Starting brushless DC magnetor for motorcycle

A DC brushless and magneto technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of low winding coefficient, high motor cost, poor performance, etc., achieve small torque ripple, improve utilization rate, and reduce height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

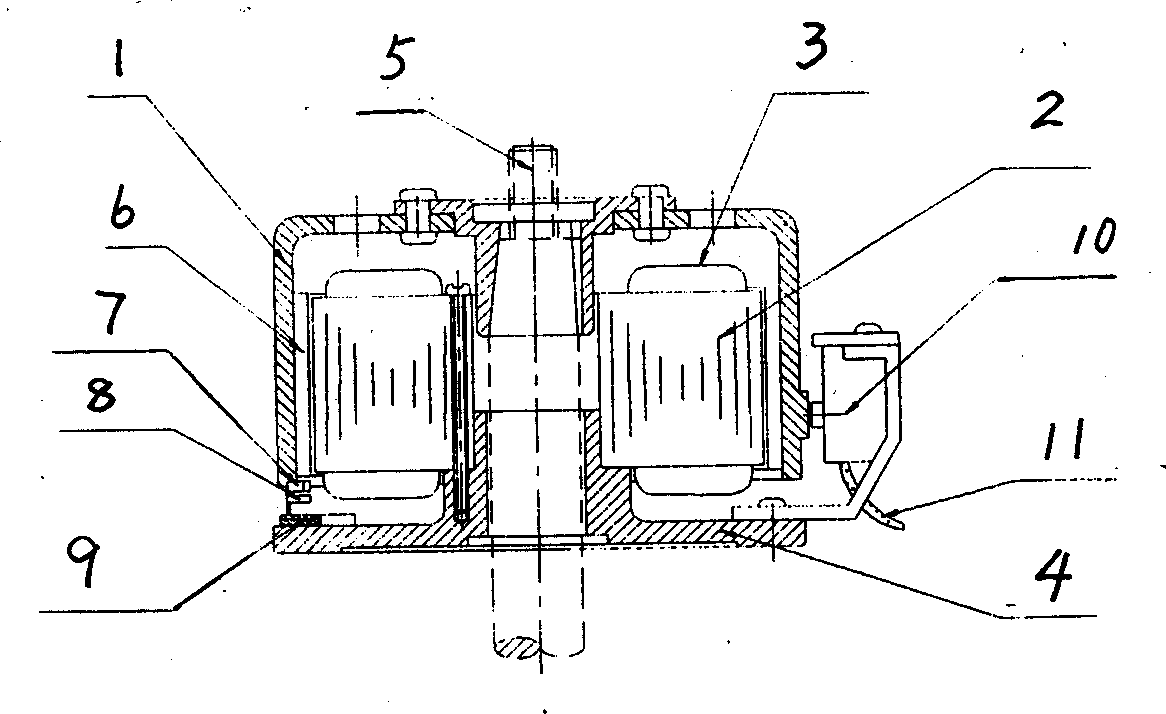

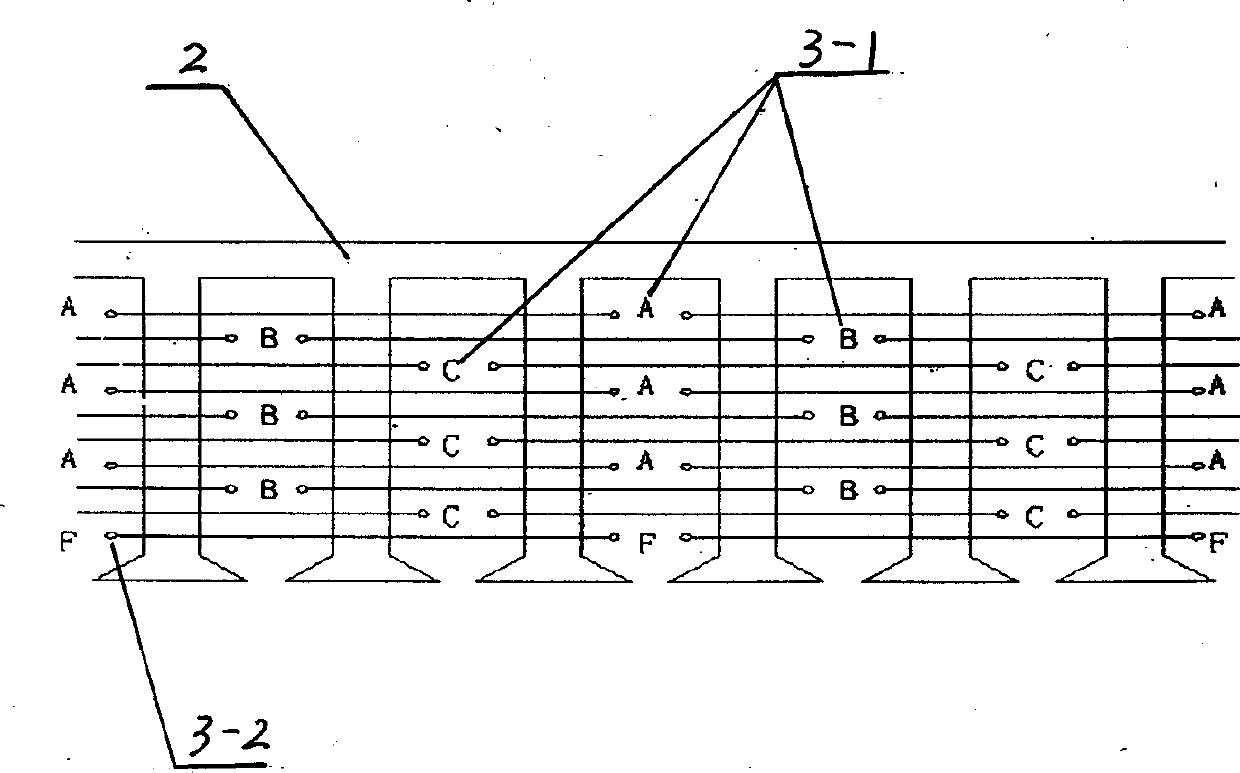

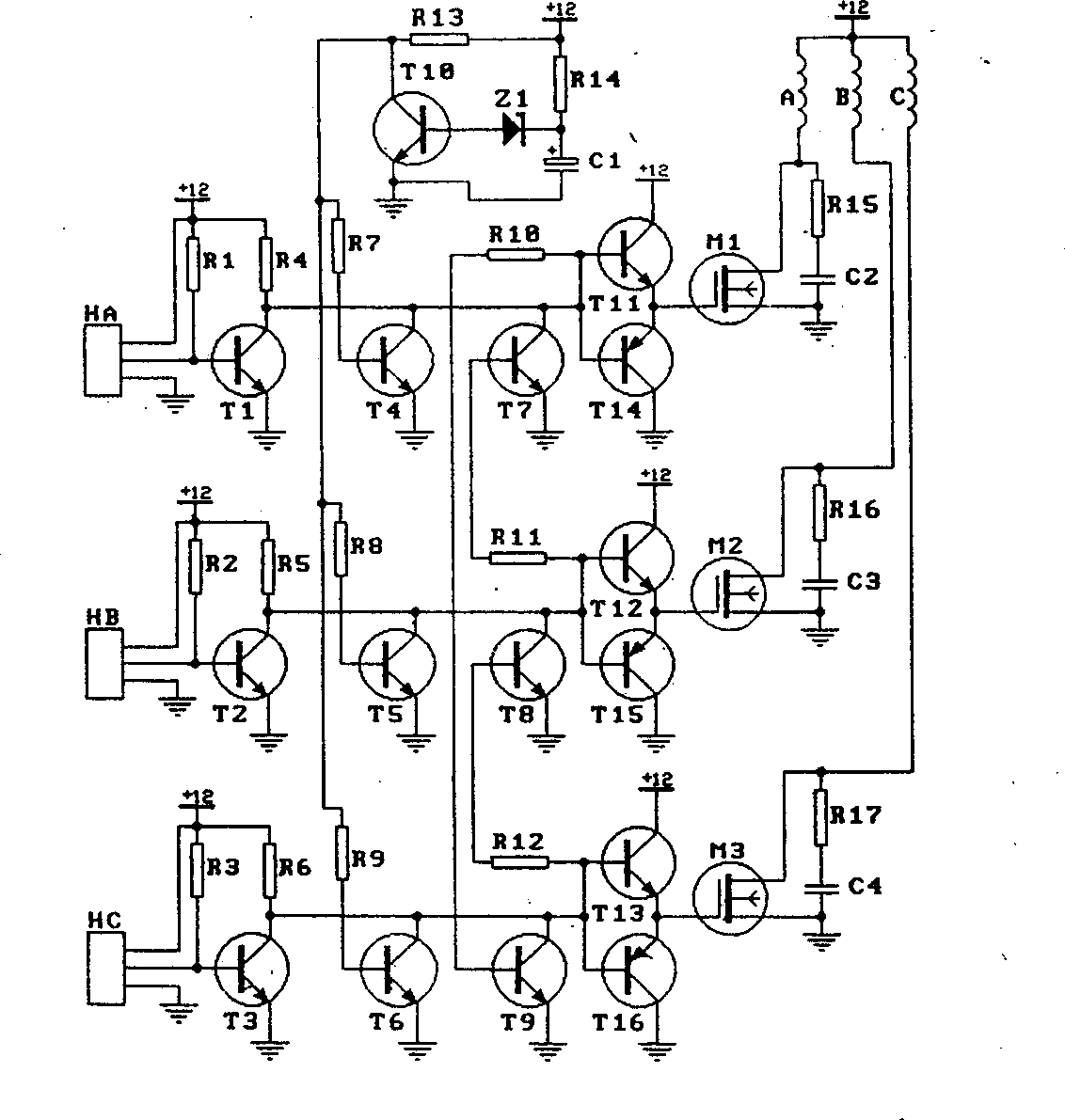

[0018] exist figure 1 Among them, the DC brushless starter magneto consists of a motor base 4, an outer rotor flywheel 1, an inner stator 2, a stator coil 3, a rotating shaft 5, a magnetic steel 6, a sensor magnetic steel 7, a Hall sensor 8, a sensor circuit board 9, and a trigger 10 and so on. Wherein, the outer rotor flywheel 1 is formed by cold drawing of low carbon steel. The inner cavity of the outer rotor flywheel 1 is evenly pasted with 6 pieces of magnetic steel 6 with alternating N and S poles, and the magnetic steel 6 can be a magnetic steel tile made of common and cheap ferrite magnetic steel. Eighteen coil slots are arranged on the inner stator 2 . Since the inner stator 2 of the present invention adopts multi-layer span-slot full-pitch windings, in order to obtain greater electromagnetic torque and reduce pulsation, the pole arc angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com