Method for multiple cutoff machining of rare earth magnet

a rare earth magnet and multiple cutting technology, applied in the direction of magnetic bodies, working accessories, manufacturing tools, etc., can solve the problems of low productivity of machining technology using id blades, parts cannot be formed, and lowering manufacturing yield, so as to reduce the effective diameter and reduce the effect of effective height and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

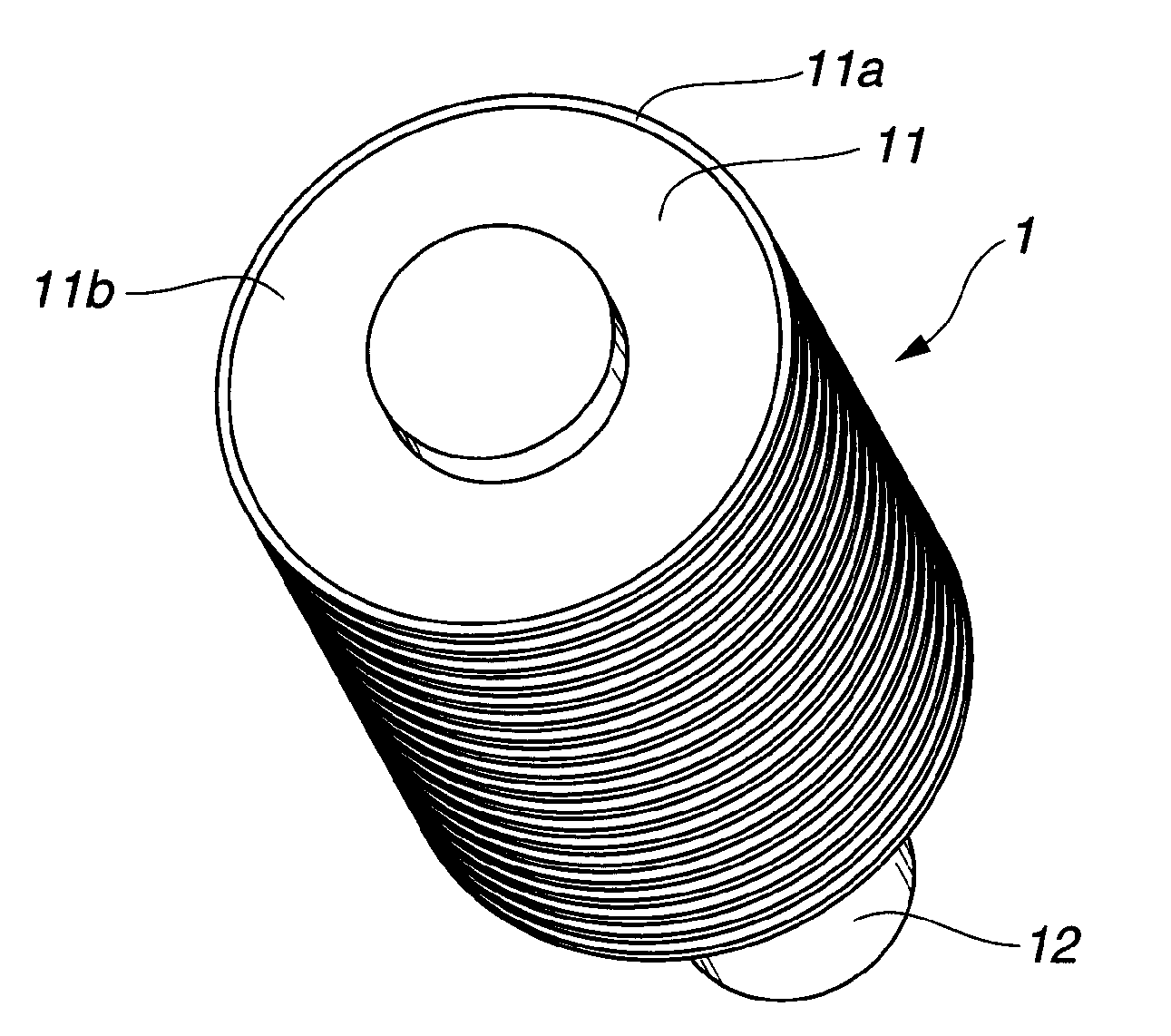

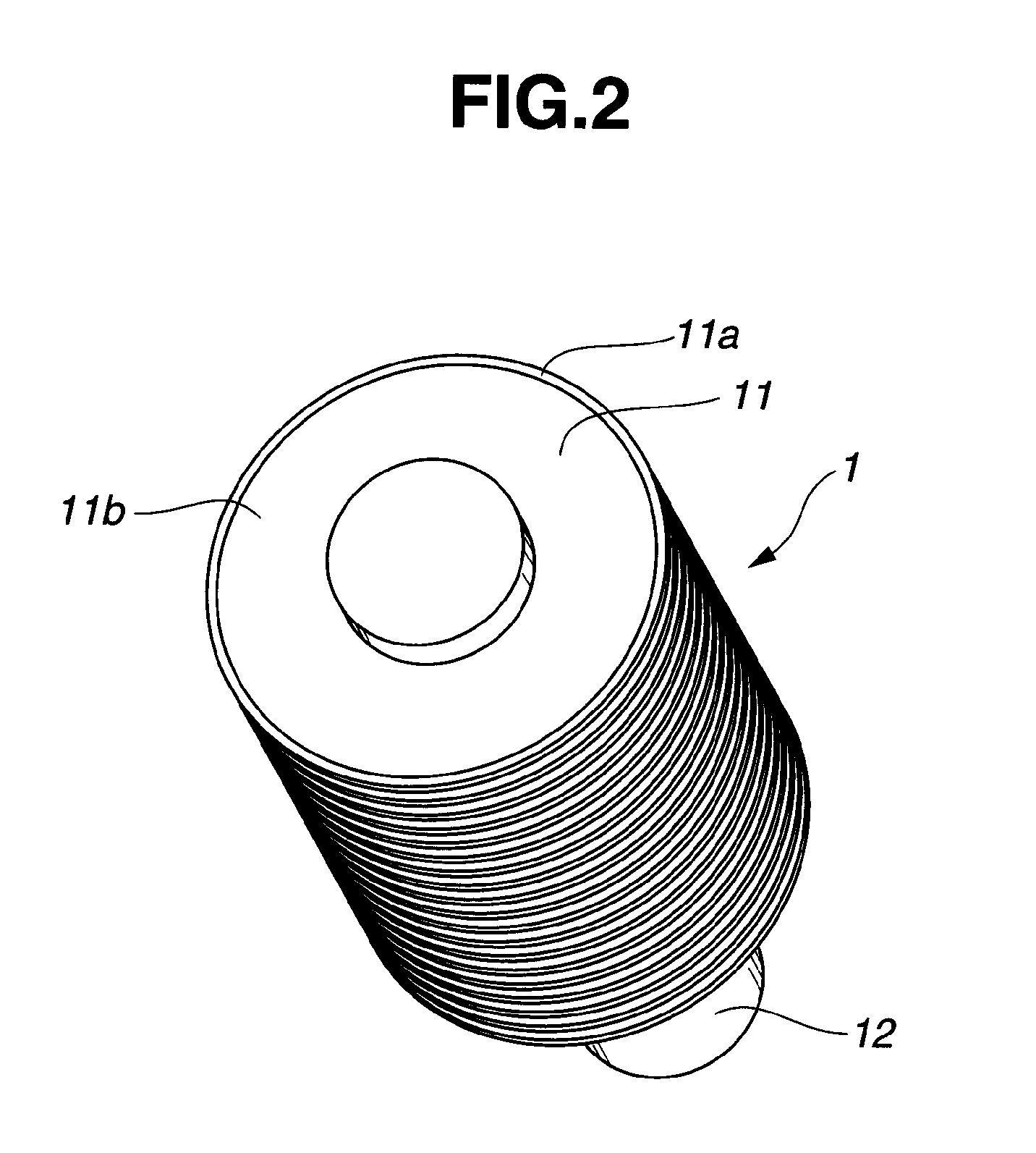

[0071]OD blades (cutoff abrasive blades) were fabricated by providing a doughnut-shaped disk core of cemented carbide (consisting of WC 90 wt % / Co 10 wt %) having an outer diameter 120 mm, inner diameter 40 mm, and thickness 0.3 mm, and bonding, by the resin bonding technique, artificial diamond abrasive grains to an outer peripheral rim of the core to form an abrasive section (peripheral cutting part) containing 25% by volume of diamond grains with an average particle size of 150 μm. The axial extension of the abrasive section from the core was 0.05 mm on each side, that is, the abrasive portion had a width of 0.4 mm (in the thickness direction of the core).

[0072]Using the OD blades, a cutting test was carried out on a workpiece which was a sintered Nd—Fe—B magnet block. The test conditions are as follows. A multiple blade assembly was manufactured by coaxially mounting 41 OD blades on a shaft at an axial spacing of 2.1 mm, with spacers interposed therebetween. The spacers each had...

example 2

