Double-stator split tooth type cylindrical linear motor

A linear motor and double stator technology, applied in electromechanical devices, electrical components, magnetic circuit shape/style/structure, etc., can solve problems such as poor position control, performance needs to be optimized, vibration and noise, etc., to achieve improved output performance, low magnetic Effects of resistance and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

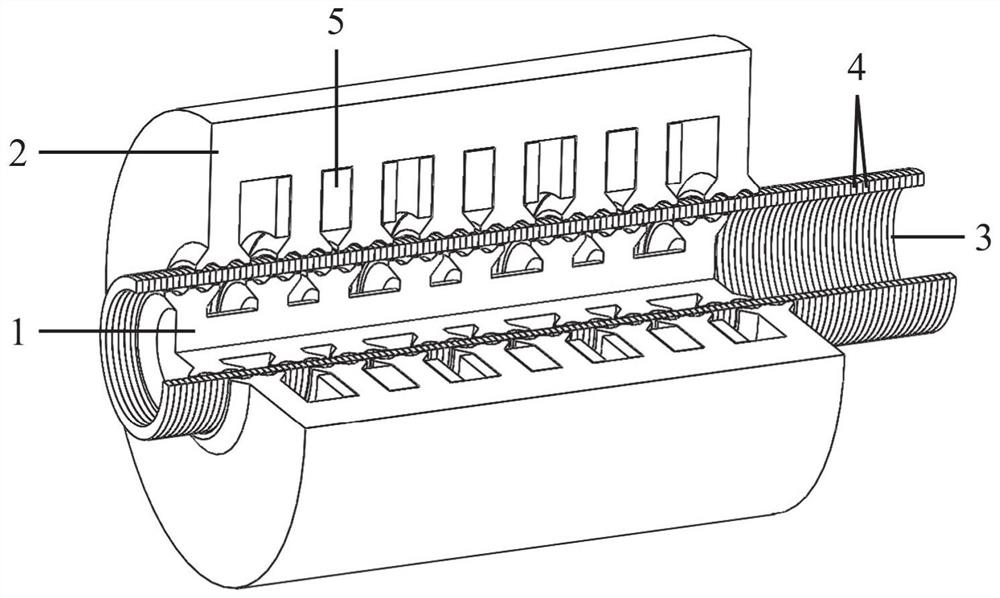

[0026] The purpose of this embodiment is to provide a double-stator split-tooth cylindrical linear motor.

