Single-phase capacitor motor

A technology of electric motor and single-phase power supply, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve problems such as difficulty in further improving winding coefficient, failure to effectively eliminate harmonics, and difficulty in further improving starting performance, electromagnetic vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

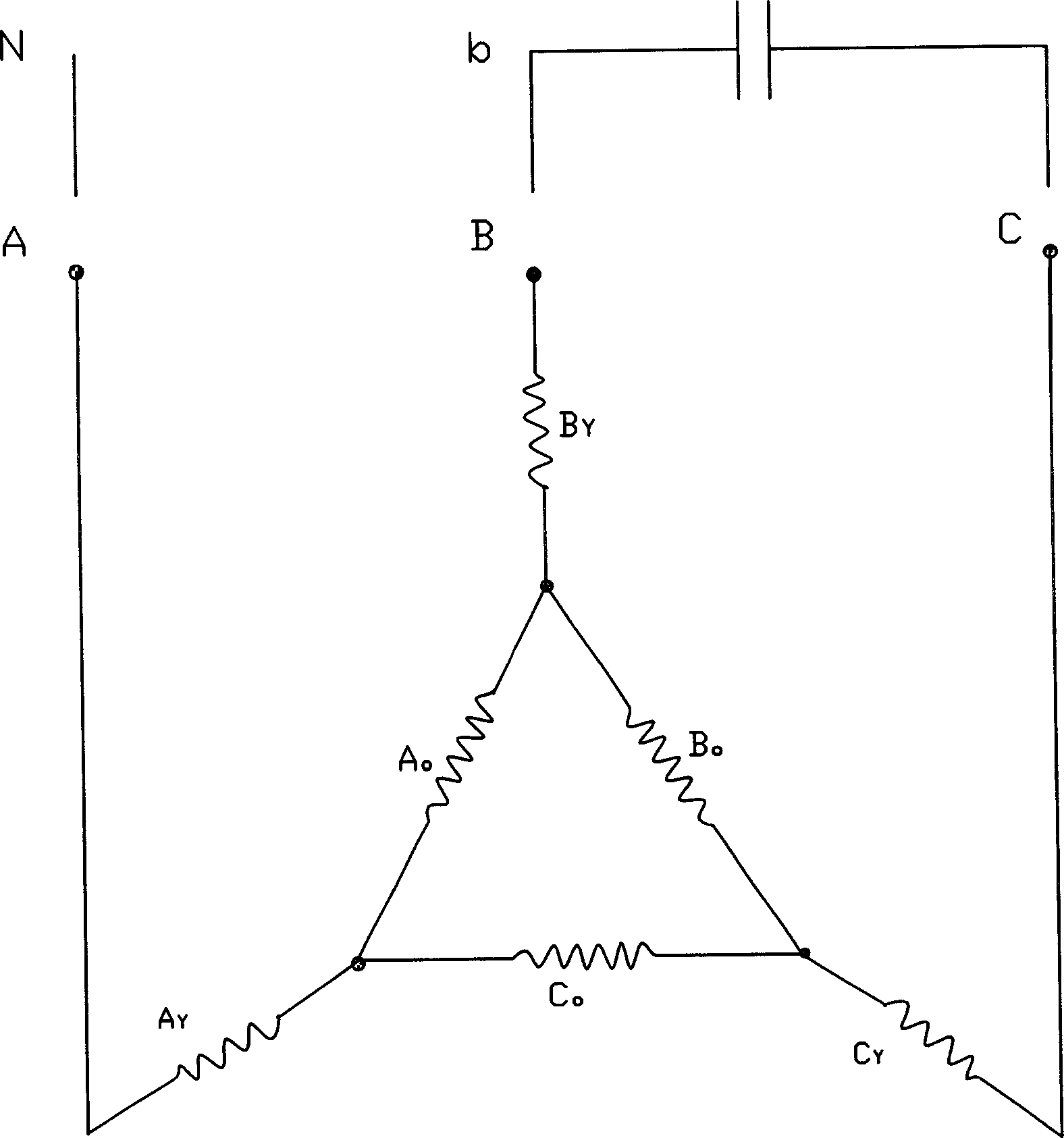

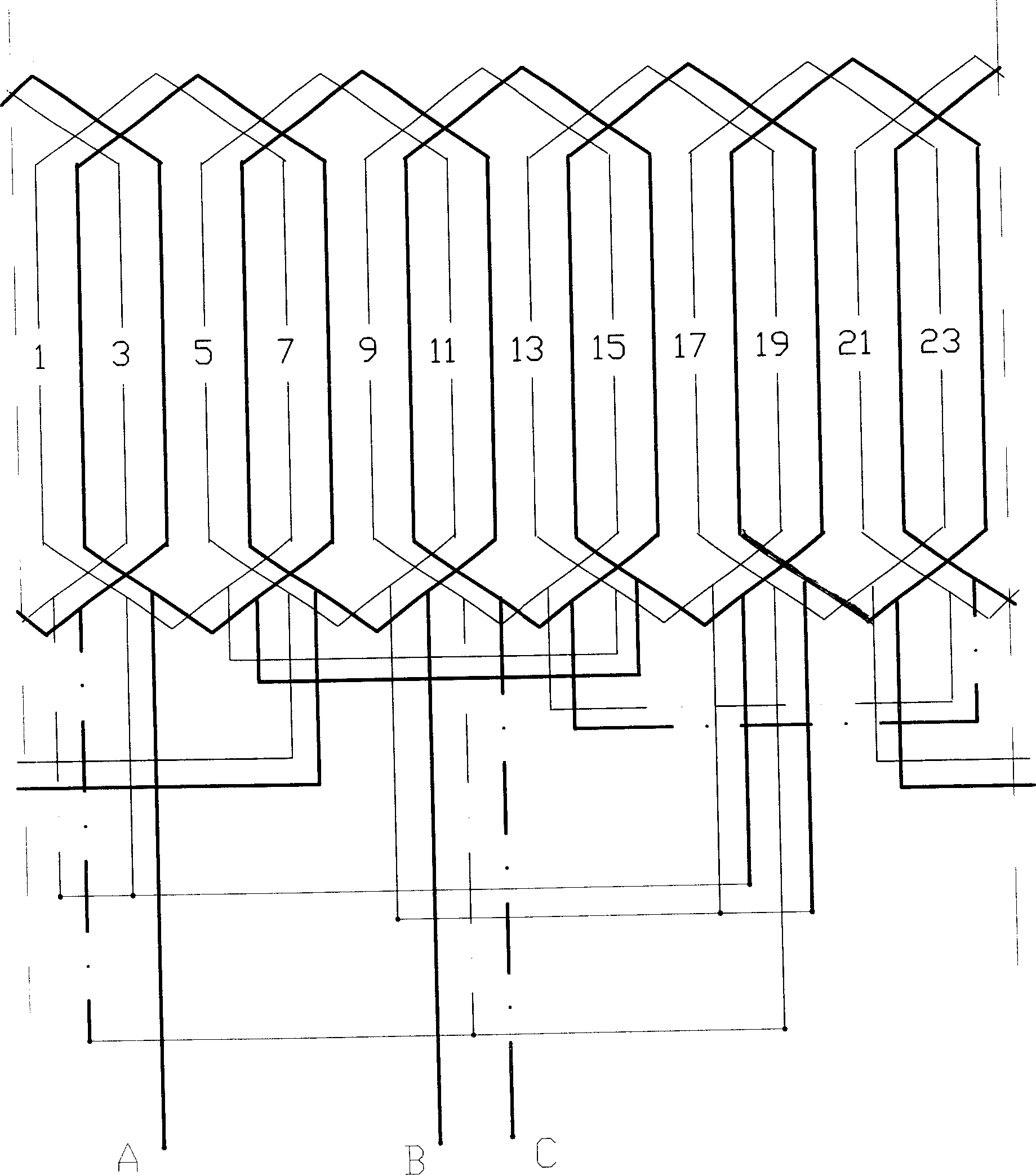

[0014] The wiring of the single-phase capacitor motor in the embodiment of the present invention is as follows: figure 1 As shown, the winding distribution is as figure 2 shown. It is based on a 180W single-phase capacitor running motor for washing machines in the prior art that meets the requirements of the national industry standard JB / T3758, and is formed by re-embedding and wiring the stator winding.

[0015] Its structure that follows the prior art includes:

[0016] - 24-slot stator core;

[0017] ——The lead-out line A connected to the N pole of the neutral line of the single-phase power supply, the two lead-out lines B and C connected across the capacitor, and the b-pole of the phase line of the single-phase power supply is connected to the lead-out line B or C;

[0018] - squirrel cage rotors and other mechanical mechanisms.

[0019] Reinsert and wire the stator winding of the single-phase capacitor motor as follows:

[0020] Such as figure 1 As shown, the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com