[0084]OD blades (cutoff abrasive blades) were fabricated by providing a doughnut-shaped disk core of cemented carbide (consisting of WC 90 wt % / Co 10 wt %) having an outer diameter 115 mm, inner diameter 40 mm, and thickness 0.35 mm, and bonding, by the resin bonding technique, artificial diamond abrasive grains to an outer peripheral rim of the core to form an abrasive section (peripheral cutting part) containing 25% by volume of diamond grains with an average particle size of 150 μm. The axial extension of the abrasive section from the core was 0.025 mm on each side, that is, the abrasive portion had a width of 0.4 mm (in the thickness direction of the core).

[0085]Using the OD blades, a cutting test was carried out on a workpiece which was a sintered Nd—Fe—B magnet block. The test conditions are as follows. A multiple blade assembly was manufactured by coaxially mounting 42 OD blades on a shaft at an axial spacing of 2.1 mm, with spacers interposed therebetween. The spacers each h...

example 3

[0094]OD blades (cutoff abrasive blades) were fabricated by providing a doughnut-shaped disk core of cemented carbide (consisting of WC 90 wt % / Co 10 wt %) having an outer diameter 145 mm, inner diameter 40 mm, and thickness 0.5 mm, and bonding, by the resin bonding technique, artificial diamond abrasive grains to an outer peripheral rim of the core to form an abrasive section (peripheral cutting part) containing 25% by volume of diamond grains with an average particle size of 150 μm. The axial extension of the abrasive section from the core was 0.05 mm on each side, that is, the abrasive portion had a width of 0.6 mm (in the thickness direction of the core).

[0095]Using the OD blades, a cutting test was carried out on a workpiece which was a sintered Nd—Fe—B magnet block. The test conditions are as follows. A multiple blade assembly was manufactured by coaxially mounting 14 OD blades on a shaft at an axial spacing of 3.1 mm, with spacers interposed therebetween. The spacers each had...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com