element 1, and the other end of the inner filter element 5 is installed with an airflow guide cone 3;

[0044] The external dirty air to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com