Device for constructing a carcass for a vehicle tire

A technology for tires and carcass, applied in tires, applications, household appliances, etc., can solve the problem that tires with a tire size of 13 inches or smaller cannot be used, and achieve the effect of short time for size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

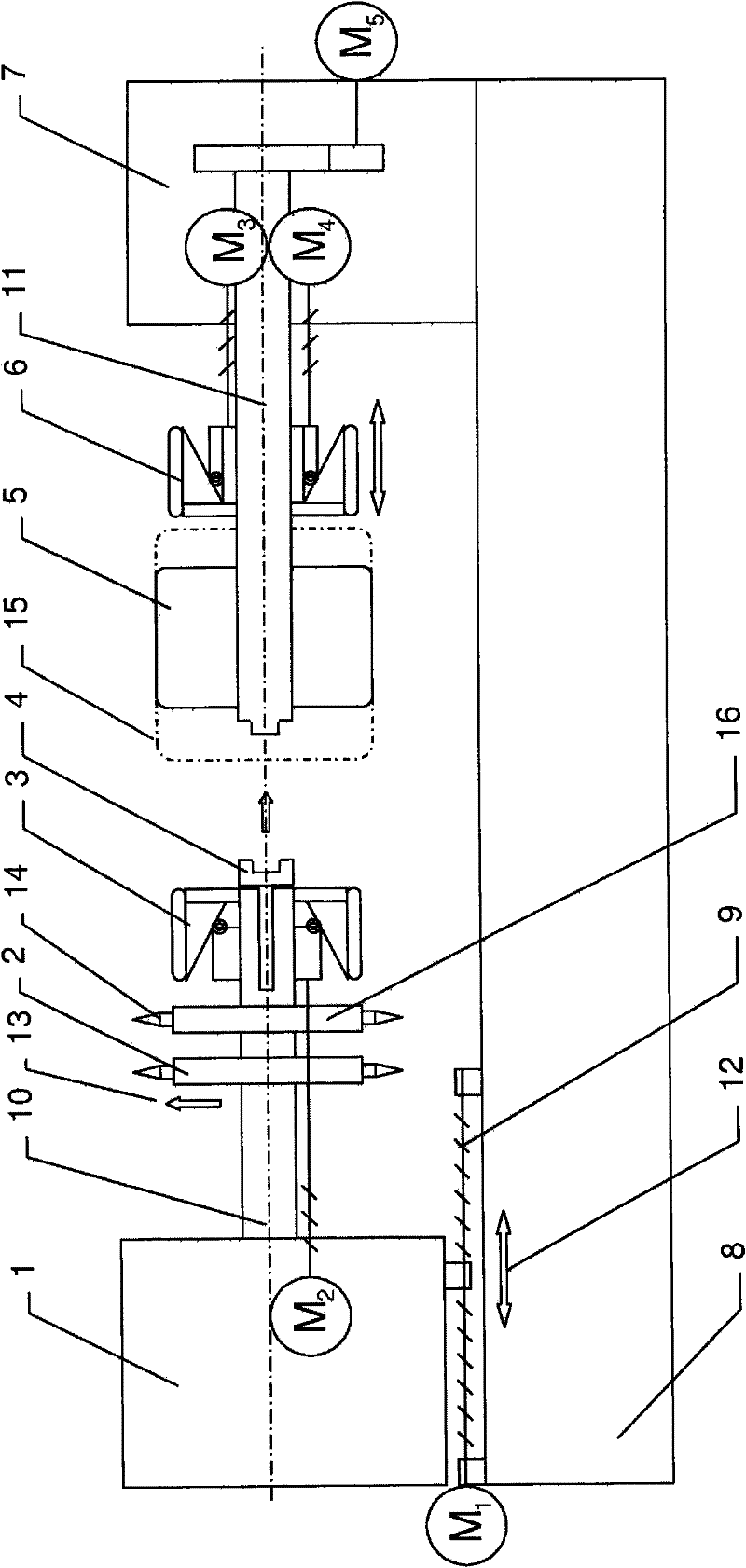

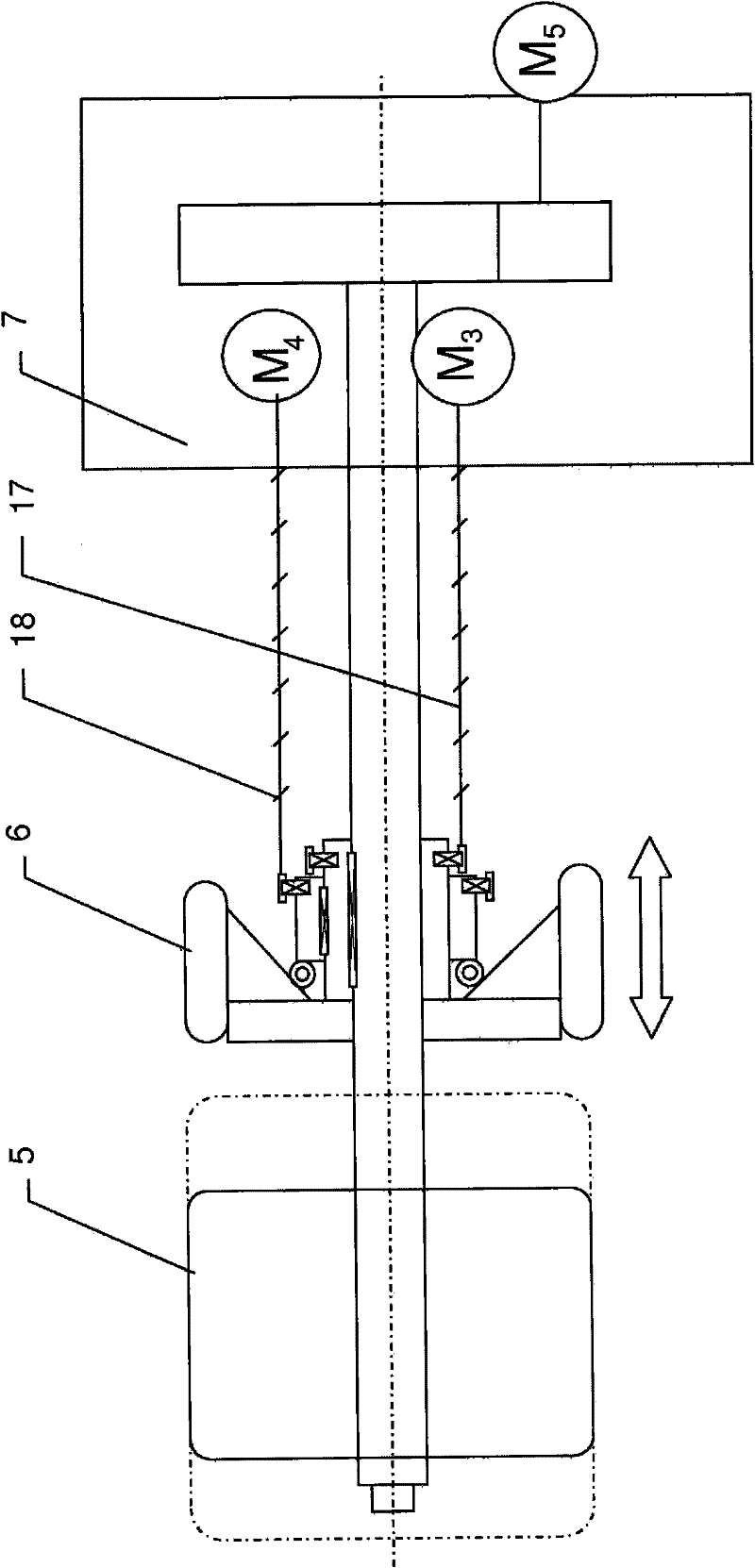

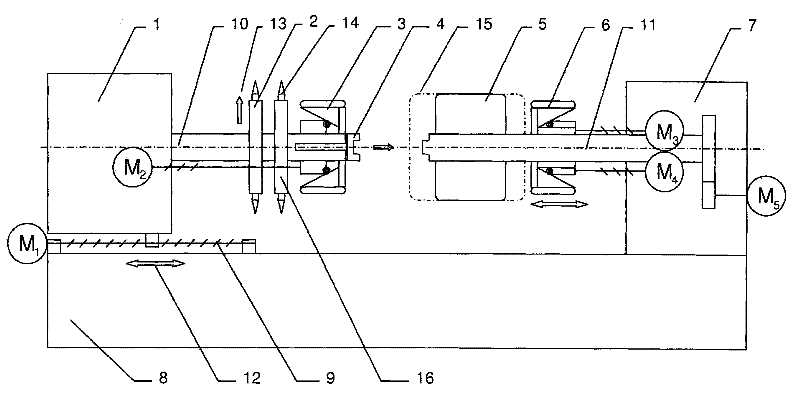

[0046] figure 1 The device is shown in a basic position. The device comprises a building or carcass drum 5 , which is rotatably arranged on a drive shaft 11 . The drive shaft 11 is rotatably installed in the spindle box 7 and driven by the motor M5. The dashed line 15 shows a possible wider building drum, which can likewise be arranged on the drive shaft 11 , eg for larger tire sizes. Arranged on both sides of the building drum 5 is a left airbag holder 3 and a right airbag holder 6 . The right airbag carrier 6 is moved in its axial position along the shaft 11 by the electric motor M3. The axial position of the airbag carrier 6 depends on the tire carcass which is subject to corresponding requirements. The diameter adjustment of the balloon support in the radial direction 13 is carried out by means of the electric motor M4. The balloon holders 3 and 6 are equipped on their outer circumference with inflatable balloons which wrap, inter alia, the insertion ends around the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com