Brushless double-fed motor wound rotor winding and manufacturing method thereof

A technology of wound rotors and doubly-fed motors, which is applied in electric components, asynchronous induction motors, manufacturing motor generators, etc., and can solve problems such as low utilization of winding layout space, affecting winding performance, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

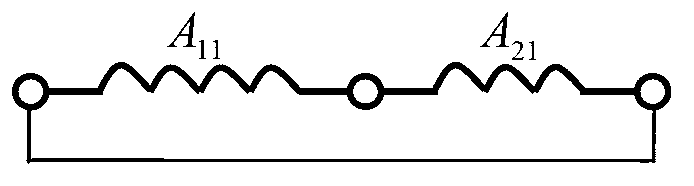

[0024] There is a brushless double-fed motor rotor, where p 1 =2,p 2 =4, z=54, a wound rotor winding scheme composed of two sets of multi-phase sub-windings superimposed.

[0025] According to the above method, then the number of phases m=p 1 +p 2 =2+4=6, the number of basic slots per phase z φ =z / m=54 / 6=9.

[0026] Consider first the first set of subwindings. It is assumed that the sub-winding is a double-layer winding, because each phase is composed of sequentially numbered coils in series, if the number of coils n is taken at this time 1 =z φ =9, its corresponding phase bandwidth, although for p 1 =2 may be suitable, but for p 2 =4 may be too large, which will cause p 2 =5 The winding coefficient is too low, so some coils must be removed, as for how much to remove, and the coil pitch y 1 , can only be determined after harmonic analysis. take n here 1 =6φ =9, and y 1 =7. And because the number of phases is m=6, the winding space of each phase differs by 2π / m in...

Embodiment 2

[0029] A brushless doubly-fed motor rotor, p 1 =2,p 2 =4, z=84, a wound rotor winding scheme composed of two sets of multi-phase sub-windings superimposed.

[0030] According to the above method, then the number of phases m=p 1 +p 2 =2+4=6, the number of basic slots per phase z φ =z / m=84 / 6=14.

[0031] A scheme for the arrangement of the coil slot numbers, for the first set of sub-windings, take n 1 =9, and y 1 =12, then the slot numbers of the coils of each phase are: A 11 Phase (1, 2, 3, 4, 5, 6, 7, 8, 9); A 12 Phase (43, 44, 45, 46, 47, 48, 49, 50, 51); B 11 Phase (15, 16, 17, 18, 19, 20, 21, 22, 23); B 12 Phase (57, 58, 59, 60, 61, 62, 63, 64, 65); C 11 Phase (29, 30, 31, 32, 33, 34, 35, 36, 37); C 12 phase (71, 72, 73, 74, 75, 76, 77, 78, 79).

[0032] For the second set of sub-windings, because it is a single-layer winding, if the coil pitch is y 2 =9, the coil slot number should be: n 2 =z / (p 1 +p 2 )-y 2 =84 / (2+4)-9=5, the slot number of each phase coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com