Ultraviolet light polymerization super-hydrophobic transparent wear-resistant coating and preparation method thereof

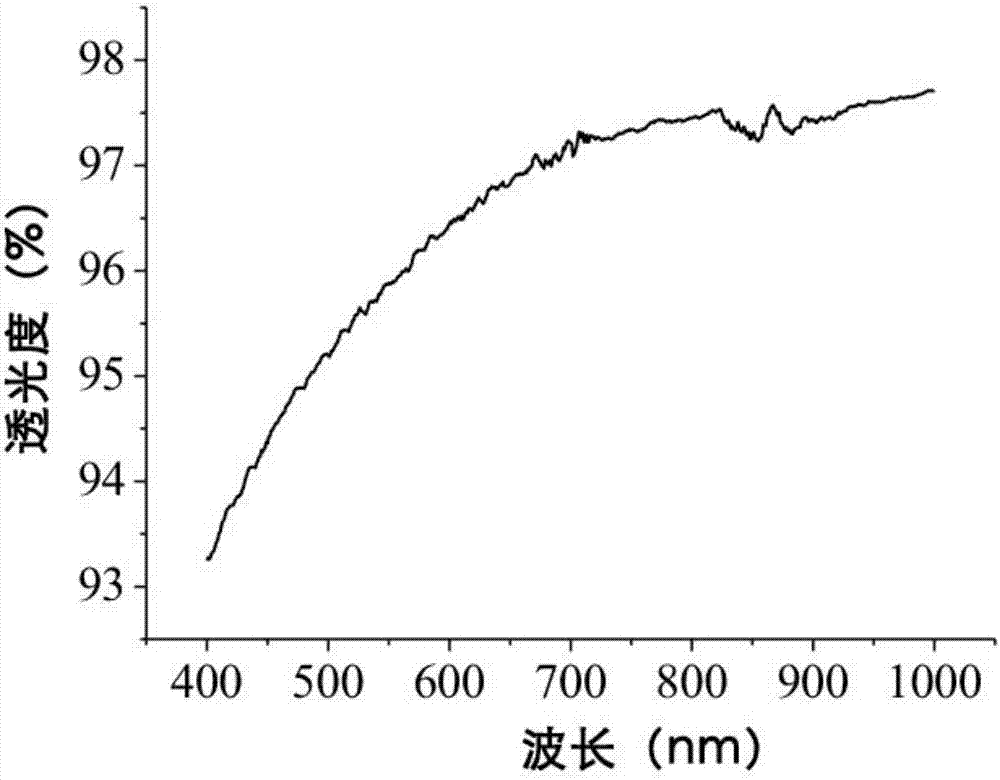

A technology of wear-resistant coating and ultraviolet light, which is applied in coatings, devices for coating liquid on the surface, pre-treatment of surfaces, etc., can solve the problem that the effective hardness of the coating cannot be guaranteed, the coating strength is not high enough, and the coating business is limited problems such as the application of chemicalization, to achieve the effect of ensuring optical transparency, improving wear resistance and hardness, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

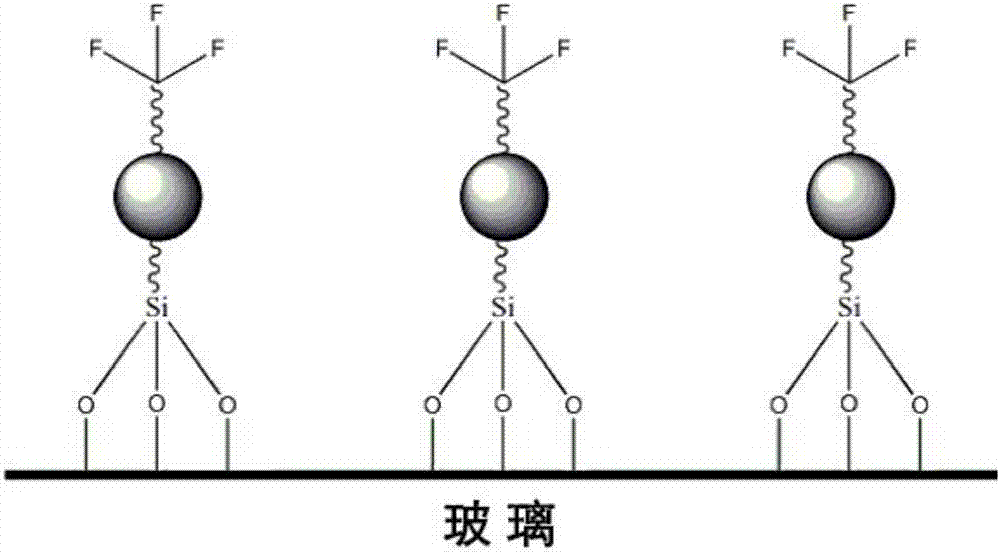

[0018] The invention provides a method for preparing an ultraviolet light-cured superhydrophobic transparent wear-resistant coating, the specific steps are as follows:

[0019] In the first step, the transparent substrate is activated and pretreated.

