Exhaust system for internal combustion engine and vehicle with exhaust system

A technology for exhaust systems and internal combustion engines, which is applied in exhaust treatment, exhaust devices, gas chambers, etc., and can solve problems such as attenuation and high consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

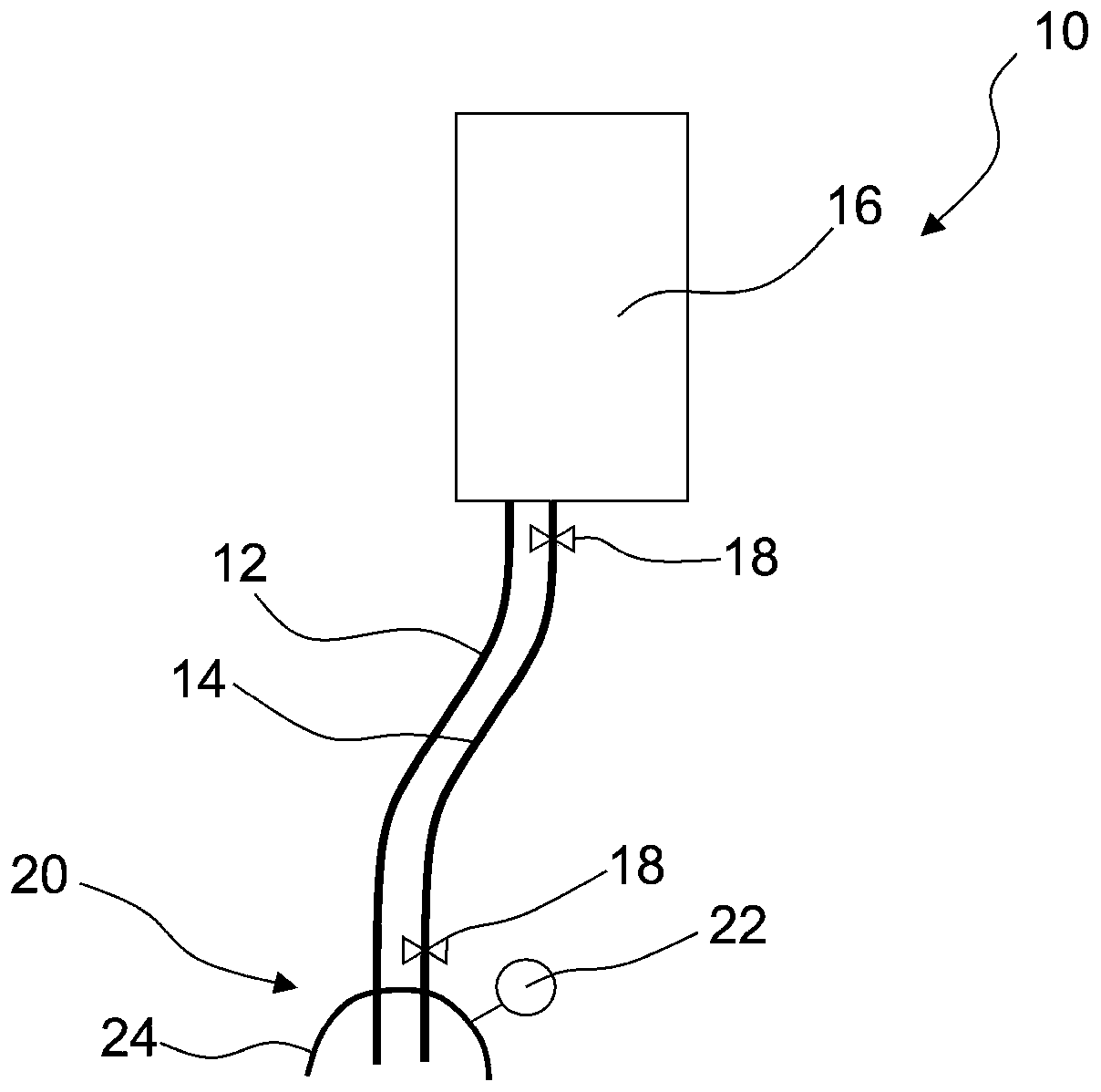

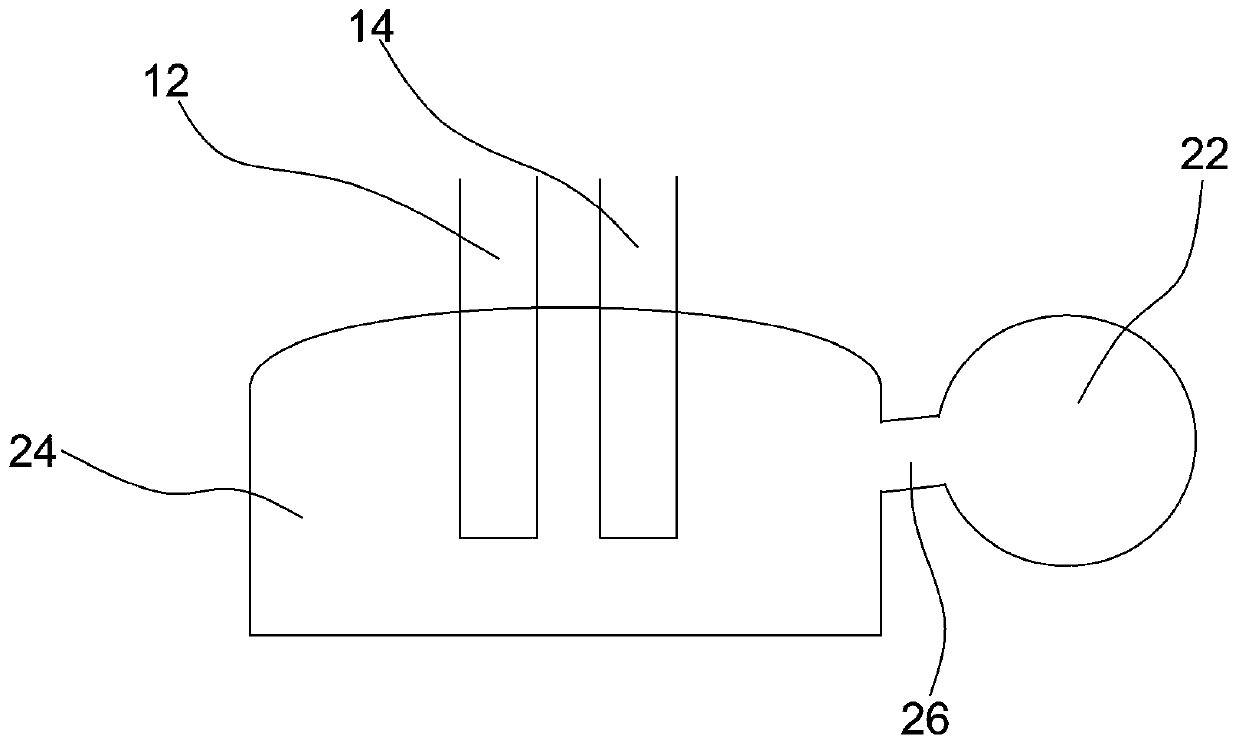

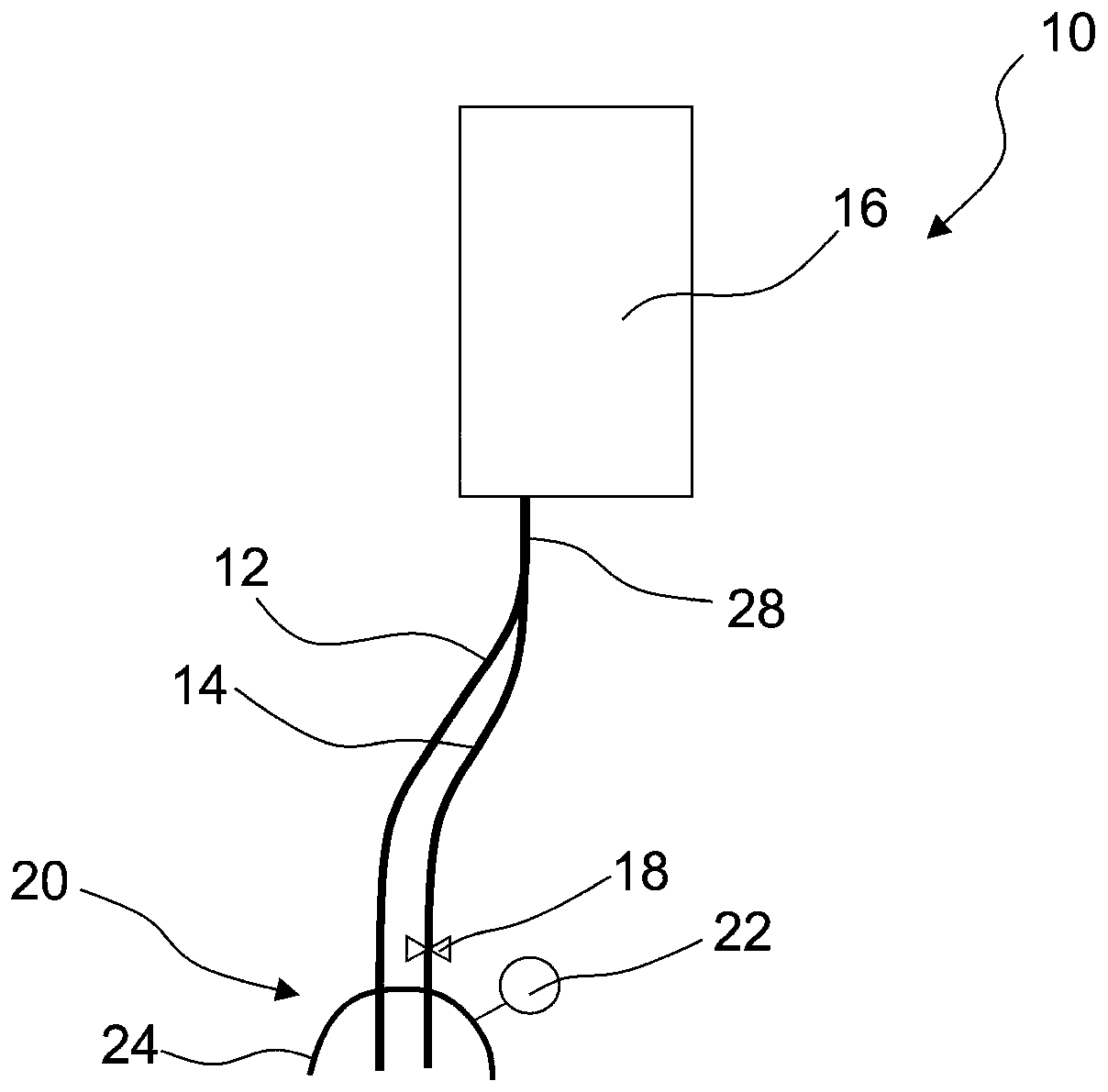

[0045] The exhaust system 10 comprises two exhaust pipes 12 , 14 which extend adjacently, in particular parallel, in the longitudinal direction of the vehicle. In this case, the exhaust lines 12 , 14 are arranged downstream of the intermediate silencer 16 and are in flow connection with the silencer body of the intermediate silencer 16 . That is, the exhaust pipes 12, 14 extend from the center muffler 16 to the exhaust outlet.

[0046] Arranged in one of the two exhaust lines 12 , 14 is a valve 18 which can selectively block or release the flow path through the corresponding exhaust line 14 . The valve 18 comprises, for example, a flap.

[0047] exist figure 1Two alternative possible positions of the valve 18 are shown in , near the upstream or downstream end of the exhaust pipe 14 . In practice, however, usually only one valve 18 is arranged in the exhaust pipe 12 , 14 .

[0048] When the valve 18 is closed, the effective flow cross section of the exhaust system 10 is red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com