Rare earth magnet and production process thereof

一种稀土磁体、磁体的技术,应用在磁体、电感/变压器/磁铁制造、磁性物体等方向,能够解决高矫顽磁力、剩磁降低的程度增大、不利于获得等问题,达到提高矫顽磁力、优异批量生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

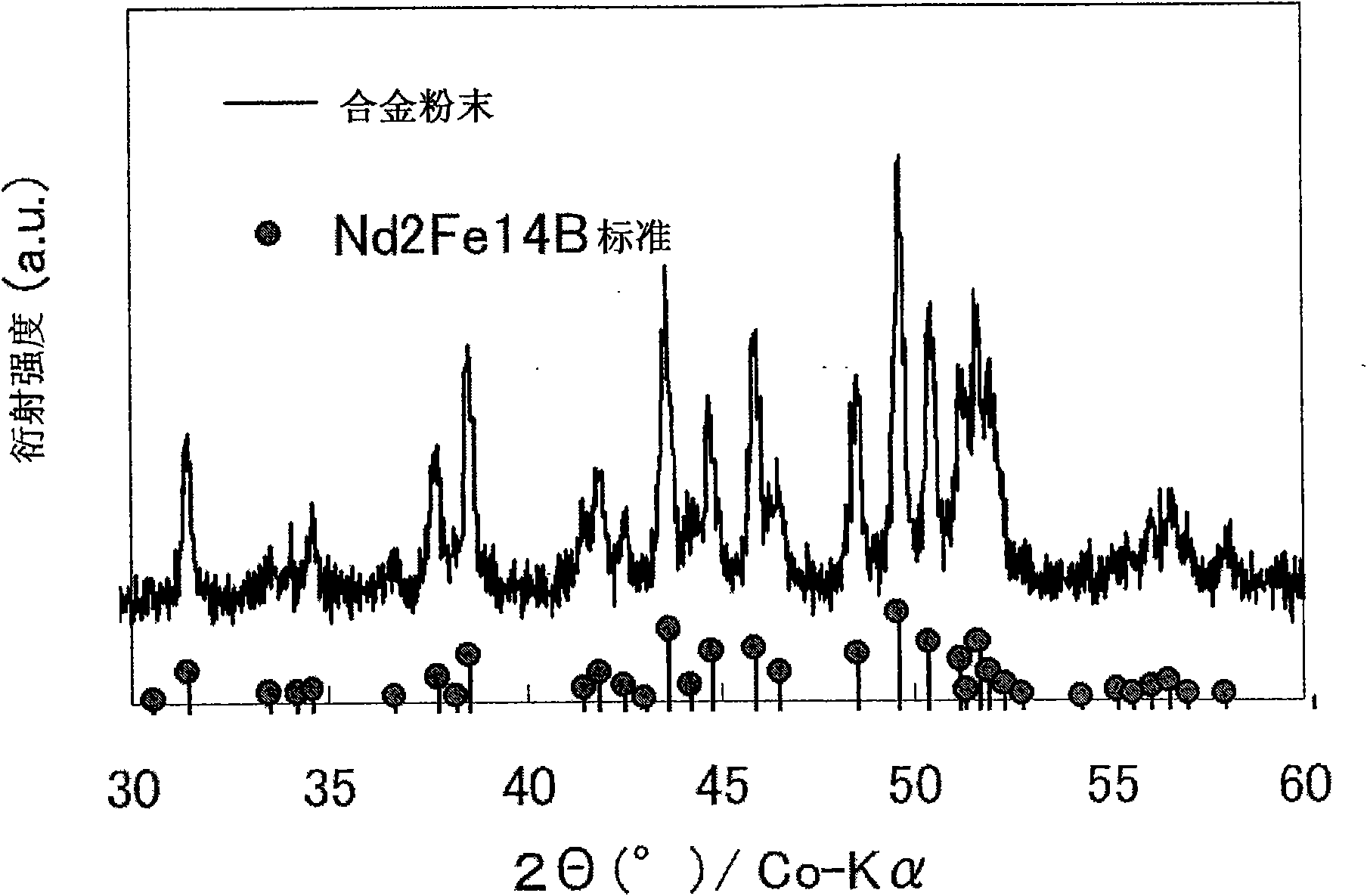

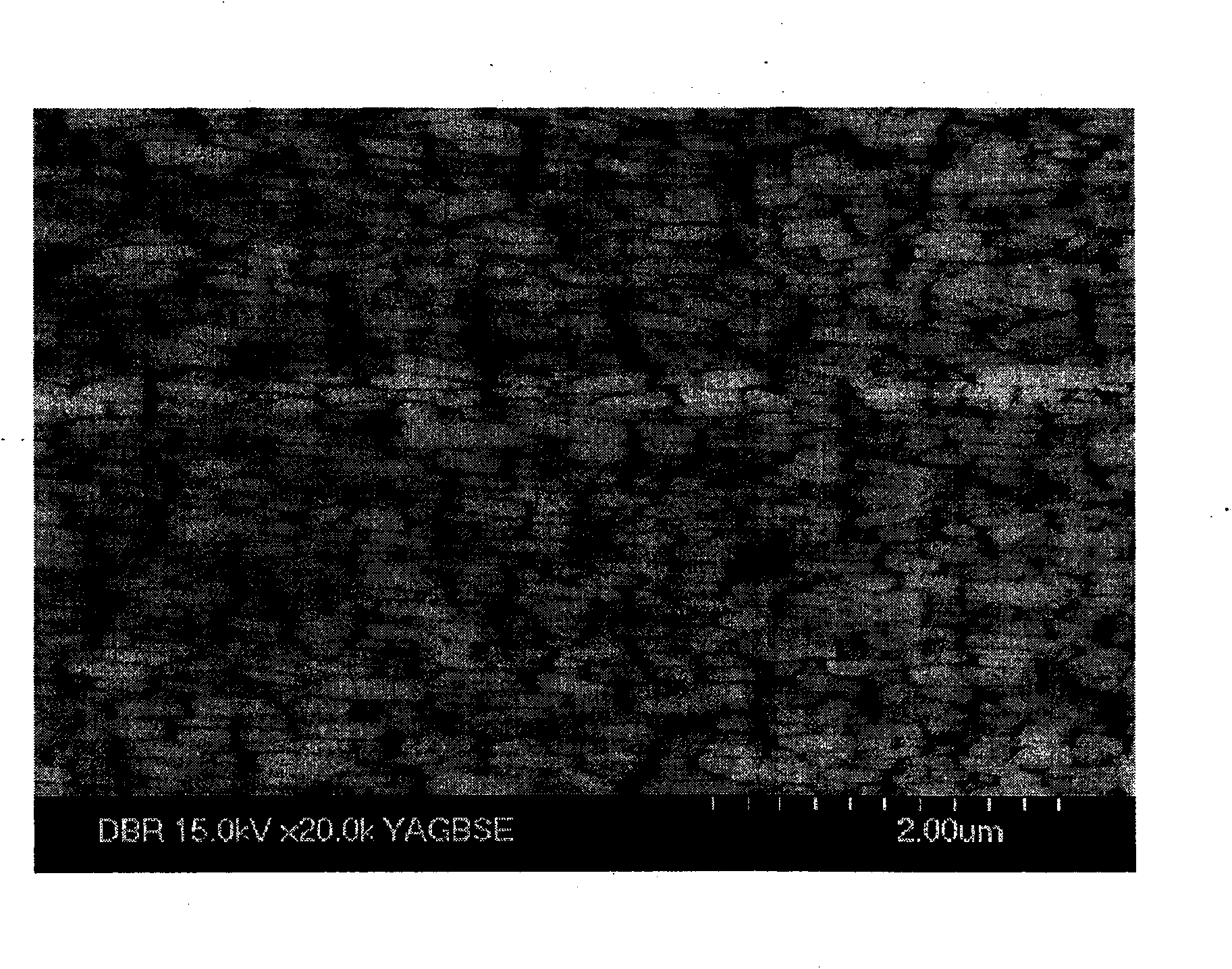

[0090] Other examples of the production method of the R-X-B series alloy powder include a method of melting-casting the R-X-B series alloy having the above predetermined composition to obtain an ingot, storing the ingot at a high temperature of about 800° C. and releasing hydrogen gas, thereby Obtain R-X-B alloy powder. According to this method, an ingot is stored at a high temperature and hydrogen gas is released, thereby pulverizing the ingot to an extent of about several hundreds of micrometers, and at the same time obtaining a powder having a crystal structure of fine recrystallized grains, wherein the recrystallized grains The grain size is several hundred nanometers, and the recrystallized grains are deposited by their azimuthal alignment. The R-X-B-based alloy powder (so-called HDDR powder) thus obtained is a powder having magnetic anisotropy.

[0091] Next, the RH metal and / or RH alloy is prepared. Examples of methods for producing such powders include the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com