Three-chamber regenerative thermal oxidizer (RTO) regenerative combustion furnace with purging pipeline

A technology for regenerative combustion and pipe purge, which is applied in the direction of combustion methods, combustion types, incinerators, etc. It can solve the problems of affecting appearance, messy pipelines, and poor cleanliness, and achieves regular pipeline layout, clean gas source, and low resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

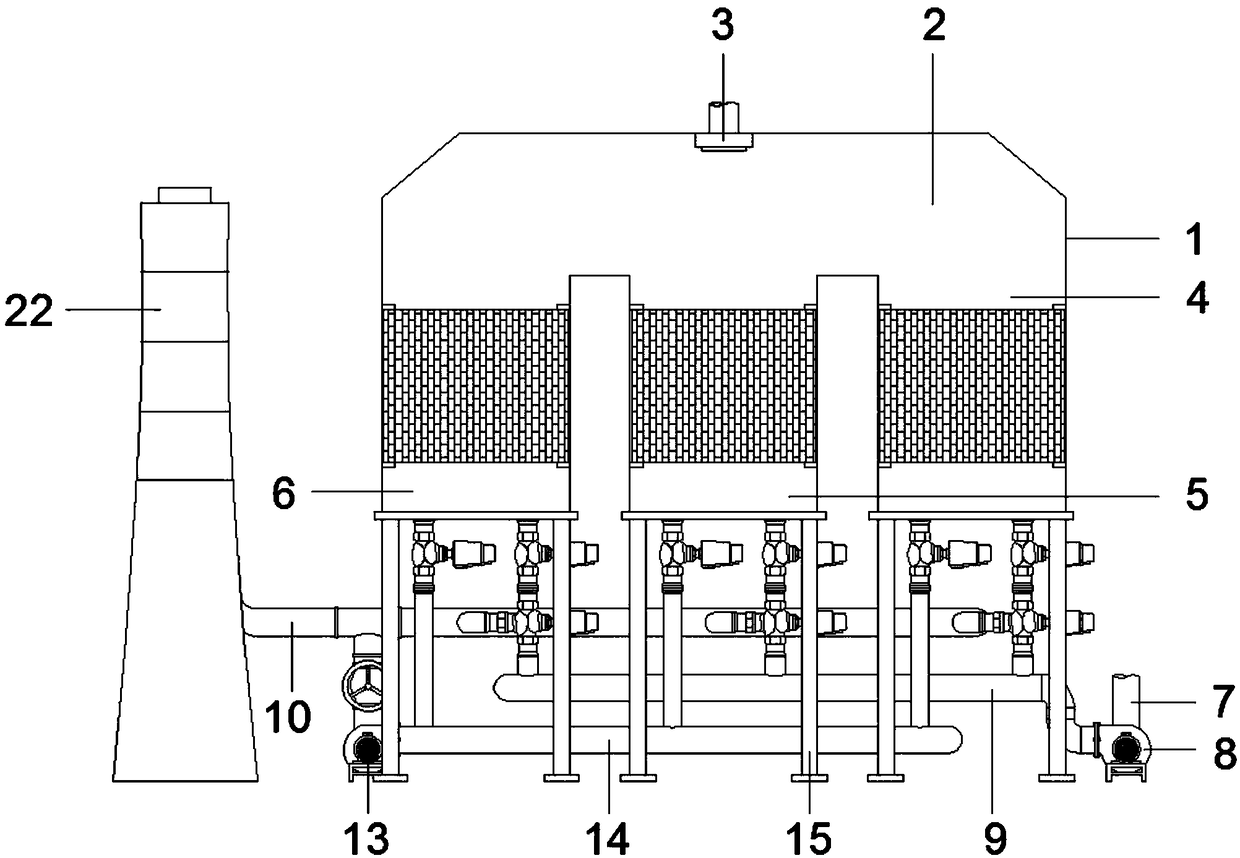

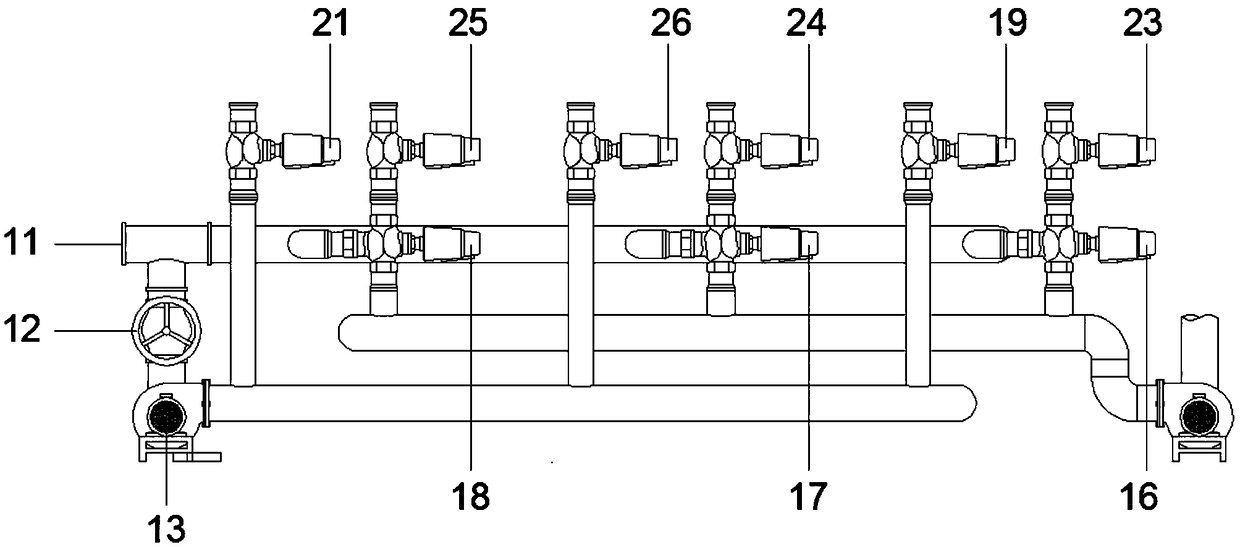

[0024] as attached figure 1 and figure 2The shown three-chamber RTO regenerative combustion furnace body with purge pipeline of the present invention includes: furnace body 1, combustion chamber 2, burner 3, first regenerator 4, second regenerator 5, third Regenerator 6, waste gas pipe 7, main fan 8, air intake pipe 9, exhaust pipe 10, exhaust tee 11, flow control valve 12, reverse blower 13, reverse blow pipe 14, support leg 15, first pneumatic Three-way valve 16, second pneumatic three-way valve 17, third pneumatic three-way valve 18, first pneumatic valve 19, second pneumatic valve 20, third pneumatic valve 21, chimney 22, fourth pneumatic valve 23, fifth Pneumatic valve 24, the sixth pneumatic valve 25; the combustion chamber 2 is arranged inside the furnace body 1; the burner 3 is arranged on the top of the combustion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com