Gas filtration and dust removal device

A technology for filtering dust removal device and filtering device, which is applied in the directions of gas treatment, dispersed particle filtering, transportation and packaging, etc., can solve the problems of large unevenness of fluidization, inability to clean well, and poor backflushing effect, etc. Achieve the effect of prolonging the backflushing time, improving the filtration effect and filtration efficiency, and increasing the effect of fluidized backflushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

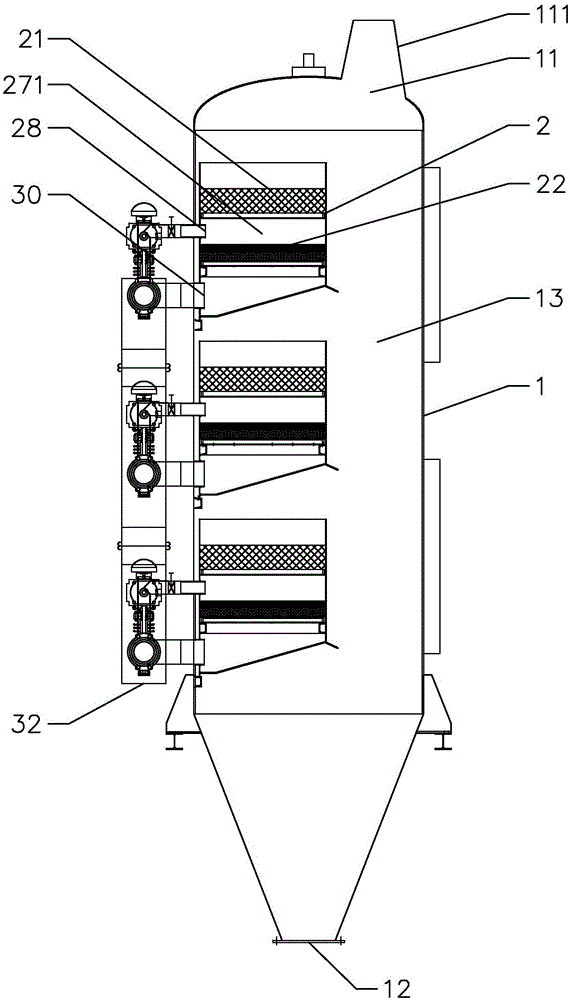

[0033] Such as figure 1 As shown in -2, the present invention provides a gas filter and dust removal device, comprising a housing 1 and a filter device 2 disposed in the housing 1. The filter device 2 is provided with multiple and arranged along the height direction of the housing 1. In this embodiment, the filter There are three devices 2 and they are evenly spaced along the height direction of the shell 1. Of course, the number of filter devices is different according to the different use environments. The shell 1 is provided with an air inlet 11 and an air outlet, and the air inlet 11 There is an air intake pipe 111 integrally formed with the shell 1, the air intake pipe 111 is in the shape of a cone with a small top and a large bottom, the bottom of the shell 1 is provided with a dust outlet 12, the inside of the shell 1 is provided with a dust collection channel 13, and a filter device 2 Including a first filter layer 21 and a second filter layer 22, the first filter laye...

Embodiment 2

[0049] The difference between this embodiment and the first embodiment lies in that the pressurization layer is different.