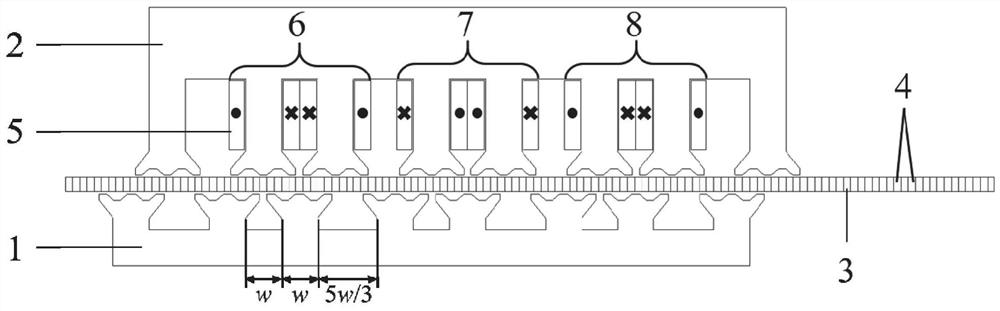

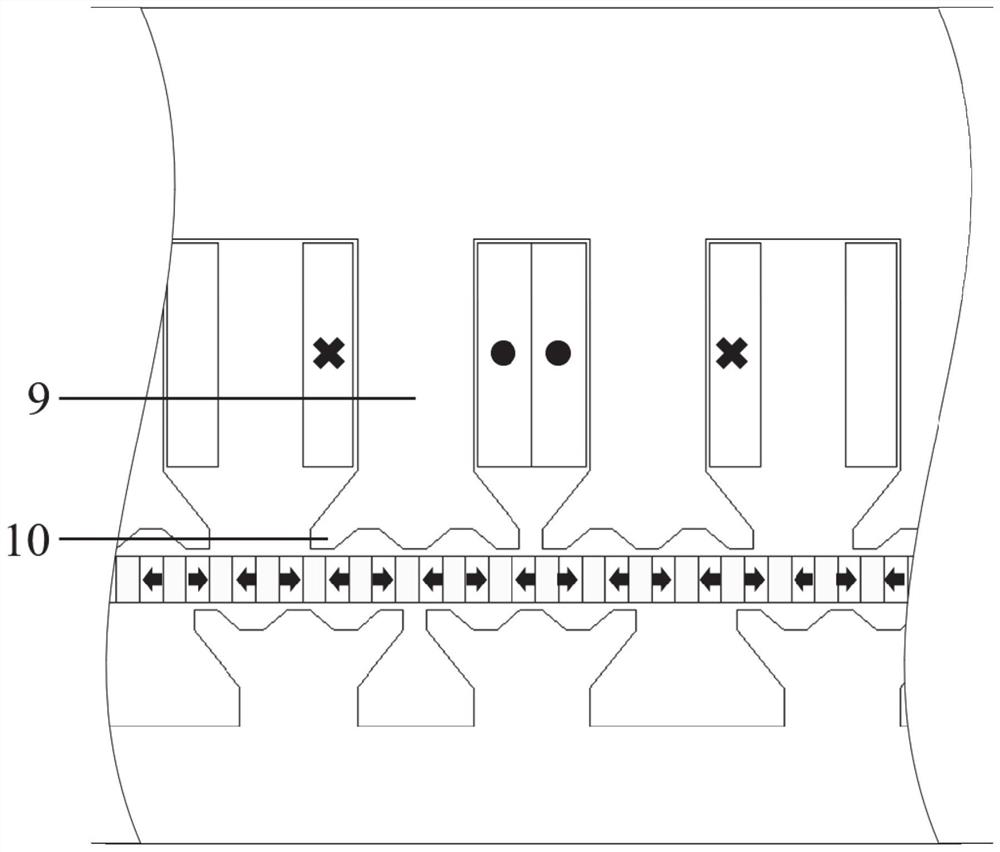

[0027] A double-stator split-tooth cylindrical linear motor, including a mover, an inner stator and an outer stator that face each other and are arranged on both sides of the mover. The mover is a magnet-condensing permanent magnet structure, and the permanent magnet is along The moving direction of the mover is magnetized horizontally, and the magnetization directions of the two adjacent permanent magnets are opposite;

[0028] The main stator teeth of the inner stator and the outer stator are provided with several split teeth, the outer stator is provided with a phase group concentrated coil winding, the inner stator has no winding, and the two stators have a certain air gap distance from the mover respectively. The air gap distances are equal, and the two stators have an offset of the main stator tooth width along the moving direction of the mover.

[0029] Specifica...

Embodiment 2

[0040] The purpose of this embodiment is to provide a driving mechanism / power mechanism.

[0041] A driving mechanism / power mechanism, which adopts the above-mentioned double-stator split-tooth cylindrical linear motor, the linear motor includes: a mover and an inner stator and an outer stator facing each other and arranged on both sides of the mover. The mover is a magnet-concentrating permanent magnet structure, and the permanent magnet is magnetized horizontally along the moving direction of the mover, and the magnetization directions of two adjacent permanent magnets are opposite;

[0042] The main stator teeth of the inner stator and the outer stator are provided with several split teeth, the outer stator is provided with a phase group concentrated coil winding, the inner stator has no winding, and the two stators have a certain air gap distance from the mover respectively. The air gap distances are equal, and the two stators have an offset of the main stator tooth width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com