Method for manufacturing injection-molding rare-earth radial magnetic ring

A technology of injection molding and rare earth magnetic powder, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0058] Three grades of nylon 12 were selected as the binder alone or mixed as the binder, namely nylon A, nylon B and nylon C. The characteristics are shown in Table 1.

[0059] Table I

[0060]

[0061] Description of the processing conditions of embodiment 1-5:

[0062] 1. Anisotropic rare earth magnetic powder content: 92% (by weight)

[0063] 2. Barrel temperature of the twin-screw extruder: 170°C at the feed end - 200°C at the discharge end

[0064] 3. Injection machine barrel temperature: 200-260°C

[0065] 4. Injection mold temperature: 80°C

[0066] 5. Injection pressure: 1080kg / cm 2

[0067] 6. Orientation magnetic field: 18kOe

[0068] 7. Sample size: a disc with a diameter of 12mm and a thickness of 7mm.

[0069] The data of embodiment 1-5 are shown in table two

[0070] Table II

[0071]

Embodiment 6-10

[0073] Description of embodiment 6-10 processing conditions:

[0074] 1. The traditional method of adding antioxidant: mechanically mix antioxidant powder with magnetic powder and nylon in a high-speed mixer.

[0075] 2. The traditional coupling agent addition method: Dilute the coupling agent with a solvent and mix it with magnetic powder and nylon in a high-speed mixer; mix it mechanically at a mixture temperature of 60-80°C, and remove the solvent while mixing. until the solvent is completely removed.

[0076] 3. The amount of EBS added: 0.1% of the weight of nylon

[0077] 4. Nylon: 8% of the magnetic powder weight, nylon C and nylon B each account for 50% (weight ratio)

[0078] 5. Coupling dose: 0.6% of the weight of magnetic powder

[0079] 6. The barrel temperature of the injection machine: 200-260°C.

[0080] The data of embodiment 6-10 are shown in table three

[0081] Table three

[0082]

[0083] 2. Injection molding rare earth anisotropic radiation...

Embodiment 11

[0085] Anisotropic rare-earth magnet formed by radiating an orientation magnetic field.