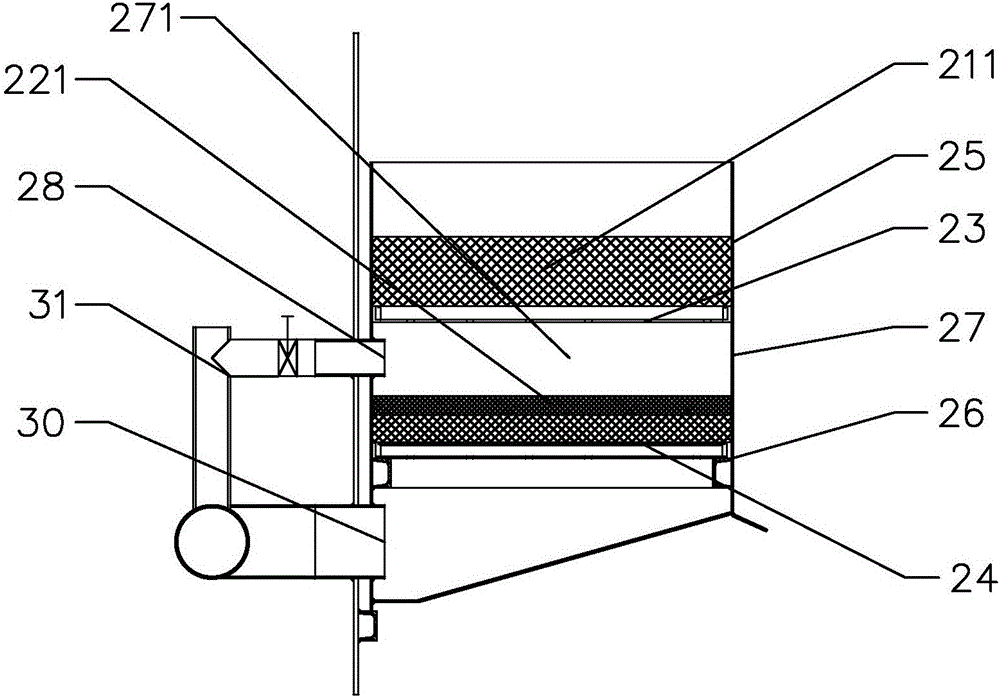

[0050] Such as figure 2 As shown, in this embodiment, the pressurized layer includes a pressurized air intake pipe 29 extending into the channel 271, a pressurized air intake 28 is arranged on the pressurized air intake pipe 29, and the pressurized air intake 28 faces the first filter layer 21. There are multiple supercharging air inlets 28 and they are evenly distributed on the supercharging air intake pipe 29 .

[0051] The benefit of this embodiment is that, by setting the pressurized air intake pipe extending into the passage, and setting the pressurized air intake on the pressurized air intake pipe, the reverse air can be better blown to the first filter layer, so that The first filter layer can better obtain the blowback pressure, which further increases the blowback volume of the first filter layer to ensure that the powder or dust on the first ...

Embodiment 3

[0053] The difference between this embodiment and the first embodiment lies in that the pressurization layer is different.

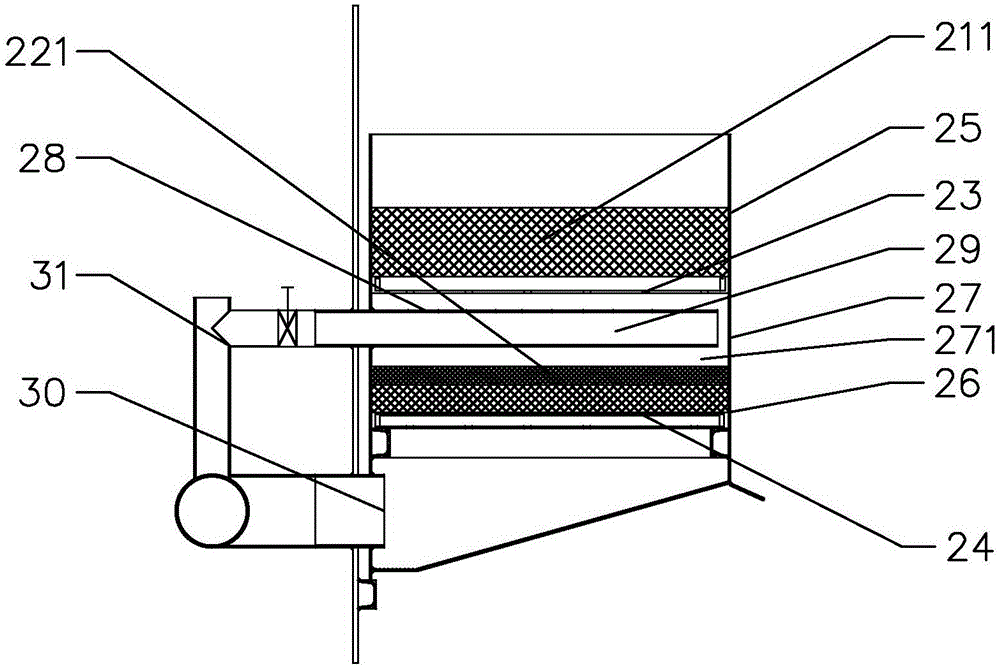

[0054] Such as Figure 4 , 5 As shown, in this embodiment, the pressurized layer includes a channel 271. The channel 271 is in the shape of a small cone with a small top and a large bottom. The channel 271 is provided with a first connection port that communicates with the first filter layer 21 and communicates with the second filter layer 22. The area of the first connection port is smaller than the area of the second connection port, and the filtration area of the first filter layer 21 is equal to the area of the first connection port.

[0055] The advantage of this embodiment is that the pressurized layer includes a channel, the channel is provided with a first connection port communicated with the first filter layer and a second connection port communicated with the second filter layer, and the area of the first connection port is smaller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com