Composite sealing material

A composite sealing and inorganic filler technology, applied in other chemical processes, chemical instruments and methods, etc., to achieve the effects of improving important performance, improving comprehensive performance, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

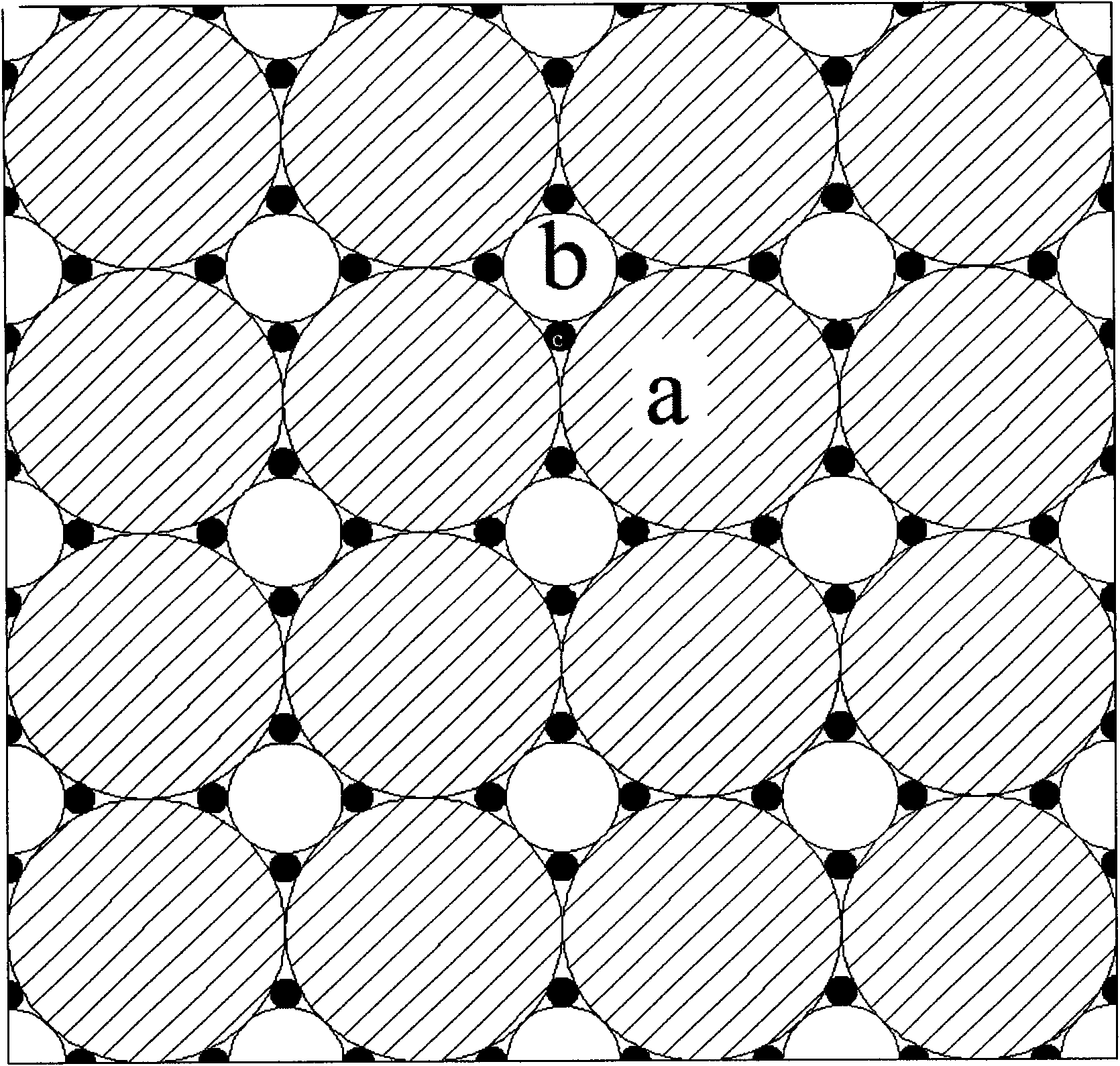

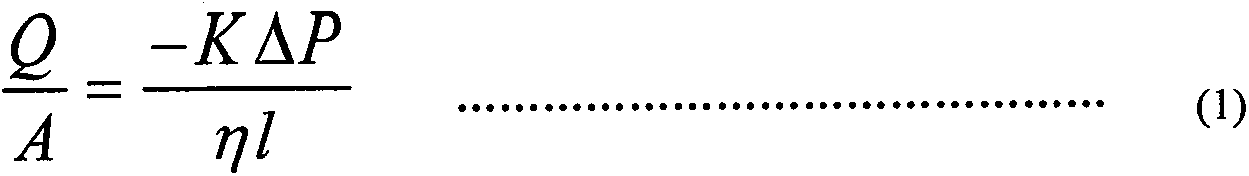

Method used

Image

Examples

Embodiment 1

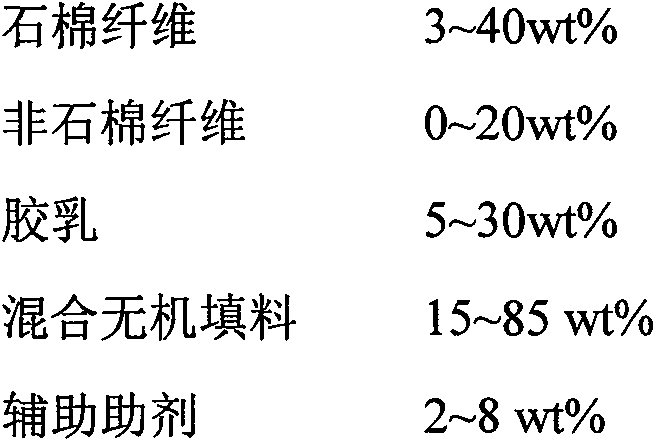

[0031] Embodiment 1: the weight ratio of each component in asbestos or non-asbestos fiber composite sealing material formula is:

[0032]

[0033] The mixed inorganic filler consists of 65% of 1 # Calcium Carbonate, 25% of 2 # calcium carbonate and 10% of 3 # Calcium carbonate graded. The average particle size of each filler used in gradation is shown in Table 1.

[0034] Table 1

[0035] Filling number 1 # calcium carbonate 2 # calcium carbonate 3 # calcium carbonate Average particle size / micron 3.98 1.64 0.48

[0036] According to the above raw material proportioning, the formula of the invention example 1 and the single filler (sample 2: 100% 1 # Calcium carbonate filler; sample 3: 100% 3 # Calcium carbonate filler) the same formula were carried out papermaking method sheet test. The performance comparison of the three sealing material samples is shown in Table 2.

[0037] Table 2

[0038]

[0039] As can be seen from Table 2,...

Embodiment 2

[0040] Embodiment 2: the weight ratio of each component in asbestos or non-asbestos fiber composite sealing material formula is:

[0041]

[0042] where the mixed inorganic filler consists of 50% of 1 # Talc powder, 30% of 2 # Talc, 14% of 1 # Kaolin and 6% of 2 # Kaolin graded. The average particle size of each filler used in gradation is shown in Table 3.