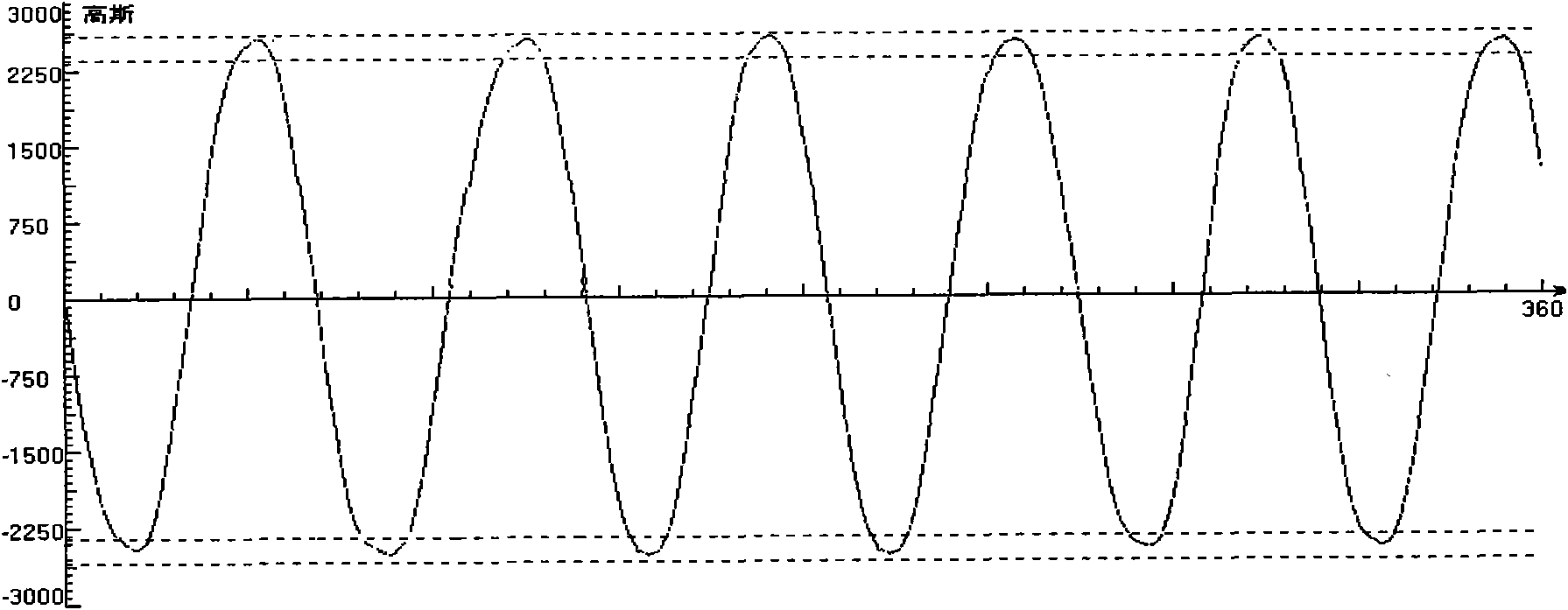

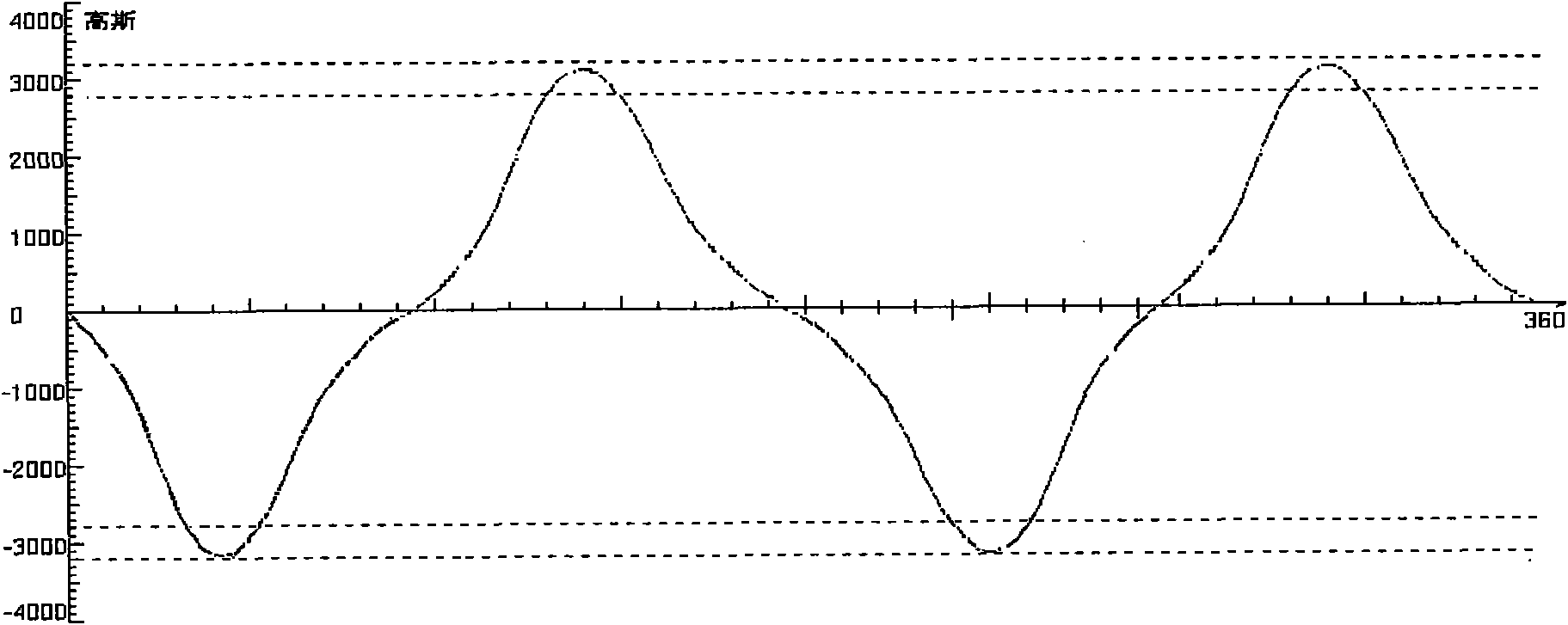

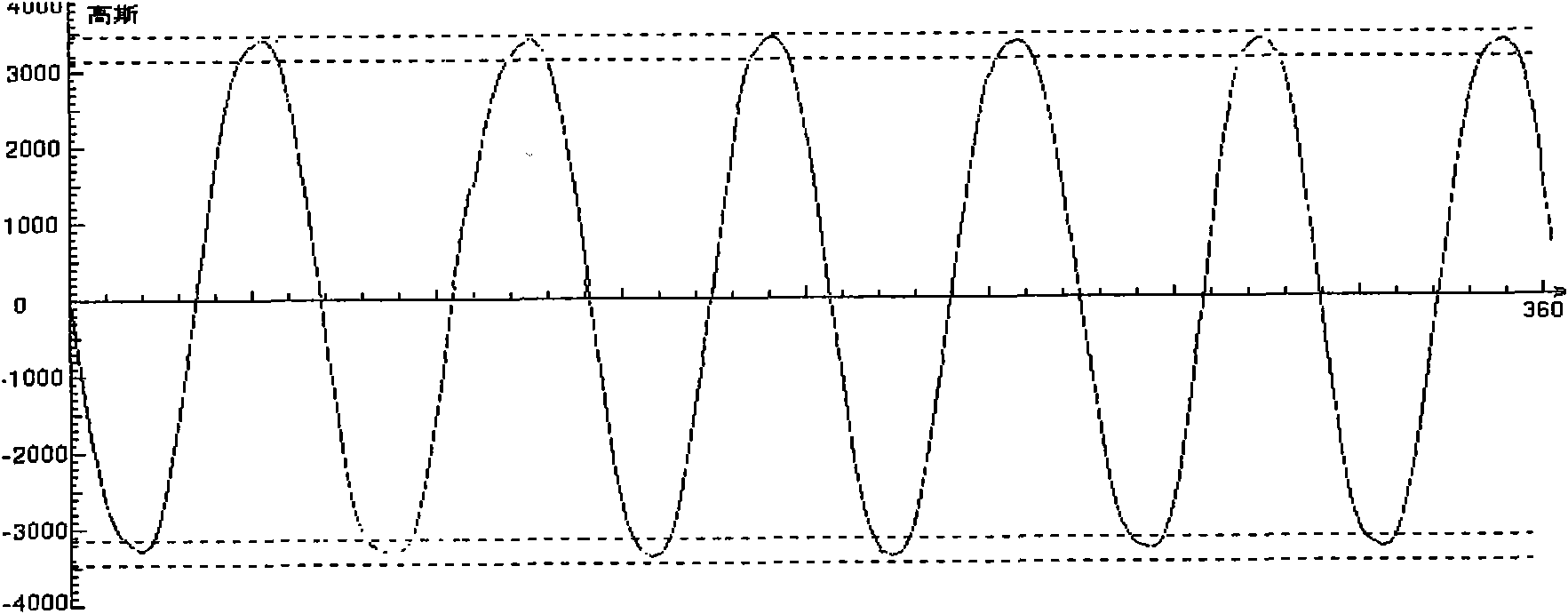

[0086] Using a general-purpose injection machine without an electromagnetic field device, a magnetic field orientation mold was produced by using the first orientation magnetic field method of the present invention, and the measured radiation orientation magnetic field reached 14.5KOe. An anisotropic rare-earth magnet formed by a radiation orientation magnetic field with a size of φ22.6×φ18.6×6 mm was injection-molded using the mold. Because the ring magnet formed by radiation orientation is radial 2 poles, that is, the inner surface is N pole; the outer surface is S pole, or the inner surface is S pole; the outer surface is N pole, and the magnet actually used is For multi-pole, this embodiment uses a pulse magnetization power supply with a multi-pole magnetization device to magnetize the injection-molded ring magnet into a 12-pole magnet. The magnetic flux density distribution on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com