Light power three-phase motor

A three-phase motor, low-power technology, applied to the shape/style/structure of the winding conductor, can solve the problems of process difficulties, harmonics cannot be effectively eliminated, and it is difficult to further improve the start-up performance, electromagnetic vibration noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

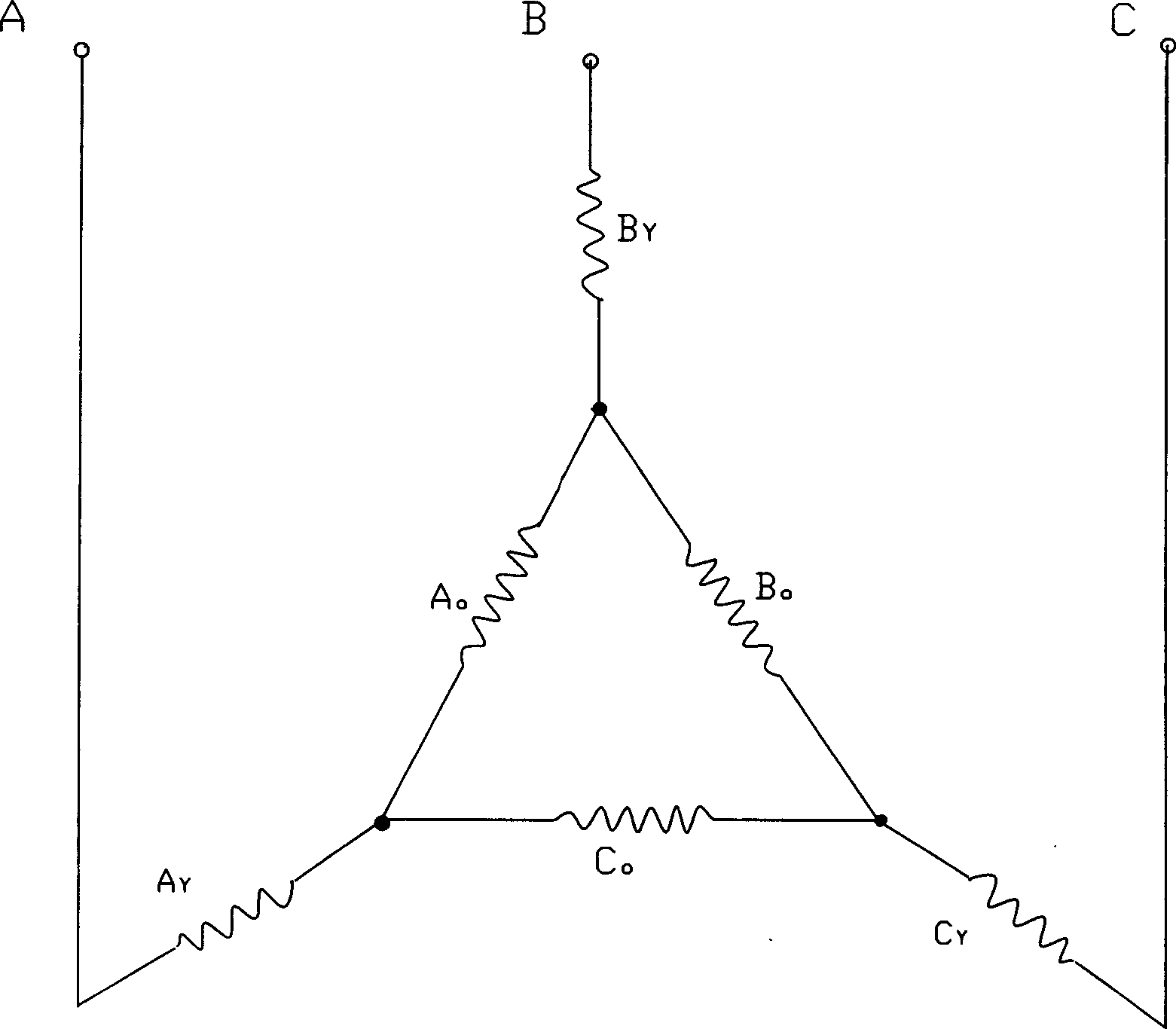

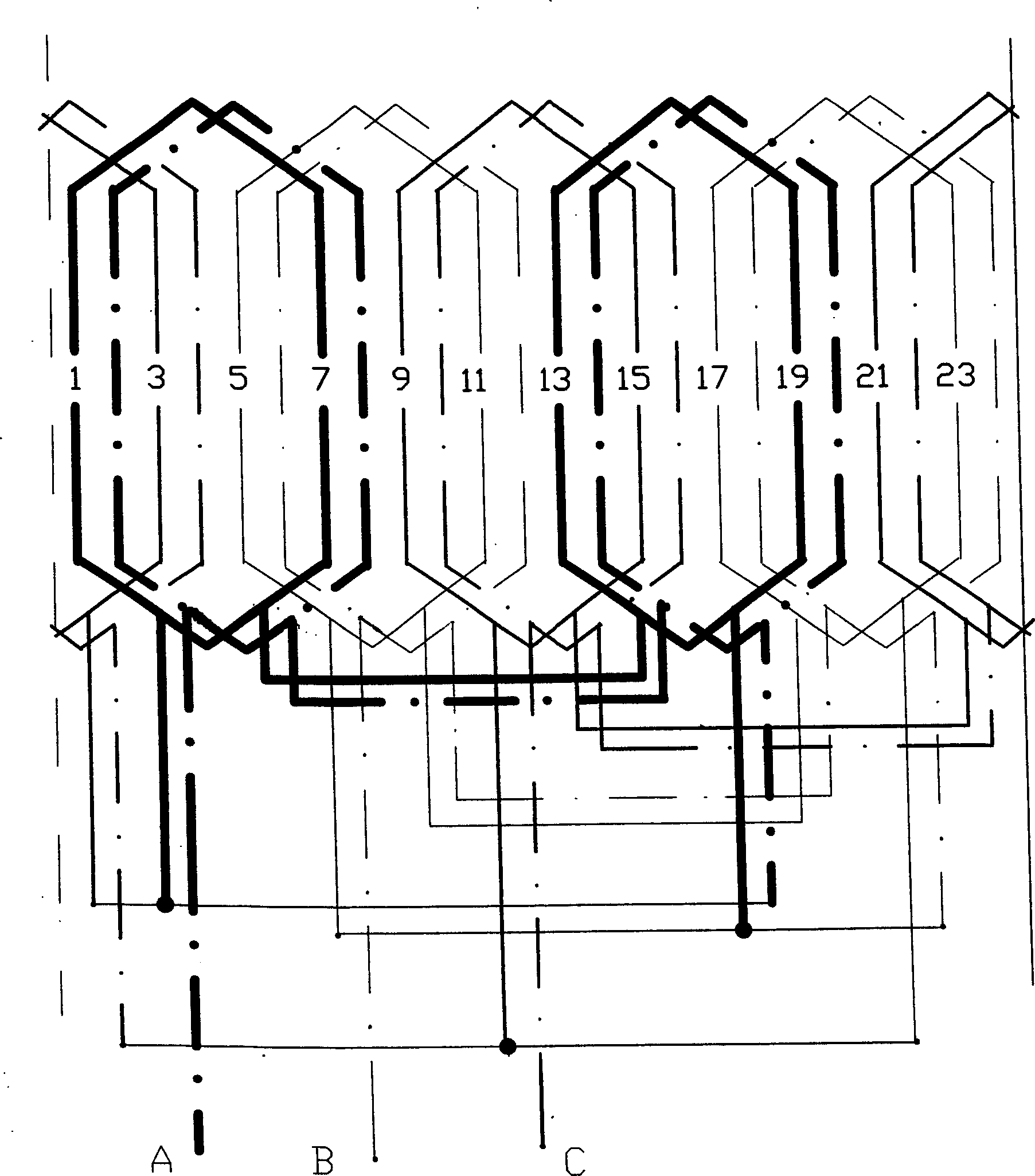

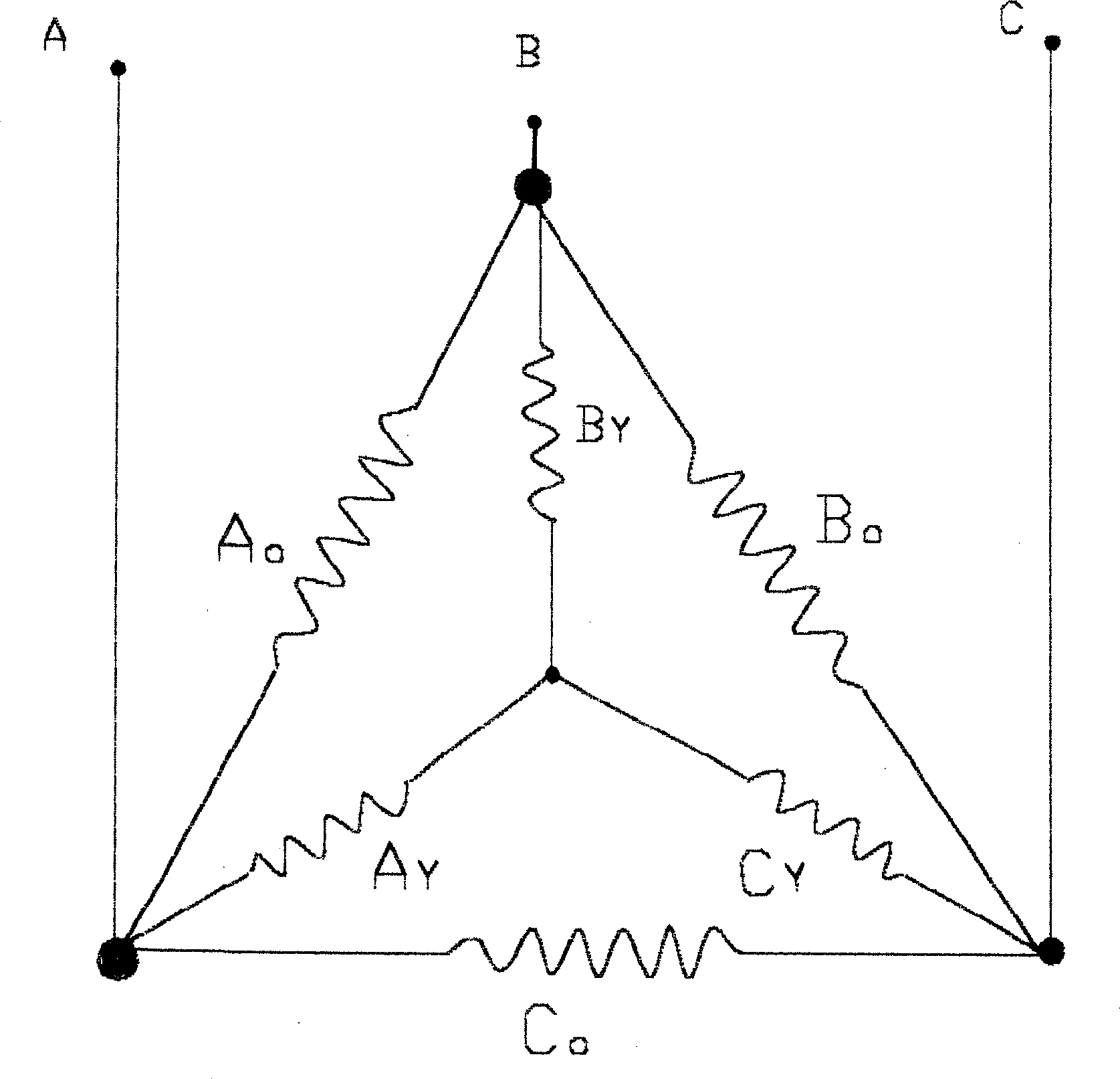

[0021] The motor wiring of the first embodiment of the present invention is as follows: figure 1 As shown, the winding distribution is as figure 2 shown. It is based on the 24-slot stator core, squirrel cage rotor and other mechanical mechanisms of a 4-pole 180W single-phase capacitor running motor for washing machines that meet the requirements of the national industry standard JB / T3758. Embedded and wired:

[0022] Such as figure 1 , the stator winding includes a star winding part composed of three-phase windings Ay, By, Cy and a delta winding part composed of three-phase windings Ao, Bo, Co. The beginnings of Ay, By, and Cy are connected to the three-phase power terminals A, B, and C respectively; the beginnings of Ao and the end of Co are connected to the end of Ay; the beginnings of Bo and the end of Ao are connected to the end of By; the beginnings of Co and the end of Bo The end of is connected to the end of Cy.

[0023] The stator winding is figure 2 The windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com