[0043] table 3

[0044] Numbering 1 # talcum powder 2 # talcum powder 1 # Kaolin 2 # Kaolin Average particle size / micron 8.01 3.22 1.23 0.31

[0045] According to the above raw material proportioning, the formula of the invention example 2 and the single filler (sample 5: 100% 1 # Talc filler; sample 6: 100% 2 # The same formulation of kaolin filler) was carried out papermaking method sheet test respectively. The performance comparison of the three sealing material samples is shown in Table 4.

[0046] Table 4

[0047]

[0048] As can be seen from Table 4, with the use ...

Embodiment 3

[0049] Embodiment 3: the weight ratio of each component in asbestos or non-asbestos fiber composite sealing material formula is:

[0050]

[0051] The mixed inorganic filler consists of 45% of 1 # Talc, 28% of 2 # Talc, 17% of 1 # Kaolin and 10% of 3 # Calcium carbonate graded. The average particle size of each filler used in gradation is shown in Table 5.

[0052] table 5

[0053] Numbering 1 # talcum powder 2 # talcum powder 1 # Kaolin 3 # calcium carbonate Average particle size / micron 8.01 3.22 1.23 0.48

[0054] According to the above raw material proportioning, the formula of the invention example 3 and the single filler (sample 8: 100% 2 # Talc filler; sample 9: 100%3 # Calcium carbonate filler) the same formula were carried out papermaking method sheet test. The performance comparison of the three sealing material samples is shown in Table 6.

[0055] Table 6

[0056]

[0057] As can be seen from Table 6, with the use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com