[0020] The transparent substrate used in the present invention is not particularly limited, and can be selected from existing materials with optically transparent properties (light transmittance greater than 80%). The transparent substrate used in the present invention can be glass, transparent ceramics, ITO (Indium Tin Oxide Semiconductor Transparent Conductive Film), polyethylene terephthalate, polybutylene terephthalate and polyethylene naphthalate Ethyl acetate, polyethylene, polypropylene, cellophane, diacetyl cellulose, triacetyl cellulose, acetyl cellulose butyrate, polyvinyl chloride, polyvinylidene chloride, polyvinyl alcohol, ethylene-vinyl acetate copolymer , polystyrene, polycarbonate, polymethylpentene, polysulfone...

Embodiment 1

[0046] Soak the glass substrate in piranha washing solution to remove the residual organic solvent on the surface, and dry it for future use. Take 10 parts of silane coupling agent and add it to 100 parts of methanol, soak the cleaned glass substrate and keep it at room temperature for 10 hours, and the alkyl group activates the surface structure of the glass substrate.

[0047] Take 5 parts of gas-phase nano-alumina, whose particle size distribution is 50-80nm, and add it to 100 parts of methanol; in addition, adjust the pH value of the solution to 3-4, stir and react for 12 hours under the condition of 30-45°C water bath, and finally obtain active nanoparticles of the dispersion.

[0048] Take 50 parts of the dispersion, add 0.5 parts of 2-perfluorooctylethyl methacrylate, 1.5 parts of trimethylolpropane triacrylate, and 0.25 parts of 1-hydroxycyclohexyl phenyl ketone, stir and mix evenly, and prepare Get the coating solution.

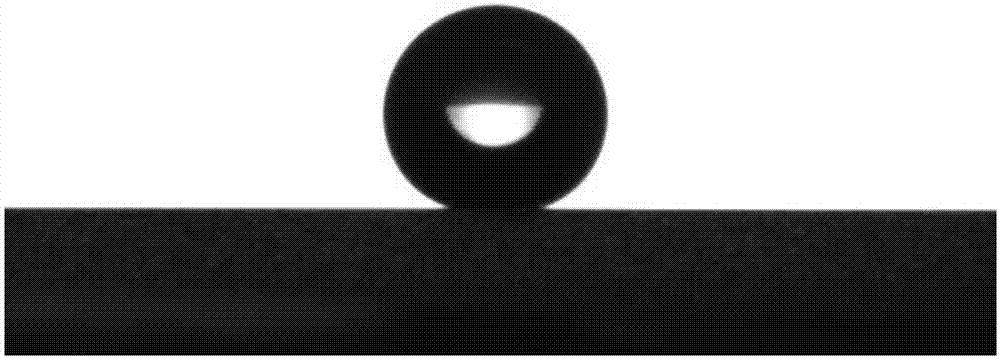

[0049] Spray the prepared coating solution o...

Embodiment 2

[0051] The glass substrate is cleaned and dried with ethanol solvent, and then placed in a plasma cleaning machine for plasma pretreatment of the glass surface structure. Add 10 parts of silane coupling agent to 100 parts of ethanol, soak the pretreated glass sheet at room temperature for 10 hours, and activate the surface structure of the glass sheet with the alkyl group.

[0052] Take 5 parts of nano-ZnO powder, the particle size distribution is 20-40nm, add it to 100 parts of n-propanol, and adjust the pH value of the solution to 3-4, stir and react for 24 hours in a water bath at 40-50°C, and finally obtain active nano-ZnO powder. dispersion of particles.

[0053] Take 50 parts of the dispersion liquid, add 0.5 parts of perfluorobutyl ethyl acrylate, 1.5 parts of methyl methacrylate, 0.25 parts of 2-hydroxy-2-methyl-1-phenylacetone, stir and mix evenly to obtain the coating cloth liquid.

[0054] Spray the prepared coating solution on the alkylated transparent glass, dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com